Professional Documents

Culture Documents

ER LK Mines

ER LK Mines

Uploaded by

saji kumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ER LK Mines

ER LK Mines

Uploaded by

saji kumarCopyright:

Available Formats

1

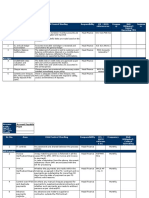

ACC LIMITED KYMORE CEMENT WORKS

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

IDENTI

FICATI

ON OF

DEPT./AREA:

BAMANGAON MINES

ENERG

````

Y

ASPEC

TS

AND

PRIORI

SR.NO. AREA

ZATIO

N

Raw Mill 1

MACHINE OR

ZONE

AS ON 01/03/2012

ENERGY ASPECT

ELECTRICAL

ENERGY

BELT CONVEYO

RATED

KW

75

ELECTRICAL

ENERGY

12 Raw Mill 1

DOC NO. KCW/IMS/BMG/ER

POTENTIAL

OF SAVING

ACTUAL KW

61 3

APP

LIC

ABL

POSSIBILITY

TECHNOLO

POTENTIAL E

FOR USAGE

GICAL

FOR WASTE LEG

OF

FEASIBILIT

HEAT

AL

RENEWABLE

Y

RECOVERY REQ

ENERGY

UIR

EME

NT

REVISION NO.00

SIG

NIFI

CA

NC STATUS OF

E

SIGNIFICANCE

NU

MB YES

ER

NA 6

CURRENT CONTROLS

NO

NO

Regul

arlly

monit OCPoring KCW/

Regularlly monitoring

and IMS/

and catching of false air

catch K1/O

ing of CP/1

false

air

NA 10 YES

BM1-BALL MIL

ELECTRICAL

ENERGY

14

NA 10 Yes

Repla

ce

existi

ng

flash

drier

fan

with

high

effice

incy

fan

(50%

)

No

FN1-FAN-1,RA

ELECTRICAL

ENERGY

53 Raw Mill 1

1200

1194 3

NA 10 Yes

SEPAX FAN_KY

Prepared by

Approved By

Issued by

CONT

ROLS REMAR

KS

REQUI

RED

GRR

IMPKCW/

IMS/

K1/M

P/20

Sepa

x fan

flow

shoul

d be

OCPreduc

KCW/

ed

IMS/

and

K1/O

false

CP/1

air

shoul

d be

arrest

ed

Issue date:

ACC LIMITED KYMORE CEMENT WORKS

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

IDENTI

FICATI

ON OF

DEPT./AREA:

BAMANGAON MINES

ENERG

````

Y

ASPEC

TS

AND

PRIORI

SR.NO. AREA

ZATIO

N

58

MACHINE OR

ZONE

Raw mill01

AS ON 01/03/2012

ENERGY ASPECT

ELECTRICAL

ENERGY

RATED

KW

DOC NO. KCW/IMS/BMG/ER

POTENTIAL

OF SAVING

ACTUAL KW

APP

LIC

ABL

POSSIBILITY

TECHNOLO

POTENTIAL E

FOR USAGE

GICAL

FOR WASTE LEG

OF

FEASIBILIT

HEAT

AL

RENEWABLE

Y

RECOVERY REQ

ENERGY

UIR

EME

NT

10

NA 13 Yes

AS5-AIR SLIDE

Prepared by

Approved By

REVISION NO.00

SIG

NIFI

CA

NC STATUS OF

E

SIGNIFICANCE

NU

MB YES

ER

Issued by

CURRENT CONTROLS

NO

----

CONT

ROLS REMAR

KS

REQUI

RED

Redu

ce

the

powe

r

cons

umpti

on by

instal

IMPlation

KCW/

of

IMS/

VVVF

K1/M

D for

P/21

low

capa

city

blow

er(St

udy

to be

Done

)

Issue date:

ACC LIMITED LAKHERI CEMENT WORKS

F01(LK/EnMS/PR/20)

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

DOC NO. LK/EnMS/Mines/ER

DEPT./AREA: Mines

SR.NO.

