Professional Documents

Culture Documents

Hanson 2010

Hanson 2010

Uploaded by

Sajid Mohy Ul DinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hanson 2010

Hanson 2010

Uploaded by

Sajid Mohy Ul DinCopyright:

Available Formats

J. Dairy Sci.

93:801807

doi:10.3168/jds.2009-2694

American Dairy Science Association, 2010.

Evaluation of increased vitamin D fortification in high-temperature,

short-timeprocessed 2% milk, UHT-processed 2% fat

chocolate milk, and low-fat strawberry yogurt

A. L. Hanson* and L. E. Metzger1

*Midwest Dairy Food Research Center, Food Science & Nutrition Department, University of Minnesota, St. Paul 55108

Midwest Dairy Food Research Center, Dairy Science Department, South Dakota State University, Dairy-Micro Building, SDM 314, Brookings

57007

ABSTRACT

The objective of this study was to determine the effect of increased vitamin D fortification (250 IU/serving) of high-temperature, short-time (HTST)processed

2% fat milk, UHT-processed 2% fat chocolate milk,

and low-fat strawberry yogurt on the sensory characteristics and stability of vitamin D during processing

and storage. Three replicates of HTST pasteurized 2%

fat milk, UHT pasteurized 2% fat chocolate milk, and

low-fat strawberry yogurt were manufactured. Each of

the 3 replicates for all products contained a control

(no vitamin D fortification), a treatment group with

100 IU vitamin D/serving (current level of vitamin D

fortification), and a treatment group with 250 IU vitamin D/serving. A cold-water dispersible vitamin D3

concentrate was used for all fortifications. The HTSTprocessed 2% fat milk was stored for 21 d, with vitamin

D analysis done before processing and on d 0, 14, and

21. Sensory analysis was conducted on d 14. The UHTprocessed 2% fat chocolate milk was stored for 60 d,

with vitamin D analysis done before processing and on

d 0, 40, and 60. Sensory analysis was conducted on d

40. Low-fat strawberry yogurt was stored for 42 d, with

vitamin D analysis done before processing, and on d 0,

28, and 42. Sensory analysis was conducted on d 28.

Vitamin D levels in the fortified products were found to

be similar to the target levels of fortification (100 and

250 IU vitamin D per serving) for all products, indicating no loss of vitamin D during processing. Vitamin D

was also found to be stable over the shelf life of each

product. Increasing the fortification of vitamin D from

100 to 250 IU/serving did not result in a change in the

sensory characteristics of HTST-processed 2% fat milk,

UHT-processed 2% fat chocolate milk, or low-fat strawberry yogurt. These results indicate that it is feasible to

Received September 2, 2009.

Accepted October 31, 2009.

1

Corresponding author: Lloyd.Metzger@sdstate.edu

increase vitamin D fortification from 100 to 250 IU per

serving in these products.

Key words: vitamin D, stability, fortification, dairy

product

INTRODUCTION

Vitamin D is necessary for proper skeletal development and plays a fundamental role in regulating serum

calcium and phosphorus concentrations in the body.

Vitamin D is not technically classified as an essential

nutrient in the body because it can be photosynthesized in the skin as a result of exposure to solar UVB

radiation (Holick, 1994). However, at latitudes above

40N or below 40S, no photosynthesized vitamin D is

produced in the skin for several months of the year, and

supplementation of vitamin D is required to prevent

deficiency (Webb et al., 1988; Ladizesky et al., 1995).

Additionally, use of sunscreen can limit the amount

of vitamin D produced in the skin from sun exposure

(Hollis, 2005). Determining the recommendation for

adequate intake of vitamin D is difficult because most

studies are confounded by several factors related to

vitamin D production in the skin.

The first recommended dietary allowance for vitamin

D in the United States was established in 1941 and set

at 400 IU for adults. The value of 400 IU was determined based on a teaspoon of cod liver oil, which was

found to be capable of preventing rickets (Park, 1940).

Dietary recommendations have changed substantially

since the 1940s and currently the term dietary reference intakes is used to collectively describe 4 terms

including estimated average requirement (EAR), recommended dietary allowance (RDA), adequate intake

(AI), and tolerable upper intake level (UL; National

Academy of Sciences, 1997). The purpose of the RDA

is to serve as a goal for daily intake of individuals.

The RDA is calculated from the EAR and is equal to

the EAR plus 2 standard deviations of the EAR. The

EAR is the daily intake value that is estimated to meet

the requirements of 50% of the individuals in a spe-

801

802

HANSON AND METZGER

cific group. However, in the case of vitamin D there is

not sufficient scientific evidence available to determine

an EAR. Consequently, the AI is used instead of the

RDA. The AI is determined based on experimentally

determined intake levels or approximations of observed

mean nutrient intakes by a group of healthy people.

As further research is conducted, it may be possible to

replace AI estimates with EARs and RDAs.

Vitamin D deficiency contributes to diseases such

as childhood rickets, osteoporosis, and osteomalacia,

and being deficient in vitamin D has been shown to

increase the risk of developing cancers, osteoporotic

fractures, and autoimmune diseases (Holick, 2002). It

is estimated that a significant portion (3040%) of the

US population is deficient in vitamin D (Thomas et

al., 1998). Additionally, publications on vitamin D deficiency have suggested that the recommended adequate

intake of vitamin D is too low and should be increased

to at least 800 IU for adults (Holick, 2007; Brannon

et al., 2008). However, the potential for vitamin D

intoxication also needs to be considered when contemplating an increase in the AI of vitamin D. Toxicity

levels have been shown to be substantially higher than

originally estimated, and Vieth (1999) has shown no

adverse effects at supplementation levels 2 times the

current recommended intake. Additionally, Heaney et

al. (2003) showed no adverse effects at a level of 10,000

IU per day for a period of 5 mo. Consequently, vitamin

D intoxication as a result of an increase in the AI of

vitamin D does not appear to be a major concern and

an increase in the AI of vitamin D to at least 800 IU

is expected.

In the United States, all forms of fluid milk are

currently fortified with 100 IU of vitamin D per serving (240 mL). Milk has been fortified with vitamin D

for more than 50 yr, and fluid milk is generally the

main medium of vitamin D fortification in the United

States. However, the per capita consumption of fluid

white milk in the United States has steadily declined in

the last 50 yr (International Dairy Foods Association,

2008). Consequently, the level of dietary vitamin D in

the US diet provided by fluid milk has declined, and

targeted supplementation of high-risk groups, as well as

fortification of a larger variety of products with vitamin

D, has been recommended (Calvo and Whiting, 2003).

