Professional Documents

Culture Documents

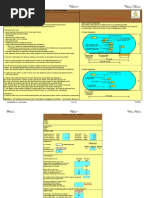

Functional Specification APPLICATION - 2360dew2 2360 Chromatograph Controller Application Software

Functional Specification APPLICATION - 2360dew2 2360 Chromatograph Controller Application Software

Uploaded by

Ruben Ortiz CaramCopyright:

Available Formats

You might also like

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Lab Report No.4 Moisture Content Specific Gravity Unit WeightDocument30 pagesLab Report No.4 Moisture Content Specific Gravity Unit WeightAngela Salada50% (2)

- BMS T&C ManualDocument25 pagesBMS T&C ManualRini Puspitasari100% (1)

- Bleed Rates of ControllersDocument35 pagesBleed Rates of Controllersalkhwarizmi1968No ratings yet

- API 12j SizingDocument8 pagesAPI 12j SizingsegunoyesNo ratings yet

- Cadwork 2D ManualDocument73 pagesCadwork 2D ManualRuben Ortiz CaramNo ratings yet

- Is 6940 1982 PDFDocument41 pagesIs 6940 1982 PDFDwi Kristianto100% (1)

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- PG ReadmeDocument14 pagesPG ReadmeBrian MayNo ratings yet

- Tender22 8Document38 pagesTender22 8er_bhavin3119100% (1)

- Alicat Scientific MFCs-Technology & BenefitsDocument6 pagesAlicat Scientific MFCs-Technology & BenefitsyuvionfireNo ratings yet

- HCDP Danalyzerdan An 42 NGC An HDCP 700xaDocument4 pagesHCDP Danalyzerdan An 42 NGC An HDCP 700xakenangrok2009No ratings yet

- En-DTR CMK-02Document51 pagesEn-DTR CMK-02Henry MaedaNo ratings yet

- Item Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912Document7 pagesItem Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- GTS Functional Requirements Fiscal Metering Final Version 1.5Document20 pagesGTS Functional Requirements Fiscal Metering Final Version 1.5Henry MaedaNo ratings yet

- 080000B Com With GCDocument6 pages080000B Com With GCsyed jeelani ahmedNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- May 93Document28 pagesMay 93yundtech974No ratings yet

- GAS-Guard 8: Answers For EnergyDocument6 pagesGAS-Guard 8: Answers For Energyeross_saptaNo ratings yet

- Mitsubishi Pga 300Document7 pagesMitsubishi Pga 300kirikupappNo ratings yet

- CompressorDocument27 pagesCompressorsoxal100% (1)

- VCCDocument8 pagesVCCRaden AditiyaNo ratings yet

- Section 22 - Sulfur RecoveryDocument145 pagesSection 22 - Sulfur RecoveryCHANADAS100% (1)

- Hw4 Software Version 3 Humidity and Temperature Adjustment Airchip 3000 DevicesDocument24 pagesHw4 Software Version 3 Humidity and Temperature Adjustment Airchip 3000 Deviceshsingnan.instrumentNo ratings yet

- E M HW4v3 A2 001 - 15Document26 pagesE M HW4v3 A2 001 - 15hsingnan.instrumentNo ratings yet

- Flow ComputersDocument11 pagesFlow ComputersKarthik ChockkalingamNo ratings yet

- An Arduino Micro-Controller Operated Automobile Air Conditioning SystemDocument14 pagesAn Arduino Micro-Controller Operated Automobile Air Conditioning Systemgodwinraj123No ratings yet

- Edrm Rohr2 Featurelist-32 1Document35 pagesEdrm Rohr2 Featurelist-32 1Yuliyan StoyanovNo ratings yet

- Design and AnalysisDocument5 pagesDesign and AnalysiscliveNo ratings yet

- Using The Fluke 5000A-RH/T With MET/CAL V6.11Document15 pagesUsing The Fluke 5000A-RH/T With MET/CAL V6.11KhoilnNo ratings yet

- PCD SF 191Document7 pagesPCD SF 191mNo ratings yet

- Gas Calibration Method v2Document9 pagesGas Calibration Method v2Mazhar MahadzirNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- ISO 4267-2 - 1988 - Part 2 Dynamic Measurement - INDDocument2 pagesISO 4267-2 - 1988 - Part 2 Dynamic Measurement - INDYuri MateusNo ratings yet

- User - Manual GW-DLMS-232-SL7 - 5.102 - enDocument16 pagesUser - Manual GW-DLMS-232-SL7 - 5.102 - enel mahdi BendaoudNo ratings yet

- RC2 Series Screw Compressor Technical Manual PDFDocument84 pagesRC2 Series Screw Compressor Technical Manual PDFJoseNo ratings yet

- Hydrostatic Tank Gauging System: Reference ManualDocument34 pagesHydrostatic Tank Gauging System: Reference ManualionpanaNo ratings yet

- Perception - Desktop ReleaseNotesDocument15 pagesPerception - Desktop ReleaseNotessvismaelNo ratings yet

- Elster-Instromet Encal3000 GCDocument0 pagesElster-Instromet Encal3000 GCsaid_rahmansyah4750No ratings yet

- Course DescriptionDocument3 pagesCourse DescriptionnboulegrouneNo ratings yet

- 104 Uncertainty Analysis Ultrasonic Meter Calibration ProcessDocument11 pages104 Uncertainty Analysis Ultrasonic Meter Calibration ProcessTran Quoc VinhNo ratings yet

- Probe Coeffcient CalculatorDocument9 pagesProbe Coeffcient CalculatorBAN ZANGHANANo ratings yet

- Calculation Cooling Compressors: January 2016Document11 pagesCalculation Cooling Compressors: January 2016RIDONo ratings yet

- Calculation Cooling Compressors: January 2016Document11 pagesCalculation Cooling Compressors: January 2016RIDONo ratings yet

- ML11241A211 - Emergency Diesel Generator Engine Monitoring Program (EDGEMP)Document18 pagesML11241A211 - Emergency Diesel Generator Engine Monitoring Program (EDGEMP)EnformableNo ratings yet

- PipelineStudio Gas Simulator Module Compressors - English - AllDocument29 pagesPipelineStudio Gas Simulator Module Compressors - English - AllgcarreongNo ratings yet

- E M HW4v3 A2 001 - 10Document25 pagesE M HW4v3 A2 001 - 10hsingnan.instrumentNo ratings yet

- Organisation Internationale de Métrologie Légale: International RecommendationDocument15 pagesOrganisation Internationale de Métrologie Légale: International RecommendationGlobal QualityNo ratings yet

- Comparison of Calculation Standards of NGL and LPGDocument22 pagesComparison of Calculation Standards of NGL and LPGmotaleby100% (1)

- Mechanical Engineering: CAESAR II Receives TD12 Approval by TranscoDocument20 pagesMechanical Engineering: CAESAR II Receives TD12 Approval by TranscofileseekerNo ratings yet

- Furnace ManualDocument12 pagesFurnace ManualMoonjoo LeeNo ratings yet

- 04 2014 024 Tomaszewski RysinskiDocument4 pages04 2014 024 Tomaszewski RysinskiratheeshNo ratings yet

- Air&gas-Design Pr.29576Document18 pagesAir&gas-Design Pr.29576JKKNo ratings yet

- Standards Publication Technical Corrigendum: Doc No: QP-STD - S - 036Document24 pagesStandards Publication Technical Corrigendum: Doc No: QP-STD - S - 036samynathan_bvsNo ratings yet

- Discussion On Modern Trend in MeasuremenDocument23 pagesDiscussion On Modern Trend in MeasuremenTitipong PulbunrojNo ratings yet

- Computer Aided Design Module For A Binary Distillation ColumnDocument8 pagesComputer Aided Design Module For A Binary Distillation ColumnnhutuyetonlineNo ratings yet

- Stair CaseDocument2 pagesStair CasevanacharlabobbyNo ratings yet

- Air & Gas Compressors World Summary: Market Values & Financials by CountryFrom EverandAir & Gas Compressors World Summary: Market Values & Financials by CountryNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- Remote Automation Solutions Gss Quick Guide: Communication Between A Roc809 and A Roc809 Using Modbustcp/IpDocument11 pagesRemote Automation Solutions Gss Quick Guide: Communication Between A Roc809 and A Roc809 Using Modbustcp/IpRuben Ortiz CaramNo ratings yet

- Quick Start Guide: Photo All-In-OneDocument120 pagesQuick Start Guide: Photo All-In-OneRuben Ortiz CaramNo ratings yet

- Uniguard ManualDocument30 pagesUniguard ManualRuben Ortiz CaramNo ratings yet

- Advanced USM Diagnostics TechWpaperDocument12 pagesAdvanced USM Diagnostics TechWpaperRuben Ortiz CaramNo ratings yet

