Professional Documents

Culture Documents

Drying Nerium Oleander in An Indirect Solar Dryer Using Phase Change Material As An Energy Storage Medium

Drying Nerium Oleander in An Indirect Solar Dryer Using Phase Change Material As An Energy Storage Medium

Uploaded by

LogeshMechCopyright:

Available Formats

You might also like

- Service Instruction For Servo Cylinder Type PBEDDocument2 pagesService Instruction For Servo Cylinder Type PBEDДжон Диллинджер100% (1)

- Tech Information Basic Weber TuningDocument6 pagesTech Information Basic Weber TuningYacullsNo ratings yet

- Application of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural ConvectionDocument9 pagesApplication of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural Convectionhicham El FeroualiNo ratings yet

- Mathematical Modeling of Thin Layer Solar Drying of Sultana GrapesDocument9 pagesMathematical Modeling of Thin Layer Solar Drying of Sultana GrapesNEFTALI VAZQUEZ ESPINOSANo ratings yet

- Design and Analysis of A Solar Dryer ForDocument7 pagesDesign and Analysis of A Solar Dryer ForYousup AliNo ratings yet

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 pagesDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupNo ratings yet

- Energy Conversion and Management: S.M. Shalaby, M.A. BekDocument8 pagesEnergy Conversion and Management: S.M. Shalaby, M.A. BekRab NawazNo ratings yet

- Design and Development of Solar Dryer Cabinet With Thermal Energy StorageDocument5 pagesDesign and Development of Solar Dryer Cabinet With Thermal Energy Storage11751175No ratings yet

- Mathematical Modeling of Drying Characteristics of Tropical FruitsDocument6 pagesMathematical Modeling of Drying Characteristics of Tropical FruitsNEFTALI VAZQUEZ ESPINOSANo ratings yet

- CFD Investigation of A Solar Dryer With Thermal Storage by Rocks and by Phase Change MaterialDocument4 pagesCFD Investigation of A Solar Dryer With Thermal Storage by Rocks and by Phase Change Materialhicham El FeroualiNo ratings yet

- Hybrid Solar-Gas-Electric Dryer Optimization With Genetic AlgorithmsDocument8 pagesHybrid Solar-Gas-Electric Dryer Optimization With Genetic Algorithmshicham El FeroualiNo ratings yet

- Development of Solar Dryer Incorporated With Evacuated Tube CollectorDocument4 pagesDevelopment of Solar Dryer Incorporated With Evacuated Tube Collectormailsk123No ratings yet

- Design and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalDocument4 pagesDesign and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalBahynorerama DpNo ratings yet

- Drying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerDocument5 pagesDrying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerMuhammad Maulana SidikNo ratings yet

- Design and Development of Solar Air Dryer For Drying of Apricot For Ladhak RegionDocument10 pagesDesign and Development of Solar Air Dryer For Drying of Apricot For Ladhak RegionkolkNo ratings yet

- Research Article: An Experimental Study of Vegetable Solar Drying Systems With and Without Auxiliary HeatDocument9 pagesResearch Article: An Experimental Study of Vegetable Solar Drying Systems With and Without Auxiliary HeatJuan PeraltaNo ratings yet

- UniformityDocument34 pagesUniformityPUBG SORRYNo ratings yet

- Kinetics of Apricot Thin Layer Drying in A Mixed and Indirect Mode SolarDocument6 pagesKinetics of Apricot Thin Layer Drying in A Mixed and Indirect Mode SolarNEFTALI VAZQUEZ ESPINOSANo ratings yet

- Design, Development and Performance Evaluation of A Large-Scale HybridDocument11 pagesDesign, Development and Performance Evaluation of A Large-Scale Hybridvotewi2286No ratings yet

- Performance Enhancement of NaturalDocument11 pagesPerformance Enhancement of Naturaldatdreams2No ratings yet

- Ijme V7i1p105Document4 pagesIjme V7i1p105Shubham kumarNo ratings yet

- Ders Notu 4 MidilliDocument18 pagesDers Notu 4 MidilliDiksha SurekaNo ratings yet

- Solar Drying of Whole Mint Plant Under Natural and Forced ConvectionDocument8 pagesSolar Drying of Whole Mint Plant Under Natural and Forced ConvectionVishvanath KardiNo ratings yet

- Effective Utilization of Solar Energy in Air Dryer: M. Joseph Stalin & P. BarathDocument10 pagesEffective Utilization of Solar Energy in Air Dryer: M. Joseph Stalin & P. BarathTJPRC PublicationsNo ratings yet

- Experimental Study of A Heat Pump Assisted General Purpose Tray Dryer With Backup HeaterDocument6 pagesExperimental Study of A Heat Pump Assisted General Purpose Tray Dryer With Backup HeaterGRD JournalsNo ratings yet

- Performance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitDocument7 pagesPerformance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitVishvesh T SNo ratings yet

- J - Advanced Research - 2024-Kinetic Modelling MoringaDocument9 pagesJ - Advanced Research - 2024-Kinetic Modelling MoringaAdrie OktavioNo ratings yet

- Case Studies in Thermal Engineering: S. Nabnean, P. NimnuanDocument11 pagesCase Studies in Thermal Engineering: S. Nabnean, P. NimnuanCarlos BispoNo ratings yet

- Drying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateDocument6 pagesDrying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateAJER JOURNALNo ratings yet

- Energy Efficiency of A Solar Drying SystemDocument4 pagesEnergy Efficiency of A Solar Drying SystemMarco Antonio Miranda RodriguezNo ratings yet

- Determination of Suitable Thin Layer Drying Curve Model For Some Vegetables and FruitsDocument10 pagesDetermination of Suitable Thin Layer Drying Curve Model For Some Vegetables and FruitsLe Quoc TuanNo ratings yet

- Energy and Exergy Analysis of Cassava Starch Dried in Hybrid Solar DryerDocument16 pagesEnergy and Exergy Analysis of Cassava Starch Dried in Hybrid Solar DryerEvan EduardNo ratings yet

- Chilly Tunnel DryingDocument3 pagesChilly Tunnel Dryingdeepakmehta2812No ratings yet

- Design and Development of Walk-In Type HemicylindrDocument10 pagesDesign and Development of Walk-In Type HemicylindrMaite ZuritaNo ratings yet

- Nergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and DisseminationDocument16 pagesNergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and Disseminationshribavan2373No ratings yet