In contrast to the declining consumption of fluid

milk, consumption of flavored milk drinks and yogurt

has increased substantially in the last 20 yr; these products had a per capita consumption of 6.59 and 5.23

kg, respectively, in 2007 (International Dairy Foods Association, 2008). Consequently, utilization of flavored

milk drinks and yogurt as additional mediums for supplying vitamin D to consumers can compensate for a

reduction in the consumption of white milk. During

Journal of Dairy Science Vol. 93 No. 2, 2010

yogurt and flavored milk manufacture, the milk base

is processed in a manner similar to that used for fluid

milk. Consequently, the fortification techniques used

for fluid milk (FDA, 2007) can also be used in flavored

milk and yogurt manufacture.

Several studies have been conducted on the stability

of vitamin D in milk and other dairy products (Renken

and Warthesen, 1993; Upreti et al., 2002; Kazmi et al.,

2007; Wagner et al., 2008). These studies have all indicated that vitamin D is stable during processing and

storage. However, these studies evaluated vitamin D

stability at the current fortification level (100 IU/serving) or did not include sensory analysis to determine

if vitamin D fortification had an effect on the sensory

characteristics of dairy products. Because an increase in

the fortification level of vitamin D has been suggested,

the effect of an increased fortification level on vitamin

D stability and sensory characteristics is warranted.

The objective of this study was to determine the effect

of increased vitamin D fortification (250 IU/serving) of

HTST-processed 2% fat milk, UHT-processed 2% fat

chocolate milk, and low-fat strawberry yogurt on the

sensory characteristics and stability of vitamin D during processing and storage.

MATERIALS AND METHODS

Manufacturing Procedures

HTST-Processed 2% Fat Milk Preparation.

Three 54.5-kg batches of 2% fat milk were prepared

by standardizing raw skim with raw cream. One batch

was the control treatment and was not fortified with

vitamin D. One batch was used to prepare the 100 IU/

serving (240 mL) treatment, and one batch was used to

prepare the 250 IU/serving (240 mL) treatment. Both

of the vitamin D treatments were fortified with dry,

water-dispersible vitamin D concentrate (vitamin D3

type CWS, 100,000 IU/g, DSM Nutritional Products,

Parsippany, NJ). For the 100 IU/serving treatment, the

vitamin D concentrate was used to prepare an initial

dilution containing 2.2 g of vitamin D supplement and

97.8 g of distilled water, whereas for the 250 IU/serving treatment, the vitamin D supplement was used to

prepare an initial dilution contain 5.5 g of vitamin D

supplement and 94.5 g of distilled water. A 10.5-g aliquot of each respective dilution was added to 54.5 kg of

standardized milk (skim and cream) to obtain the 100

IU/serving and 250 IU/serving treatments. After being

thoroughly mixed, the 3 treatments were homogenized

(13.8/3.4 MPa), pasteurized at 73C for 15 s using a

plate heat exchanger (Super Plate, Cherry-Burrell

Corp., Chicago, IL), packaged in half-gallon opaque

plastic containers, and stored for 21 d at 4C. All 3

OUR INDUSTRY TODAY

batches were prepared in triplicate using 3 different lots

of raw skim and raw cream. Samples of the milk were

collected from each treatment before pasteurization and

at 0, 14, and 21 d of storage. Each sample was analyzed

for vitamin D in duplicate by Silliker Laboratories

(Chicago Heights, IL) using an HPLC-based method

(Reynolds and Judd, 1984). The fat, protein, and total

solids content of each sample after pasteurization were

determined by using an infrared analyzer (FT120, Foss

North America, Minneapolis, MN).

UHT-Processed 2% Fat Chocolate Milk Preparation. Three 34.9-kg batches of 2% fat chocolate

milk were prepared by first standardizing raw skim

with raw cream to obtain three 32.7-kg batches of

2.15% fat milk. Subsequently, 0.39 kg of cocoa powder

(Main Street Ingredients, La Crosse, WI), 1.64 kg of

sugar (American Crystal, Moorhead, MN), 164 g of

carrageenan (TIC Gums, Belcamp, MD), and 20 g of

vanilla (Robertet Flavors, Piscataway, NJ) were added

to each batch of standardized milk. After addition of

all ingredients, each batch was thoroughly mixed. One

batch served as the control and was not fortified with

vitamin D. One batch was the 100 IU/serving (240 mL)

treatment and was fortified with dry, water-dispersible

vitamin D concentrate (Vitamin D3 type CWS, 100,000

IU/g, DSM Nutritional Products). For this treatment,

the vitamin D supplement was used to prepare an initial dilution containing 1.41 g of vitamin D supplement

and 98.59 g of distilled water. A 10.5-g aliquot of the

dilution was added to the 2% fat chocolate milk. One

batch was the 250 IU/serving (240 mL) treatment and

was also fortified with dry, water-dispersible vitamin D

supplement (vitamin D3 type CWS, 100,000 IU/g, DSM

Nutritional Products). For this treatment, the vitamin

D supplement was used to prepare an initial dilution

containing 3.52 g of vitamin D supplement and 96.48

g of distilled water. A 10.5-g aliquot of the dilution

was added to the 2% fat chocolate milk. After being

thoroughly mixed, the 3 treatments were UHT pasteurized at 138C for 2 s and homogenized (13.8/3.4 MPa)

using a laboratory-scale MicroThermics UHT processing unit (MicroThermics Inc., Raleigh, NC), aseptically

packaged into sterilized opaque plastic containers, and

stored at 4C. All 3 batches were prepared in triplicate using 3 different lots of raw skim and raw cream.

Samples of the chocolate milk were collected from each

treatment before UHT processing and at 0, 40, and 60

d of storage. Each sample was analyzed for vitamin D

in duplicate by Silliker Laboratories using an HPLCbased method (Reynolds and Judd, 1984). The fat and

total protein of each sample after pasteurization were

determined by Mojonnier and Kjeldahl total nitrogen

analysis, respectively (Wehr and Frank, 2004).

803

Low-Fat Strawberry Yogurt Product Preparation. Initially, three 15.45-kg batches of yogurt base

were prepared by combining 14.13 kg of 1.8% fat

raw milk, 0.77 kg of nonfat dry milk (Plainview Milk

Products, Plainview, MN), 0.42 kg of sugar (American Crystal), 88 g of gelatin (Continental Colloids,

West Chicago, IL), and 34 g of modified corn starch

(National Starch, Bridgewater, NJ). One batch served

as the control and was not fortified with vitamin D.