- IRA-4SS Automatic Insertion Instrument Regulator: Engineering CompanyDocument2 pagesIRA-4SS Automatic Insertion Instrument Regulator: Engineering CompanyRuben Ortiz CaramNo ratings yet

- WP Roc809 Modbus Tcpiprev2Document11 pagesWP Roc809 Modbus Tcpiprev2Ruben Ortiz CaramNo ratings yet

- JVC KD600 Manual de Usuario PDFDocument127 pagesJVC KD600 Manual de Usuario PDFRuben Ortiz CaramNo ratings yet

- M F P T P A: Oving ROM Ipeline O Rocess PplicationsDocument8 pagesM F P T P A: Oving ROM Ipeline O Rocess PplicationsRuben Ortiz CaramNo ratings yet

- Process Flow and Level ProcessDocument72 pagesProcess Flow and Level ProcessAqibHanifNo ratings yet

- ROC800L Remote Operations Controller PDFDocument8 pagesROC800L Remote Operations Controller PDFRuben Ortiz CaramNo ratings yet

- Cadwork Manual List enDocument46 pagesCadwork Manual List enRuben Ortiz CaramNo ratings yet

- Protector de Tension VAL-MS 120ST para IzozogDocument9 pagesProtector de Tension VAL-MS 120ST para IzozogRuben Ortiz CaramNo ratings yet

- Density MeterDocument6 pagesDensity Metercarito3165No ratings yet

- Fluid Mech ProblemsDocument2 pagesFluid Mech ProblemsMarky SantosNo ratings yet

- Moisture and Total Solids AnalysisDocument44 pagesMoisture and Total Solids AnalysisNicholas BoampongNo ratings yet

- Analysis of Volatile Oils PDFDocument40 pagesAnalysis of Volatile Oils PDFKhara TeanoTanNo ratings yet

- Uns 923 0308 enDocument28 pagesUns 923 0308 enkhalid belabedNo ratings yet

- D3171-15 Matrix Burn OffDocument11 pagesD3171-15 Matrix Burn OffadiNo ratings yet

- FM 01 Property New Fluid MechanicsDocument82 pagesFM 01 Property New Fluid MechanicsSebastiánRodríguezNo ratings yet

- Lab 01 - Fluid PropertiesDocument5 pagesLab 01 - Fluid PropertiesAswaja313No ratings yet

- Grou P No. Expr T No.: Engr Shevanee Ruth G. Dela CruzDocument4 pagesGrou P No. Expr T No.: Engr Shevanee Ruth G. Dela CruzCarla Jade MesinaNo ratings yet

- Mix Design SpecificationDocument38 pagesMix Design SpecificationRohan Dhatbale100% (1)

- VOLUME CalculationDocument13 pagesVOLUME Calculationmanpreet sainiNo ratings yet

- (Astm C188-78 Density of Hydraulic Cement) : RatingDocument3 pages(Astm C188-78 Density of Hydraulic Cement) : RatingMarvin Lucky AllasNo ratings yet

- APChem Lab 01 DenistyDocument7 pagesAPChem Lab 01 DenistyKris Garman CarterNo ratings yet

- CIVE 3833 Spring 2021 Problem Set 1Document1 pageCIVE 3833 Spring 2021 Problem Set 1Ahmed MaherNo ratings yet

- 10-15-01 Baking Quality of Angel-Cake FlourDocument4 pages10-15-01 Baking Quality of Angel-Cake FlourMuhammad Farhan HidayatNo ratings yet

- NDT ProcessingFilms TechDataDocument17 pagesNDT ProcessingFilms TechDataAli Ben AmorNo ratings yet

- Experiment No. 2: Marshall Stability Test For Bitumen Mix DesignDocument12 pagesExperiment No. 2: Marshall Stability Test For Bitumen Mix DesignKanishka Sarkar100% (1)

- Measurements of Densities and Specific Gravity: CE121L - A06Document7 pagesMeasurements of Densities and Specific Gravity: CE121L - A06Kiesha SantosNo ratings yet

- U3 Thermal Expansion in Solids and LiquidsDocument5 pagesU3 Thermal Expansion in Solids and LiquidsMUHAMMAD AMEERUL AIFFIX BIN GHAZALINo ratings yet

- EN Flooded IOM 001 DCS 1002M - 0310Document19 pagesEN Flooded IOM 001 DCS 1002M - 0310dinkoheNo ratings yet

- "Gas Density & Specific Gravity": A Report Submitted by The Students: Sajjad Kareem & Karar Shaker YoussefDocument10 pages"Gas Density & Specific Gravity": A Report Submitted by The Students: Sajjad Kareem & Karar Shaker Youssefسجاد كريم هاشم سماويNo ratings yet

- DOL - LIEGE-#647222-00-007-518-v1 API 650 Final ReportDocument15 pagesDOL - LIEGE-#647222-00-007-518-v1 API 650 Final ReportDominoHevyNo ratings yet

- Assignment Chep 353l1Document4 pagesAssignment Chep 353l1Joshua Arrojo100% (3)

- Transportation Engineering Lab ManualDocument42 pagesTransportation Engineering Lab Manualउमेश गावंडे89% (9)

- Formula Compilation of HGEDocument22 pagesFormula Compilation of HGEistanistan27No ratings yet

- PH Handout QnsDocument31 pagesPH Handout QnsAZORYNo ratings yet

- Calibration of Volumetric Glassware ProcDocument3 pagesCalibration of Volumetric Glassware ProcCucu AlbertNo ratings yet

- Food Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen DewettinckDocument8 pagesFood Bioscience: Arifin Dwi Saputro, Davy Van de Walle, Koen Dewettincklaycang malangNo ratings yet

Functional Specification APPLICATION - 2360dew2 2360 Chromatograph Controller Application Software

Functional Specification APPLICATION - 2360dew2 2360 Chromatograph Controller Application Software

Uploaded by

Ruben Ortiz CaramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Functional Specification APPLICATION - 2360dew2 2360 Chromatograph Controller Application Software

Functional Specification APPLICATION - 2360dew2 2360 Chromatograph Controller Application Software

Uploaded by

Ruben Ortiz CaramCopyright:

Available Formats

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

Copyright Daniel Europe Ltd. 2000.

FUNCTIONAL SPECIFICATION

APPLICATION 2360Dew2

2360 Chromatograph controller Application

Software

Prepared by

Checked by

REV

DATE

31/7/00

Title

Title

PAGES CHANGED

First release.

Date

Date

ECN

N/A

Copyright of this document is reserved by Daniel Europe Limited. It is issued on condition that it is not reproduced, copied or

disclosed to a third party either wholly or in part, without the written consent of the above.

Revision 0 July 2000

Page 0 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

2360 Chromatograph controller Application

Software

APPLICATION 2360Dew2

+

APPLICATION MANUAL

AND FUNCTIONAL SPECIFICATION

Revision 1 July 2000

Page 1 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

TABLE of CONTENTS

REFERENCES..............................................................................................................................................................................3

1. INTRODUCTION..................................................................................................................................................................4

2. MON MENUS.........................................................................................................................................................................5

2.1 APPLICATION/SYSTEM MENU.................................................................................................................................6

2.2 APPLICATION / USER DEFINED MENUS................................................................................................................7

3. DEWPOINT CALCULATIONS OPERATOR ENTRIES...............................................................................................9

3.1 USER DEFINED / NUMERIC MENU.......................................................................................................................10

4. DEWPOINT CALCULATIONS STATUS VALUES........................................................................................................10

5. ISO 6976 CALCULATIONS................................................................................................................................................11

6. PRINTED REPORTS...........................................................................................................................................................16

6.1 DEWCALC DATA REPORT.......................................................................................................................................17

6.2 ANALYSIS REPORT.....................................................................................................................................................19

6.3 24HR SHORT REPORT................................................................................................................................................20

6.4 24HR CURRENT REPORT..........................................................................................................................................21

7. MODBUS COMMUNICATIONS.......................................................................................................................................22

8. COMPONENT CODES.......................................................................................................................................................26

APPENDIX 1: DEWPOINT CALCULATION GASES.........................................................................................................27

Revision 1 July 2000

Page 2 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

References

[1]

Danalyzer / 2350 Gas Chromatograph

Hardware Reference Manual

Daniel Flow Products, Inc.

Houston, Texas.

[2]

Gas Chromatograph Software Operations

User Reference Manual

Daniel Flow Products, Inc.

Houston, Texas.

[3]

International Standards Organisation

ISO 6976 (1995):E

Natural Gas - Calculation of calorific values, density, relative density and

Wobbe index

from composition.

Second Edition 1995 - 12 - 01

Corrected and reprinted 1999 -03.

Revision 1 July 2000

Page 3 of 29

2360 Gas Chromatograph Controller

2360Dew2

1.

