Professional Documents

Culture Documents

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology

Uploaded by

HCTL OpenCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Soundcraft Efx12 Efx8 MixerDocument2 pagesSoundcraft Efx12 Efx8 MixerGabriel Saucedo100% (3)

- Pioneer Deh-2950mp 2990mp PDFDocument70 pagesPioneer Deh-2950mp 2990mp PDFAxl Mendoza100% (3)

- Protection of Load in Electrical Power System by Using Arc Extinguish System and Relay in MATLAB/SIMULINKDocument7 pagesProtection of Load in Electrical Power System by Using Arc Extinguish System and Relay in MATLAB/SIMULINKHCTL OpenNo ratings yet

- Design of A Bioreactor Landfill For Delhi CityDocument13 pagesDesign of A Bioreactor Landfill For Delhi CityHCTL OpenNo ratings yet

- Biomethanation of Municipal Solid WasteDocument10 pagesBiomethanation of Municipal Solid WasteHCTL OpenNo ratings yet

- Study On Video CompressionDocument7 pagesStudy On Video CompressionHCTL OpenNo ratings yet

- A Literature Review On Ergonomics of Indian Small Auto-Vehicles Seat Design For Passenger Comfort and SafetyDocument8 pagesA Literature Review On Ergonomics of Indian Small Auto-Vehicles Seat Design For Passenger Comfort and SafetyHCTL OpenNo ratings yet

- Identification of Tigers Through Their Pugmark Using Pattern RecognitionDocument8 pagesIdentification of Tigers Through Their Pugmark Using Pattern RecognitionHCTL OpenNo ratings yet

- Computation of Power of A Motor in Electric Vehicle Under City Tra Ffic and Dynamic Conditions.Document11 pagesComputation of Power of A Motor in Electric Vehicle Under City Tra Ffic and Dynamic Conditions.HCTL OpenNo ratings yet

- Modelling of A Power Train For Plug in Electric VehiclesDocument17 pagesModelling of A Power Train For Plug in Electric VehiclesHCTL OpenNo ratings yet

- Automatic Rationing For Public Distribution System (PDS) Using RFID and GSM Module To Prevent Irregularities.Document10 pagesAutomatic Rationing For Public Distribution System (PDS) Using RFID and GSM Module To Prevent Irregularities.HCTL OpenNo ratings yet

- Development of FSM Based Running Disparity Controlled 8b/10b Encoder/Decoder With Fast Error Detection Mechanism.Document14 pagesDevelopment of FSM Based Running Disparity Controlled 8b/10b Encoder/Decoder With Fast Error Detection Mechanism.HCTL OpenNo ratings yet

- Lse - Ac.uk Storage LIBRARY Secondary Libfile Shared Repository Content Centre For Learning Technology Trends in Education TechnologyDocument36 pagesLse - Ac.uk Storage LIBRARY Secondary Libfile Shared Repository Content Centre For Learning Technology Trends in Education TechnologyrksoffnerNo ratings yet

- Anixter Thermocouple and RTD Wire Wire Wisdom enDocument2 pagesAnixter Thermocouple and RTD Wire Wire Wisdom enFelipe GustavoNo ratings yet

- PC450 (LC, HD) - 8 UEN02244-00 Diagrams & DrawingsDocument34 pagesPC450 (LC, HD) - 8 UEN02244-00 Diagrams & DrawingsdatphuongNo ratings yet

- Celtx Script Owners ManualDocument26 pagesCeltx Script Owners ManualMike VentureNo ratings yet

- " Build and Test Voltmeter Using PMMC..": Under The Guidance ofDocument10 pages" Build and Test Voltmeter Using PMMC..": Under The Guidance ofOnkar ChavanNo ratings yet

- Xerox DC-2125-Service ManualDocument277 pagesXerox DC-2125-Service Manualvinh dượcNo ratings yet

- Clad V9.02Document57 pagesClad V9.02Walid AmriNo ratings yet

- Frequently Asked Questions GRBL Wiki GitHubDocument7 pagesFrequently Asked Questions GRBL Wiki GitHubMarky MaypoNo ratings yet