One batch was the 100 IU/serving (227 g) treatment

and was fortified with dry, water-dispersible vitamin

D supplement (Vitamin D3 type CWS, 100,000 IU/g,

DSM Nutritional Products). For this treatment, an

initial dilution was prepared using 0.80 g of vitamin D

supplement and 99.2 g of distilled water. A 10.5-g aliquot of the dilution was added to the yogurt base. One

batch was the 250 IU/serving (227 g) treatment and

was also fortified with dry, water-dispersible vitamin

D supplement (vitamin D3 type CWS, 100,000 IU/g,

DSM Nutritional Products). For this treatment, an

initial dilution was prepared using 2.0 g of vitamin D

supplement and 98 g of distilled water. A 10.5-g aliquot

of the dilution was added to the yogurt base. After being thoroughly mixed, each yogurt base was heated to

85C for 30 min, cooled to 54C, homogenized (13.8/3.4

MPa), cooled to 43C, and inoculated with 2.1 g of

direct vat set culture (Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus thermophilus, Danisco USA,

Madison, WI). Each yogurt base was incubated at 43C

until a pH of 4.6 was reached. After reaching pH 4.6,

each yogurt base was transferred to a cooler (4C) and

stored overnight. Finally, each 18.18-kg batch of yogurt

was prepared by mixing 15.45 kg of fermented yogurt

base with 2.73 kg of strawberry puree (Denali Ingredients, New Berlin, WI). The final product was packaged

into 250-g plastic containers and stored at 4C. All 3

batches were prepared in triplicate using 3 different lots

of raw milk. Samples of the final yogurt were collected

at 0, 28, and 42 d of storage. Each sample was analyzed

for vitamin D in duplicate by Silliker Laboratories

using an HPLC-based method (Reynolds and Judd,

1984). The fat and total protein of each yogurt were

determined by Mojonnier and Kjeldahl total nitrogen

analysis, respectively (Wehr and Frank, 2004).

Statistical Analysis

A 3 3 randomized complete block design was used

for the HTST-processed 2% fat milk, UHT-processed

2% fat chocolate milk, and low-fat strawberry yogurt

studies. In each study the 3 treatments (control, 100

IU vitamin D per serving, and 250 IU vitamin D per

serving) were made from the same standardized milk

Journal of Dairy Science Vol. 93 No. 2, 2010

804

HANSON AND METZGER

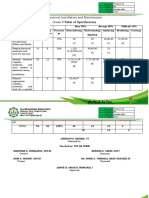

Table 1. Vitamin D content (mean of 3 replicates) of HTST-processed 2% fat milk during 21 d of storage at 4C

Day 0

Treatment

Control

100 IU1/serving

250 IU1/serving

Day 14

Day 21

Mean

SD

Mean

SD

Mean

SD

<10

110

275

4.73

2.65

<10

111

281

2.00

7.57

<10

111

279

2.52

3.00

Values reported as international units (IU) of vitamin D per serving.

and were replicated 3 times using different lots of milk.

Storage stability of vitamin D in each product was

analyzed using a repeated measures design. Analysis of

variance was performed to obtain the mean squares and

P-values using SAS software (SAS Institute, 1990). All

data were analyzed at a significance level of 0.05.

Sensory Analysis

A replicated triangle test was performed using a

panel of 30 to 35 judges at the Sensory Center (Department of Food Science and Nutrition, University of

Minnesota) to detect differences in the overall sensory

attributes of the control and vitamin D-fortified HTSTprocessed 2% fat milk samples after 14 d of refrigerated

storage. Each judge received 2 triangle tests. In one

test, the fortified milk (100 IU) was the odd sample.

In the other test, the control was the odd sample. This

was also done for the 250 IU versus control and 100 IU

versus 250 IU milks. Each judge was asked to identify

the odd sample. The nature of the odd sample and the

order of samples in each set were balanced. Normal

distribution, as an approximation for binomial distribution, was used for data analysis (Lawless and Heymann,

1998). The chance probability of getting both triangle

tests correct was 1/9. Statistics were performed at a

0.05 significance level. The same procedures were used

for the UHT-processed 2% fat chocolate milk and the

low-fat strawberry yogurt. All samples were stored at

4C before analysis. Sensory analysis was conducted after 40 d of refrigerated storage for the 2% fat chocolate

milk and after 28 d for the low-fat strawberry yogurt.

Triangle tests for each product were replicated for the 3

batches of HTST-processed 2% fat milk, UHT-processed

2% fat chocolate milk, and low-fat strawberry yogurt.

RESULTS AND DISCUSSION

HTST-Processed 2% Fat Milk

There were no significant (P > 0.05) differences

among the treatments in the composition of the HTSTprocessed 2% fat milk. The mean fat, protein, and total

solids contents among the treatments ranged from 1.96

to 2.06%, 3.09 to 3.10%, and 10.54 to 10.57%, respectively. There were no significant (P > 0.05) differences

in the vitamin D content of the 100 IU treatment (108

IU/serving before processing and 110 IU/serving after

processing) or the 250 IU treatments (276 IU/serving

before processing and 275 IU/serving after processing)

before and after processing. The mean vitamin D results of the 3 replicates of HTST-processed 2% fat milk

at 0, 14, and 21 d of refrigerated storage are shown in

Table 1. The level of vitamin D in each treatment at 0

d of storage was close to the targeted levels of fortification (100 and 250 IU/serving). Additionally, there was

no significant (P > 0.05) change in vitamin D during

the 21-d storage period. These results demonstrate that

an increase in vitamin D fortification from 100 to 250

IU/serving does not affect vitamin D stability during

processing and storage over the typical shelf life (21 d)

at either fortification level (100 or 250 IU) in HTSTprocessed 2% fat milk. Previous studies have also

determined that vitamin D is not affected by HTST

processing (Wagner et al., 2008) and that it is stable

during storage at 4C (Renken and Warthesen, 1993).

The results for the sensory analysis (triangle test) of

the 3 replicates of HTST-processed 2% fat milk conducted at 14 d of storage are shown in Table 2. There

was no significant (P > 0.05) difference between any

treatments in all 3 replicates. These results demonstrate

Table 2. Sensory analysis (triangle test) of HTST-processed 2% milk at 14 d of refrigerated storage at 4C

Control vs. 100 IU

Replicate

1

2

3

Control vs. 250 IU

100 IU vs. 250 IU

No. correct

Z-score

P-value

No. correct

Z-score

P-value

No. correct

Z-score

P-value

4

2

3

0.10

1.07

2.23

0.43

0.87

1.00

5

5

5

0.68

0.68

0.68

0.24

0.25

0.23

3

6

4

0.48

1.26

0.10

0.66

0.19

0.42

Indicates number of judges correctly selecting the odd sample in both triangle tests; 30 judges were used in all replicates.