User guide to application

Introduction

This document provides a functional specification and user guide to the specific

facilities in a 2360 dual detector C9+ chromatograph controller which has been

loaded with application software 2360Dew2. Also read the Gas Chromatograph

software and hardware manuals, ref. [1] and ref.[2] which provide a general

guide to the instrument.

2360Dew2 is application software for a C9+ (or better) dual detector analyser

which calculates the Dewpoint Temperature of the natural gas mixture, in

addition to the usual gas calculations. It also calculates an estimate of the

cricondentherm (maximum dew temperature above this temperature no

liquid will form at any pressure).

The operator can choose between either of 2 dewpoint calculation methods

(the results usually differ by about 2 Degrees C):

1. PR

(Peng Robinson gas equation of state)

2. RKS

(Redlich Kwong Soave gas equation of state).

The operator can specify up to 4 gas pressures and after each gas analysis

(irrespective of stream number), the software will calculate the dewpoint

temperature at each of these pressures, and also the cricondentherm

(maximum dewpoint temperature at any pressure). The temperature units are

Degrees centrigade, the pressures are specified in bars (absolute). The 4

pressures to be used in the calculation can be entered at the keypad, or using

MON, or sent over a communications link using SIM_2251 Modbus.

The 4 calculated dew temperatures, and the value of the cricondentherm and

the cricondentherm pressure can be read over Modbus (User Modbus or

SIM_2251).

The dewpoint temperature is sensitive to small amounts of the heavy

hydrocarbons (C9 and above) and also to the break down of each Carbon

number into the different isomers. In order to take account of this the dewpoint

calculations can use breakdowns of the measured components up to normal

C18, and also into the different isomers of C6..C9. The operator can define

each gas which could be included in the dew calculations (93 gases in all, see

Appendix 1) as being either a measured component, or as being a defined

fraction of a measured component. For example a C9+ measurement could be

broken into operator defined fractions of normal C9 through to normal C15. It

is expected that the breakdowns would be established by a laboratory analysis

carried out at regular intervals.

The calculated dewpoint temperatures and cricondentherm appear on the

standard analysis report. In addition a new Dewcalc Data report gives the

results and the actual extended analysis used in the dew calculation which

may include many more gases than that on the standard analysis report.

Revision 1 July 2000

Page 4 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

The application allows 128 averages to be defined and stores 32 records of

each (1232 if an expanded memory card is fitted).

The current and last completed average values of all 128 averages can be read

over the Modbus communications link.

2360Dew2 also includes 2 summary reports of daily (24 hour) averages. These

are called 24Hr Short and 24Hr Current. They can both be printed, as with

any other report, either by operator request, or automatically. The 24Hr Short

report is intended for printing automatically at the end of each 24 hour average

period and shows the latest and previous daily averages. The 24Current report

shows the average values so far for the current day, and the last complete

average. The reports are shown in section 4.

This application uses the ISO 6976 (1995) standard, ref. [3], to calculate the

other gas properties, including calorific values, density and compressibility, all

at reference conditions. The operator can select the reference conditions, and

the units to be used for heating values.

All calculated values are available as analog signals (4..20mA) and can be read

via a serial communications link as Modbus registers.

All calculated results appear in the analysis reports (both those printed locally

on the serial printer connected to the 2350, and those printed or displayed at a

PC using the

MON software package).

2.

Mon menus

The MON menus are standard, as described in ref. [1], except for the System

menu, and the User Defined Numeric and Selection menus.

The first dewpoint temperature (DewTemp1), and the cricondentherm

temperature and pressure can be specified in the MON menus for limit alarms,

averages, user defined calculations, analogue output signals, and user defined

Modbus, using the following variable names:

DewTemp1

: cus_str_data field3

cricondentherm temperature : cus_str_data field4

cricondentherm pressure

: cus_str_data field5.

Revision 1 July 2000

Page 5 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

2.1 Application/System menu

The table below describes the System screen variables, and whether or not they

can be edited by the MON operator.

Name

Description

Default

strmseq

Stream Sequence. Defines the order of stream

analysis. A set of stream numbers separated

by commas. E.g. 1,2,2.

NOTES: all the numbers must be valid

streams as defined in the Streams menu. The

(optional) auxiliary stream sequence can be

edited by pressing F2.

Analyser Name. Defines the GC unit name.

Maximum 12 characters.

Type of GC controller

System Description. Maximum 28 characters.

Edit

?

Yes

Model500

Yes

2360

Daniel

European

dew

analysis.

13000

64

5

5 10

No

Yes

<Offline>

No

METRIC

Yes

128

No

32

No

166

2360Dew

No

No

anlyzr_name

unit_type

system_desc

cgmbufsiz

max_peaks

num_valves

trace 1

BOS_Rev

metric

max_avgs

max_avg_rec

s

cfg_revision

cfg_name

Revision 1 July 2000

Chromatogram buffer size.

Maximum number of peaks

Number of chromatographic valves

Defines analog output to be used to provide a

chromatogram on a chart recorder. First value

is analog output number, second number is

the baseline offset. The default is to use

analog output 5 as an optional chromatogram

trace.

Revision of BOS eprom firmware in the

connected controller, or <Offline> if not

connected.

whether or not to use METRIC base conditions.

For ISO calculations, this MUST be left set at

METRIC.

Maximum total number of averages which can

be defined.

Maximum number of records which will be

maintained for each average.

NOTE: if an expanded memory board is fitted

to the controller, the number of records stored

is increased to 1232.

Revision of application software.

The name of the application file ( name.bin )

originally supplied. (customer modified

configurations should be saved to a different

Page 6 of 29

No

No

No

Yes

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

name).

Revision 1 July 2000

Page 7 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

2.2 Application / User Defined Menus

The User Defined / Selection menu is used to define dewpoint calculation

method, and also the reference temperatures and units used in the ISO 6976

calculations.

Note that the operator can define TWO sets (primary and secondary) of reference

conditions and heating value units. The application calculates two sets (primary

and secondary) of results. The MON user can, if required, add the secondary

results to analysis reports by turning ON the required secondary values in the

Application / Calculations / Control menu.

Each set of reference conditions consists of two reference temperatures, i.e. the

reference temperature used for Metering (Trm), and the reference temperature

used for combustion (Trc), as described in the ISO 6976 standard, ref.[3]. The

reference pressure is always 1.01325 bar.

The following table (overleaf) describes the User Defined / Selection menu. All

values can be changed by the MON user.

Revision 1 July 2000

Page 8 of 29

2360 Gas Chromatograph Controller

2360Dew2

Name

CVTABLE_pri

CVTABLE_se

c

CVUnits_pri

CVUnits_sec

DewMeth

User guide to application

Description

Primary reference temperatures.

The reference combustion temperature

can be 0, 15, 20 or 25 DegC.

The reference metering temperature can

be 0,15 or 20 DegC.

Secondary reference temperatures.

Default

Trc15_Trm15

Primary units for calorific value.

Secondary units for calorific value.

MJ_per_kg

MJ_per_m3

Dewpoint calculation method, PR or

RKS.

EnableCalMa Enable Calibration/Maintenance

n

indicator.

If set to ENABLE, Discrete Output 5 is

turned ON when a calibration is in

progress or the GC is in maintenance

mode.

EnableComA Enable Common Alarm indicator.

lm

IF set to ENABLE_NC or ENABLE_NO,

then Discrete Output 4 is used as a

Common Alarm indicator, either in

Normally Closed mode (NC) or Normally

Open mode (NO).

Maint_mode Select Maintenance Mode. Set to ON to

put the GC into Maintenance Mode. If

the GC is in maintenance mode, none of

the Modbus registers get updated.

Repeat_Chec Perform repeatability checks on

k

calibration runs (based on ISO 6974)

Run_Aux_se

Run Auxiliary stream Sequence.

q

Select ON to use the auxiliary stream

sequence rather than the main stream

sequence.

Revision 1 July 2000

(Trc =15DegC

Trm=15DegC)

Trc25_Trm00

RKS

ENABLE

ENABLE_NC

OFF

OFF

OFF

Page 9 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

3. Dewpoint calculations operator entries.

The choice of calculation method (PR or RKS) is made in the User Defined /

Selection menu.

The 4 pressures to be used are DewPres1..DewPres4, in units of bar (absolute) in

the User Defined / Numeric menu. For convenience, the resulting dew

temperatures and calculation status values are displayed in the same menu.

The gases used in the dewpoint calculation are also defined in the User Defined /

Numeric menu. For convenience the 93 gases available are split into groups a..o,

which appear in alphabetical order. The complete list is in Appendix 1. Any of the

93 gases supported in the dewpoint calculation can be specified as an operator

defined fraction of any of the measured components:

Each gas is assigned a number which is used as follows:

0.0

x.0

x.ffff -

this gas is not used in the dew calculations.

this gas is component no. x in the component data table.

this gas is fraction 0.ffff of component no. x.

e.g

e_NC9 14.0

and:

e_NC9

f_NC10

f_NC11

f_NC12

indicates that Normal C9 is component 14 in the CDT.

