Professional Documents

Culture Documents

NORM Guide For The TDE Man in The Field

NORM Guide For The TDE Man in The Field

Uploaded by

rdos14Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NORM Guide For The TDE Man in The Field

NORM Guide For The TDE Man in The Field

Uploaded by

rdos14Copyright:

Available Formats

NORM guide for the TDE man in the field

From:

DSV, MB Rig 22 (TDE/1412)

To:

DSV Rig 1, 3, 19, 65, 66, 21, and 22

Cc:

TDE, TDE/D, TDE/95, TDE/95D, TDE/95HSE, PLS/1, HSE,

OSA, Senior RPS (Omar), OTS/25 (NDF), TDE/11, TDE/12,

TDE/121, TDE/13, TDE/131, TDE/14, TDE/141, TDE/S (File).

Subject: Norm Guide for the TDE man in the field Revision 0.0

ODE Ref:

Date:

TDE/2001/

22 September 2001

The following Norm guide is meant to be a supplementary (TDE

specific) guide in addition to the existing NORM manual. It is meant

to be a complete guide on how to deal with Norm whenever a well

re-entry is made. It does not replace or supersede the NORM

manual.

In case of special circumstances an amendment will be written if

needed.

An electronic version of this document, including all the

attachments, can be found on the departmental network drive J:Drive\OM_all\TDE_all\Full Access\TDE HSE\TDE NORM Guidelines

TDE/1412

(Author)

TDE/141

TDE

TDE/D

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

TDE/14

NORM guide for the TDE man in the field.

NORM guide for the TDE man in the field

(TDE Rig Personnels procedure for handling

and shipping material with NORM

contamination).

This procedure is intended to be a field guide for the TDE

department on how to handle and ship material which has NORM.

Reference is made to AFPC NORM manual (Document No:

1.HSE.8.000) and to course material from the NORM course in OMAR

(Attachment 6).

The procedure outlines the steps taken from the point that NORM is

detected up until the material which has NORM has arrived at the

NORM plant (also called NDF, Norm Decontamination Facility,

Decontamination plant).

Note 1: Pulling NORM contaminated tubing is regarded as a nonroutine operation (see NORM manual 1.HSE.8002, page 4).

Note 2: MBDO is providing the NORM PPE and the measuring

instruments under the workover contracts, while AFPC is

providing material to wrap externally contaminated tubing

(plastic sheets). For rigs which do not have NORM PPE

included in the rig contract, see attachment 10 for list of

AFPC equipment available along with Mesc numbers.

Note 3: Alpha and Beta readings for wet and dry conditions may be

different. For example, a joint of tubing may measure 20cps

Beta when pulled out of hole (ie wet condition), while after a

couple of days (pipe is now dry), the Beta may read 40cps

and there may also be some alpha. This is why we always

double check the non-NORM items prior to back loading. Wet

and dry Gamma readings are usually the same.

Note 4: Before starting work on a well, the location, xmas tree, cellar

and location isolation valve/flowline shall be surveyed for

NORM. This is done by the respective CPFs RPS. The

handover certificate from the Senior Production Supervisor

(OPX/x) shall always be accompanied by this Norm survey.

The rig personnel should always make an independent check

as standard practice.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Note 5: There may be NORM contaminated items lying around the

location eg off cuts from old flowlines. It is advisable to

check around the location, and measure items that look

suspicious. Contact CPFs Senior Production Supervisor if any

NORM contaminated items are found.

Note 6: There may be radioactive sludge in the xmas tree or at top

of stuck wireline plugs. NORM contaminated sludge can be

disposed off at the nearest CPF (talk to CPFs RPS). The

sludge needs to be contained eg in plastic bag and/or

drum, accompanied by a shipping manifest and a Norm

survey report (006-SF1).

Note 7: NORM contaminated PPE can be disposed off at the nearest

CPF (talk to CPFs RPS). The PPE needs to be put in a plastic

bag and/or drum, accompanied by shipping manifest and a

Norm survey report (006-SF1).

Note 8: The CPFs RPS will assist with everything relating to NORM.

It is therefore advisable to use him as much as possible (to

do surveys and to fill in paperwork).

1. POH, lay down tubing.

Measure tubing for NORM.

If NORM, take precautions as per the NORM manual (Alpha, Beta and

Gamma levels versus PPE, handling, exposure limits and

containment of the NORM.

See Attachment 5 for extract from HSE manual 1.HSE.8.004

Protective equipment).