Journal of Dairy Science Vol. 93 No. 2, 2010

805

OUR INDUSTRY TODAY

Table 3. Vitamin D content (mean of 3 replicates) of UHT-processed 2% fat chocolate milk during 60 d of storage at 4C

Day 0

Treatment

Control

100 IU1/serving

250 IU1/serving

1

Day 40

Day 60

Mean

SD

Mean

SD

Mean

SD

<10

106

265

3.61

19.97

<10

105

254

6.24

24.42

<10

103

251

6.66

9.61

Values reported as international units (IU) of vitamin D per serving.

that fortification of HTST-processed 2% fat milk with

vitamin D, irrespective of the fortification level (100

or 250 IU/serving), will not result in a change in the

sensory characteristics.

The results for the sensory analysis (triangle test)

of the 3 replicates of UHT 2% fat chocolate milk conducted at 40 d of storage are shown in Table 4. There

were no significant (P > 0.05) differences between any

treatments in all 3 replicates. These results demonstrate

that fortification of UHT-processed 2% fat chocolate

milk with vitamin D, irrespective of the fortification

level (100 or 250 IU/serving), will not result in a change

in the sensory characteristics.

UHT-Processed 2% Fat Chocolate Milk

There were no significant (P > 0.05) differences

among the treatments in the composition of the UHTprocessed 2% fat chocolate milk. The mean fat and protein contents among the treatments ranged from 2.04 to

2.06% and from 3.33 to 3.38%, respectively. There were

no significant (P > 0.05) differences in the vitamin D

content of the 100 IU treatment (109 IU/serving before

processing and 106 IU/serving after processing) or the

250 IU treatments (257 IU/serving before processing

and 264 IU/serving after processing) before and after

processing. The mean vitamin D results for the 3 replicates of UHT-processed 2% fat chocolate milk at 0,

40, and 60 d of refrigerated storage are shown in Table

3. The level of vitamin D in each treatment at 0 d of

storage was close to the targeted levels of fortification

(100 and 250 IU). Additionally, there was no significant

(P > 0.05) change in the level of vitamin D during

the 60-d storage period. These results demonstrate

that an increase in vitamin D fortification from 100

to 250 IU/serving does not affect vitamin D stability

during processing, and storage over the typical shelf life

(60 d) at either fortification level (100 or 250 IU) in

UHT-processed 2% fat chocolate milk. The stability of

vitamin D to UHT processing is not surprising because

vitamin D in milk has been reported to be stable to

sterilization (Hartman and Dryden, 1974).

Low-Fat Strawberry Yogurt

There were no significant (P > 0.05) differences

among the treatments in the composition of the low-fat

strawberry yogurt. The mean fat and protein contents

among the treatments ranged from 1.38 to 1.42% and

from 4.55 to 4.65%, respectively. The mean vitamin D

results of the 3 replicates of low-fat strawberry yogurt

at 0, 28, and 42 d of refrigerated storage are shown in

Table 5. The level of vitamin D in each treatment at

0 d of storage was slightly higher than the targeted

levels of fortification (100 and 250 IU). There was no

significant (P > 0.05) change in vitamin D during the

42-d storage period. These results demonstrate that vitamin D fortification at 100 or 250 IU/serving is stable

over the typical shelf life (42 d) of low-fat strawberry

yogurt. Previous research has also found that vitamin

D was unaffected by yogurt fermentation and that it

was stable during storage at 4C (Kazmi et al., 2007).

The results for the sensory analysis (triangle test) of

the 3 replicates of low-fat strawberry yogurt conducted

at 28 d of storage are shown in Table 6. In all 3 replicates there was no significant (P > 0.05) difference

Table 4. Sensory analysis (triangle test) of UHT-processed 2% chocolate milk at 40 d of refrigerated storage at 4C

Control vs. 100 IU

Replicate

1

2

3

Control vs. 250 IU

100 IU vs. 250 IU

No. correct1

Z-score

P-value

No. correct

Z-score

P-value

No. correct

Z-score

P-value

3

5

5

0.48

0.60

0.60

0.74

0.25

0.25

4

5

5

0.10

0.60

0.60

0.52

0.25

0.25

7

3

2

1.84

0.54

1.11

0.07

0.68

0.87

Indicates number of judges correctly selecting the odd sample in both triangle tests; 34, 31, and 31 judges were used in replicates 1, 2, and 3,

respectively.

Journal of Dairy Science Vol. 93 No. 2, 2010

806

HANSON AND METZGER

Table 5. Vitamin D content (mean of 3 replicates) of low-fat strawberry yogurt during 42 d of storage at 4C

Day 0

Treatment

Control

100 IU1/serving

250 IU1/serving

Day 28

Day 42

Mean

SD

Mean

SD

Mean

SD

<10

122

287

16.52

32.72

<10

120

298

15.10

25.42

<10

125

294

12.12

22.48

Values reported as international units (IU) of vitamin D per serving.

Table 6. Sensory analysis (triangle test) of low-fat strawberry yogurt at 28 d of refrigerated storage at 4C

Control vs. 100 IU

Replicate

1

2

3

Control vs. 250 IU

100 IU vs. 250 IU

No. correct1

Z-score

P-value

No. correct1

Z-score

P-value

No. correct1

Z-score

P-value

8

6

6

2.42

1.02

1.17

0.01

0.15

0.12

4

5

1

0.10

0.46

1.68

0.42

0.29

0.97

2

4

5

1.07

0.09

0.60

0.86

0.50

0.25

1

Indicates number of judges correctly selecting the odd sample in both triangle tests; 30, 33, and 31 judges were used in replicates 1, 2, and 3,

respectively.

between the control treatment and the 250 IU treatment, or between the 100 IU treatment and the 250 IU

treatment. In one replicate, the sensory panel detected

a significant (P < 0.05) difference between the control

and the 100 IU treatment. This significant difference

appears to be unrelated to vitamin D fortification

because there were no significant differences between

the other 2 replicates or between the control and 250

IU in any replicate. We speculate that this significant

difference may have been related to the yogurt processing conditions of this treatment because minor changes

in fermentation characteristics or the extent of stirring

before packaging can have an effect on yogurt texture,

which may have been detected by the sensory panel.

These results demonstrate that fortification of low-fat

strawberry yogurt with vitamin D, irrespective of the

fortification level (100 or 250 IU/serving), will not result in a change in the sensory characteristics.