- GC9403 Application Notes Ver04 - 20141206Document24 pagesGC9403 Application Notes Ver04 - 20141206SpecShareNo ratings yet

- Service Manual: FS-X3, FS-X1Document71 pagesService Manual: FS-X3, FS-X1videosonNo ratings yet

- Huawei XPIC Hardware ConnectionDocument27 pagesHuawei XPIC Hardware Connectionibrahim nabil100% (1)

- 5 MARKS QUESTIONS Final PDFDocument5 pages5 MARKS QUESTIONS Final PDFAditya KinariwalaNo ratings yet

- X400 Series Transmitter Product Sheet Overview 26 Apr 2017Document2 pagesX400 Series Transmitter Product Sheet Overview 26 Apr 2017Muthukumar RadhakrishnanNo ratings yet

- CPF 1.1 Tutorial 13-Oct-2009Document43 pagesCPF 1.1 Tutorial 13-Oct-2009Santosh NanduriNo ratings yet

- Deltav Virtualization Hardware: Deltav Distributed Control System Product Data SheetDocument14 pagesDeltav Virtualization Hardware: Deltav Distributed Control System Product Data SheetvenkatsrmeeeNo ratings yet

- 01-MCC400 Single Line Diagram For TWPS MCC of TLM PlantDocument13 pages01-MCC400 Single Line Diagram For TWPS MCC of TLM PlantVidiya NovelinNo ratings yet

- EthernetDocument85 pagesEthernetMuhammad Sohail100% (1)

- Techno QuizDocument4 pagesTechno QuizYza VelleNo ratings yet

- Forti ExtenderDocument6 pagesForti Extenderderic soonNo ratings yet

- Digital Modes OverviewDocument22 pagesDigital Modes OverviewBenjamin DoverNo ratings yet

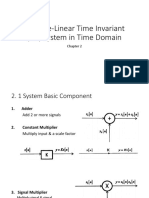

- CH 2 LTIDocument23 pagesCH 2 LTIFarhanNo ratings yet

- BSNL (Training Report)Document55 pagesBSNL (Training Report)Aditya PrasadNo ratings yet

- 1KW MPSG Portable Off-Grid Solar Power System - 202104Document1 page1KW MPSG Portable Off-Grid Solar Power System - 202104Alberto Chacon PinzonNo ratings yet

- MT6571 Android ScatterDocument5 pagesMT6571 Android ScatterwewerwerwerNo ratings yet

- User Manual: Earthfault Compensation Controller EFC50Document122 pagesUser Manual: Earthfault Compensation Controller EFC50Ichim NasuiNo ratings yet

- SIEPAN 8PU Low Voltage Switchboards Technology by SiemensDocument4 pagesSIEPAN 8PU Low Voltage Switchboards Technology by SiemensaayushNo ratings yet

- Shortcircuit ANSIDocument48 pagesShortcircuit ANSIVasudevan KunjithapathamNo ratings yet

- 001-80994 AN80994 Design Considerations For Electrical Fast Transient EFT Immunity PDFDocument48 pages001-80994 AN80994 Design Considerations For Electrical Fast Transient EFT Immunity PDFFaouzi TlemcenNo ratings yet

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology

Uploaded by

HCTL OpenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology

Uploaded by

HCTL OpenCopyright:

Available Formats

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Low Leakage and High

Density 4T CMOS SRAM in

45nm Technology

Puna Kumar Rajak1, Dr. S. N. Singh2, Amit Kumar Rajak3,

Sravan Kumar Kankanala4

puna.itgpa@gmail.com

Abstract

This paper presents a novel CMOS based 4T SRAM, it is highly dense and capable

for low power application. The Novel 4T SRAM consumes less power and has less

leakage current as well as less read and write time. It is capable of storing the bits

efficiently. The novel cell size is 26.46% smaller than the conventional sixtransistor SRAM cell using same design rules without any performance

degradation. The simulation result of 4T SRAM show that there is extensive

enhancement in performance of the proposed circuit parameters like delay, power

consumption and leakage current. The Novel 4T SRAM has been analysed on

Cadence Virtuoso v6.1.5 in 45 nm Technology.