A PTW needs to be raised whenever pulling NORM contaminated

tubing.

Material with NORM is to be kept separate, at a dedicated place.

Choose a suitable area, +/- 200m away from location (the dedicated

area should be downwind from the location). The rigs NORM area

needs to be marked with warning signs in English and Arabic and

also cordoned off with warning tape.

Break subassemblies which are NORM contaminated.

Ensure that the item being measured is far enough away from the

other recovered items in order to avoid erroneous readings due to

accumulated effects or magnetism. It is good practice to double

check the background level, if reading higher or lower than normal

background level the item needs to be moved further away.

Separating a joint of tubing +/-1 m away from the other joints is

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

usually enough in order to eliminate magnetic and accumulated

effects. Magnetic effects often disappear after 3-4 days.

As a general rule it should be remembered that contamination

needs to be contained;

Protectors are very good for containing internal contamination.

Flanges and items not suitable for standard protectors, need to be

properly covered with plastic.

If there is external contamination, then the contamination needs

to be contained, in order to avoid rig and location to be

contaminated. Cover the rig floor and catwalk with plastic, wrap

tubing as soon as it has been laid down, transport tubing to rigs

storage area. To POH externally contaminated tubing is a very slow

and labor intensive process. It should be emphasized to the rig crew

that it is expected to take long time, and that people must not start

to cut corners in order to save time. See pictures below for

examples of external contamination.

Picture 1.1.a: Tubing with external scale

Picture 1.1.b: Bad practice.

2. Measure tubing for NORM.

Note 1:

typical background levels are: Alpha: 0.04 cps, Beta: 2

3 cps, Gamma: 0.09 mSv/hr.

Note 2: during POH, it may be practical to measure only every 510joints. Also, as long as the rig is working in NORM mode

(ie handling NORM contaminated tubulars), measuring every

5-10joint is sufficient, as this will minimize the exposure of

the crews.

Note3: prior to back loading of NORM free equipment, every joint

that is considered NORM free has to be re-measured. It is

advisable to have CPFs RPS to do this, in order to have an

independent check and also to avoid rig personnel being tied

up with this work.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Make a table, with columns for Internal, External (contact), External

(working distance) for each of Alpha, Beta and Gamma. (see

example attachment 1 and 2).

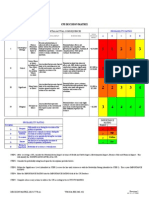

Trigger levels for sending equipment to the NORM plant (extract

from 1.HSE.8001 section 1.4):

Alpha:

1 cps above background

Beta:

5 cps above background

Gamma:

0.5 mSv/hr

As an example, if an item reads 6cps Beta and the background level

is 2.4 cps, then the item does not need to be sent to the Norm plant.

Readings below background may be due to magnetic interference. A

wipe test will confirm whether there is NORM or not.

A wipe test is taken as follows: Wipe a tissue over the surface to be

surveyed, cover an area of +/- 300cm2. Take the wipe to a low

background area, and if wet allow to dry as any Alpha contamination

will be shielded by the moisture. Hold the wipe as close as possible

to the probe without touching it and note any response from the

rate meter. For a standard wipe (300 cm2), the response should be

multiplied by a factor of two in order to reflect the required level of

protection (See 1.HSE.8004, pages 5 and 6).

If in doubt, call the RPA or RPS to get verification of readings and

advice on whether to send to NORM plant or not.

Take wipe test of some of the joints (ie the highest readings and

those with less than back ground), in order to double check for

external contamination.

If no NORM: then measure all items again before loading onto truck.

It is advisable to have CPFs RPS to do this. Ensure that the shipping

manifest and MRV clearly states No NORM and also that the

shipping manifest is accompanied by Radiological Survey and

NORM Precaution Report (Form number 006-SF1), which clearly

shall state that there is no NORM in the shipment. RPS will assist in

filling in those forms, if required.

Ensure that all joints with NORM contamination is numbered and has

well number written onto it.

Ensure that once finished POH or RIH NORM contaminated

equipment, that all handling gear is checked for NORM (eg slips,

tongs, elevator).

RPA telephone number: 32509

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

RPS telephone numbers:

Omar

: 32560

Tanak

: 36314

Thayyem : 34812

El Ward

: 38113

If you cannot get hold of the RPS, then call the safety advisor:

Safety advisors telephone numbers (e-mail addresses in brackets):

Omar

: 32213/32214 (Omar HSE adviser AFPC OPO/HSE)

Tanak

: 36313/36314 (Tanak HSE adviser AFPC OSA/1W)

Thayyem : 34513

(Thayyem Safety AFPC OSA/1T)

El Ward

: 38113

(El Ward Safety adviser AFPC OPW/11HSE)

If you cannot get hold of RPS or safety advisor, then try the control

room, they always know the whereabouts of RPS and safety advisor.