AREA

MACHINE OR

ZONE

EQUIPMENT

CODE

WOBBLER

1

MOTOR 122

Mines

11

Mines

12

Mines

13

Mines

15

Mines

16

Mines

W0 01

COMRESSOR

MOTOR 122CP-01

WATER PUMP

MOTOR 122WP-01

WATER PUMP

MOTOR 122WP-02

WATER PUMP

MOTOR 122WP-02

WATER PUMP

MOTOR 122WP-03

Excavator-1

REVISION NO. 00

IDENTIFICATION

OF ENERGY ASPECTS AND PRIORIZATION

POSSIBILITY

POTENTIAL APPLICABLE

STATUS OF

TECHNOLO FOR USAGE

POTENTIAL

FOR WASTE

LEGAL

SIGNIFICANC SIGNIFICANCE

ENERGY ASPECT

GICAL

OF

OF SAVING

HEAT

REQUIREMEN E NUMBER

FEASIBILITY RENEWABLE

YES

NO

RECOVERY

T

ENERGY

122-CP-01

122-WP-01

122-WP-02

122-WP-02

122-WP-03

18

NA

10

YES

Manual

ELECTRICAL

ENERGY

NA

YES

DOL

ELECTRICAL

ENERGY

NA

YES

DOL

To provide auto

level controller

ELECTRICAL

ENERGY

NA

YES

DOL

To provide auto

level controller

ELECTRICAL

ENERGY

NA

DOL

To provide auto

level controller

ELECTRICAL

ENERGY

NA

HSD

NA

10

DOL

1.Following the

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

LK.111-4B3

Excavator-4

19

Mines

LK.111-4B4

Excavator-5

20

Mines

LK.111-4B5

Dumper-1

21

Mines

Prepared by

LK.191-4K1

Approved By

CONTROLS REQUIRED

LK.111-4B1

Issued by

maintenance

shedule.

2.

Following the SOP

for proper

operation

ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

1.Following

operation ofthe

the

Planned

equipment.

maintenance

shedule.

2.

Following the SOP

for proper

1.Following

operation ofthe

the

Planned

equipment.

maintenance

shedule.

2.

Following the SOP

for proper

operation of the

equipment.

Date: 01/12/2012

REMARKS

To provide double

gate and clame

shell to reduce

frequent start stop

and to increase

TPH

To arrest leakages

and optimize

pressure set point

ELECTRICAL

ENERGY

Excavator-3

Mines

CURRENT CONTROLS

122 - W0-01

17

Mines

FORMAT NO.

To provide auto

level controller

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Issue date:

ACC LIMITED LAKHERI CEMENT WORKS

F01(LK/EnMS/PR/20)

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

DOC NO. LK/EnMS/Mines/ER

DEPT./AREA: Mines

SR.NO.

AREA

MACHINE OR

ZONE

Dumper-2

EQUIPMENT

CODE

22

Mines

FORMAT NO.

REVISION NO. 00

IDENTIFICATION

OF ENERGY ASPECTS AND PRIORIZATION

POSSIBILITY

POTENTIAL APPLICABLE

STATUS OF

TECHNOLO FOR USAGE

POTENTIAL

FOR WASTE

LEGAL

SIGNIFICANC SIGNIFICANCE

ENERGY ASPECT

GICAL

OF

CURRENT CONTROLS

1.Following

the

OF SAVING

HEAT

REQUIREMEN E NUMBER

FEASIBILITY RENEWABLE

Planned

RECOVERY

T

ENERGY

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

HSD

NA

10

LK.191-4K2

Dumper-3

23

Mines

LK.191-4K3

Dumper-4

24

Mines

LK.191-4K4

Dumper-7

25

Mines

LK.191-4K7

Dumper-8

26

Mines

LK.191-4K8

Dozer

27

Mines

LK.111-4D1

Compressor

28

Mines

No.1

Compressor

LK.111-4Y1

29

Mines

No.3

ICM260 Drill

LK.111-4Y3

30

Mines

Prepared by

LK.111-4B1

Approved By

Issued by

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

1.Following

operation ofthe

the

Planned

equipment.