Verification of Accurate Fortification

Although this study and previous research studies

have found that vitamin D is stable in milk and dairy

products during processing and storage, in the early

1990s Holick et al. (1992) reported that only 29% of

commercial milk samples fortified with vitamin D had

measured concentrations of vitamin D that were within

80 to 120% of the label claim. Since the early 1990s, the

Pasteurized Milk Ordinance has been revised to require

each manufacturer to conduct annual testing of milk

products for vitamin D level by a FDA-certified laboratory. This change in the Pasteurized Milk Ordinance

appears to have resulted in improved label compliance:

Journal of Dairy Science Vol. 93 No. 2, 2010

in a recent USDA study, 77% of milk products tested

were very close to or within the labeled level of vitamin

D (Holden et al., 2009). These studies highlight the importance of verification of proper fortification of vitamin

D. Consequently, if the vitamin D fortification level of

dairy products is increased from 100 to 250 IU/serving,

verification of proper fortification is warranted.

CONCLUSIONS

Vitamin D fortification at 250 IU/serving was stable

over the shelf lives of HTST-processed 2% fat milk,

UHT-processed 2% fat chocolate milk, and low-fat

strawberry yogurt. No effect on the sensory characteristics of these products was found by increasing vitamin D fortification from 100 to 250 IU/serving. These

results demonstrate that a feasible strategy to increase

vitamin D supplementation is to increase the fortification level of milk from 100 to 250 IU/serving as well

as increase the range of dairy products fortified with

vitamin D.

ACKNOWLEDGMENTS

We thank Dairy Management Inc. (Rosemont, IL)

and Midwest Dairy Association (St. Paul, MN) for financial support.

REFERENCES

Brannon, P. M., E. A. Yetley, R. L. Bailey, and M. F. Picciano.

2008. Overview of conference Vitamin D and Health in the 21st

Century: An Update . Am. J. Clin. Nutr. 88(Suppl.):483S490S.

Calvo, M. S., and S. J. Whiting. 2003. Prevalence of vitamin D

insufficiency in Canada and the United States: Importance to

OUR INDUSTRY TODAY

health status and efficacy of current food fortification and dietary

supplement use. Nutr. Rev. 61:107113.

FDA. 2007. Appendix O. Vitamin fortification of fluid milk products.

Pages 336340 in Grade A Pasteurized Milk Ordinance. US

Department of Health and Human Services, Washington, DC.

Hartman, A. M., and L. P. Dryden. 1974. Vitamins in milk and milk

products. Pages 325401 in Fundamental of Dairy Chemistry. 2nd

ed. B. H. Webb, A. H. Johnson, and J. A. Alford, ed. AVI/Van

Norstrand Reinhold, New York, NY.

Heaney, R. P., K. M. Davies, T. C. Chen, M. F. Holick, and M.

J. Barger-Lux. 2003. Human serum 25-hydroxycholecalciferol

response to extended oral dosing with cholecalciferol. Am. J. Clin.

Nutr. 77:204210.

Holden, J. M., K. Y. Patterson, J. Exler, R. L. Horst, L. E. Lemar,

and K. M. Phillips. 2009. Vitamin D3 content of fortified yogurt

and milk as determined by the USDA National Food and Nutrient

Analysis Program. FASEB J. 23:112.8.

Holick, M. F. 1994. McCollum Award Lecture: Vitamin D: New

horizons for the 21st century. Am. J. Clin. Nutr. 60:619630.

Holick, M. F. 2002. Vitamin D, The underappreciated D-lightful

hormone that is important for skeletal and cellular health. Curr.

Opin. Endocrinol. Diabetes 9:8798.

Holick, M. F. 2007. Vitamin D deficiency. N. Engl. J. Med. 357:266

281.

Holick, M. F., Q. Shao, W. W. Liu, and T. C. Chen. 1992. The vitamin

D content of fortified milk and infant formula. N. Engl. J. Med.

326:11731177.

Hollis, B. W. 2005. Circulating 25-hydroxyvitamin D levels indicative

of vitamin D sufficiency: Implications for establishing a new

effective dietary intake recommendation for vitamin D. J. Nutr.

135:317322.

International Dairy Foods Association. 2008. Dairy Facts. IDFA,

Washington, DC.

Kazmi, S. A., R. Vieth, and D. Rousseau. 2007. Vitamin D3 fortification

and quantification in processed dairy products. Int. Dairy J.

17:753759.

Ladizesky, M., Z. Lu, B. Oliver, N. San Roman, S. Diaz, M. F.

Holick, and C. Mautalen. 1995. Solar ultraviolet B radiation and

photoproduction of vitamin D3 in central and southern areas of

Argentina. J. Bone Miner. Res. 10:545549.

807

Lawless, H. T., and H. Heymann. 1998. Appendix II. Nonparameter

and binomial-based statistical methods. Pages 679699 in Sensory

Evaluation of Food: Principles and Practices. Chapman & Hall,

New York, NY.

National Academy of Sciences. 1997. Dietary Reference Intakes for

Calcium, Phosphorus, Magnesium, Vitamin D and Fluoride.

National Academy of Sciences, Institute of Medicine, Food and

Nutrition Board. National Academy Press, Washington, DC.

Park, E. A. 1940. The therapy of rickets. J. Am. Med. Assoc. 115:370

379.

Renken, S. A., and J. J. Warthesen. 1993. Vitamin D stability in milk.

J. Food Sci. 58:552555.

Reynolds, S. L., and H. J. Judd. 1984. Rapid procedure for the

determination of vitamins A and D in fortified skim milk powder

using high performance liquid chromatography. Analyst (Lond.)

109:489492.

SAS Institute. 1990. SAS Users Guide: Statistics. Version 6 ed. SAS

Inst. Inc., Cary, NC.

Thomas, M. K., D. M. Lloyd-Jones, R. I. Thadani, A. C. Shaw, D. J.

Deraska, B. T. Kitch, E. C. Vamvakas, I. M. Dick, R. L. Prince, and

J. S. Finkelstein. 1998. Hypovitaminosis D in medical inpatients.

N. Engl. J. Med. 338:777783.

Upreti, P., V. V. Mistry, and J. J. Warthesen. 2002. Estimation and

fortification of Vitamin D3 in pasteurized process cheese. J. Dairy

Sci. 85:31733181.

Vieth, R. 1999. Vitamin D supplementation, 25-hydroxyvitamin D

concentrations, and safety. Am. J. Clin. Nutr. 69:842856.

Wagner, D., D. Rousseau, G. Sidhom, M. Pouliot, P. Audet, and R.

Vieth. 2008. Vitamin D3 fortification, quantification, and longterm stability in Cheddar and low-fat cheeses. J. Agric. Food

Chem. 56:79647969.