14.54

14.20

14.15

14.09

indicates that component 14 is 54% NC9,

20% NC10,

15% NC11,

9% NC12.

The default values in the application are correct for a C9+ analysis in which all of

the C9+ is assumed to be n_C9.

The calculated dew temperatures are printed on reports with a resolution of 0.1

Degrees Centigrade. The cricondentherm values are estimates based on the

sampling values near the previous calculated value after any large change in

composition the estimated maximum temperature will normally converge to within

1 degree after 2 analysis runs.

Revision 1 July 2000

Page 10 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

3.1 User Defined / Numeric menu.

The complete contents of the User Defined / Numeric menu are:

DewPres1

DewPres2

DewPres3

DewPres4

- pressure used for Stream 1 dewpoint calculation, bar (absolute).

DewTemp1..4 - calculated dewpoint temperatures for each stream, Degrees

Centigrade.

DewStat1..4

- dewpoint calculation status values, see section 4.

a_Methane..o_Trieth_gly : gases used in the dewpoint calculation see Appendix 1.

4. Dewpoint calculations status values.

The dewpoint and cricondentherm calculations can fail to give a valid result for

various reasons, e.g. pressure out of range, fluid is always gas at this pressure, etc.

The status values for each of the 5 streams are displayed an the Analysis and Dew

Calculation reports and can be read out as Modbus registers (sim_2251). A zero

value means that the calculation is OK, other values indicate an error.

The meanings of the status values are:

0 (OK)

1 (Err1)

2 (Err2)

3 (Err3)

4 (Err4)

5 (Err5)

6 (Err6)

normally OK.

- calculation is valid.

- no valid solution to gas equation found.

- mole% values are all zero if analysis is OK check Numeric menu.

- calculated fugacities too large probably unrealistic composition.

- single phase no liquid phase at this pressure

- pressure value (from operator or Modbus) is negative.

- (cricondentherm only) no maximum found next analysis

Revision 1 July 2000

Page 11 of 29

2360 Gas Chromatograph Controller

2360Dew2

5.

User guide to application

ISO 6976 Calculations

The calculation of the gas properties is done according to ISO 6976(1995):E, using

either a molar, mass or volume based calculation of calorific value. The reference

combustion temperature can be 0, 15, 20 or 25 DegC. The reference metering

temperature can be 0, 15 or 20 DegC.

5.1

Ideal Gas Calorific Values

The calorific values of the gas mixture are calculated on a molar basis, mass basis,

or volume basis, depending on the calorific value units selected by the CVUnits

parameters.

The calorific values are calculated at combustion temperatures of either 0 DegC,

15 DegC, 20 DegC or 25 DegC, depending on the CVTable parameter. The heating

values for the individual components are taken from ISO 6976:1995(E), Table 3,

using the values for the chosen combustion temperature.

5.1.1

Molar basis: CVUnits = MJ_per_mol.

(MJ/mole)

Ref. ISO 6976:1995(E), section 5.1, equation (4).

N

HSUP-Dry(molar) =

3

(CONCNj * Hj )

j=1

))))))))))))))))))) * ))))

100

1

MJ/mole

1000

Where:

HSUP-Dry(molar) = Ideal gas superior dry calorific value of the gas sample,

in

MJ/mole

CONCNj

mole %.

Normalised (if selected) concentration of component "j", in

Hj

=

kJ/mole.

"100"

"1000"

Revision 1 July 2000

fractions.

Heating values from ISO 6976 Table3, in

Total number of gas components.

Converts mole percentages to mole

Converts kJ/mole to MJ/mole.

Page 12 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

5.1.2 Mass basis: CVUnits = MJ_per_kg.

(MJ/kg)

Ref. ISO 6976:1995(E), section 6.1, equation (5).

HSUP-Dry(mass) =

1000 * HSUP-Dry(molar) / M

MJ/kg

where:

HSUP-Dry(mass) = Ideal gas superior dry calorific value of the gas sample, in

MJ/kg.

"1000"

Converts MJ/mole to kJ/mole.

M = molar mass of the mixture

N

1/100 * ( CONCNj * Mj )

j=1

Mj

= the molar mass of component j taken from ISO 6976:1995(E) Table 1.

5.1.3 Volume basis: CVUnits = MJ_per_m3

OR kJ_per_m3

OR kCal_per_m3

OR kWhr_per_m3

(MJ/m3)

(kJ/m3)

(kCalories/m3)

(kWattHours/m3)

Ref. ISO 6976:1995(E), section 7.1, equation (8).

The metering reference temperature is specified by the CVTable parameter.

The metering reference pressure is 1.01325 bar

HSUP-Dry(volume)

CVUnits

1000

Factor

HSUP-Dry(molar)

p2/(R*T2)

where:

HSUP-Dry(volume) =

"1000"

Ideal gas superior dry calorific value of the gas

sample, in the units selected by CVUnits..

Converts MJ/mole to kJ/mole.

p2 is the metering reference pressure = 101.325 kPa.

B.1)

R is the universal gas constant = 8.314510 J.mol/K

(ISO 6976:1995(E) ,

T2 is the metering reference temperature in degrees Kelvin,

= Reference temperature (DegC) + 273.15

Revision 1 July 2000

degK

Page 13 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

Factor converts from Mj/m3 to the required units:

If CVUnits = MJ_per_m3

Factor = 1.

If CVUnits = kJ_per_m3

Factor = 1000.

If CVUnits = Kcal_per_m3

Factor

=

238.8459

If CVUnits = KWHr_per_m3

Factor

=

0.2777778

NOTE: Inferior calorific values are calculated in the same way, except that

the Inferior values from ISO Table 3 are used.

5.2

Ideal relative gas density

Ref ISO 6976:1995(E), section 8.1, equation (11).

N

Ideal Relative density = 1/100 * 1/Mair

* CONCj * Mj

j=1

where:

Mair is the molar mass of standard dry air = 28.9626 kg/kmol.

5.3

Real gas relative density

Ref. ISO 6976:1995(E), section 8.2, equation (14).

The relative density of the real gas is calculated as:

D

ideal relative density

( Zair / Zmix )

Where:

Zair is the compressibility factor of dry standard air at the selected metering

reference temperature, 1.01325 bar.

If metering temperature = 0 DegC, Zair = 0.99941

If metering temperature = 15 DegC, Zair = 0.99958

If metering temperature = 20 DegC, Zair = 0.99963.

Zmix is the compressibility factor of the gas sample at the selected metering

reference temperature, 1.01325 bar, calculated as in the next section.

Revision 1 July 2000

Page 14 of 29

2360 Gas Chromatograph Controller

2360Dew2

5.4

User guide to application

Compressibility

Ref. ISO 6976:1995(E), section 4.2, equation (3).

The compressibility factor Zmix is calculated at the selected metering

reference temperature, 1.01325 bar.

Zmix

1 - (x1 Tb1 + x2 Tb2 + x3 Tb3 + ...xn Tbn)2

where:

Zmix

Tb1, Tb2, .. Tbn

5.5

Compressibility of total gas sample.

=

Summation factors for each component, taken

from ISO 6976:1995(E), Table 2, using the values for

the selected metering reference temperature,

1.01325 bar.

Real gas dry calorific values

Ref. ISO 6976:1995(E), section 7.2, equation (10).

The ideal gas values for CV and density have to be corrected to real gas

values.

No correction is required if the calorific values are calculated on a molar or

mass basis.

If volumetric units are chosen the calorific values are corrected as:

Real gas CV = Ideal gas CV / Zmix

5.6

Real gas saturated calorific values

The calorific values on a water saturated gas basis are calculated from the

dry gas calorific values according to equation F.2 (excluded volume effect) in

ISO6976:1995(E).

The secondary effects described in section F.3 and F.4 are ignored.

CORR. HSUP SAT

CORR. HSUP DRY * ( p2 - pw) / p2.

Where :

p2 is the metering reference pressure = 1.01325 bar.

pw is the saturation vapour pressure of water at the selected metering

reference temperature:

If the metering reference temperature is 0

DegC,

(p2-pw)/p2 =

0.99397,

If the metering reference temperature is 15 DegC,

(p2-pw)/p2 =

Revision 1 July 2000

Page 15 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

0.98317,

If the metering reference temperature is 20 DegC,

0.97693.

Revision 1 July 2000

(p2-pw)/p2 =

Page 16 of 29

2360 Gas Chromatograph Controller

2360Dew2

5.7

User guide to application

Wobbe Index

The Wobbe index of the sample gas is calculated according to ISO6976(1995):E

section 8.2, equation (16).

NOTE: since the ISO 6976 standard defines the Wobbe Index as being derived from

the calorific value on a volumetric basis, the Wobbe Index is always in units of

MJ/m3, irrespective of the 'CVUnits' selected for the calorific value. It is based on

the volumetric superior dry calorific value, in units of MJ/m3.