Control room telephone numbers:

Omar

: 32212

Tanak

: 36312

Thayyem : 34512

El Ward

: 38112

3. Make list of items with NORM.

Also ensure that all NORM contaminated equipment is numbered

and marked with well number.

4. Obtain work order.

Fill in work order request form as per attachment 1 and 2.

Give form to the CPF planner for the area. The CPF planner will make

a work order, which he will give to you straight away.

CPF planners telephone numbers (fax numbers in brackets):

Omar:

32244

(142)

Tanak:

36321

(149)

Thayyem: 34594

(188)

El Ward:

36321

(149) (Same as Tanak)

5. Call NORM plant manager.

Inform NORM plant manager of the quantities of equipment and

levels of NORM. Agree with the NORM plant manager on the day for

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

shipment. This will enable him to make space available in the NORM

plant. Give NORM plant manager at least three days notice.

NORM plant manager: ext 32552.

AFPC NDF representative (OTS/25): ext 32761

6. Arrange transport.

Call PLS/1 and order trucks. Give PLS/1 at least two days notice.

Make it clear to PLS/1 that shipment will be NORM contaminated.

This ensures that he sends AFPC trucks and not spot hired trucks.

PLS/1: Julian Harrison / Mike Gibson, ext 34576.

7. Prepare paperwork.

Prepare paperwork / forms as per attachment 1, ie. MRV, Shipping

Manifest, Work order, Radiological Survey and NORM Precaution

Report (006-SF1), Shipping Form Norm Materials/Equipment

(008-SF1), Norm Shipment Vehicle Survey Form (008-SF2), Norm

Inventory Form (006-SF3), Norm Contaminated Equipment,

Materials and Waste Registration Form (006-SF2), Table with Norm

readings from the equipment (rig-made table). It is important to

include the information as it is done in the attached examples.

Note: the MRV is important, as the items which are ok will be

returned to stock after cleaning.

8. On the day of shipment.

Measure truck for NORM prior to loading. This to ensure there is no

previous contamination of the vehicle.

Load the truck. Ensure that all pipe is fitted with protectors.

For internally contaminated tubulars protectors will be sufficient to

contain the NORM contamination (Alpha and Beta will not go

through a protector. Gamma cannot be stopped anyway). For

internally contaminated Xmas trees, it is sufficient to cap the ends

with e.g. heavy duty plastic (attachment 4).

For externally contaminated tubulars, the preferred way from the

drilling crew point of view, would be to wrap the load of tubing as a

whole, however the NDF can only handle individually wrapped joints

or bundles of maximum 3 joints of tubing. Therefore the currently

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

and only accepted procedure is, to have each joint individually

wrapped, to allow processing of the load in the NDF.

Survey the truck and complete the form Norm Shipment Vehicle

Survey Form (008-SF2) (see example attachment 1 and 2). Ensure

that truck and driver details are filled in correctly.

Give all paperwork to the truck driver (make sure a copy is kept on

the rig for future reference and trace-ability).

Label the truck with NORM tags, so that the load is identified as

NORM contaminated.

Release the truck, with instruction of going straight to the NORM

plant.

Inspect handling equipment such as forklift truck and pipe racks for

NORM. Clean if necessary.

Note: It is advisable to have RPS present on the day of shipment to

measure/confirm readings and to witness trucks being

loaded/inspected before dispatch.

9. Inform NORM plant.

Inform the NORM plant of time of departure of truck and estimated

time of arrival of truck at NORM plant.

NORM plant manager: ext 32552.

AFPC NDF representative (OTS/25): ext 32761.

NOTES:

1. If NORM plant is full use OPO NORM storage yard. Paperwork is

to be routed via OPO in such cases. This needs to be agreed with

OPO (via TDE/95).

2. There are discussions ongoing about setting up a NORM transit

yard in OMAR. Check with NORM plant if in doubt of this

temporary yards existence.

3. Radioactive protection instruments need to be

inspected/calibrated by RPA/RPS at regular intervals (Monthly).

Records need to be kept at the rig (attachment 7).

END of procedure.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Attachments:

1. Paperwork required. Note that the paperwork shall follow the

shipment.