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation

ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation ofthe

the

1.Following

equipment.

Planned

maintenance

shedule.

2.

Following the SOP

for proper

operation of the

equipment.

CONTROLS REQUIRED

Date: 01/12/2012

REMARKS

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Timely callibration

& replacement of

uel pump

Issue date:

ACC LIMITED LAKHERI CEMENT WORKS

F01(LK/EnMS/PR/20)

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

DOC NO. LK/EnMS/Mines/ER

DEPT./AREA: Mines

SR.NO.

AREA

Prepared by

MACHINE OR

ZONE

Approved By

EQUIPMENT

CODE

IDENTIFICATION

OF ENERGY ASPECTS AND PRIORIZATION

POSSIBILITY

POTENTIAL APPLICABLE

STATUS OF

TECHNOLO FOR USAGE

POTENTIAL

FOR WASTE

LEGAL

SIGNIFICANC SIGNIFICANCE

ENERGY ASPECT

GICAL

OF

OF SAVING

HEAT

REQUIREMEN E NUMBER

FEASIBILITY RENEWABLE

RECOVERY

T

ENERGY

Issued by

FORMAT NO.

REVISION NO. 00

CURRENT CONTROLS

CONTROLS REQUIRED

Date: 01/12/2012

REMARKS

Issue date:

ACC LIMITED LAKHERI CEMENT WORKS

F01(LK/EnMS/PR/20)

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

DOC NO. LK/EnMS/Mines/ER

DEPT./AREA: Mines

SR.NO.

AREA

Prepared by

MACHINE OR

ZONE

Approved By

EQUIPMENT

CODE

IDENTIFICATION

OF ENERGY ASPECTS AND PRIORIZATION

POSSIBILITY

POTENTIAL APPLICABLE

STATUS OF

TECHNOLO FOR USAGE

POTENTIAL

FOR WASTE

LEGAL

SIGNIFICANC SIGNIFICANCE

ENERGY ASPECT

GICAL

OF

OF SAVING

HEAT

REQUIREMEN E NUMBER

FEASIBILITY RENEWABLE

RECOVERY

T

ENERGY

Issued by

FORMAT NO.

REVISION NO. 00

CURRENT CONTROLS

CONTROLS REQUIRED

Date: 01/12/2012

REMARKS

Issue date:

ACC LIMITED LAKHERI CEMENT WORKS

F01(LK/EnMS/PR/20)

ENERGY MANGEMENT SYSTEM_ENERGY REVIEW (ER)

DOC NO. LK/EnMS/Mines/ER

DEPT./AREA: Mines

SR.NO.

AREA

Prepared by

MACHINE OR

ZONE

Approved By

EQUIPMENT

CODE

IDENTIFICATION

OF ENERGY ASPECTS AND PRIORIZATION

POSSIBILITY

POTENTIAL APPLICABLE

STATUS OF

TECHNOLO FOR USAGE

POTENTIAL

FOR WASTE

LEGAL

SIGNIFICANC SIGNIFICANCE

ENERGY ASPECT

GICAL

OF

OF SAVING

HEAT

REQUIREMEN E NUMBER

FEASIBILITY RENEWABLE

RECOVERY

T

ENERGY

Issued by

FORMAT NO.