Webb, A. R., L. Kline, and M. F. Holick. 1988. Influence of season

and latitude on cutaneous synthesis of vitamin D3: Exposure to

winter sunlight in Boston and Edmonton will not promote vitamin

D3 synthesis in human skin. J. Clin. Endocrinol. Metab. 67:373

378.

Wehr, H. M., and J. E. Frank. 2004. Standard Methods for the

Examination of Dairy Products. 17th ed. American Public Health

Association, Washington, DC.

Journal of Dairy Science Vol. 93 No. 2, 2010

You might also like

- ORE - UK Dental Reference BooksDocument4 pagesORE - UK Dental Reference BooksKisshore Reddy50% (2)

- Linking Anthropology: History ClothingDocument5 pagesLinking Anthropology: History ClothingSajid Mohy Ul DinNo ratings yet

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- Hanson, A.L. Metzger, L.E. 2010Document7 pagesHanson, A.L. Metzger, L.E. 2010PetronelaNo ratings yet

- Fortification of Cheddar Cheese With Vitamin D Does Not Alter Cheese Flavor PerceptionDocument7 pagesFortification of Cheddar Cheese With Vitamin D Does Not Alter Cheese Flavor PerceptionWahab KhanNo ratings yet

- Fortification of Cheese With Vitamin D Using Dairy Protein Emulsions As Delivery SystemsDocument7 pagesFortification of Cheese With Vitamin D Using Dairy Protein Emulsions As Delivery SystemsWahab KhanNo ratings yet

- Advances in Human Milk Fortification With Added SupplementsDocument9 pagesAdvances in Human Milk Fortification With Added SupplementsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Vitamins Research PaperDocument6 pagesVitamins Research Papergbjtjrwgf100% (1)

- RevisinvitaminaD PDFDocument13 pagesRevisinvitaminaD PDFVanessa DominguezNo ratings yet

- International Dairy Journal: ArticleinfoDocument6 pagesInternational Dairy Journal: ArticleinfoWahab KhanNo ratings yet

- Vitamin DDocument14 pagesVitamin Dapi-252656907No ratings yet

- Fortified TeaDocument12 pagesFortified TeaRahul TripathiNo ratings yet

- Nutrients: Nutrients and Dietary Patterns Related To OsteoporosisDocument16 pagesNutrients: Nutrients and Dietary Patterns Related To Osteoporosisdafa bintangNo ratings yet

- Biesalski Vitamin D RecommendationsDocument7 pagesBiesalski Vitamin D RecommendationsAleem MuhammadNo ratings yet

- Vitamin D: Ask Ods ODS Email ListDocument11 pagesVitamin D: Ask Ods ODS Email ListntnquynhproNo ratings yet

- Yogurt Forti Fication With Chickpea (Cicer Arietinum) Flour: Physicochemical and Sensory EffectsDocument8 pagesYogurt Forti Fication With Chickpea (Cicer Arietinum) Flour: Physicochemical and Sensory EffectsATHIRA M.NAIRNo ratings yet

- Characteristics of Wild Blueberry-Soy Beverages: R.M. Potter, M.P. Dougherty, W.A. Halteman, M.E. CamireDocument8 pagesCharacteristics of Wild Blueberry-Soy Beverages: R.M. Potter, M.P. Dougherty, W.A. Halteman, M.E. CamirejapoleonaNo ratings yet

- مقاله دومDocument8 pagesمقاله دومjilitwoNo ratings yet

- Vitamin D Thesis PDFDocument7 pagesVitamin D Thesis PDFbsr3rf42100% (2)

- Cod Liver Oil, The Ratio of Vitamins A and D, Frequent Respiratory Tract Infections, and Vitamin D Deficiency in Young Children in The United StatesDocument9 pagesCod Liver Oil, The Ratio of Vitamins A and D, Frequent Respiratory Tract Infections, and Vitamin D Deficiency in Young Children in The United StatesArum Fristia WilujengNo ratings yet

- GR Bioavailability AJCN2012 PDFDocument7 pagesGR Bioavailability AJCN2012 PDFSMKN 1 GerokgakNo ratings yet

- Study On The Effects of Different Sterilization Methods and Storage Conditions On Milk QualityDocument7 pagesStudy On The Effects of Different Sterilization Methods and Storage Conditions On Milk QualitySubhankar MaityNo ratings yet

- Cod Liver Oil The Ratio of Vitamins A and D FrequeDocument9 pagesCod Liver Oil The Ratio of Vitamins A and D Frequereg ethicalNo ratings yet

- Production and Quality Assessment of Functional Yoghurt Enriched With CoconutDocument6 pagesProduction and Quality Assessment of Functional Yoghurt Enriched With CoconutembunNo ratings yet

- Antioxidant and Antigenotoxic Effect of Dairy Products Supplemented With Red Ginseng ExtractDocument9 pagesAntioxidant and Antigenotoxic Effect of Dairy Products Supplemented With Red Ginseng ExtractJEDYANNo ratings yet

- Responsive Documents - CREW: FTC: Regarding Indoor Tanning Association: 5/15/14 - Batch Two, Part TwoDocument700 pagesResponsive Documents - CREW: FTC: Regarding Indoor Tanning Association: 5/15/14 - Batch Two, Part TwoCREWNo ratings yet

- Food Chemistry: Janneke Verkaik-Kloosterman, S. Marije Seves, Marga C. OckéDocument7 pagesFood Chemistry: Janneke Verkaik-Kloosterman, S. Marije Seves, Marga C. OckéLunirioNo ratings yet

- Ashutosh Synopsis DahiDocument17 pagesAshutosh Synopsis DahiAshutosh MasihNo ratings yet

- Nutrition Recommendations in Pregnancy and LactationDocument17 pagesNutrition Recommendations in Pregnancy and LactationDodi TambunNo ratings yet

- Vitamin D: World's Healthiest Foods Rich in VitaminDocument13 pagesVitamin D: World's Healthiest Foods Rich in VitaminGusti Arya YunediNo ratings yet

- Facts About Milk 2Document15 pagesFacts About Milk 2hanisah ahmad jaafarNo ratings yet

- Accepted Manuscript: Animal Feed Science and TechnologyDocument53 pagesAccepted Manuscript: Animal Feed Science and TechnologyGabriela Casarotto DanielNo ratings yet

- Health and Nutritional Benefits of DairyDocument3 pagesHealth and Nutritional Benefits of DairyMiguel RuizNo ratings yet

- 03 2022 UpToDate Vitamin D Insufficiency and Deficiency in Children and AdolescentsDocument37 pages03 2022 UpToDate Vitamin D Insufficiency and Deficiency in Children and Adolescentssheyla alegreNo ratings yet

- 1 s2.0 S0022030220310195 MainDocument10 pages1 s2.0 S0022030220310195 MainEddy WibowoNo ratings yet