Keywords

CMOS 4T SRAM, cell delay, Low leakage, low power consumption, 45nm technology.

Introduction

Static RAM is widely used in battery operated Embedded System. Where, we need to

operate device at low power consumption and its required less area as well as power

efficient. Static RAM used in processors is very fast as compared to other memory

storage medium as it needs less read and write timing [1]. Low power SRAMs have turn

into a significant part of many VLSI circuits because of its storage application. Rising size

of on-chip memories particularly on components like microprocessors, makes SRAMs a

significant circuit, since its power consumption is high as compared to other circuit due to

large number of cells used. Its high usage in processors makes it crucial circuit that

decides the speed of processor. Also in different VLSI chips, the power dissipation has

turn into a significant consideration due to the improved integration, operational speeds

and the volatile enlargement of portable appliances. With enhance in number of memory

cells, additional power will be consumed still in the standby mode. The memory cells are

frequently implemented by arrays of compactly packed SRAM cells for high performance,

a lesser amount of leakage and power consumption optimizing the cell ratio of the cell

and getting better the peripheral circuitry like precharge circuitry, write circuitry, sense

amplifier etc. Cell ratio plays an significant role in stabilizing the output of the cell [2]. The

proposed cell is using a lesser amount of power supply, since the technology is scaled

one. There are numerous configurations of memory cell that has been proposed.

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 1

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Conventional CMOS 6T SRAM cell is power competent in standby mode and has

improved protection to transient noise and voltage variation than four transistor resistive

load cell. That's why it is ideal over resistive load cell for high speed and low power

applications [5]. Stable Data withholding remains, the main purpose when scheming any

configuration of memory cell. Generally majority of the bits stored are '0'. To read a bit in

the conventional 6T SRAM cell one of two bit-lines must be discharged to low apart from

of written value. Due to balance in configuration the power consumption in both writing '0'

and ' l' are the usually same. This is also true in case of read operation. Since in cell, an

irresistible majority of the write and read bits are 0, transitions always take place on bit

lines in both writing '0' and reading '0'. Hence this causes high dynamic power

consumption during read/write operation in conventional 6T SRAM cell [2]. Our intention

is to develop a SRAM cell with four transistors to decrease the cell area size with better

performance and power consumption enhancement. In section II the 6T SRAM cell is

presented. Section III represents the novel 4T configuration of the cell. This segment also

discusses the working of the cell. Segment IV discuss about the read and write operation

of the proposed cell. Segment V discusses the leakage current of the cell and its

calculation. Segment VI discusses about the delay at different nodes of the cell. Segment

VII discusses about the circuitry of the cell including precharge, write and sense amplifier

circuitry. Segment VIII throws light on the power consumption of the cell and its

calculation at different nodes. Segment IX shows the layout of proposed cell. Conclusions

are drawn in the last segment.

Conventional 6T SRAM Configuration

Static read/write (or random access) memory (SRAM) is able to read and write data into its

memory cells and retain the memory contents as long as the power supply voltage is

provided. Currently SRAM are manufactured in the CMOS technology which offers very

low static power dissipation, superior noise margin and switching speed. The cells of the

CMOS SRAM are based on a simple latch circuit. The conventional six-transistor (6T)

SRAM is developed of two cross-coupled inverters and two access transistors, linking the

cell to the bit lines. The inverters constitute the storage element and the access transistors

are used to approach the outside. The cell is symmetrical and has a comparatively large

area. No special process steps are needed and it is fully compatible with standard CMOS

processes.

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 2

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Figure 1: Conventional 6T SRAM Cell [3]

Proposed 4T SRAM Cell

Figure 2: A proposed 4T SRAM cell in 45 nm Technology

A proposed circuit configuration of 4T SRAM is shown in fig. 2. In this circuit instead of

NMOS, PMOS is used as a pass transistor. Stored bit are available at nodes ST and STB.