The reference temperatures used for the Wobbe index calculation are those

defined by the CVTable parameter.

Corrected HSUP-DRY

=

_____________________

T Real Relative Density

WOBBE Index

MJ/m3

The inferior Wobbe Index is also calculated, same as above, but using the Inferior

calorific value.

5.8

Weight percentage calculation

(CONCn) (MWn)

WT%n

__________________________

* 100

3 (CONCi * MWi)

i=1

where:

WT%n

CONCn

MWn

=

Weight % of component "n".

Concentration in mole % of component "n"

=

Molecular weight of component "n".

(CONCi * MWi)

Sum of weights of all components in sample

i=1

Revision 1 July 2000

Page 17 of 29

2360 Gas Chromatograph Controller

2360Dew2

6.

User guide to application

Printed Reports

The reports produced with this application are standard reports, apart from the

Analysis report which includes the ISO 6976 calculated results, as shown below,

and the 24Hr Short and 24Hr Current average reports. The Analysis report can be

modified by the MON operator using the Calculations/Control menu, e.g. to include

secondary results, or to remove unwanted items.

The following reports are shown in the following pages:

1.

2.

3.

4.

Dewcalc Data

Analysis

24Hr Short

24Hr Current.

Revision 1 July 2000

Page 18 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

6.1 Dewcalc Data report

Dew Temperature Calculation Report

Date: Wed Jul 26 20:40:09 2000

Stream: 2 Stream 2

Analyzer: Model 500

Fisher Rosemount Oil and Gas, Daniel Europe

Hydrocarbon C9+ dewpoint analysis

Dewpoint temperature

= 34.5

Dewpoint temperature

= 34.6

Dewpoint temperature

= 28.8

Dewpoint temperature

= 18.3

Cricondentherm (max dew temp.) = 35.4

Selected calculation method is RKS

DegC at 20. barA,

DegC at 40. barA,

DegC at 60. barA,

DegC at 80. barA,

DegC at 33. barA,

status is OK

status is OK

status is OK

status is OK

status is OK

Extended analysis data used on latest dewpoint calculation:

Number of components = 33

Component

--------Methane

Ethane

Propane

N-butane

I-butane

N-pentane

I-pentane

Neo-pentane

N-hexane

Nitrogen

CO2

N-C7

N-C8

N-C9

N-C10

2-methylpentane

3-methylpentane

2,2-dimethylC4

2,3-dimethylC4

2,3dimethylC5

2,2,3-trimethC4

3,3-dimethylC5

3-methylhexane

3-ethylpentane

Revision 1 July 2000

Total mole= 100.00000

Mole

----90.89000

2.00000

2.00000

0.01900

0.01800

0.10300

0.03200

0.02800

0.00500

2.00000

2.80000

0.02500

0.01500

0.01000

0.00200

0.00100

0.00100

0.00200

0.00100

0.00500

0.00500

0.00500

0.00500

0.00500

Page 19 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

2,2,4-trimethC5 0.00300

2,2-dimethylC6 0.00300

2,2,3-trimethC5 0.00300

2,3,4-trimethC5 0.00300

2,3-dimethylC6 0.00300

2,3,5-trimethC5 0.00200

2,5-dimethylC5 0.00200

N-undecane

0.00200

N-dodecane

0.00200

0.00000

0.00000

0.00000

0.00000

0.00000

Revision 1 July 2000

Page 20 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

6.2 Analysis Report

Analysis

Date-Time: 10/30/97 14:13

Stream: 2 Stream 2

Analyzer: Model 500

Company: Daniel Europe

Analysis Time: 225

Mode: ANLY

Strm Seq:2

Reference Temperature - Combustion DEGC

Reference Temperature - Metering

DEGC

Calorific Value - Units

Component

Name

Cycle Time: 240

Cycle Start Time: 14:10

Primary

15.00

15.00

MJ/kg

Secondary

25.00

0.00

MJ/m3

Mole

Weight Relative Superior CV Inferior CV Superior CV Inferior CV

Percent Percent Density Pri Units

Pri Units

Sec Units

Sec Units

C6+ 47/35/17

0.0979

PROPANE

0.5737

i-BUTANE

0.0860

n-BUTANE

0.1117

NEOPENTANE

0.0000

i-PENTANE

0.0377

n-PENTANE

0.0340

NITROGEN

1.6515

METHANE

93.5113

CARBON DIOXIDE 0.7592

ETHANE

3.1370

TOTALS

100.0000

0.5444

1.4661

0.2898

0.3762

0.0000

0.1578

0.1420

2.6811

86.9398

1.9364

5.4665

100.0000

0.0032

0.0087

0.0017

0.0022

0.0000

0.0009

0.0008

0.0160

0.5180

0.0115

0.0326

0.5958

0.2642

0.7385

0.1431

0.1864

0.0000

0.0772

0.0696

0.0000

48.3152

0.0000

2.8399

52.6341

0.2448

0.6794

0.1320

0.1720

0.0000

0.0714

0.0644

0.0000

43.4991

0.0000

2.5975

47.4607

0.2033

0.5680

0.1101

0.1434

0.0000

0.0594

0.0536

0.0000

37.1570

0.0000

2.1843

40.4790

0.1885

0.5229

0.1016

0.1324

0.0000

0.0550

0.0496

0.0000

33.4844

0.0000

1.9995

36.5338

'*' indicates user-defined components

Primary

Compressibility Factor (Z) @ 1.01325 BARS & 15.0 DEG. C = 0.99777

Base Pressure

1.01325 bar

---------------------------------------------------------------------Real Superior CV - Dry - Primary

=

52.6341 MJ/kg

Real Superior CV - Sat - Primary

=

51.7483 MJ/kg

Real Inferior CV - Dry - Primary

=

47.4607 MJ/kg

Real Inferior CV - Sat - Primary

=

46.6620 MJ/kg

Real Relative Density Gas - Primary =

0.5969

Real Gas Density - Primary

=

0.7314 kg/m3

Real Wobbe index - Sup - Primary =

49.83 MJ/m3

Real Wobbe index - Inf - Primary

=

44.93 MJ/m3

Average Molar Mass

=

17.256

Total Unnormalized Mole Percent =

99.981

Dewpoint temperature

= 34.5

Dewpoint temperature

= 34.6

Dewpoint temperature

= 28.8

Dewpoint temperature

= 18.3

Cricondentherm (max dew temp.) = 35.4

Revision 1 July 2000

DegC at 20. barA,

DegC at 40. barA,

DegC at 60. barA,

DegC at 80. barA,

DegC at 33. barA,

status is OK

status is OK

status is OK

status is OK

status is OK

Page 21 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

6.3 24Hr Short Report

24 Hour Averages Short Report from 28/01/00 12:44

Company: Daniel Industries

Analyser: Model 500

LATEST PREVIOUS

Start:

Start:

27/11/00 26/11/00

07:00

07:00

Stop:

Stop:

28/11/00 27/11/00

07:00

07:00

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Superior CV Dry - Pri Units

Inferior CV Dry - Pri Units

Compressibility Factor - Pri

Gas Density kg/m3 - Pri

Revision 1 July 2000

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

n-HEXANE

0.07569

PROPANE

1.14281

i-BUTANE

0.13210

n-BUTANE

0.20678

i-PENTANE

0.04463

NITROGEN

1.01558

METHANE

92.04070

CARBON DIOXIDE 1.03607

ETHANE

4.30562

46.88340

42.21450

0.98498

0.75568

0.07568

1.14230

0.13204

0.20672

0.04475

1.01499

92.04280

1.03562

4.30507

46.88560

42.21640

0.98498

0.75566

Page 22 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

6.4 24Hr Current Report

24 Hour Averages CURRENT Report from 28/11/00 12:48 Analyser: Model 500

Company: Daniel Industries

CURRENT

Start:

28/11/00

07:00

Stop:

29/11/00

07:00

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Mole Percent

Superior CV Dry - Pri Units

Inferior CV Dry - Pri Units

Compressibility Factor - Pri

Gas Density kg/m3 - Pri

Revision 1 July 2000

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

Stream 2

PREVIOUS

Start:

27/11/00

07:00

Stop:

28/11/00

07:00

n-HEXANE

0.07569

0.07569

PROPANE

1.14281

1.14281

i-BUTANE

0.13210

0.13210

n-BUTANE

0.20678

0.20678

i-PENTANE

0.04463

0.04463

NITROGEN

1.01588

1.01558

METHANE

92.04070 92.04070

CARBON DIOXIDE 1.03607

1.03607

ETHANE

4.30562

4.30562

46.88340 46.88340

42.21450 42.21450

0.98498

0.98498

0.75568

0.75568

Page 23 of 29

2360 Gas Chromatograph Controller

2360Dew2

7.