REVISION NO. 00

CURRENT CONTROLS

CONTROLS REQUIRED

Date: 01/12/2012

REMARKS

Issue date:

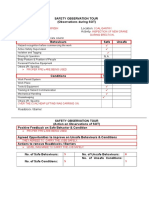

SAVING POTENTIAL RATING (A)

TECHNOLOGICAL/ IMPLEMENTATION

FEASIBILITY RATING (B)

Less than Rs 10000/annum

easy to implement well

established

technology/method, very

simple changes are

required

10

Less than Rs 100,000/annum

Minor changes are

required

Less than Rs 1,000,000 per

annum

Major

interventions/changes are

required

more than Rs 1,000,000 per

annum

10

Technology not available

or not a proven technology

Note

Give 1 mark bonus if the potential for waste heat recovery is there

Give 2 marks bonus if the selected option is renewable

options will not be significant in any case when, either A Or B is zero

Prepared by

Approved By

Issued by

Issue date:

You might also like

- CHP SopDocument26 pagesCHP Sopkalyanm20351550% (2)

- Relay Setting Calculation SheetDocument25 pagesRelay Setting Calculation SheetSARAVANAN A100% (8)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- ChecklistDocument14 pagesChecklistInstrument SCINo ratings yet

- STAGE II, UNIT # 2 (1X600MW) : ProjectDocument14 pagesSTAGE II, UNIT # 2 (1X600MW) : ProjectRukma Goud ShakkariNo ratings yet

- Insulation SpecificationsDocument18 pagesInsulation SpecificationsDarshan PanchalNo ratings yet

- Load List For B127 Cluster Well PlatformDocument24 pagesLoad List For B127 Cluster Well Platformpokiri100% (1)

- Data Sheet & SLDDocument22 pagesData Sheet & SLDvaithy2011100% (1)

- DPT Report - U1Document88 pagesDPT Report - U1kannagi198No ratings yet

- Design Calculation Cathodic Protection Impressed Cureent SystemDocument13 pagesDesign Calculation Cathodic Protection Impressed Cureent Systemadeoye_okunoye100% (1)

- Design Calculation Cathodic Protection Impressed Cureent SystemDocument13 pagesDesign Calculation Cathodic Protection Impressed Cureent SystemPandipperumal SankaralingamNo ratings yet

- Fuel Oil I&C Conceptual Basic Design: I.P.D.C. Project: Shirvan Gas Turbine Power Plant (Bop2 Portion)Document14 pagesFuel Oil I&C Conceptual Basic Design: I.P.D.C. Project: Shirvan Gas Turbine Power Plant (Bop2 Portion)Ehsan PourangNo ratings yet

- 8474L 013 ML 002 ADocument338 pages8474L 013 ML 002 ANinhHoàngHảiNo ratings yet

- SOP For ESPDocument10 pagesSOP For ESPOmprakash DansenaNo ratings yet

- EGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatorDocument4 pagesEGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatordrkongalaNo ratings yet

- Intent of AMC 2. Equipment Information 3. Hydraulics Checklist 4. Transmission Checklist 5. Electrical and C&I Checklist 6. Overall Machine ChecklistDocument13 pagesIntent of AMC 2. Equipment Information 3. Hydraulics Checklist 4. Transmission Checklist 5. Electrical and C&I Checklist 6. Overall Machine Checklistsufiyanahmed1611No ratings yet

- TSPL P143 Qap 818 00Document3 pagesTSPL P143 Qap 818 00venka07No ratings yet

- Design Basis Report PDFDocument27 pagesDesign Basis Report PDFStephen BridgesNo ratings yet

- Energy AuditDocument32 pagesEnergy AuditromeshmoreyNo ratings yet

- Ele Spe Ohl Ye Ykr PP Ceg 001 Rev 1Document25 pagesEle Spe Ohl Ye Ykr PP Ceg 001 Rev 1Jayabalan R KNo ratings yet

- Energy Consumption Norms For Cement Sector Under Energy Conservation Act - 2001Document28 pagesEnergy Consumption Norms For Cement Sector Under Energy Conservation Act - 2001Sarah FrazierNo ratings yet

- Generator Performance MonitoringDocument44 pagesGenerator Performance MonitoringharisankarNo ratings yet