- J AERG Journal of Chemical and Pharmaceutical Sciences Ftwi Y Hagos Solar Drier ModelingDocument10 pagesJ AERG Journal of Chemical and Pharmaceutical Sciences Ftwi Y Hagos Solar Drier ModelingFtwi Yohaness HagosNo ratings yet

- Esteem 17Document5 pagesEsteem 17PremSagarJasujaNo ratings yet

- Determination of Suitable Thin Layer Drying Curve Model For Apple SlicesDocument6 pagesDetermination of Suitable Thin Layer Drying Curve Model For Apple Slicesvele2ionut100% (1)

- Pengeringan BawanDocument8 pagesPengeringan BawanDandy eight8No ratings yet

- Design and Analysis of Solar Dryer For Mid-Latitude Region: SciencedirectDocument13 pagesDesign and Analysis of Solar Dryer For Mid-Latitude Region: SciencedirectBahynorerama DpNo ratings yet

- Rancang Bangun Kolektor Pelat Datar Energi Surya Untuk Sistem Pengeringan Pasca PanenDocument15 pagesRancang Bangun Kolektor Pelat Datar Energi Surya Untuk Sistem Pengeringan Pasca PanenNur AfifahNo ratings yet

- 36 Tale Geramitcioski FinalDocument3 pages36 Tale Geramitcioski FinalNemacNo ratings yet

- Design and Construction of A Solar Dryer For MangoDocument8 pagesDesign and Construction of A Solar Dryer For MangoIboyaima singhNo ratings yet

- Design of Solar Bagasse DryerDocument9 pagesDesign of Solar Bagasse DryerDr. Mahesh GopalNo ratings yet

- Solar Air Dryer Performance Evaluation Using Locally Available MaterialsDocument7 pagesSolar Air Dryer Performance Evaluation Using Locally Available MaterialsIJRASETPublicationsNo ratings yet

- Design and CFD Analysis of Food Dryer UsDocument14 pagesDesign and CFD Analysis of Food Dryer UsShubham kumarNo ratings yet

- Low Cost Material Used To Construct Effective Box Type Solar DryerDocument7 pagesLow Cost Material Used To Construct Effective Box Type Solar DryerndvprsdNo ratings yet

- 38 Ijmperddec201838Document14 pages38 Ijmperddec201838TJPRC PublicationsNo ratings yet

- Ids 2022Document7 pagesIds 2022zhor El hallaouiNo ratings yet

- Performance Analysis of A Solar DryerDocument11 pagesPerformance Analysis of A Solar DryerSerge KewouNo ratings yet

- Ijmet: ©iaemeDocument8 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Evaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementDocument7 pagesEvaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementMildred CullenNo ratings yet

- Hussain2019 PDFDocument8 pagesHussain2019 PDFĐức HòaNo ratings yet

- Computational Fluid Dynamics Analysis of Greenhouse Solar DryerDocument19 pagesComputational Fluid Dynamics Analysis of Greenhouse Solar DryerPurusothamanManiNo ratings yet

- WP Contentuploadspapersv3i5H96670712823 PDFDocument18 pagesWP Contentuploadspapersv3i5H96670712823 PDFsamsonNo ratings yet

- Numerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat SystemDocument18 pagesNumerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat Systemgazali belhajNo ratings yet

- 3different Varieties of Tomato 2018Document10 pages3different Varieties of Tomato 2018kamalNo ratings yet

- Cross Flow Paddy Dryer Application Using Infrared Gas BurnerDocument11 pagesCross Flow Paddy Dryer Application Using Infrared Gas BurnerZaharanNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Cold Inflow-Free Solar Chimney: Design and ApplicationsFrom EverandCold Inflow-Free Solar Chimney: Design and ApplicationsMd. Mizanur RahmanNo ratings yet

- Global Vegetation Dynamics: Concepts and Applications in the MC1 ModelFrom EverandGlobal Vegetation Dynamics: Concepts and Applications in the MC1 ModelDominique BacheletNo ratings yet

- T 002236Document4 pagesT 002236v2304451No ratings yet

- Decommissioning Technician PDFDocument2 pagesDecommissioning Technician PDFIamSajid JatoiNo ratings yet

- MSDS TaecDocument7 pagesMSDS TaecMuhammad FikriansyahNo ratings yet

- Cartagena Part3 Aerosols CompositionDocument62 pagesCartagena Part3 Aerosols CompositionEDWARDNo ratings yet

- Danish Resume - 2023 Pages 1 4 IEEEDocument4 pagesDanish Resume - 2023 Pages 1 4 IEEEDanish D.RNo ratings yet

- Price List: LTM 019A W.E.F 02.04.2022Document60 pagesPrice List: LTM 019A W.E.F 02.04.2022Ashish100% (1)

- OrganicChemistryVol2 TextDocument701 pagesOrganicChemistryVol2 TextIsrar Ulhaq100% (2)

- J Box - XMTDocument27 pagesJ Box - XMTVladeta JevremovićNo ratings yet

- Technical Schedule A To D & H Pkg-2Document69 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- Tech Tool FAQs v1 28 October20151Document12 pagesTech Tool FAQs v1 28 October20151NoeRtjahya AhmadNo ratings yet

- Hassan Ali CV AC TechDocument3 pagesHassan Ali CV AC TechMuhammad Javed BhattiNo ratings yet

- 3HAC2914-1 M98 IRB1400 Product Manual DSQC311 SMB Unit DescriptionDocument8 pages3HAC2914-1 M98 IRB1400 Product Manual DSQC311 SMB Unit DescriptionAnonymous smdEgZN2IeNo ratings yet

- Session 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Document31 pagesSession 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Ruslan ZakirovNo ratings yet

- Compair 5217.2.H2 - 1188753 Operator Handbook English SUVINCA-DIANADocument208 pagesCompair 5217.2.H2 - 1188753 Operator Handbook English SUVINCA-DIANAjvicher61No ratings yet

- OsiSense XU - XUX1ARCNT16Document6 pagesOsiSense XU - XUX1ARCNT16Top Hayons AlgerieNo ratings yet

- Duty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerDocument3 pagesDuty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerHawaz BeyeneNo ratings yet

- B Shifting ToolDocument1 pageB Shifting ToolAmanda Delgado67% (3)

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- CGa Series 3 Boiler Manual 0520Document68 pagesCGa Series 3 Boiler Manual 0520Sonaina KhanNo ratings yet

- Lab 1a Wind Tunnel Testing Principles & Lift and Drag Coefficients On An AirfoilDocument6 pagesLab 1a Wind Tunnel Testing Principles & Lift and Drag Coefficients On An Airfoilzeeshan khanNo ratings yet