2. Blank master copies of the forms in attachment 1.

3. Photographs with examples on how to wrap externally

contaminated tubing.

4. Photographs of typical load with internal contamination.

5. Protective equipment levels extract from HSE manual

1.HSE.8.004 and from NORM course in OMAR)

6. Course notes from:

Basic Norm/LSA awareness course',

'NORM/LSA awareness course for supervisors',

'NORM tester (RPT) course - supplementary notes'.

7. Blank form for recording NORM Measurement Equipment checks

and calibrations.

8. Definition of RPA, RPS and RPT.

9. List of positions who are qualified RPTs on MB Rig 21 and 22.

10. List of AFPC NORM PPE (with Mesc numbers).

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

Attachment 1 Paperwork required. Note that the paperwork shall

follow the shipment.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Attachment 2 - Blank master copies of the forms in attachment 1.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

Attachment 3 - Photographs with examples on how to wrap

externally contaminated tubing.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Attachment 4 - Photograph of typical load with internal

contamination.

Note that for tubing, it is sufficient with protectors. Make sure

protectors are closed type not the open type.

For xmas tree, blind flanges are fine to use. If blind flanges not

practical/available, then simply use some plastic. Ensure the plastic

is properly secured, as it easily can get loose during transport.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

ATTACHMENT 5.

Extract from NORM course hand-out.

Work precautions with contamination are based on the following

readings, above background, using the DP2R/4 alpha/beta

contamination probe:

Beta count-rate: >15 cps but <150 cps

Alpha count rate: > 2 cps but < 15 cps

Filtering facepiece respirator type P3 (FFP3) or a half-face respirator

with type P3 filter. Goggles, gloves, head covering, boots and a long

sleeved, disposable or impervious coverall should be worn and any

cuts or abrasions effectively covered with a waterproof dressing

before entering a vessel or a tank. Appropriate aspects of these

precautions should be taken for work on other equipment (eg

handling tubulars on a workover).

At a measured level of 150 cps (Beta) or 15 cps (Alpha)

OSA/1 must be contacted and a higher level of protection

may be specified. The protection requirements will be based on

the measurement guidelines in the attached extract from

1.HSE.8.004 (Respiratory protective equipment levels) but will also

take into account other factors such as specific work conditions, the

potential for uncovering higher levels of contamination, whether the

contamination is fixed or loose, control procedures, worker

expertise and level of supervision.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Attachment 6 Course notes

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

Attachment 7 Blank for recording NORM measurement equipment

calibration history.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Attachment 8 Definition RPT, RPS, RPA

RPT = Radioactive Protection Technician. He can use instruments.

Every CPF has a few RPTs. In addition, rigs key personnel should be

trained to RPT level, in order to do measurements and fill in

paperwork.

RPS = Radioactive Protection Supervisor. Each CPF has a RPS. He is

the leader for the RPTs. He is the man to call for assistance.

RPA = Radioactive Protection Advisor. Person filling this position is in

Omar. He has overview over training, does instrument calibration.

He is the leader for all the RPSs.

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

Attachment 9 - List of personnel (positions) who are qualified RPTs

on Workover rigs.

DSV

TP

NTP

Drillers

Crane operator

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

Attachment 10 - List of AFPC NORM PPE (with Mesc numbers)

The PPE below is available from PLS/2 on Omar.

Be aware that the workover rigs have PPE included in the contract.

MESC NO

ITEM DESCRIPTION

44.81.23.010.9

cover, 100l

Drum, steel, 1mm plate, open top, removable

68.85.12.102.9

Tape, self adhesive, anti-corrosion, width=50mm

78.71.33.223.1

Sheet, polymethyl methacrylate, clear,

2000x1220x2mm

78.71.33.241.1

Sheet, polymethyl methacrylate, clear,

2000x1220x5mm

88.95.52.312.9

Decontafix, 500ml tin, decontamination paste for

LSA

88.95.52.313.9

Decodusch-S, 1l bottle, decontam. agent, for

skin/hair

88.95.52.314.9

Hakavit, 1l bottle, skin paste after

decontamination

88.95.52.316.9

Haka-dekopur, 30kg canister, cold clean

88.95.52.317.9

Hakapur, 30gk canister, decontaminating agent

88.95.52.318.9

Hakapur AS, 10l canister, decontaminating agent

95.11.35.197.9

Bag, sample, PVC, 0.3mm thick, size:

1300x650mm

95.11.35.272.9

Bag, sample, transparent polythene, 0.125mm

thick

95.11.35.274.9

Bag, sample, transparent polythene, 0.125mm

thick

95.14.91.010.9

Rags, cotton, in 25kg bags

96.43.10.712.9

yellow

Boots, safety, polyur./Rubber, oil&acid resist,

96.43.10.714.9

yellow

Boots, safety, polyur./Rubber, oil&acid resist,

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field.