- PCPL 0532 4 407 03Document4 pagesPCPL 0532 4 407 03tceterexNo ratings yet

- ENQUIRY SPEC OF TURBINES Rev Compressed PDFDocument184 pagesENQUIRY SPEC OF TURBINES Rev Compressed PDFumeshNo ratings yet

- Sewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power PlantDocument5 pagesSewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power Plantnourfarmajid0% (1)

- Welfare Facilities MSTDocument41 pagesWelfare Facilities MSTjunaidsaheed3No ratings yet

- A 1Document2 pagesA 1king_athurNo ratings yet

- Kmpp-06-Ele-CA-004 Calculation of Earthing & Lightning Protection Systems - Terminal Station Rev0Document13 pagesKmpp-06-Ele-CA-004 Calculation of Earthing & Lightning Protection Systems - Terminal Station Rev0moosuhaibNo ratings yet

- Haryana Power 800mwDocument61 pagesHaryana Power 800mwprakashkumarsinghgkp01No ratings yet

- Site Comments Datasheets-DG SetDocument14 pagesSite Comments Datasheets-DG Setavinashpratap100% (1)

- Taller Manuales ANAV Cristian y SimónDocument4 pagesTaller Manuales ANAV Cristian y SimónCalavero Pal RatoNo ratings yet

- MPR April 2014 Xen DivisionDocument14 pagesMPR April 2014 Xen DivisionVikas MenariaNo ratings yet

- Technical Specification Turbine - JabalpurDocument111 pagesTechnical Specification Turbine - Jabalpursusmita.sivasankaranNo ratings yet

- Vol II Rev 0Document637 pagesVol II Rev 0Anonymous nwByj9LNo ratings yet

- 0330 405 PVI Y 204 01 Datasheet of 24V BatteryDocument9 pages0330 405 PVI Y 204 01 Datasheet of 24V BatteryPrashant PalNo ratings yet

- Power Transformers DatasheetDocument3 pagesPower Transformers DatasheetMuhammad Ibad AlamNo ratings yet

- TrafoDocument5 pagesTrafoAnonymous vcadX45TD7No ratings yet

- Natural Gas System Equipment List: I.P.D.CDocument5 pagesNatural Gas System Equipment List: I.P.D.CepbamdadNo ratings yet

- Edgington Oil Id 800264 An 471225 Eng EvalDocument14 pagesEdgington Oil Id 800264 An 471225 Eng Evalapi-242947664No ratings yet

- NRC Inspection Manual: Temporary Instruction 2515/176Document10 pagesNRC Inspection Manual: Temporary Instruction 2515/176Kg SubramanianNo ratings yet

- Reliability Based MaintenanceDocument35 pagesReliability Based MaintenanceManoj PaneriNo ratings yet

- Standard Maintenance Procedure For LT Motor MaintenanceDocument4 pagesStandard Maintenance Procedure For LT Motor Maintenancesudhansu8behera100% (1)

- Commissioning Procedure For EDGDocument51 pagesCommissioning Procedure For EDGDani100% (3)

- Gen-Spc-Elc-6102 - Rev. BDocument13 pagesGen-Spc-Elc-6102 - Rev. BAHMED AMIRANo ratings yet

- Work InstructionDocument114 pagesWork Instructiondevan_andNo ratings yet

- ICCP - Claim 80 FINAL DRAWING & OPERATION MANUALDocument52 pagesICCP - Claim 80 FINAL DRAWING & OPERATION MANUALИван ПарлапановNo ratings yet

- ESP Seminar Raipur DT 1.2.11Document92 pagesESP Seminar Raipur DT 1.2.11Tanmoy ChakrabortyNo ratings yet

- SP - DS LTDocument13 pagesSP - DS LTsakhr fahdNo ratings yet

- Energy Audit PresentationDocument30 pagesEnergy Audit PresentationSikander Girgoukar100% (1)

- ProjectDocument8 pagesProjectanup_nairNo ratings yet

- Division 16 - Electrical WorkDocument326 pagesDivision 16 - Electrical WorknawajhaNo ratings yet