PM2 (pass transistor) is key factor through which we invoked data read and write

operation at BL (bit line) whose controlling signal is WL (word line). In inactive mode of

cell (when read or write operation not perform) PM2 is OFF. When 0 stored at ST node

PM0 is ON and STB node pulled up to VDD. When 1 stored at ST node NM0 is ON and

STB node pulled down to GND. As STB node goes low then PM1 will be ON and ST

node pulled up to GND (where transistor PM1 is used as refresh circuit). Signal high

stored at ST node uses leakage current at input-output point BL (BL is precharge with

VDD) through pass transistor PM2.

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 3

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Figure 3 and figure 4 shows the transient analysis of the cell when bit 0 and bit 1is

written to the cell respectively. Pass transistor PM2 (via WL signals) is kept in ON

condition. And the required signal (1 in case of writing 1 and 0 in case of writing 0) to

be written is connected to Bit Line through write circuitry, where Bit Line is floated earlier

than this step. It has been found that the bits are efficiently stored and are stable.

Figure 3: Waveform of new cell with write 0.

Figure 4: Waveform of new cell with write 1.

Read and Write Operation

Waveforms of Write 0 and write 1 are shown in Fig. 3 and Fig. 4. During write operation

Pass transistor PM2 is ON and subsequent operations are performed on different

transistors and nodes in the proposed SRAM cell:

1) Bit-line driving: For the write operation, information (data) is set on bit-line (BL), and

then word-line (WL) asserted to GND.

2) Cell flipping: This step includes two states as follows:

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 4

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

a) Data is zero: In this state, ST node pulled up to GND by pass transistor PM2, and

therefore the Load transistor PM0 will be ON, and STB node will be pulled up to VDD.

b) Data is one: In this state, ST node pulled up to VDD by pass transistor PM2, and

therefore the drive transistor NM0 will be ON, and STB node will be pulled down to GND

and positive feedback created by PM1 and NM0.

3) Bit-line driving: At the end of write operation, cell will go to idle mode and WL and bitline asserted to VDD and VDD, respectively.

During read operation we look following steps:

1) Bit-line charging: For a read, bit-line is charged to VDD, and then floated.

2) Word-line activation: In this step WL is asserted to GND and two states can be

considered:

a) Voltage of ST node is high: When voltage of ST node is high, the voltage of bit-line is

pulled down to high and this voltage is sensed by sense amplifier.

b) Voltage of ST node is low: When voltage of ST node is low, the voltage of bit-line

pulled up to low voltage by the pass transistor which is sensed by the sense amplifier.

3) Sensing: Figure 6 shows possible circuit schematic of sense amplifier in 45nm

technology node that may be used for reading data from new cell [2]. Sense amplifier

sense signal from bit line and gives the output at bit (DO) and bit complement (DOC).

4) Idle mode: At the end of read operation, cell will go to idle mode and bit-line asserted to

VDD.

Figure 5: Sense amplifier schematic of proposed cell [3]

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 5

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Figure 6 shows the simulation result of reading signals from the proposed 4T SRAM cell.

Where, ST and STB nodes hold information during read operation. WL (word Line) is

describing controlling signal of pass transistor PM2.

Figure 6: Reading data from the proposed SRAM cell

Leakage Current

In one state, novel 4T SRAM cell must retains its data using the leakage current

of the pass or access transistor (when zero stored) and in the other state the ST

SRAM cell must retains its data using positive feedback (when one stored). Table I

shows the comparison of leakage current of the previous 5T cells and conventional 6T

cells with the proposed 4T SRAM cell. An additional benefit of using this cell is that we

can use conventional pre-charge circuitry for this SRAM cell. The simulated results shows

that this cell is having very less leakage current that is a advantage to battery operated

devices. The simulated leakage current is shown in Fig. 7 and Fig. 8.

Table I. Leakage comparison of the proposed cell with the previous results

Sr.

No.

Parameters

For write 1

in st node

For write 0

in st node

For write 1

in stb node

For write 0

in stb node

2

3

4

Leakage

in

previous

5T cell[3]

6.61 pA

Leakage

in 6T

cell. [3]

Leakage in

proposed

4T cell

-32.10 nA

-7.58 nA

5.14 pA

9.20 nA

0.987 nA

-475.88 fA

-0.229 nA

-4.419 nA

-5.415 pA

94.11 nA

0.62 nA

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 6

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Figure 7: Leakages at various nodes during write 0

Figure 8: Leakages at various nodes during write 1.