96.43.10.716.9

yellow

Boots, safety, polyur./Rubber, oil&acid resist,

96.43.10.717.9

yellow

Boots, safety, polyur./Rubber, oil&acid resist,

96.43.10.718.9

yellow

Boots, safety, polyur./Rubber, oil&acid resist,

96.43.10.720.9

yellow

Boots, safety, polyur./Rubber, oil&acid resist,

96.43.11.872.9

Rubber overshoes size M

96.43.11.874.9

Rubber overshoes size L

96.43.11.876.9

Rubber overshoes size XL

96.43.20.402.9

Gloves, rubber, light weight, flock lined, yellow, M

96.43.20.604.1

Gloves, PVC, chemical resistant, medium size

96.43.20.606.1

Gloves, PVC, chemical resistant, large size

96.43.90.660.1

coated

Overall, disposable, with hood, white, small,

96.43.90.662.1

coated

Overall, disposable, with hood, white, medium,

96.43.90.664.1

coated

Overall, disposable, with hood, white, large,

96.43.90.666.1

coated

Overall, disposable, with hood, white, extra large,

96.49.10.220.9

shields

Spectacles, safety, polycar, clear lens & side

96.49.10.221.9

shields

Spectacles, safety, polycar, tinted lens & side

96.49.10.484.9

3,4.9

Goggles, full view wide vision, EN166B, impact

96.58.10.050.9

Respirator, filter, face, disposable, FFP3

96.58.10.190.9

Mask, half face, c/w screw in P3 disposable filter

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

NORM guide for the TDE man in the field

96.58.10.195.9

Filter, P3, for half face mask

96.58.10.351.9

LSA

Mask, full face, supervisor, with screw-in P3 filter,

96.58.10.361.9

20401

Canister, dust, fine particle, f/use w/sup.mask

96.58.10.362.9

Canister, P3, for full face mask 20401 or 1710521

96.58.10.363.9

Canister, A/P3, f/full face mask 20401 or 1710521

96.64.73.404.8

1000pcs/roll

Label, self adhesive, radioactivity, 25x25mm,

96.64.73.705.9

roll

Tape, safety, black/yellow, with LSA, 33mx50mm

(end)

/var/www/apps/conversion/tmp/scratch_7/279918509.doc

You might also like

- LPG Safety Distance GuideDocument53 pagesLPG Safety Distance GuideJavierfox98100% (7)

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv Sharma0% (1)

- Chapter - 10 Recommended Practice For ESP Failure AnalysisDocument64 pagesChapter - 10 Recommended Practice For ESP Failure Analysisdewidar123492% (12)

- JP For Radiography TestDocument16 pagesJP For Radiography Testsubudhiprasanna100% (1)

- HAZID Worksheet FORM Rev.25 May 2012 - Timas & Premier Oil IndonesiaDocument15 pagesHAZID Worksheet FORM Rev.25 May 2012 - Timas & Premier Oil IndonesiaMohdNajib Mahmud100% (4)

- Wireline Equipment Standard-Norsok PDFDocument14 pagesWireline Equipment Standard-Norsok PDFRio de Mario100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- TT Platform Rig Evaluation Matrix - FINALDocument9 pagesTT Platform Rig Evaluation Matrix - FINALrdos14100% (1)

- Procemin 2015 Building The World's Largest HPGR - The HRC™3000 at The Morenci Metcalf ConcentratorDocument20 pagesProcemin 2015 Building The World's Largest HPGR - The HRC™3000 at The Morenci Metcalf ConcentratorNereo Spengler100% (1)

- NORMS - SP1170: Edocs - HTM RadiationDocument10 pagesNORMS - SP1170: Edocs - HTM Radiationjoenediath9345No ratings yet

- Deinking Cell 1-25Document25 pagesDeinking Cell 1-25onlywork35No ratings yet

- PTS 20162Document53 pagesPTS 20162ronelbarafaeldiegoNo ratings yet

- Apv Valves Da3plus Atex GBDocument48 pagesApv Valves Da3plus Atex GBSimon MinneNo ratings yet