User guide to application

Modbus Communications

The Modbus registers available to a SIM_2251 port are listed below:

Booleans (coils)

1001..1005

Digital output signals 1..5

1006..1010

Digital input signals 1..6

16 Bit Integers

3001 .. 3016

3017 .. 3032

3033

3034

3035

3036

3037

3038

3039

3040

3041

3042

3043

3044

3045

3046

3047

3048..3057

3058

3059

3060

3061

3062.3065

3066..3081

Component codes (current component table) - see section 7 for the code meanings.

as above

Analysis elapsed time (1/30th secs)

Stream last analysed

8 bit stream mask - bit 0 indicates that the component table is used with

stream 1

bit 7 indicates that the component table is used with stream 8

Current month number

Current day

Current Year

Current Hour

Current Minute

Start of Cycle Month

" day

" year

" hour

" minute

Alarm status bits - see ref.[2] for meanings.

as above.

Limit alarms, see ref.[2] for meaning.

New data flag, set to 1 when data is available

(host should reset it to zero after reading the data)

Analysis / Calibration flag

1 = last completed run was an analysis run

0 = last completed run was a calibration run

Flag set to 1 when 24 hour average archives are updated (once per day).

Stream last analysed

New data flags for streams 2..5, set to 1 on new data for the specific stream.

(reset to zero when a difference stream completes)

Indirect calibration - reference component codes for components 1..16

Revision 1 July 2000

Page 24 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

3082..3097

3098

3099..3102

( the default value of zero means indirect calibration is not used)

As above for Component Table 2 (rather than 1)

CV units used on last analysis.

Valid data flags, each set to 1 on any alarm free analysis, else 0.

(4 copies intended for 4 host computers, one on each serial port).

3103

3104..3107

3108

Dewpoint calculation method: 1 = PR, 2=RKS.

Dewpoint calculation status values for dew pressures 1..4.

Dewpoint calculation status for cricondentherm calculation.

32 Bit integers

5001

Analysis cycle time ( in 1/30 second units)

5002

Calibration cycle time ( in 1/30 second units )

32 bit Real Numbers

7001..7016 Mole % results

7017..7032 Weight % results

7033

Dry superior CV

}

7034

Saturated superior CV

}

7035

Real Relative density

}

7036

Compressibility Z

}

7037

Wobbe index superior

}

7038

Unnormalised sum of mole % values

7039

Molar mass of the gas mixture

7040..7044 User Defined Calculations 1..5

7045

Not used .

7046

Dry superior CV

}

7047

Saturated superior CV

}

7048

Dry inferior CV

}

7049

Sat inferior CV

}

7050

Compressibility Z

}

7051

Real Relative density

}

7052

Real Density Kg/m3

}

7053

Wobbe index superior

}

7054

Wobbe index inferior

}

7055..7069 Current averages 1 .. 15

7070..7084 First archive of averages 1 .. 15

7085

Analog input 1 value

7086

Analog input 2 value

7087

Dry inferior CV

}

7088

Sat inferior CV

}

7089

Wobbe index inferior

}

Revision 1 July 2000

primary results

secondary results

primary results

Page 25 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

7090

7091

7092

7093

7094

7095..7110

Real Density Kg/m3

}

number of calbration runs performed.

number of above calibration runs included in the averaged values.

auto calibration start time (hours).

stream sequence (eg 12345 for 1,2,3,4,5)

Response Factor 1..16 used on last run.

7111

7112

7113

7114

7115

7116

7117

7118

7119

7120

7121

7122

Dry superior CV

Saturated superior CV

Dry inferior CV

Saturated inferior CV

Compressibility Z

Real Relative density

Real Density Kg/m3

Wobbe index superior

Wobbe index inferior

Molar mass

Un-normalised sum

Calibration Stream Number

7123..7126

Not used

7127..7162

7271..7306

7307..7342

User defined averages 1..36, current AVERAGE values

(NOTE: First 15 are repeats of registers 7055..7069)

User defined averages 1..36, current MAXIMUM values

User defined averages 1..36, current MINIMUM values

User defined averages 1..36, first (most recent) archive, AVERAGE values

(NOTE: First 15 are repeats of registers 7070..7084)

User defined averages 1..36, first (most recent) archive, MAXIMUM values

User defined averages 1..36, first (most recent) archive, MINIMUM values

7343..7378

7379..7414

7415..7450

User defined averages 1..36, second archive, AVERAGE values

User defined averages 1..36, second archive, MAXIMUM values

User defined averages 1..36, second archive, MINIMUM values

7343..7378

7379..7414

7415..7450

User defined averages 1..36, second archive, AVERAGE values

User defined averages 1..36, second archive, MAXIMUM values

User defined averages 1..36, second archive, MINIMUM values

7451..7486

7487..7522

User defined averages 1..36, third archive, AVERAGE values

User defined averages 1..36, third archive, MAXIMUM values

7163..7198

7199..7234

7235..7270

Revision 1 July 2000

}

}

}

}

}

}

}

}

}

}

}

primary results from last calibration.

Page 26 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

7523..7558

7559..7574

7575..7590

7591..7606

7607..7622

7623..7638

User defined averages 1..36, third archive, MINIMUM values

Multi-level calibration coefficient a components 1..16

Multi-level calibration coefficient b components 1..16

Multi-level calibration coefficient c components 1..16

Multi-level calibration coefficient d components 1..16

Indirect Calibration - Relative Response factors for components 1..16.

7639..7718

7719..7721

Repeat of 7559..7638 above, for component table 2 (rather than 1).

Spare

7722

7723

7724

7725

7726

7727

7728

7729

Dew temperature (DegC) at Dew pressure 1.

Dew temperature (DegC) at Dew pressure 2.

Dew temperature (DegC) at Dew pressure 3.

Dew temperature (DegC) at Dew pressure 4.

Dew pressure 1, barA (Read/write).

Dew pressure 2, barA (Read/write).

Dew pressure 3, barA (Read/write).

Dew pressure 4, barA (Read/write).

7730..7857

7858..7985

Current values of 128 user defined averages

Latest completed average values as above.

7986

7987

7988

7989

7990

7991

7992

7993

7994

7995

Cricondentherm (max dew temperature), stream 1, DegC.

Cricondentherm (max dew temperature), stream 2, DegC.

Cricondentherm (max dew temperature), stream 3, DegC.

Cricondentherm (max dew temperature), stream 4, DegC.

Cricondentherm (max dew temperature), stream 5, DegC.

Cricondentherm pressure, stream 1, barA.

Cricondentherm pressure, stream 2, barA.

Cricondentherm pressure, stream 3, barA.

Cricondentherm pressure, stream 4, barA.

Cricondentherm pressure, stream 5, barA.

Revision 1 July 2000

Page 27 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

Note: all the sim_2251 registers above are Read Only, apart from 3058, the new data flag,

and the Dew pressures 7726..7729, which are Read/Write.

In addition, registers 9001..9060 are available, as defined in the 2350 Software manual, ref.[1].

These can be used, amongst other things, to read and set the date and time in the controller.

8.

Component codes

The following lists the component codes (2551 compatible) which are used in

Modbus registers 3001..3032.

Code

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

Component Name

Methane

Ethane

Propane

i-Butane

n-Butane

i-Pentane

n-Pentane

neo-Pentane

C6+ 47/35/17

C6+ 50/50/00

C6+ 50/25/25

C6+ 57/28/14

Hydrogen

Helium

Nitrogen

Carbon Monoxide

Oxygen

Carbon Dioxide

N2O

n-Nonane

n-Octane

Ethylene

Acetylene

Propylene

Propadiene

125

n-Decane

Code

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150..

161*

--

Component Name

Air

i-Butene

Butene-1

C4=1

Trans-2-butene

CIS-2-Butene

Butenes

Butanes

1,3-Butadiene

1,2-Butadiene

Ethylene oxide

1-Pentene

not used

n-Hexane

H2S

CS2

Not used

Sulfur dioxide

Water

n-Heptane

Argon

C3+

C4+

C5+

User defined components

* Code 150 is the first user defined component in the table, 151 the second, etc.

Revision 1 July 2000

Page 28 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

Appendix 1

Dewpoint calculation gases

This is the complete set of gas components which are in the User Defined / Numeric menu.

Each can be defined as a fraction of a measured component.