Delay

Delay of the cell depends on the consumption of time between the cells from

input (BL) to output [6]. Assessment of the cell delay between 5T , 6T & 4T shows in

the table below.

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 7

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Table I. Delay comparison of the proposed cell with the previous cells.

Sl. No.

Parameters

Delay of

previous

5T cell

[2]

Delay of

conventional

6T cell [2]

Delay at

ST

Delay at

STB

2.453 ns

14.24 ps

0.839 ns

Delay of

new 5T

SRAM

cell

(180nm)[3]

23 ps

Delay of

new 5T

SRAM

cell

(45nm)[3]

5.13 ps

Delay of

new 4T

SRAM

cell

(45nm)

2.853ps

47.72 ps

46 ps

17.66 ps

16.62ps

This table shows that 4T cell delay in ST and STB node is less than 6T cell delay

in ST and STB node. It means 4T is superior to 6T.

SRAM Schematic

The possible schematic of sense amplifier for the proposed SRAM is shown in Fig. 6 [2].

The DC and transient response of the sense amplifier schematic is shown in Fig. 9. From

Fig. 9, we can say that this amplifier is close to idle switch characteristics.

Figure 10 shows the circuitry of memory cell as well as proposed SRAM cell, precharge,

write and sense amplifier circuitry.

Figure 9: DC and transient analysis of sense amplifiers

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 8

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

Figure 10: Circuitry of memory cell including 4T SRAM cell, pre-charge, write and sense

amplifier circuitry.

Power Consumption

Power consumption of the SRAM memory cell depends on the consumption of the power

of the active transistor (under operation) [4]. Power consumption of the 4T SRAM cell is

shows in the table below.

Sr.

No.

Parameters Power

Power

Consumption Consumption

in

in 6T cell [3]

previous 5T

cell [3]

For write 1

6.62 pW

0.011 pW

in st node

Power

Consumption

in proposed

4T cell

2.66 fW

For write 0

in st node

0.465 pW

0.003 pW

4.52 fW

For write 1

in stb node

5.14 pW

30 pW

0.014 fW

For write 0

in stb node

5.422 pW

28 pW

0.005 fW

Layout

Figure 11 shows the layout of the proposed 4T SRAM cell in 45nm technology node.

Length where fixed and widths as in schematic have been used in making this layout.

Pass transistor uses large widths as compared to other cells. The proposed 4T cell

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 9

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

requires 2.53 m 2 areas. 6T cell requires 3.438 m2 areas [2]. Hence the proposed cell is

26.46 % less than the conventional 6T SRAM cell and it is 2.69% smaller than the

previous 5T configuration [3].

Figure 11: Layout of proposed 4T SRAM cell in 45nm technology node.

Conclusion

With the goal of achieving a low leakage and high density

memory cell, we

developed a 4T CMOS SRAM cell. Leakage current found during write 0 or 1 at node

in which the transistor is OFF. Hence the proposed cell is 26.46 % less than the

conventional 6T SRAM cell and it is 2.69% smaller than the previous 5T configuration.

Proposed 4T SRAM is faster than the conventional 6T SRAM cell. Power consumption is

decreases in huge amount as compared to 6T and 5T.

Acknowledgements

This work has done in the VLSI Lab at NIT Jamshedpur. Professor and Head of the

Department provided us cadence environment to complete this work.

References

[1] K. Khare, N. Khare, V.K. Kulhade and P. Deshpande, VLSI Design And Analysis of

Low Power 6T SRAM Cell Using Cadence Tool, IEEE International Conference

on

Semiconductor Electronics, Nov. 2008, pp. 117121.

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 10

HCTL Open International Journal of Technology Innovations and Research (IJTIR)

http://ijtir.hctl.org

Volume 15, May 2015

e-ISSN: 2321-1814, ISBN (Print): 978-1-62951-974-6

[2] S. Akashe, S. Bhushan and S. Sharma, High Density and Low Leakage Current

Based 5T SRAM Cell Using 45 nm Technology, International Conference on

Nanoscience, Engineering and Technology (ICONSET), Nov. 2011. pp. 346-350.