- SMP For DP TransmitterDocument4 pagesSMP For DP TransmitterROHIT SINGHNo ratings yet

- PFP ProcedureDocument6 pagesPFP ProcedureRamesh100% (1)

- Procedure For Cable Laying - 03Document14 pagesProcedure For Cable Laying - 03RamaKrishna ANo ratings yet

- Method Statement FormatDocument11 pagesMethod Statement FormatPrem Preetham Dsouza100% (1)

- Excavation Removal-PlanDocument34 pagesExcavation Removal-PlanABDELKADER BENABDALLAHNo ratings yet

- In-Place Density of Bituminous Mixes Using The Nuclear Moisture-Density Gauge Fop For Waqtc TM 8 ScopeDocument8 pagesIn-Place Density of Bituminous Mixes Using The Nuclear Moisture-Density Gauge Fop For Waqtc TM 8 ScopeAldrin SantosNo ratings yet

- Bag Filter Installation - Manual-1Document22 pagesBag Filter Installation - Manual-1kISHORE100% (4)

- HAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaDocument15 pagesHAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaMatthew BennettNo ratings yet

- PE D HA PRO 001 01 E - ATEX Procedure For ProjectsDocument29 pagesPE D HA PRO 001 01 E - ATEX Procedure For ProjectsagaricusNo ratings yet

- 01 Supplementary Guidance For Reporting Hydrocarbon ReleasesDocument12 pages01 Supplementary Guidance For Reporting Hydrocarbon ReleasesFreddy TanNo ratings yet

- LoggingDocument6 pagesLogginglurekalurekaNo ratings yet

- Antenna Pattern Measurement Guide 2020Document46 pagesAntenna Pattern Measurement Guide 2020Ryan KeyNo ratings yet

- ISGOTT 6 Breakdown of POI For InspectorsDocument4 pagesISGOTT 6 Breakdown of POI For InspectorsSam BNo ratings yet

- Partial Discharge Equipment PDFDocument6 pagesPartial Discharge Equipment PDFSellappan MuthusamyNo ratings yet

- da-DKDocument284 pagesda-DKEmilioNo ratings yet

- PRESSURISEDDocument17 pagesPRESSURISEDrahigi8656No ratings yet

- PTC Thermistors: Limit Temperature Sensors, Probe AssembliesDocument7 pagesPTC Thermistors: Limit Temperature Sensors, Probe AssembliesNeko DalekoNo ratings yet

- Q A Fike Webinar Explosion Risk Assessment and Explosion Protection DoDocument3 pagesQ A Fike Webinar Explosion Risk Assessment and Explosion Protection DoAda-MNo ratings yet

- TSP Number TSP Title Task Number(s) / Title(s) Effective Date Supersedes TSP(S) TSP Users Proponent Comments / Recommen-DationsDocument22 pagesTSP Number TSP Title Task Number(s) / Title(s) Effective Date Supersedes TSP(S) TSP Users Proponent Comments / Recommen-DationsLo Shun FatNo ratings yet

- TOFD PresentationDocument18 pagesTOFD PresentationSai Krishna Yellapu100% (7)

- Jet Engine Test CellDocument8 pagesJet Engine Test Cellkordamirimohammad4No ratings yet

- 03-LEK-1050 Drill 12.25 Inch SectionDocument4 pages03-LEK-1050 Drill 12.25 Inch SectionDrilling Engineering ChannelNo ratings yet

- Apv Valves sv1 Atex GBDocument42 pagesApv Valves sv1 Atex GBKim HenyeonNo ratings yet

- THERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 SDocument4 pagesTHERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 Smayito12093120No ratings yet

- 3 1 TR 1Document6 pages3 1 TR 1Valdemar Alonso Ojeda SotoNo ratings yet

- TSP Number TSP Title Task Number(s) / Title(s) Effective Date Supersedes TSP(S) TSP Users Proponent Comments / Recommen-DationsDocument23 pagesTSP Number TSP Title Task Number(s) / Title(s) Effective Date Supersedes TSP(S) TSP Users Proponent Comments / Recommen-DationsLo Shun FatNo ratings yet

- TLD User ManualDocument12 pagesTLD User Manualveronika rahayuNo ratings yet

- C00M04 HPL E - MC 304a XX MDS 0001 PDFDocument18 pagesC00M04 HPL E - MC 304a XX MDS 0001 PDFRUPESH KUMARNo ratings yet