User defined/Numeric menu name

--------------------------------------------

Gas

-----------------------------------------

Formula

-------------------

Group a natural gas components up to C5.

a_Methane

a_Ethane

a_Propane

a_I_butane

a_N_butane

a_I_pentane

a_N_pentane

a_Neopentane

a_CO2

a_Nitrogen

methane

ethane

propane

iso-butane

n-butane

iso-pentane

n-pentane

neo-pentane

carbon dioxide

nitrogen

CH4

C2H6

C3H8

C4H10

C4H10

C5H12

C5H12

C5H12

CO2

N2

Group b C6 isomers

bN_C6

b_2methylC5

b_3methylC5

b_22dimethC4

b_23dimethC4

n-hexane

2-methlypentane

3-methlypentane

2,2-dimethlybutane

2,3-dimethlybutane

C6H14

C6H14

C6H14

C6H14

C6H14

Group c C7 isomers

cN_C7

c_3methylC6

c_3ethylC5

c_2methylC6

c_24dimethC5

c_33dimethC5

c_23dimethC5

c_22dimethC5

c_223trimC4

n-heptane

3-methylhexane

3-ethylpentane

2-methylhexane

2,4-dimethylpentane

3,3-dimethylpentane

2,3-dimethylpentane

2,2-dimethylpentane

2,2,3-trimethylbutane

C7H16

C7H16

C7H16

C7H16

C7H16

C7H16

C7H16

C7H16

C7H16

Group d C8 isomers

dN_C8

d_2methylC7

d_3methylC7

d_4methylC7

d_22dimethC6

d_23dimethC6

d_24dimethC6

d_25dimethC6

d_33dimethC6

d_34dimethC6

d_223trimC5

d_224trimC5

d_234trimC5

n-octane

2-methylhepane

3-methylheptane

4-methylheptane

2,2-dimethylhexane

2,3-dimethylhexane

2,4-dimethylhexane

2,5-dimethylhexane

3,3-dimethylhexane

3,4-dimethylhexane

2,2,3-trimethylpentane

2,2,4-trimethylpentane

2,3,4-trimethylpentane

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

C8H18

Revision 1 July 2000

Page 29 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

Group e C9 isomers

eN_C9

e_3methylC8

e_25dimethC7

e_225trimC6

n-nonane

3-methyloctane

2,5-dimethylheptane

2,2,5-trimethylhexane

C9H20

C9H20

C9H20

C9H20

Group f C10 isomers

fN_C10

f_22dimethC8

f_3methylC9

n-decane

2,2-dimethyloctane

3-methylnonane

C10H22

C10H22

C10H22

Group g normal heavy alkanes, nC10..nC18

g_N_C11

g_N_C12

g_N_C13

g_N_C14

g_N_C15

g_N_C16

g_N_C17

g_N_C18

n-undecane

n-dododecane

n-tridecane

n-tetradecane

n-pentadecane

n-hexadecane

n-heptadecane

n-octadecane

C11H24

C12H26

C13H28

C14H30

C15H32

C16H34

C17H36

C18H38

Group h non-organics

h_H2S

h_Hydrogen

h_Water

h_CO

h_Helium

h_COS

h_NO2

hydrogen sulfide

hydrogen

water

carbon monoxide

helium

carbonyl sulfide

nitrogen dioxide

H2S

H2

H2O

CO

He

COS

NO2

Group i dienes and arenes

i_Propadiene

i_12butdiene

i_12pendiene

i_Benzene

i_Toluene

i_O_xylene

i_M_xylene

i_P_xylene

propadiene

1,2-butadiene

1,2-pentadiene

benzene

toluene

o-xylene

m-xylene

p-xylene

C3H4

C4H6

C5H8

C6H6

C7H8

C8H10

C8H10

C8H10

Group j alcohols

j_Methanol

j_Ethanol

j_1_Butanol

methanol

ethanol

1-butanol

CH4O

C2H6O

C4H10O

Group k mercaptans

k_MethMercpt

k_EthMercpt

methyl mercaptan

ethyl mercaptan

CH4S

C2H6S

Group l cycloalkanes

l_CycloC5

l_CycloC6

l_MethCycC5

l_MethCycC6

l_EthylCycC5

l_NpropCycC5

l_EthylCycC6

l_NpropCycC6

cyclopentane

cyclohexane

methylcyclopentane

methylcyclohexane

ethylcyclopentane

n-propylcyclopentane

ethylcyclohexane

n-propylcyclohexane

C5H10

C6H12

C6H12

C7H14

C7H14

C8H16

C8H16

C9H18

Revision 1 July 2000

Page 30 of 29

2360 Gas Chromatograph Controller

2360Dew2

User guide to application

Group m alkenes

m_Ethylene

m_Propylene

m_1_butene

m_1_pentene

m_2m1_butene

m_2m2_pntene

m_CycHexene

m_1_hexene

m_1_heptene

m_1_octene

ethylene

propylene

1-butene

1-pentene

2-methyl-1-butene

2-methyl-2-pentene

cyclohexene

1-hexene

1-heptene

1-octene

C2H4

C3H6

C4H8

C5H10

C5H10

C6H12

C6H10

C6H12

C7H14

C8H16

Group n alkynes

n_Propyne

n_1_pentyne

propyne

1-pentyne

C3H4

C5H8

Group o glycol

o_Trieth_gly

triethlyene glycol

C6H14O4

Revision 1 July 2000

Page 31 of 29

You might also like

- Api 2540Document8 pagesApi 2540biondimi100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Lab Report No.4 Moisture Content Specific Gravity Unit WeightDocument30 pagesLab Report No.4 Moisture Content Specific Gravity Unit WeightAngela Salada50% (2)

- BMS T&C ManualDocument25 pagesBMS T&C ManualRini Puspitasari100% (1)

- Bleed Rates of ControllersDocument35 pagesBleed Rates of Controllersalkhwarizmi1968No ratings yet

- API 12j SizingDocument8 pagesAPI 12j SizingsegunoyesNo ratings yet

- Cadwork 2D ManualDocument73 pagesCadwork 2D ManualRuben Ortiz CaramNo ratings yet

- Is 6940 1982 PDFDocument41 pagesIs 6940 1982 PDFDwi Kristianto100% (1)

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- PG ReadmeDocument14 pagesPG ReadmeBrian MayNo ratings yet

- Tender22 8Document38 pagesTender22 8er_bhavin3119100% (1)

- Alicat Scientific MFCs-Technology & BenefitsDocument6 pagesAlicat Scientific MFCs-Technology & BenefitsyuvionfireNo ratings yet

- HCDP Danalyzerdan An 42 NGC An HDCP 700xaDocument4 pagesHCDP Danalyzerdan An 42 NGC An HDCP 700xakenangrok2009No ratings yet

- En-DTR CMK-02Document51 pagesEn-DTR CMK-02Henry MaedaNo ratings yet

- Item Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912Document7 pagesItem Reference Description Qty.: Refrigeration. Advanced Module Ref: 0912A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- GTS Functional Requirements Fiscal Metering Final Version 1.5Document20 pagesGTS Functional Requirements Fiscal Metering Final Version 1.5Henry MaedaNo ratings yet

- 080000B Com With GCDocument6 pages080000B Com With GCsyed jeelani ahmedNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- May 93Document28 pagesMay 93yundtech974No ratings yet

- GAS-Guard 8: Answers For EnergyDocument6 pagesGAS-Guard 8: Answers For Energyeross_saptaNo ratings yet

- Mitsubishi Pga 300Document7 pagesMitsubishi Pga 300kirikupappNo ratings yet

- CompressorDocument27 pagesCompressorsoxal100% (1)

- VCCDocument8 pagesVCCRaden AditiyaNo ratings yet

- Section 22 - Sulfur RecoveryDocument145 pagesSection 22 - Sulfur RecoveryCHANADAS100% (1)

- Hw4 Software Version 3 Humidity and Temperature Adjustment Airchip 3000 DevicesDocument24 pagesHw4 Software Version 3 Humidity and Temperature Adjustment Airchip 3000 Deviceshsingnan.instrumentNo ratings yet

- E M HW4v3 A2 001 - 15Document26 pagesE M HW4v3 A2 001 - 15hsingnan.instrumentNo ratings yet

- Flow ComputersDocument11 pagesFlow ComputersKarthik ChockkalingamNo ratings yet

- An Arduino Micro-Controller Operated Automobile Air Conditioning SystemDocument14 pagesAn Arduino Micro-Controller Operated Automobile Air Conditioning Systemgodwinraj123No ratings yet

- Edrm Rohr2 Featurelist-32 1Document35 pagesEdrm Rohr2 Featurelist-32 1Yuliyan StoyanovNo ratings yet

- Design and AnalysisDocument5 pagesDesign and AnalysiscliveNo ratings yet

- Using The Fluke 5000A-RH/T With MET/CAL V6.11Document15 pagesUsing The Fluke 5000A-RH/T With MET/CAL V6.11KhoilnNo ratings yet

- PCD SF 191Document7 pagesPCD SF 191mNo ratings yet

- Gas Calibration Method v2Document9 pagesGas Calibration Method v2Mazhar MahadzirNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- ISO 4267-2 - 1988 - Part 2 Dynamic Measurement - INDDocument2 pagesISO 4267-2 - 1988 - Part 2 Dynamic Measurement - INDYuri MateusNo ratings yet