- Quality Attributes of High Protein Ice Cream Prepared by Incorporation Of0Awhey Protein IsolateDocument8 pagesQuality Attributes of High Protein Ice Cream Prepared by Incorporation Of0Awhey Protein IsolateSaha EtaNo ratings yet

- Pi Is 0022030217302977Document8 pagesPi Is 0022030217302977Marlindah SNo ratings yet

- ChaptersDocument139 pagesChaptersDark PrincessNo ratings yet

- Milk and Dairy Q&ADocument4 pagesMilk and Dairy Q&AgarralfaNo ratings yet

- Vitamin D - Health Professional Fact SheetDocument13 pagesVitamin D - Health Professional Fact SheetTahir AliNo ratings yet

- Journal of Biotechnology: Anargyros N. Moulas, Maria Vaiou TDocument11 pagesJournal of Biotechnology: Anargyros N. Moulas, Maria Vaiou TWahab KhanNo ratings yet

- DownloadDocument14 pagesDownloadRohit LauvanshiNo ratings yet

- Yoghurt and Dairy Snacks Presented For Sale To An Australian Consumer: Are They Becoming Less Healthy?Document6 pagesYoghurt and Dairy Snacks Presented For Sale To An Australian Consumer: Are They Becoming Less Healthy?Margaret DivyaNo ratings yet

- Entrepreneurial Opportunity in Whey As A BeverageDocument11 pagesEntrepreneurial Opportunity in Whey As A BeverageMADHUR DIXITNo ratings yet

- Hal 00930630Document21 pagesHal 00930630prijedor2023No ratings yet

- Therapeutic Potential of Milk Whey: July 2017Document15 pagesTherapeutic Potential of Milk Whey: July 2017José Manuel Pais-ChanfrauNo ratings yet

- Baking Properties of Milk Protein-Coated Wheat Bran: ArticleDocument16 pagesBaking Properties of Milk Protein-Coated Wheat Bran: ArticleAna María TorresNo ratings yet

- Milk Fortification With Plant Based Vit D3Document12 pagesMilk Fortification With Plant Based Vit D3Ambrosiya Neo-MedicineNo ratings yet

- Genbio Mango Wheatmilk Research Paper AutosavedDocument12 pagesGenbio Mango Wheatmilk Research Paper AutosavedJamieshawn Pardillo Salazar TapisNo ratings yet

- Art 1Document10 pagesArt 1Maria RosaNo ratings yet

- Dietary Vitamin D Dose-Response in Healthy Children 2 To 8 y of Age: A 12-wk Randomized Controlled Trial Using Forti Ed FoodsDocument27 pagesDietary Vitamin D Dose-Response in Healthy Children 2 To 8 y of Age: A 12-wk Randomized Controlled Trial Using Forti Ed FoodsNikolett FaragóNo ratings yet

- 2021 - Hemmati Et Al.Document11 pages2021 - Hemmati Et Al.Lourdes LandoniNo ratings yet

- Author's Accepted Manuscript: Biocatalysis and Agricultural BiotechnologyDocument29 pagesAuthor's Accepted Manuscript: Biocatalysis and Agricultural BiotechnologyLaxmana NaikNo ratings yet

- LWT - Food Science and TechnologyDocument8 pagesLWT - Food Science and TechnologySamantha Rosas RosasNo ratings yet

- Milk Fortification: Submitted To: Submitted By: Dr.N.S. Rathore Sir Geetanjali 3 Year (F.T)Document14 pagesMilk Fortification: Submitted To: Submitted By: Dr.N.S. Rathore Sir Geetanjali 3 Year (F.T)Geetanjali KatyNo ratings yet

- Published in The JournalDocument5 pagesPublished in The Journalrikaseo rikaNo ratings yet

- Class Rep SeminarDocument10 pagesClass Rep SeminarMuhammad Abdullahi AliyuNo ratings yet

- LWT - Food Science and Technology: F. Zare, C.P. Champagne, B.K. Simpson, V. Orsat, J.I. BoyeDocument6 pagesLWT - Food Science and Technology: F. Zare, C.P. Champagne, B.K. Simpson, V. Orsat, J.I. BoyetuittuitNo ratings yet

- 6 - Vitamin D Requirements - Current and Future. WEAVER, FLEET AJCN DEC04Document5 pages6 - Vitamin D Requirements - Current and Future. WEAVER, FLEET AJCN DEC04ytreffalNo ratings yet

- Beverages: B-Vitamins Determination in Donkey MilkDocument10 pagesBeverages: B-Vitamins Determination in Donkey MilkLatamsila AtamNo ratings yet

- 4 Vitamin 2012 PrintDocument6 pages4 Vitamin 2012 PrintLuis Matos ReyesNo ratings yet

- Recent Advances in Liquid Organic Hydrogen Carriers: An Alcohol-Based Hydrogen EconomyDocument15 pagesRecent Advances in Liquid Organic Hydrogen Carriers: An Alcohol-Based Hydrogen EconomySajid Mohy Ul Din100% (1)

- An Inter Disciplinary Review of The Literature On Mental Illness Disclosure in The Workplace Implications For Human Resource ManagementDocument38 pagesAn Inter Disciplinary Review of The Literature On Mental Illness Disclosure in The Workplace Implications For Human Resource ManagementSajid Mohy Ul DinNo ratings yet

- Intrinsic and Extrinsic Motivation For University Staff Satisfaction: Confirmatory Composite Analysis and Confirmatory Factor AnalysisDocument27 pagesIntrinsic and Extrinsic Motivation For University Staff Satisfaction: Confirmatory Composite Analysis and Confirmatory Factor AnalysisSajid Mohy Ul DinNo ratings yet

- Insurance Activity and Economic Performance: Fresh Evidence From Asymmetric Panel Causality TestsDocument20 pagesInsurance Activity and Economic Performance: Fresh Evidence From Asymmetric Panel Causality TestsSajid Mohy Ul DinNo ratings yet

- The Impact of Corporate Social Responsibility On Firms' Financial Performance in South AfricaDocument23 pagesThe Impact of Corporate Social Responsibility On Firms' Financial Performance in South AfricaSajid Mohy Ul DinNo ratings yet

- Institutional Quality and Initial Public Offering Underpricing: Evidence From Hong KongDocument12 pagesInstitutional Quality and Initial Public Offering Underpricing: Evidence From Hong KongSajid Mohy Ul DinNo ratings yet