- TVA Flowmeter For Saturated Steam Service: Installation and Maintenance InstructionsDocument36 pagesTVA Flowmeter For Saturated Steam Service: Installation and Maintenance InstructionsGiordano DornellesNo ratings yet

- Fmp-Uls Universal Liquid Sensor: Installation GuideDocument10 pagesFmp-Uls Universal Liquid Sensor: Installation GuideDavidNo ratings yet

- Fike Webinar Dust Hazards Analysis Questions and AnswersDocument3 pagesFike Webinar Dust Hazards Analysis Questions and AnswersAda-MNo ratings yet

- B4304Document9 pagesB4304jamesearl_cubillasNo ratings yet

- Hac BasicDocument3 pagesHac BasicLuqman OsmanNo ratings yet

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSDocument11 pagesMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- T441Document5 pagesT441Pratik PrajapatiNo ratings yet

- SPE/IADC-185283-MS Leveraging CLD Potentials: Optimizing Economics Through Dynamic Well ControlDocument10 pagesSPE/IADC-185283-MS Leveraging CLD Potentials: Optimizing Economics Through Dynamic Well Control叶芊No ratings yet

- it-ITDocument292 pagesit-ITJavier Enrrique Iglesias PelcastreNo ratings yet

- Safety Critical ElementsDocument2 pagesSafety Critical Elementsdtr17No ratings yet

- Spec Antena GpsDocument4 pagesSpec Antena GpsfadewaeNo ratings yet

- Scope and Summary: CautionDocument3 pagesScope and Summary: Cautionrafael_figueroaNo ratings yet

- Batching Units - Pumps Series Akl - TPZ: Instructions ManualDocument19 pagesBatching Units - Pumps Series Akl - TPZ: Instructions Manualconstantin.iacomi3837No ratings yet

- Technical Handbook 1kW DME STATION LDB-102Document882 pagesTechnical Handbook 1kW DME STATION LDB-102Krishna Ghimire60% (5)

- RDSO PE SPEC AC 0138-2009 Rev-1Document23 pagesRDSO PE SPEC AC 0138-2009 Rev-1Rahul MauryaNo ratings yet

- Pressure Gauge: Product NameDocument11 pagesPressure Gauge: Product NameLinh LyNo ratings yet

- Oxygen & Nitrogen Gas Lines: Page 1 of 4Document4 pagesOxygen & Nitrogen Gas Lines: Page 1 of 4qamar sayedNo ratings yet

- LEMTEK45E English Version Rev1Document35 pagesLEMTEK45E English Version Rev1ambiya086114No ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- 9 Words That Woman UseDocument1 page9 Words That Woman Userdos14No ratings yet

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- Buoyancy Factor (BF) Buoyancy Factor Using Mud Weight, PPGDocument2 pagesBuoyancy Factor (BF) Buoyancy Factor Using Mud Weight, PPGrdos14No ratings yet

- HG658 V2 Home Gateway: User GuideDocument54 pagesHG658 V2 Home Gateway: User Guiderdos14No ratings yet

- PP010000734 02Document2 pagesPP010000734 02rdos140% (1)

- Web Interface User's Guide: ADSL Ethernet & USB Combo RouterDocument64 pagesWeb Interface User's Guide: ADSL Ethernet & USB Combo Routerrdos14No ratings yet

- Candidate Screening Form: Evaluating Ubd, MPD, Air/Mist/Aerated/Foam Drilling TechniquesDocument2 pagesCandidate Screening Form: Evaluating Ubd, MPD, Air/Mist/Aerated/Foam Drilling Techniquesrdos14No ratings yet

- Offshore201607 DLDocument83 pagesOffshore201607 DLrdos14No ratings yet

- Design Index PDC PDFDocument2 pagesDesign Index PDC PDFrdos14No ratings yet

- Decision MatrixDocument12 pagesDecision Matrixrdos14No ratings yet

- Evaluation of Drilling Rig SelectionDocument39 pagesEvaluation of Drilling Rig Selectionamithakim100% (4)

- Deepwater Landing String DesignDocument6 pagesDeepwater Landing String Designrdos14No ratings yet

- Jha Basic Risk MatrixDocument1 pageJha Basic Risk Matrixrdos14No ratings yet

- Chap2 Shell Design PracticeDocument6 pagesChap2 Shell Design Practicerdos14No ratings yet

- Shell Casing and Tubing Design Guide: Appendix 1 - Specialty Well DesignsDocument1 pageShell Casing and Tubing Design Guide: Appendix 1 - Specialty Well Designsrdos14No ratings yet