- LA Bay 1BDocument3 pagesLA Bay 1BMohammad AsadNo ratings yet

- Gen SPC Elc 6610 Rev. BDocument11 pagesGen SPC Elc 6610 Rev. BAHMED AMIRANo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Advances in Energy Systems: The Large-scale Renewable Energy Integration ChallengeFrom EverandAdvances in Energy Systems: The Large-scale Renewable Energy Integration ChallengeNo ratings yet

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- Energy Finance and Economics: Analysis and Valuation, Risk Management, and the Future of EnergyFrom EverandEnergy Finance and Economics: Analysis and Valuation, Risk Management, and the Future of EnergyRating: 5 out of 5 stars5/5 (2)

- Wave and Tidal EnergyFrom EverandWave and Tidal EnergyDeborah GreavesNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- Sop For Operation of EotDocument2 pagesSop For Operation of Eotsaji kumarNo ratings yet

- Pre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)Document3 pagesPre Installation Lab Requirements: (For Arl XRF 9900 Intellipower Series Spectrometer - 1200W)saji kumarNo ratings yet

- TASK - Clinker - Loading - in - RakeDocument2 pagesTASK - Clinker - Loading - in - Rakesaji kumarNo ratings yet

- Unloading by TrucksDocument2 pagesUnloading by Truckssaji kumarNo ratings yet

- Invoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare WeightDocument1 pageInvoice Was Made, With Weight of Clinker by Difference of Gross Weight and Tare Weightsaji kumarNo ratings yet

- Dammurage Study FormatDocument2 pagesDammurage Study Formatsaji kumarNo ratings yet

- 1.microscopy - Glass Content in Slag SOPDocument1 page1.microscopy - Glass Content in Slag SOPsaji kumarNo ratings yet

- Standard Operating Procedures 1Document1 pageStandard Operating Procedures 1saji kumarNo ratings yet

- North - PV Var - Summary LK MarDocument3 pagesNorth - PV Var - Summary LK Marsaji kumarNo ratings yet

- Heo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain ShellDocument6 pagesHeo Operator: Token Empolyee Name Mobile Number DOZAR/Loader Clain Shellsaji kumarNo ratings yet

- SOP - 22 - Preparation of Activated GypsumDocument2 pagesSOP - 22 - Preparation of Activated Gypsumsaji kumarNo ratings yet

- 1.1 Program KymoreDocument2 pages1.1 Program Kymoresaji kumarNo ratings yet

- B K Singh Sot Dec06Document1 pageB K Singh Sot Dec06saji kumarNo ratings yet

- Ot SlipDocument1 pageOt Slipsaji kumarNo ratings yet

- M.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: ActivityDocument2 pagesM.P.Singh & B.K.Singh Coal Mill CCR 27/03/06 Mill Operation: Observer's Name: Location: Date: Activitysaji kumarNo ratings yet

- Visit To DelhiDocument11 pagesVisit To Delhisaji kumarNo ratings yet

- Compliance Checklist - PlantDocument36 pagesCompliance Checklist - Plantsaji kumarNo ratings yet

- Please Tick in Appropriate Column: Roadblock / BarrierDocument1 pagePlease Tick in Appropriate Column: Roadblock / Barriersaji kumarNo ratings yet

- Procurement Process Guide V 5.0 - Final CompressedDocument114 pagesProcurement Process Guide V 5.0 - Final Compressedsaji kumar100% (1)

- Chapter 3a Geometry of CrystalsDocument72 pagesChapter 3a Geometry of Crystalssaji kumar100% (1)

- BH15/SN23 BH15/SN30Document17 pagesBH15/SN23 BH15/SN30saji kumarNo ratings yet

- Mines Bore Hole Sample Analysis Test Results (Durg)Document4 pagesMines Bore Hole Sample Analysis Test Results (Durg)saji kumarNo ratings yet