- Oxidation CorrosionDocument17 pagesOxidation CorrosionGise GSNo ratings yet

- Kitchen Exhaust System DesignDocument4 pagesKitchen Exhaust System Designebru_alpaslan100% (2)

- Manual NCT-3000 (En) PDFDocument15 pagesManual NCT-3000 (En) PDFvintiloiusNo ratings yet

- Partnership With NulledDocument2 pagesPartnership With NulledAnonymous kEkbtYX0jNo ratings yet

- Solid Shell Connection in Finite Element AnalysisDocument21 pagesSolid Shell Connection in Finite Element AnalysisvilukNo ratings yet

- Slip and CutDocument2 pagesSlip and CutAnonymous Vb1Tsv106100% (1)

- Ruthmann Steiger 270 CeltnisDocument261 pagesRuthmann Steiger 270 CeltnisIlgvars StaldeNo ratings yet

- Optical MicrometerDocument2 pagesOptical MicrometerrubensNo ratings yet

Drying Nerium Oleander in An Indirect Solar Dryer Using Phase Change Material As An Energy Storage Medium

Drying Nerium Oleander in An Indirect Solar Dryer Using Phase Change Material As An Energy Storage Medium

Uploaded by

LogeshMechOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drying Nerium Oleander in An Indirect Solar Dryer Using Phase Change Material As An Energy Storage Medium

Drying Nerium Oleander in An Indirect Solar Dryer Using Phase Change Material As An Energy Storage Medium

Uploaded by

LogeshMechCopyright:

Available Formats

Journal of Clean Energy Technologies, Vol. 3, No.

3, May 2015

Drying Nerium Oleander in an Indirect Solar Dryer Using

Phase Change Material as an Energy Storage Medium

S. M. Shalaby and M. A. Bek

researchers [7]-[11] utilized the PCM in solar drying system.

Although these studies show that the implementing of the

PCM in the solar dryer improves thermal performance of the

drying system, it ignores the heat losses. Besides, they do not

examine their drying system for drying medical plants.

In this work, for the first time, the Nerium Oleander was

dried at its prescribed drying temperature (502.5 C) in an

indirect solar dryer (ISD), in which the PCM storage unit is

located at the inner bottom of the drying compartment to

reduce the heat losses.

AbstractIn this work, the Nerium Oleander was dried at its

prescribed drying temperature (502.5 C) in indirect solar

dryer (ISD) using phase change material (PCM) as energy

storage medium. 12 kg of paraffin wax were used as a latent

heat thermal storage. From the experimental obtained results it

is found that the ISD implementing PCM as thermal storage

medium successfully maintains the temperature of drying air

around 50 C for seven consecutive hours. It is also found that

the temperature of drying air is higher than ambient

temperature by 2.5-5 C after sunset for 5 hrs at least. This

profile of the temperature of drying air helps reaching the final

moisture content of Nerium Oleander after 14 hrs. Nine thin

layer drying mathematical models were tested to specify the

suitable model for describing the drying behavior of the Nerium

Oleander. It was found that Midilli and Kucuk model is

convenient to describe the thin layer solar drying of Nerium

Oleander.

II. MEASUREMENTS AND EXPERIMENTAL PREPARATION

Index TermsSolar drying, nerium oleander, energy storage,

PCM.

I. INTRODUCTION

Medical plant loses its valuable contents when it is

exposed to direct solar radiation or when treated with high

oven temperature. So there is deep need for a new design for

the indirect solar dryer that is able to dry the medical plants

and maintain all its valuable contents at the same time.

Moreover, the valuable medical plants will be dried then it

will be economically beneficial as a result of storing it and/or

exporting it.

Nerium Oleander is used as a decorative tree for both

streets and school gardens neglecting its medical content. The

chemical analysis of Nerium Oleander indicates a large

amount of glycoside as reported in [1], [2]. The glycoside

medical component is economically important as it is used in

heart treatment [3], [4].

A few types of medical plants are dried using the indirect

solar dryer such as mints [5], [6] and thymus [5]. Although

most of these studies concern the drying curves and their

suitable mathematical modeling description, they ignore the

important factor of the best desired plants drying

temperature.

The phase change material (PCM) ability to store large

amount of thermal energy during its melting process and

benefit of it under constant temperature later, makes it

excellent tool to improve the solar drying system. Limited

Manuscript received March 27, 2014; revised June 28, 2014. This work

was funded by the research projects program, Research fund, Tanta

University, Egypt, Grants (TU-04-31-03).

S. M. Shalaby and M. A. Bek are with the Department of Engineering

Physics and Mathematics, Faculty of Engineering, Tanta University, Tanta,

Egypt (e-mail: saleh_shalaby@yahoo.com, malibec2005!@yahoo.com).

DOI: 10.7763/JOCET.2015.V3.191

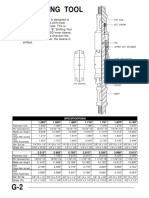

The ISD was designed and fabricated in the Solar Energy

Laboratory workshop, Faculty of Engineering, Tanta

University. Complete design details of the air heater, drying

compartment and PCM storage unit can be found elsewhere

[12]. The ISD implementing PCM was tested using the test

rig shown in Fig. 1. The experiments were conducted

outdoors during October 2013. The global solar radiation on

a (30o) tilted surface, I, was measured using a high precision

Pyranometer model MS-802 (sensitivity of 7.03 (volts/W

m2)). Calibrated K-Type thermocouples (0 to 1100 C)

coupled with KYORITSU KEW1011 multimeter were used

to measure the temperatures at different locations of the

heater and drying compartment as seen in Fig. 1. The

temperatures of the drying air at each tray were measured and

its average value,

, was obtained. A three-phase

induction motor (Type K 120 T, 0.75 HP, 2.5 A, 390 V, 50

Hz, 2610 r/min) coupled with a fan (0.3 m diameter) was used

to blow the air to the drying compartment. The air flow rate

was controlled and measured with the help of SJ 300 Hitachi

inverter and pitot tube, respectively.

1-Solar air heater; 2-Pyranometer; 3-The room wall; 4-The room roof; 5Flowing air; 6-PVC tube; 7-Inverter; 8-Three phase induction motor coupled

with fan; 9-Pitot tube; 10-U tube manometer; 11-Drying compartment; 12PCM; 13-Trays; 14-Thermocouple positions.

Fig. 1. A schematic diagram of the experimental setup.