- Introduction Resposibilities and AdministrationDocument22 pagesIntroduction Resposibilities and Administrationrdos14No ratings yet

- Safety Management (Management)Document6 pagesSafety Management (Management)Akash AkNo ratings yet

- Techspecs fx180 240 EngDocument2 pagesTechspecs fx180 240 EngmjgosslerNo ratings yet

- Doctorknow Application PaperDocument12 pagesDoctorknow Application PaperLake HouseNo ratings yet

- 10318-00-153-PD-0002 Welding Maps and Piping ReportingDocument24 pages10318-00-153-PD-0002 Welding Maps and Piping ReportingAnanthakrishnan VNo ratings yet

- Atl: Atlas Transformation Language: ATLAS Group Lina & Inria NantesDocument62 pagesAtl: Atlas Transformation Language: ATLAS Group Lina & Inria NantesDiana SeguroNo ratings yet

- Media Rolls f5Document2 pagesMedia Rolls f5LBNo ratings yet

- Opearting SystemDocument25 pagesOpearting SystemlovishsindhwaniNo ratings yet

- Electrical Engineering Question Paper-II: - Kirchoff's LossDocument25 pagesElectrical Engineering Question Paper-II: - Kirchoff's LossbasavarajNo ratings yet

- Chattisgarh Swami Vivekanand Technical University, BhilaiDocument21 pagesChattisgarh Swami Vivekanand Technical University, BhilaiNiket SurawaseNo ratings yet

- A Chinese Checkersplaying ProgramDocument26 pagesA Chinese Checkersplaying ProgramramachandraNo ratings yet

- Ict DesignationDocument3 pagesIct DesignationMyung DaeNo ratings yet

- "Greater Baku Regional Development Plan" (GBRDP) ProjectDocument114 pages"Greater Baku Regional Development Plan" (GBRDP) ProjectRyan French100% (2)

- 399a PDFDocument47 pages399a PDFJuan Juan100% (1)

- Errata, Rule Clarifications, Timing Structures, and Frequently Asked Questions V2.2Document19 pagesErrata, Rule Clarifications, Timing Structures, and Frequently Asked Questions V2.2MasterofsanctityNo ratings yet

- A Comparative Study of Different Materials of Connecting Rod: A ReviewDocument4 pagesA Comparative Study of Different Materials of Connecting Rod: A ReviewSairaj AcharyNo ratings yet

- Rebar GuideDocument30 pagesRebar GuideAmro HassaninNo ratings yet

- Spa 20008080VDocument1 pageSpa 20008080Vmichele DSNo ratings yet

- Deckpro 800: High Hardness Chemical Resistant Seamless FlooringDocument2 pagesDeckpro 800: High Hardness Chemical Resistant Seamless FlooringMyraNo ratings yet

- Public Administration Unit-9 Scientific Management-F.W. TaylorDocument9 pagesPublic Administration Unit-9 Scientific Management-F.W. TaylorDeepika Sharma100% (2)

- Fabrication of Cylindrical Cam Shaper MachineDocument11 pagesFabrication of Cylindrical Cam Shaper MachineretechNo ratings yet

- NDT Radiation SafetyDocument33 pagesNDT Radiation SafetyRamakrishnan AmbiSubbiahNo ratings yet

- Matlab Based Electromagnetics 1St Edition Notaros Solutions Manual Full Chapter PDFDocument23 pagesMatlab Based Electromagnetics 1St Edition Notaros Solutions Manual Full Chapter PDFkathylutzrogcbxditz100% (12)

- Java PDFDocument56 pagesJava PDFglam girlNo ratings yet

- Pressure Reducing Regulator FISHER Manual Serie 64Document8 pagesPressure Reducing Regulator FISHER Manual Serie 64Billy Isea DenaroNo ratings yet

- JSP, Servlet, JSTL and Mysql Simple Crud ApplicationDocument10 pagesJSP, Servlet, JSTL and Mysql Simple Crud ApplicationDiego GarciaNo ratings yet

- Revised - Roads Works Daily Permit FormatDocument1 pageRevised - Roads Works Daily Permit Formatsalauddin0mohammedNo ratings yet

- Technical Service BulletinDocument15 pagesTechnical Service BulletinVASEKNo ratings yet

- Project Report Water Logging ThaneDocument79 pagesProject Report Water Logging Thaneavinash_mokashi707378% (9)