[3] Rohin Gupta, Sandeep Singh Gill, Navneet Kaur, A Novel Low Leakage and High

Density 5T CMOS SRAM Cell in 45nm Technology, IEEE Conference

Publication,

2014, Page(s): 1-6.

[4] J. M. Rabaey, A. Chandrakasan and B. Nikolic, Digital Integrated Circuits, 2nd ed.,

Prentice-Hall of India Private limited, 2005, pp. 272-282.

[5] V.S. Babu, Solid State Device and Technology, 3rd ed., Pearson Publication, 2008.

[6] K. Martin, Digital Integrated Circuit Design, Oxford University Press, New York, 2000.

This article is an open access article distributed under the terms and conditions of the

Creative Commons Attribution 4.0 International License

(https://creativecommons.org/licenses/by/4.0/).

2015 by the Authors. Licensed by HCTL Open, India.

Puna Kumar Rajak, Dr. S. N. Singh, Amit Kumar Rajak, Sravan Kumar Kankanala,

Low Leakage and High Density 4T CMOS SRAM in 45nm Technology.

Page 11

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Soundcraft Efx12 Efx8 MixerDocument2 pagesSoundcraft Efx12 Efx8 MixerGabriel Saucedo100% (3)

- Pioneer Deh-2950mp 2990mp PDFDocument70 pagesPioneer Deh-2950mp 2990mp PDFAxl Mendoza100% (3)

- Protection of Load in Electrical Power System by Using Arc Extinguish System and Relay in MATLAB/SIMULINKDocument7 pagesProtection of Load in Electrical Power System by Using Arc Extinguish System and Relay in MATLAB/SIMULINKHCTL OpenNo ratings yet

- Design of A Bioreactor Landfill For Delhi CityDocument13 pagesDesign of A Bioreactor Landfill For Delhi CityHCTL OpenNo ratings yet

- Biomethanation of Municipal Solid WasteDocument10 pagesBiomethanation of Municipal Solid WasteHCTL OpenNo ratings yet

- Study On Video CompressionDocument7 pagesStudy On Video CompressionHCTL OpenNo ratings yet

- A Literature Review On Ergonomics of Indian Small Auto-Vehicles Seat Design For Passenger Comfort and SafetyDocument8 pagesA Literature Review On Ergonomics of Indian Small Auto-Vehicles Seat Design For Passenger Comfort and SafetyHCTL OpenNo ratings yet

- Identification of Tigers Through Their Pugmark Using Pattern RecognitionDocument8 pagesIdentification of Tigers Through Their Pugmark Using Pattern RecognitionHCTL OpenNo ratings yet

- Computation of Power of A Motor in Electric Vehicle Under City Tra Ffic and Dynamic Conditions.Document11 pagesComputation of Power of A Motor in Electric Vehicle Under City Tra Ffic and Dynamic Conditions.HCTL OpenNo ratings yet

- Modelling of A Power Train For Plug in Electric VehiclesDocument17 pagesModelling of A Power Train For Plug in Electric VehiclesHCTL OpenNo ratings yet

- Automatic Rationing For Public Distribution System (PDS) Using RFID and GSM Module To Prevent Irregularities.Document10 pagesAutomatic Rationing For Public Distribution System (PDS) Using RFID and GSM Module To Prevent Irregularities.HCTL OpenNo ratings yet

- Development of FSM Based Running Disparity Controlled 8b/10b Encoder/Decoder With Fast Error Detection Mechanism.Document14 pagesDevelopment of FSM Based Running Disparity Controlled 8b/10b Encoder/Decoder With Fast Error Detection Mechanism.HCTL OpenNo ratings yet

- Lse - Ac.uk Storage LIBRARY Secondary Libfile Shared Repository Content Centre For Learning Technology Trends in Education TechnologyDocument36 pagesLse - Ac.uk Storage LIBRARY Secondary Libfile Shared Repository Content Centre For Learning Technology Trends in Education TechnologyrksoffnerNo ratings yet