176

Journal of Clean Energy Technologies, Vol. 3, No. 3, May 2015

The Nerium Oleander was collected from the faculty of

pharmacys research farm in order to be dried by the ISD.

There are several considerations which took place during the

drying process. Initially the spoiled plants were discarded to

avoid products contamination from bacteria. Moreover,

selected plants of same size were chosen carefully to ensure

the physical characteristics uniformity. Then the selected

plants were cleaned using tab water to remove any undesired

materials. Cotton clothes were used to remove any water

remains from the surface of the plants.

In order to determine the initial moisture content, the

plants were weighed while they were fresh then dried at

electric oven for 48 hours on 70C and the dried products

were weighed for the second time. A digital balance, type

300-9213/b 125A, of readability 0.0001 gm was used to

measure the mass of the sample every 60 minutes until it

reaches a constant weight.

The drying thermal efficiency is given as [18]:

(8)

TABLE I: MATHEMATICAL MODELS APPLIED TO THE SOLAR DRYING

CURVES

Model

Model equation

Reference

name

A. Drying Parameters

In this section, the governing equations of the drying

process and its basic definitions are introduced. The initial

moisture content on dry base M 0 d is defined as the mass of

Similarly,

m0 md

md

m0 md

m0

MR exp( kt)

[19]

Page

MR exp( kt )

[20]

Modified

Page

Henderson

and Pabis

Logarithmi

c

MR exp( (kt) n )

[21]

MR a exp(kt)

[22]

MR a exp( kt) c

[23]

MR a exp(k 0 t ) b exp( k1t )

[24]

Modified

Henderson

and Pabis

Verma et

al.

Midilli and

Kucuk

(1)

MR a exp( kt) b exp( gt ) c exp( ht )

MR a exp( kt) (1 a) exp( gt )

MR a exp( kt n ) bt

(2)

The moisture content M td at any given time on dry base is

computed using the following expression as presented in

[14]:

MR

N

( M 1)mt

M td od

1

m

0

x2

(3)

i 1

(4)

M t M e

M 0 M e

[27]

MR pre,i

(9)

N n

MR

i 1

MR pre,i

exp,i

(10)

where MRexp.i stands for the experimental moisture ratio

found in the measurements; MR pre.i is the predicted moisture

The moisture ratio MR is defined as:

MR

[26]

exp,i

RMSE

can be calculated from the following equation [15]:

1

M tw 1

M td 1

[25]

Moreover, the thin layer drying equations given in Table I

[19]-[27] are tested to select the most suitable model for

describing the drying curve of Nerium Oleander. For model

evaluation, a nonlinear regression analysis is used. The

correlation coefficient R, the statistical parameter reduced

chi-square x2, and root mean square errors RMSE are used to

determine the quality of the fit. The higher value of R and the

lower values of x2and RMSE are chosen as the criteria for

goodness of fit. The reduced chi-square x2and the root mean

square errors RMSE are calculated as follows [28]:

M ow is calculated as follow:

M 0w

Lewis

Two term

moisture present in the sample per unit mass of dry matter in

the sample [13]:

M 0d

(7)

ratio for this measurement; N is the number of observations;

and n is the number of a models constants.

(5)

III. RESULTS AND DISCUSSIONS

The moisture ratio MR is simplified by some investigators

[6], [16] to Mt/M0 because the equilibrium moisture Me

content is significantly less than the initial moisture content

M0. In this case, (5) becomes

MR

The mass shrinkage ratio

Mt

M0

The ISD implementing PCM is used to dry Nerium

Oleander on a typical day of October 2013 where the

maximum measured values of solar radiation and ambient

temperature are 1109 W/m2 and 31C, respectively as seen in

Fig. 2. The variation of the average value of drying air

temperature

is also shown in Fig. 2. The ISD

implementing PCM as thermal storage medium successfully

maintains

around 50C for seven consecutive hours

as clearly seen in Fig. 2. It is also seen in Fig. 2 that

is

(6)

is defined as [17]:

177

Journal of Clean Energy Technologies, Vol. 3, No. 3, May 2015

higher than ambient temperature by 2.5-5C after sunset for 5

hrs at least. This profile of drying temperature helps reaching

the final moisture content of Nerium Oleander after 14 hrs as

clearly seen in Fig. 3. The shrinkage ratio is 0.367 as

calculated from (6). Variation of moisture ratio of one kg of

Nerium Oleander with drying time is shown in Fig. 4. The

thin layer drying models given in Table I are applied on the

drying curve of Nerium Oleander represented in Fig. 4 and

the obtained statistical results are summarized in Table II.

From the results of Table II it is seen that Midilli and Kucuk

model gives the highest correlation coefficient ( R 0.9981 )

and the lowest reduced chi-square ( x 2 0.000336 ) and

lowest root mean square error (

); therefore,

it is selected to describe the thin layer drying behavior of

Nerium Oleander. The thin layer drying model of Nerium

Oleander is obtained as:

MR 1.0073 exp( 0.1365t

) 0.01t

1.1306

Modified

Page

Henderson

and Pabis

Two term

T a(av)

Verma et al.

1000

60

600

40

400

20

200

Solar radiation (W/m2)

Temperature (oC)

800

Midilli and

Kucuk

10

12

14

16

18

20

22

Time of the day

Fig. 2. The variation of drying temperature VS time.

70

5/10/2013

60

50

40

0.9935

0.001033

0.02976

k 0.1822 ,

0.9972

0.000482

0.01945

0.9972

0.00053

0.01945

0.9972

0.000663

0.01945

0.9966

0.000591

0.02155

0.9981

0.000336

0.01625

a 0.9072 ,

k0 0.1822 ,

b 0.1206 ,

11

a 0.4593 ,

k 0.1822 ,

b 0.4479 ,

g 0.1822 ,

c 0.1206 ,

h 2.2 1011

a 0.8965 ,

k 0.1692 ,

a 1.0073 ,

k 0.1365 ,

n 1.1306 ,

b 0.01 .

1.0

30

Predicted value of moisture ratio

Moisture content (%)

k 0.1343

Comparison between experimental moisture ratio and that

predicted using Midilli and Kucuk model for Nerium

Oleander is shown in Fig. 5. From this figure it is clear that,

the established model (11) provided good conformity

between experimental and predicted moisture ratios, and the

predicted data generally banded around a 45straight line.

This means that, this model is valid in describing the thin

layer solar drying behavior of Nerium Oleander for given

operating drying parameters.