- User - Manual GW-DLMS-232-SL7 - 5.102 - enDocument16 pagesUser - Manual GW-DLMS-232-SL7 - 5.102 - enel mahdi BendaoudNo ratings yet

- RC2 Series Screw Compressor Technical Manual PDFDocument84 pagesRC2 Series Screw Compressor Technical Manual PDFJoseNo ratings yet

- Hydrostatic Tank Gauging System: Reference ManualDocument34 pagesHydrostatic Tank Gauging System: Reference ManualionpanaNo ratings yet

- Perception - Desktop ReleaseNotesDocument15 pagesPerception - Desktop ReleaseNotessvismaelNo ratings yet

- Elster-Instromet Encal3000 GCDocument0 pagesElster-Instromet Encal3000 GCsaid_rahmansyah4750No ratings yet

- Course DescriptionDocument3 pagesCourse DescriptionnboulegrouneNo ratings yet

- 104 Uncertainty Analysis Ultrasonic Meter Calibration ProcessDocument11 pages104 Uncertainty Analysis Ultrasonic Meter Calibration ProcessTran Quoc VinhNo ratings yet

- Probe Coeffcient CalculatorDocument9 pagesProbe Coeffcient CalculatorBAN ZANGHANANo ratings yet

- Calculation Cooling Compressors: January 2016Document11 pagesCalculation Cooling Compressors: January 2016RIDONo ratings yet

- Calculation Cooling Compressors: January 2016Document11 pagesCalculation Cooling Compressors: January 2016RIDONo ratings yet

- ML11241A211 - Emergency Diesel Generator Engine Monitoring Program (EDGEMP)Document18 pagesML11241A211 - Emergency Diesel Generator Engine Monitoring Program (EDGEMP)EnformableNo ratings yet

- PipelineStudio Gas Simulator Module Compressors - English - AllDocument29 pagesPipelineStudio Gas Simulator Module Compressors - English - AllgcarreongNo ratings yet

- E M HW4v3 A2 001 - 10Document25 pagesE M HW4v3 A2 001 - 10hsingnan.instrumentNo ratings yet

- Organisation Internationale de Métrologie Légale: International RecommendationDocument15 pagesOrganisation Internationale de Métrologie Légale: International RecommendationGlobal QualityNo ratings yet

- Comparison of Calculation Standards of NGL and LPGDocument22 pagesComparison of Calculation Standards of NGL and LPGmotaleby100% (1)

- Mechanical Engineering: CAESAR II Receives TD12 Approval by TranscoDocument20 pagesMechanical Engineering: CAESAR II Receives TD12 Approval by TranscofileseekerNo ratings yet

- Furnace ManualDocument12 pagesFurnace ManualMoonjoo LeeNo ratings yet

- 04 2014 024 Tomaszewski RysinskiDocument4 pages04 2014 024 Tomaszewski RysinskiratheeshNo ratings yet

- Air&gas-Design Pr.29576Document18 pagesAir&gas-Design Pr.29576JKKNo ratings yet

- Standards Publication Technical Corrigendum: Doc No: QP-STD - S - 036Document24 pagesStandards Publication Technical Corrigendum: Doc No: QP-STD - S - 036samynathan_bvsNo ratings yet

- Discussion On Modern Trend in MeasuremenDocument23 pagesDiscussion On Modern Trend in MeasuremenTitipong PulbunrojNo ratings yet

- Computer Aided Design Module For A Binary Distillation ColumnDocument8 pagesComputer Aided Design Module For A Binary Distillation ColumnnhutuyetonlineNo ratings yet

- Stair CaseDocument2 pagesStair CasevanacharlabobbyNo ratings yet

- Air & Gas Compressors World Summary: Market Values & Financials by CountryFrom EverandAir & Gas Compressors World Summary: Market Values & Financials by CountryNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- Remote Automation Solutions Gss Quick Guide: Communication Between A Roc809 and A Roc809 Using Modbustcp/IpDocument11 pagesRemote Automation Solutions Gss Quick Guide: Communication Between A Roc809 and A Roc809 Using Modbustcp/IpRuben Ortiz CaramNo ratings yet

- Quick Start Guide: Photo All-In-OneDocument120 pagesQuick Start Guide: Photo All-In-OneRuben Ortiz CaramNo ratings yet

- Uniguard ManualDocument30 pagesUniguard ManualRuben Ortiz CaramNo ratings yet

- Advanced USM Diagnostics TechWpaperDocument12 pagesAdvanced USM Diagnostics TechWpaperRuben Ortiz CaramNo ratings yet

- IRA-4SS Automatic Insertion Instrument Regulator: Engineering CompanyDocument2 pagesIRA-4SS Automatic Insertion Instrument Regulator: Engineering CompanyRuben Ortiz CaramNo ratings yet

- WP Roc809 Modbus Tcpiprev2Document11 pagesWP Roc809 Modbus Tcpiprev2Ruben Ortiz CaramNo ratings yet

- JVC KD600 Manual de Usuario PDFDocument127 pagesJVC KD600 Manual de Usuario PDFRuben Ortiz CaramNo ratings yet

- M F P T P A: Oving ROM Ipeline O Rocess PplicationsDocument8 pagesM F P T P A: Oving ROM Ipeline O Rocess PplicationsRuben Ortiz CaramNo ratings yet

- Process Flow and Level ProcessDocument72 pagesProcess Flow and Level ProcessAqibHanifNo ratings yet

- ROC800L Remote Operations Controller PDFDocument8 pagesROC800L Remote Operations Controller PDFRuben Ortiz CaramNo ratings yet

- Cadwork Manual List enDocument46 pagesCadwork Manual List enRuben Ortiz CaramNo ratings yet

- Protector de Tension VAL-MS 120ST para IzozogDocument9 pagesProtector de Tension VAL-MS 120ST para IzozogRuben Ortiz CaramNo ratings yet

- Density MeterDocument6 pagesDensity Metercarito3165No ratings yet

- Fluid Mech ProblemsDocument2 pagesFluid Mech ProblemsMarky SantosNo ratings yet

- Moisture and Total Solids AnalysisDocument44 pagesMoisture and Total Solids AnalysisNicholas BoampongNo ratings yet

- Analysis of Volatile Oils PDFDocument40 pagesAnalysis of Volatile Oils PDFKhara TeanoTanNo ratings yet

- Uns 923 0308 enDocument28 pagesUns 923 0308 enkhalid belabedNo ratings yet

- D3171-15 Matrix Burn OffDocument11 pagesD3171-15 Matrix Burn OffadiNo ratings yet

- FM 01 Property New Fluid MechanicsDocument82 pagesFM 01 Property New Fluid MechanicsSebastiánRodríguezNo ratings yet

- Lab 01 - Fluid PropertiesDocument5 pagesLab 01 - Fluid PropertiesAswaja313No ratings yet

- Grou P No. Expr T No.: Engr Shevanee Ruth G. Dela CruzDocument4 pagesGrou P No. Expr T No.: Engr Shevanee Ruth G. Dela CruzCarla Jade MesinaNo ratings yet

- Mix Design SpecificationDocument38 pagesMix Design SpecificationRohan Dhatbale100% (1)

- VOLUME CalculationDocument13 pagesVOLUME Calculationmanpreet sainiNo ratings yet

- (Astm C188-78 Density of Hydraulic Cement) : RatingDocument3 pages(Astm C188-78 Density of Hydraulic Cement) : RatingMarvin Lucky AllasNo ratings yet

- APChem Lab 01 DenistyDocument7 pagesAPChem Lab 01 DenistyKris Garman CarterNo ratings yet

- CIVE 3833 Spring 2021 Problem Set 1Document1 pageCIVE 3833 Spring 2021 Problem Set 1Ahmed MaherNo ratings yet

- 10-15-01 Baking Quality of Angel-Cake FlourDocument4 pages10-15-01 Baking Quality of Angel-Cake FlourMuhammad Farhan HidayatNo ratings yet

- NDT ProcessingFilms TechDataDocument17 pagesNDT ProcessingFilms TechDataAli Ben AmorNo ratings yet

- Experiment No. 2: Marshall Stability Test For Bitumen Mix DesignDocument12 pagesExperiment No. 2: Marshall Stability Test For Bitumen Mix DesignKanishka Sarkar100% (1)

- Measurements of Densities and Specific Gravity: CE121L - A06Document7 pagesMeasurements of Densities and Specific Gravity: CE121L - A06Kiesha SantosNo ratings yet

- U3 Thermal Expansion in Solids and LiquidsDocument5 pagesU3 Thermal Expansion in Solids and LiquidsMUHAMMAD AMEERUL AIFFIX BIN GHAZALINo ratings yet

- EN Flooded IOM 001 DCS 1002M - 0310Document19 pagesEN Flooded IOM 001 DCS 1002M - 0310dinkoheNo ratings yet