- Anixter Thermocouple and RTD Wire Wire Wisdom enDocument2 pagesAnixter Thermocouple and RTD Wire Wire Wisdom enFelipe GustavoNo ratings yet

- PC450 (LC, HD) - 8 UEN02244-00 Diagrams & DrawingsDocument34 pagesPC450 (LC, HD) - 8 UEN02244-00 Diagrams & DrawingsdatphuongNo ratings yet

- Celtx Script Owners ManualDocument26 pagesCeltx Script Owners ManualMike VentureNo ratings yet

- " Build and Test Voltmeter Using PMMC..": Under The Guidance ofDocument10 pages" Build and Test Voltmeter Using PMMC..": Under The Guidance ofOnkar ChavanNo ratings yet

- Xerox DC-2125-Service ManualDocument277 pagesXerox DC-2125-Service Manualvinh dượcNo ratings yet

- Clad V9.02Document57 pagesClad V9.02Walid AmriNo ratings yet

- Frequently Asked Questions GRBL Wiki GitHubDocument7 pagesFrequently Asked Questions GRBL Wiki GitHubMarky MaypoNo ratings yet

- GC9403 Application Notes Ver04 - 20141206Document24 pagesGC9403 Application Notes Ver04 - 20141206SpecShareNo ratings yet

- Service Manual: FS-X3, FS-X1Document71 pagesService Manual: FS-X3, FS-X1videosonNo ratings yet

- Huawei XPIC Hardware ConnectionDocument27 pagesHuawei XPIC Hardware Connectionibrahim nabil100% (1)

- 5 MARKS QUESTIONS Final PDFDocument5 pages5 MARKS QUESTIONS Final PDFAditya KinariwalaNo ratings yet

- X400 Series Transmitter Product Sheet Overview 26 Apr 2017Document2 pagesX400 Series Transmitter Product Sheet Overview 26 Apr 2017Muthukumar RadhakrishnanNo ratings yet

- CPF 1.1 Tutorial 13-Oct-2009Document43 pagesCPF 1.1 Tutorial 13-Oct-2009Santosh NanduriNo ratings yet

- Deltav Virtualization Hardware: Deltav Distributed Control System Product Data SheetDocument14 pagesDeltav Virtualization Hardware: Deltav Distributed Control System Product Data SheetvenkatsrmeeeNo ratings yet

- 01-MCC400 Single Line Diagram For TWPS MCC of TLM PlantDocument13 pages01-MCC400 Single Line Diagram For TWPS MCC of TLM PlantVidiya NovelinNo ratings yet

- EthernetDocument85 pagesEthernetMuhammad Sohail100% (1)

- Techno QuizDocument4 pagesTechno QuizYza VelleNo ratings yet

- Forti ExtenderDocument6 pagesForti Extenderderic soonNo ratings yet

- Digital Modes OverviewDocument22 pagesDigital Modes OverviewBenjamin DoverNo ratings yet

- CH 2 LTIDocument23 pagesCH 2 LTIFarhanNo ratings yet

- BSNL (Training Report)Document55 pagesBSNL (Training Report)Aditya PrasadNo ratings yet

- 1KW MPSG Portable Off-Grid Solar Power System - 202104Document1 page1KW MPSG Portable Off-Grid Solar Power System - 202104Alberto Chacon PinzonNo ratings yet

- MT6571 Android ScatterDocument5 pagesMT6571 Android ScatterwewerwerwerNo ratings yet

- User Manual: Earthfault Compensation Controller EFC50Document122 pagesUser Manual: Earthfault Compensation Controller EFC50Ichim NasuiNo ratings yet

- SIEPAN 8PU Low Voltage Switchboards Technology by SiemensDocument4 pagesSIEPAN 8PU Low Voltage Switchboards Technology by SiemensaayushNo ratings yet

- Shortcircuit ANSIDocument48 pagesShortcircuit ANSIVasudevan KunjithapathamNo ratings yet

- 001-80994 AN80994 Design Considerations For Electrical Fast Transient EFT Immunity PDFDocument48 pages001-80994 AN80994 Design Considerations For Electrical Fast Transient EFT Immunity PDFFaouzi TlemcenNo ratings yet