0

8

0.02712

g 3.3 1011

Solar radiation

80

0.000858

k1 8.8 10

Ta

5/10/2013

0.9946

c 0.1206

1200

100

n 0.9282

k 0.1349 ,

n 0.9282

a 0.9945 ,

a 0.9072 ,

Logarithmic

Modified

Henderson

and Pabis

(11)

120

TABLE II: STATISTICAL RESULTS OF MATHEMATICAL MODELING OF

DRYING CURVES FOR NERIUM OLEANDER

Model

Coefficients

R

x2

RMSE

Lewis

0.9935

0.000962

0.02988

k 0.1352

k 0.1558 ,

Page

0.9946

0.000858

0.02712

20

10

0

0

Drying time

10

12

14

16

(hrs)

Fig. 3. The variation of moisture content of one kg of Nerium Oleander with

the drying time.

1.2

0.8

0.6

0.4

0.2

5/10/2013

1.0

0.0

Moisture ratio (MR)

0.0

0.8

0.2

0.4

0.6

0.8

1.0

Experimental value of moisture ratio

Fig. 5. Comparison between experimental moisture ratios (MR) and that

predicted for Nerium Oleander calculated using Midilli and Kucuk model.

0.6

0.4

IV. CONCLUSIONS AND RECOMMENDATIONS FOR FUTURE

WORK

0.2

0.0

0

Drying time

10

12

The ISD implementing PCM is experimentally tested for

drying Nerium Oleander. From the experimental obtained

results it is concluded that the utilization of PCM in the ISD

smoothes the temperature of dying air and provide a suitable

14

(hrs)

Fig. 4. The variation of moisture ratio of one kg of Nerium Oleander with the

drying time.

178

Journal of Clean Energy Technologies, Vol. 3, No. 3, May 2015

temperature for drying Nerium Oleander during 14 hrs. It is

inferred that using high thermal conductive particles with

paraffin wax as energy storage material may improve the

thermal performance of the indirect solar dryer .

[10]

[11]

NOMENCLATURE

the global solar radiation on a (30o) tilted surface

(W/m2)

ISD indirect solar dryer

L

latent heat of water (kJ/kg)

Mod initial moisture content on dry base

Mow initial moisture content on wet base

Mf final moisture content

Mtd instantaneous moisture content on dry base

Mtw instantaneous moisture content on wet base

m mass flow rate of air (kg/s)

mo initial mass of the sample (kg)

md mass of the dried sample (kg)

mt

mass of the sample at any time (kg)

me

mass of water evaporated (kg)

PCM phase change material

SR

shrinkage ratio (dimensionless)

Ta

ambient temperature (C)

Tda(av) average temperature of drying air (C)

Tda(i) temperature of drying air at the entrance of the drying

compartment (C)

t

drying time (s)

Subscripts:

av

average

d

drying

i

inlet

o

outlet

th

thermal

Greek:

efficiency (dimensionless)

I

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[25]

S. Singh, S. Shenoy et al, Nerium oleander derived cardiac glycoside

oleander in is a novel inhibitor of HIV infectivity, Fitoterapia, vol. 84,

pp. 32-39, 2013.

B. S. Siddiqui, N. Khatoon, S. Begum, A. D. Farooq, K. Qamar, H. A.

Bhatti, and S. K. Ali, Flavonoid and cardenolide glycosides and a

pentacyclictriterpene from the leaves of Nerium oleander and

evaluation of cytotoxicity, Phytochemistry, vol. 77, pp. 238-244,

2012.

Y. Sreenivasan, P. B. Raghavendra, and S. K. Manna,

Oleandrin-mediated expression of Fas potentiates apoptosis in tumor

cells, J ClinImmunol, vol. 26, pp. 308-322, 2006.

P. Yang, D. G. Menter, C. Cartwright, D. Chan, S. Dixon, and M.

Suraokar, Oleandrin-mediated inhibition of human tumor cell

proliferation: Importance of Na, K-ATPase alpha subunits as drug

targets, Mol Cancer Ther., vol. 8, pp. 2319-2328, 2009.

A. A. El-Sebaii and S. M. Shalaby, Experimental investigation of an

indirect-mode forced convection solar dryer for drying thymus and

mint, Energy Conversion and Management, vol. 74, pp. 109-116,

2013.

E. K. Akpinar, Drying of mint leaves in a solar dryer and under open

sun: modeling, performance analyses, Energy Conversion and

Management, vol. 51, pp. 2407-2418, 2010.

S. Devahastin, K. W. Ng, and A. S. Mujumdar, Preliminary study of a

novel thermal storage-spouted bed contactor for particulate drying, in

Proc. 48th Canadian Chemical Engineering Conference, 1989.

S. Devahastin and S. Pitaksuriyarat, Use of latent heat storage to

conserve energy during drying and its effect on drying kinetics of a

food product, Applied Thermal Engineering, vol. 26, pp. 1705-1713,

2006.

L. M. Bal, P. Sudhakar, S. Satya, and S. N. Naik, Review of Solar

dryer with latent heat storage systems for drying agricultural food

[26]

[27]

[28]

products, Renewable and Sustainable Energy Reviews, vol.15, issue 1,

pp. 876-880, 2009.

G. Cakmak, C. Yidiz, The drying kinetics of seeded grape in solar

dryer with PCM-based solar integrated collector, Food and

Bioproducts Processing, vol. 89, pp. 103-108, 2011.

S. Esakkimuthu, A. Hassabou, C. Palaniappan, M. Spinnler, J.

Blumenberg, and R. Velraj, Experimental investigation on phase

change material based thermal storage system for solar air heating

applications, Solar Energy, vol. 88, pp. 144-153, 2013.

S. M. Shalaby and M. A. Bek, Experimental investigation of a novel

indirect solar dryer implementing PCM as energy storage medium,

Energy Conversion and Management, vol. 83, pp. 1-8, 2014.

I. Doymaz, Thin layer drying behaviour of mint leaves, Journal of

Food Engineering, vol. 74, pp. 370-375, 2006.

A. A. El-Sebaii, S. Aboul-Enein, M. R. I. Ramadan, and H. G.

El-Gohary, Experimental investigation of an indirect type natural

convection solar dryer, Energy Conversion and Management, vol. 43,

pp. 2251-2266, 2002.

M. A. Zaman and B. K. Bala, Thin layer solar drying of rough rice,

Solar Energy, vol. 42, pp. 167-171, 1989.

A. Midilli and H. Kucuk, Mathematical modeling of thin layer drying

of pistachio by using solar energy, Energy Conversion and

Management, vol. 44, pp. 1111-1122, 2003.

A. Midilli, Determination of pistachio drying behavior and conditions

in a solar drying system, Int. J. Drying Res., vol. 25, pp. 715-725,

2001.

P. P. Singh, S. Singh, and S. S. Dhaliwal, Multi-shelf domestic solar

dryer, Energy Conversion and Management, vol. 47, pp. 1799-1815,

2006.

W. K. Lewis, The drying of solid materials, Journal Indian

Engineering, vol. 5, pp. 427-433, 1921.

G. E. Page, Factors influencing the maximum rates of air drying

shelled corn in thin layers, Master Thesis, Purdue University,

Lafayette, IN, USA, 1949.

G. M. White, I. J. Ross, and R. Ponelert, Fully exposed drying of

popcorn, Transactions of the American Society of Agricultural

Engineers, vol. 24, pp. 466-468, 1981.

M. S. Chinnan, Evaluation of selected mathematical models for

describing thin layer drying of in-shell pecains, Transactions of the

American Society of Agricultural Engineers, vol. 27, pp. 610-615,

1984.

A. Yagcioglu, A. Degirmencioglu, and F. Cagatay, Drying

characteristics of laurel leaves under different conditions, in Proc. the

Seventh International Congress on Agricultural Mechanization and

Energy, Adana, Turkey. Faculty of Agriculture, Cukurova University,

1999, pp. 565-569.

S. M. Henderson, Progress in developing the thin layer drying

equation, Transactions of the American Society of Agricultural

Engineers, vol. 17, pp. 1167-1168, 1974.

V. T. Karathanos, Determination of water content of dried fruits by

drying kinetics, Journal of Food Engineering, vol. 39, pp. 337-344,

1999.

L. R. Verma, R. A. Bucklin, J. B. Endan, and F. T. Wratten, Effects of

drying air parameters on rice drying models, Transactions of the

American Society of Agricultural Engineers, vol. 28, pp. 296-301,

1985.

A. Midilli, H. Kucuk, and Z. Yapar, A new model for single layer

drying, Drying Technology, vol. 20, pp. 1503-1513, 2002.

C. Ertekin and O. Yaldiz, Drying of eggplant and selection of a

suitable thin layer drying model, Journal of Food Engineering, vol. 63,

pp. 349-359, 2004.

S. M. Shalaby was born in Tanta, Egypt, in February

1974. He completed Ph.D. degree in engineering

physics and mathematics (engineering physics) on

2012 from Tanta University, Tanta, Egypt. The thesis

entitled Investigation of thermal performance of

indirect solar drying systems. He received his M. SC.

degree in engineering physics and mathematics

(engineering physics) on 2005 from Tanta University,

Tanta, Egypt. The thesis entitled Utilization of solar

energy in some flat plate solar collectors. He finished his B. SC. degree in

machines and electrical power engineering with grade very good with

honor on 1997 from Tanta University, Tanta, Egypt.

Currently he is a lecturer at Engineering Physics and Mathematics Dep.,

Faculty of Engineering, Tanta Univ., from February 28, 2012.

He has a strong experience in the field of solar energy and its applications.

The focus of some of his current studies is the utilization of phase change

179

Journal of Clean Energy Technologies, Vol. 3, No. 3, May 2015

material as energy storage medium in solar thermal energy applications. He

is currently the principal investigator of the research project: Novel indirect

solar dryer design to dry medical plants using PCM as storage medium. He

has published several research papers in international Journals.

Dr. Shalaby is a senior member of Asia-Pacific Chemical, Biological&

Environmental Engineering Society (APCBEES). Dr. Shalaby is also a

member of Science and Engineering institute (SCIEI).

Nottingham, UK in 2011. His PhD research focused on developing a field

validated numerical model to investigate the water hydrodynamic of lake

El-Manzala, Egypt. He is interested in the development and application of

computational models to provide an improved understanding of the

fundamental processes that cause real world environmental engineering

problems, and which may assist in the design of sustainable solutions to

these problems. The focus of some of his current and recent research studies

is the modeling of the water hydrodynamics and water quality of lakes. In

addition, solar energy applications are became of his most recent interest. A

Novel indirect solar dryer to dry medical plants using PCM as storage

medium was designed and investigated. This project was funded through

Tanta University, Egypt.

M. A. Bek was born in Cairo, Egypt, in April 1972. He

completed PhD Degree in environmental engineering,

School of Chemical and Environmental Engineering,

University of Nottingham, UK. Thesis title is

Numerical simulation of the water haydrodynamics of

Lake El-Manzala, Egypt. He received his MSc degree

in applied mathematics, form Physics and Engineering

Mathematics Department, Tanta l University, Egypt,

February 2004. Thesis title is Perturbed Motion of a

dynamical System. He finished his B.Sc. degree in mechanical engineering,

Faculty of Engineering, Tanta University, EGYPT, June 1996. Currently he

is a lecturer at Engineering Physics and Mathematics Dep., Faculty of

Engineering, Tanta Univ., in addition he is a visiting lecturer at Misr

University for Technology and science. He has published several research

papers in international Journals.

He obtained his PhD in environmental engineering from the University of

180

You might also like

- Service Instruction For Servo Cylinder Type PBEDDocument2 pagesService Instruction For Servo Cylinder Type PBEDДжон Диллинджер100% (1)

- Tech Information Basic Weber TuningDocument6 pagesTech Information Basic Weber TuningYacullsNo ratings yet

- Application of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural ConvectionDocument9 pagesApplication of A Multi-Model Control With TS Fuzzy Switching To An Indirect Solar Dryer Operated in Natural Convectionhicham El FeroualiNo ratings yet

- Mathematical Modeling of Thin Layer Solar Drying of Sultana GrapesDocument9 pagesMathematical Modeling of Thin Layer Solar Drying of Sultana GrapesNEFTALI VAZQUEZ ESPINOSANo ratings yet

- Design and Analysis of A Solar Dryer ForDocument7 pagesDesign and Analysis of A Solar Dryer ForYousup AliNo ratings yet

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Document7 pagesDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupNo ratings yet

- Energy Conversion and Management: S.M. Shalaby, M.A. BekDocument8 pagesEnergy Conversion and Management: S.M. Shalaby, M.A. BekRab NawazNo ratings yet

- Design and Development of Solar Dryer Cabinet With Thermal Energy StorageDocument5 pagesDesign and Development of Solar Dryer Cabinet With Thermal Energy Storage11751175No ratings yet

- Mathematical Modeling of Drying Characteristics of Tropical FruitsDocument6 pagesMathematical Modeling of Drying Characteristics of Tropical FruitsNEFTALI VAZQUEZ ESPINOSANo ratings yet

- CFD Investigation of A Solar Dryer With Thermal Storage by Rocks and by Phase Change MaterialDocument4 pagesCFD Investigation of A Solar Dryer With Thermal Storage by Rocks and by Phase Change Materialhicham El FeroualiNo ratings yet

- Hybrid Solar-Gas-Electric Dryer Optimization With Genetic AlgorithmsDocument8 pagesHybrid Solar-Gas-Electric Dryer Optimization With Genetic Algorithmshicham El FeroualiNo ratings yet

- Development of Solar Dryer Incorporated With Evacuated Tube CollectorDocument4 pagesDevelopment of Solar Dryer Incorporated With Evacuated Tube Collectormailsk123No ratings yet

- Design and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalDocument4 pagesDesign and Performance Evaluation of Solar Dryer: P. K. Wankhade, Dr. R.S.Sapkal, Dr. V.S.SapkalBahynorerama DpNo ratings yet

- Drying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerDocument5 pagesDrying Characteristics of Lemongrass in Solar Assisted Chemical Heat Pump DryerMuhammad Maulana SidikNo ratings yet

- Design and Development of Solar Air Dryer For Drying of Apricot For Ladhak RegionDocument10 pagesDesign and Development of Solar Air Dryer For Drying of Apricot For Ladhak RegionkolkNo ratings yet

- Research Article: An Experimental Study of Vegetable Solar Drying Systems With and Without Auxiliary HeatDocument9 pagesResearch Article: An Experimental Study of Vegetable Solar Drying Systems With and Without Auxiliary HeatJuan PeraltaNo ratings yet

- UniformityDocument34 pagesUniformityPUBG SORRYNo ratings yet

- Kinetics of Apricot Thin Layer Drying in A Mixed and Indirect Mode SolarDocument6 pagesKinetics of Apricot Thin Layer Drying in A Mixed and Indirect Mode SolarNEFTALI VAZQUEZ ESPINOSANo ratings yet

- Design, Development and Performance Evaluation of A Large-Scale HybridDocument11 pagesDesign, Development and Performance Evaluation of A Large-Scale Hybridvotewi2286No ratings yet

- Performance Enhancement of NaturalDocument11 pagesPerformance Enhancement of Naturaldatdreams2No ratings yet

- Ijme V7i1p105Document4 pagesIjme V7i1p105Shubham kumarNo ratings yet

- Ders Notu 4 MidilliDocument18 pagesDers Notu 4 MidilliDiksha SurekaNo ratings yet

- Solar Drying of Whole Mint Plant Under Natural and Forced ConvectionDocument8 pagesSolar Drying of Whole Mint Plant Under Natural and Forced ConvectionVishvanath KardiNo ratings yet

- Effective Utilization of Solar Energy in Air Dryer: M. Joseph Stalin & P. BarathDocument10 pagesEffective Utilization of Solar Energy in Air Dryer: M. Joseph Stalin & P. BarathTJPRC PublicationsNo ratings yet

- Experimental Study of A Heat Pump Assisted General Purpose Tray Dryer With Backup HeaterDocument6 pagesExperimental Study of A Heat Pump Assisted General Purpose Tray Dryer With Backup HeaterGRD JournalsNo ratings yet

- Performance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitDocument7 pagesPerformance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitVishvesh T SNo ratings yet

- J - Advanced Research - 2024-Kinetic Modelling MoringaDocument9 pagesJ - Advanced Research - 2024-Kinetic Modelling MoringaAdrie OktavioNo ratings yet

- Case Studies in Thermal Engineering: S. Nabnean, P. NimnuanDocument11 pagesCase Studies in Thermal Engineering: S. Nabnean, P. NimnuanCarlos BispoNo ratings yet

- Drying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateDocument6 pagesDrying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateAJER JOURNALNo ratings yet

- Energy Efficiency of A Solar Drying SystemDocument4 pagesEnergy Efficiency of A Solar Drying SystemMarco Antonio Miranda RodriguezNo ratings yet

- Determination of Suitable Thin Layer Drying Curve Model For Some Vegetables and FruitsDocument10 pagesDetermination of Suitable Thin Layer Drying Curve Model For Some Vegetables and FruitsLe Quoc TuanNo ratings yet

- Energy and Exergy Analysis of Cassava Starch Dried in Hybrid Solar DryerDocument16 pagesEnergy and Exergy Analysis of Cassava Starch Dried in Hybrid Solar DryerEvan EduardNo ratings yet

- Chilly Tunnel DryingDocument3 pagesChilly Tunnel Dryingdeepakmehta2812No ratings yet

- Design and Development of Walk-In Type HemicylindrDocument10 pagesDesign and Development of Walk-In Type HemicylindrMaite ZuritaNo ratings yet

- Nergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and DisseminationDocument16 pagesNergy and Nvironment: A Greenhouse Type Solar Dryer For Small-Scale Dried Food Industries: Development and Disseminationshribavan2373No ratings yet

- J AERG Journal of Chemical and Pharmaceutical Sciences Ftwi Y Hagos Solar Drier ModelingDocument10 pagesJ AERG Journal of Chemical and Pharmaceutical Sciences Ftwi Y Hagos Solar Drier ModelingFtwi Yohaness HagosNo ratings yet

- Esteem 17Document5 pagesEsteem 17PremSagarJasujaNo ratings yet

- Determination of Suitable Thin Layer Drying Curve Model For Apple SlicesDocument6 pagesDetermination of Suitable Thin Layer Drying Curve Model For Apple Slicesvele2ionut100% (1)

- Pengeringan BawanDocument8 pagesPengeringan BawanDandy eight8No ratings yet

- Design and Analysis of Solar Dryer For Mid-Latitude Region: SciencedirectDocument13 pagesDesign and Analysis of Solar Dryer For Mid-Latitude Region: SciencedirectBahynorerama DpNo ratings yet

- Rancang Bangun Kolektor Pelat Datar Energi Surya Untuk Sistem Pengeringan Pasca PanenDocument15 pagesRancang Bangun Kolektor Pelat Datar Energi Surya Untuk Sistem Pengeringan Pasca PanenNur AfifahNo ratings yet

- 36 Tale Geramitcioski FinalDocument3 pages36 Tale Geramitcioski FinalNemacNo ratings yet

- Design and Construction of A Solar Dryer For MangoDocument8 pagesDesign and Construction of A Solar Dryer For MangoIboyaima singhNo ratings yet

- Design of Solar Bagasse DryerDocument9 pagesDesign of Solar Bagasse DryerDr. Mahesh GopalNo ratings yet

- Solar Air Dryer Performance Evaluation Using Locally Available MaterialsDocument7 pagesSolar Air Dryer Performance Evaluation Using Locally Available MaterialsIJRASETPublicationsNo ratings yet

- Design and CFD Analysis of Food Dryer UsDocument14 pagesDesign and CFD Analysis of Food Dryer UsShubham kumarNo ratings yet

- Low Cost Material Used To Construct Effective Box Type Solar DryerDocument7 pagesLow Cost Material Used To Construct Effective Box Type Solar DryerndvprsdNo ratings yet

- 38 Ijmperddec201838Document14 pages38 Ijmperddec201838TJPRC PublicationsNo ratings yet

- Ids 2022Document7 pagesIds 2022zhor El hallaouiNo ratings yet

- Performance Analysis of A Solar DryerDocument11 pagesPerformance Analysis of A Solar DryerSerge KewouNo ratings yet

- Ijmet: ©iaemeDocument8 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- Evaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementDocument7 pagesEvaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementMildred CullenNo ratings yet

- Hussain2019 PDFDocument8 pagesHussain2019 PDFĐức HòaNo ratings yet

- Computational Fluid Dynamics Analysis of Greenhouse Solar DryerDocument19 pagesComputational Fluid Dynamics Analysis of Greenhouse Solar DryerPurusothamanManiNo ratings yet

- WP Contentuploadspapersv3i5H96670712823 PDFDocument18 pagesWP Contentuploadspapersv3i5H96670712823 PDFsamsonNo ratings yet

- Numerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat SystemDocument18 pagesNumerical-Simulation and Experimental-Validation of The Largest Egyptian Solar Process-Heat Systemgazali belhajNo ratings yet

- 3different Varieties of Tomato 2018Document10 pages3different Varieties of Tomato 2018kamalNo ratings yet

- Cross Flow Paddy Dryer Application Using Infrared Gas BurnerDocument11 pagesCross Flow Paddy Dryer Application Using Infrared Gas BurnerZaharanNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Cold Inflow-Free Solar Chimney: Design and ApplicationsFrom EverandCold Inflow-Free Solar Chimney: Design and ApplicationsMd. Mizanur RahmanNo ratings yet

- Global Vegetation Dynamics: Concepts and Applications in the MC1 ModelFrom EverandGlobal Vegetation Dynamics: Concepts and Applications in the MC1 ModelDominique BacheletNo ratings yet

- T 002236Document4 pagesT 002236v2304451No ratings yet

- Decommissioning Technician PDFDocument2 pagesDecommissioning Technician PDFIamSajid JatoiNo ratings yet

- MSDS TaecDocument7 pagesMSDS TaecMuhammad FikriansyahNo ratings yet

- Cartagena Part3 Aerosols CompositionDocument62 pagesCartagena Part3 Aerosols CompositionEDWARDNo ratings yet

- Danish Resume - 2023 Pages 1 4 IEEEDocument4 pagesDanish Resume - 2023 Pages 1 4 IEEEDanish D.RNo ratings yet

- Price List: LTM 019A W.E.F 02.04.2022Document60 pagesPrice List: LTM 019A W.E.F 02.04.2022Ashish100% (1)

- OrganicChemistryVol2 TextDocument701 pagesOrganicChemistryVol2 TextIsrar Ulhaq100% (2)

- J Box - XMTDocument27 pagesJ Box - XMTVladeta JevremovićNo ratings yet

- Technical Schedule A To D & H Pkg-2Document69 pagesTechnical Schedule A To D & H Pkg-2vinodNo ratings yet

- Tech Tool FAQs v1 28 October20151Document12 pagesTech Tool FAQs v1 28 October20151NoeRtjahya AhmadNo ratings yet

- Hassan Ali CV AC TechDocument3 pagesHassan Ali CV AC TechMuhammad Javed BhattiNo ratings yet

- 3HAC2914-1 M98 IRB1400 Product Manual DSQC311 SMB Unit DescriptionDocument8 pages3HAC2914-1 M98 IRB1400 Product Manual DSQC311 SMB Unit DescriptionAnonymous smdEgZN2IeNo ratings yet

- Session 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Document31 pagesSession 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Ruslan ZakirovNo ratings yet

- Compair 5217.2.H2 - 1188753 Operator Handbook English SUVINCA-DIANADocument208 pagesCompair 5217.2.H2 - 1188753 Operator Handbook English SUVINCA-DIANAjvicher61No ratings yet

- OsiSense XU - XUX1ARCNT16Document6 pagesOsiSense XU - XUX1ARCNT16Top Hayons AlgerieNo ratings yet

- Duty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerDocument3 pagesDuty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerHawaz BeyeneNo ratings yet

- B Shifting ToolDocument1 pageB Shifting ToolAmanda Delgado67% (3)

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- CGa Series 3 Boiler Manual 0520Document68 pagesCGa Series 3 Boiler Manual 0520Sonaina KhanNo ratings yet

- Lab 1a Wind Tunnel Testing Principles & Lift and Drag Coefficients On An AirfoilDocument6 pagesLab 1a Wind Tunnel Testing Principles & Lift and Drag Coefficients On An Airfoilzeeshan khanNo ratings yet

- Oxidation CorrosionDocument17 pagesOxidation CorrosionGise GSNo ratings yet

- Kitchen Exhaust System DesignDocument4 pagesKitchen Exhaust System Designebru_alpaslan100% (2)

- Manual NCT-3000 (En) PDFDocument15 pagesManual NCT-3000 (En) PDFvintiloiusNo ratings yet

- Partnership With NulledDocument2 pagesPartnership With NulledAnonymous kEkbtYX0jNo ratings yet

- Solid Shell Connection in Finite Element AnalysisDocument21 pagesSolid Shell Connection in Finite Element AnalysisvilukNo ratings yet

- Slip and CutDocument2 pagesSlip and CutAnonymous Vb1Tsv106100% (1)

- Ruthmann Steiger 270 CeltnisDocument261 pagesRuthmann Steiger 270 CeltnisIlgvars StaldeNo ratings yet

- Optical MicrometerDocument2 pagesOptical MicrometerrubensNo ratings yet