- Marceau 2009Document36 pagesMarceau 2009Sajid Mohy Ul DinNo ratings yet

- A Theoretical Basis For Innovation, Institutions and Insurance Penetration NexusDocument13 pagesA Theoretical Basis For Innovation, Institutions and Insurance Penetration NexusSajid Mohy Ul DinNo ratings yet

- Student Teacher Challenges Using The Cognitive Load Theory As An Explanatory Lens PDFDocument16 pagesStudent Teacher Challenges Using The Cognitive Load Theory As An Explanatory Lens PDFSajid Mohy Ul DinNo ratings yet

- U.S. Ssecurity Ppolicy Iin Ssouth Aasia Since 9/11 - Cchallenges Aand Implications Ffor Tthe FfutureDocument16 pagesU.S. Ssecurity Ppolicy Iin Ssouth Aasia Since 9/11 - Cchallenges Aand Implications Ffor Tthe FfutureSajid Mohy Ul DinNo ratings yet

- Can 2017Document29 pagesCan 2017Sajid Mohy Ul DinNo ratings yet

- Plenary and Symposium Abstracts: Biological PsychiatryDocument1 pagePlenary and Symposium Abstracts: Biological PsychiatrySajid Mohy Ul DinNo ratings yet

- Jacob 2008Document37 pagesJacob 2008Sajid Mohy Ul DinNo ratings yet

- Content ServerDocument6 pagesContent ServerSajid Mohy Ul DinNo ratings yet

- 10 1111@j 1539-6924 2008 01030 X PDFDocument16 pages10 1111@j 1539-6924 2008 01030 X PDFSajid Mohy Ul DinNo ratings yet

- Ijse 05 2017 0194Document23 pagesIjse 05 2017 0194Sajid Mohy Ul DinNo ratings yet

- A New Era For Women? Some Reflections On Blind Spots of ICT-based Development Projects For Women's Entrepreneurship and EmpowermentDocument16 pagesA New Era For Women? Some Reflections On Blind Spots of ICT-based Development Projects For Women's Entrepreneurship and EmpowermentSajid Mohy Ul DinNo ratings yet

- 01443570210414329Document108 pages01443570210414329Sajid Mohy Ul DinNo ratings yet

- A Model Predictive Control For Renewable Energy Based AC Microgrids Without Any PID RegulatorsDocument5 pagesA Model Predictive Control For Renewable Energy Based AC Microgrids Without Any PID RegulatorsSajid Mohy Ul DinNo ratings yet

- ICV Presentation - Short VersionDocument19 pagesICV Presentation - Short VersionFamily Planning DOH 12No ratings yet

- Noise Monitoring Register Project SiteDocument2 pagesNoise Monitoring Register Project Siteshamroz khanNo ratings yet

- Safety Alert 12 2017 Drill Collar DroppedDocument1 pageSafety Alert 12 2017 Drill Collar DroppedChandrasekhar SonarNo ratings yet

- Texas Cockpit Arena Conditioning BundleDocument4 pagesTexas Cockpit Arena Conditioning BundleHanna Sobreviñas AmanteNo ratings yet

- KharanDocument4 pagesKharansuhaib_wahalaNo ratings yet

- The Importance of Obtaining A Pulpal and Periradicular Diagnosis Prior To Restorative TratmentDocument7 pagesThe Importance of Obtaining A Pulpal and Periradicular Diagnosis Prior To Restorative TratmentPaola Zermeño lunaNo ratings yet

- Cmca Lec ReviewerDocument32 pagesCmca Lec Reviewercuteathena11No ratings yet

- Phisical Activity in The Prevention and Treatment of Anxiety and DepressionDocument5 pagesPhisical Activity in The Prevention and Treatment of Anxiety and DepressionAlicia GonzálezNo ratings yet

- Q1 Tle 9 Eim TosDocument2 pagesQ1 Tle 9 Eim TosjuzielouNo ratings yet

- Student Support Material X EnglishDocument103 pagesStudent Support Material X EnglishMaydhansh KadgeNo ratings yet

- Color BlindnessDocument3 pagesColor BlindnessRainZZaKNo ratings yet

- Lecture 4a - Building Inspections - Assessment of Defects On SiteDocument101 pagesLecture 4a - Building Inspections - Assessment of Defects On SiteQila HusinNo ratings yet

- Clinic SystemDocument21 pagesClinic Systemmarlon_tayagNo ratings yet

- (Đề thi có 05 trang)Document19 pages(Đề thi có 05 trang)Lan Anh TạNo ratings yet

- Baccay Vs Baccay and Republic PDFDocument3 pagesBaccay Vs Baccay and Republic PDFRachel GeeNo ratings yet

- Jurnal Mutiple StentDocument9 pagesJurnal Mutiple StentPrima Anggreini ArinNo ratings yet

- Russell 2006Document9 pagesRussell 2006a.guptaNo ratings yet

- Dwnload Full Nursing For Wellness in Older Adults 7th Edition Miller Test Bank PDFDocument35 pagesDwnload Full Nursing For Wellness in Older Adults 7th Edition Miller Test Bank PDFmichaelcalhounjtypaegbnk100% (13)

- Sigma-Aldrich: Blue Sepharose® CL-6BDocument6 pagesSigma-Aldrich: Blue Sepharose® CL-6BGEINER ANDRES OSSA GALVISNo ratings yet

- H1 2021 Results AnnouncementDocument66 pagesH1 2021 Results AnnouncementTacio Lorran SilvaNo ratings yet

- Italicement TXactiveDocument9 pagesItalicement TXactiveLili DobrilaNo ratings yet

- Perceived Effects of The Pandemic On Small Business Performance in Barangay Ibabang Dupay Lucena City GROUP 5 11WDocument39 pagesPerceived Effects of The Pandemic On Small Business Performance in Barangay Ibabang Dupay Lucena City GROUP 5 11WDarlene BrucalNo ratings yet

- Imj JJ Iji1Iiiiiii1Document522 pagesImj JJ Iji1Iiiiiii1MT20WRE011 Girish BiradarNo ratings yet

- Clark PDFDocument8 pagesClark PDFEuge López RuizNo ratings yet

- Safety Data Sheet: Infraserv, Telephone: +49 (0) 69-305-6418Document7 pagesSafety Data Sheet: Infraserv, Telephone: +49 (0) 69-305-6418Khuon BunthaNo ratings yet

- Dukungan Keluarga Dan Keaktifan Lansia Dalam Mengikuti Program Posyandu LansiaDocument8 pagesDukungan Keluarga Dan Keaktifan Lansia Dalam Mengikuti Program Posyandu LansiaImanda SalsabhilaNo ratings yet

- DR Tommy - Cancer PainDocument60 pagesDR Tommy - Cancer Painrisalbalu100% (1)

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet