Professional Documents

Culture Documents

Synthetic Webbing & Round Sling Acceptance Criteria

Synthetic Webbing & Round Sling Acceptance Criteria

Uploaded by

rustamriyadiCopyright:

Available Formats

You might also like

- Davit CalcDocument4 pagesDavit CalcrustamriyadiNo ratings yet

- Lifting Lug STD Design 5tDocument3 pagesLifting Lug STD Design 5trustamriyadi50% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Opito Rigger TrainingDocument61 pagesOpito Rigger TrainingTasia Di100% (1)

- Wstda-Ws-1: ©2015 Web Sling & Tie Down AssociationDocument39 pagesWstda-Ws-1: ©2015 Web Sling & Tie Down AssociationAditya GuptaNo ratings yet

- BS EN 360 (2002) - Retractable Type Fall ArrestorDocument14 pagesBS EN 360 (2002) - Retractable Type Fall ArrestorGistek MarcoNo ratings yet

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocument12 pagesWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNo ratings yet

- Manual For Wire RopesDocument25 pagesManual For Wire RopesAnand Agrawal0% (1)

- Inspection of Wire Rope ProcedureDocument4 pagesInspection of Wire Rope ProceduremochisitampanNo ratings yet

- Cranes and Derricks, 4th Edition .Page400Document1 pageCranes and Derricks, 4th Edition .Page400danilolbg2903No ratings yet

- Bentley Limcon v3.63Document4 pagesBentley Limcon v3.63rustamriyadiNo ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Seminar Report On Amoled TechnologyDocument22 pagesSeminar Report On Amoled TechnologyRanjana Upadhayay88% (8)

- Synthetic Web Sling InspectionDocument11 pagesSynthetic Web Sling Inspectionamin110110No ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- Short Link Chain For Lifting Purposes - SafetyDocument26 pagesShort Link Chain For Lifting Purposes - SafetyAHMED LUOSHNo ratings yet

- Crane Safety On Construction Sites: Standards, Regulations, CertificationsDocument22 pagesCrane Safety On Construction Sites: Standards, Regulations, Certificationsedcamil100% (1)

- HookDocument5 pagesHookHarris ShehzadNo ratings yet

- Slinging Tubulars, Scaffold, BeamsDocument3 pagesSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNo ratings yet

- Suspended Platform System Conform UlDocument19 pagesSuspended Platform System Conform UlEmerson OliveiraNo ratings yet

- Lifting+Matters+Q4+2019 Final WEB LRDocument44 pagesLifting+Matters+Q4+2019 Final WEB LRMeleti Meleti MeletiouNo ratings yet

- LEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFDocument72 pagesLEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFSelva GanapathiNo ratings yet

- No. 8 - Chain & Chain SlingsDocument11 pagesNo. 8 - Chain & Chain SlingsAhmed AtefNo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- OSHA's New Rules For Crane-Suspended Personnel PlatformsDocument4 pagesOSHA's New Rules For Crane-Suspended Personnel PlatformswitwatersrandNo ratings yet

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Document2 pages0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNo ratings yet

- Inspection ChecklistsDocument43 pagesInspection Checklistsmuhammad.younisNo ratings yet

- RiggingDocument129 pagesRiggingInnocent BhaikwaNo ratings yet

- ANSI Requirements For Overhead and Gantry CranesDocument7 pagesANSI Requirements For Overhead and Gantry CranesRizki SadikinNo ratings yet

- Crane Safety Training ModuleDocument29 pagesCrane Safety Training ModuleBergensur100% (3)

- Timber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Document6 pagesTimber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Shery TentionNo ratings yet

- Wire Rope Slings: General InformationDocument16 pagesWire Rope Slings: General Informationegy pureNo ratings yet

- Certex Wire Rope Slings LR Rev3Document34 pagesCertex Wire Rope Slings LR Rev3jogi oscar sinagaNo ratings yet

- Wire Rope Slings Wire Rope SlingsDocument6 pagesWire Rope Slings Wire Rope SlingsegyinspectoryahooNo ratings yet

- Guidance To The Verification of Sockets and Davits.: Document Reference LEEA 061Document18 pagesGuidance To The Verification of Sockets and Davits.: Document Reference LEEA 061GaniyuNo ratings yet

- Iso 10325 2018Document9 pagesIso 10325 2018Julio Andrés Casal Ramos0% (1)

- Osha 29 CFR 1926.1400Document13 pagesOsha 29 CFR 1926.1400Aly MurrietaNo ratings yet

- Wire Rope Sling Tech InfoDocument6 pagesWire Rope Sling Tech InfoDaud PirriNo ratings yet

- Wire Rope InspectionDocument21 pagesWire Rope Inspectionrois100% (2)

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDocument22 pagesWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979No ratings yet

- List of Wire Rope SlingsDocument1 pageList of Wire Rope SlingskvsagarNo ratings yet

- Wire Rope SlingsDocument5 pagesWire Rope SlingsEr Faiyaz AhmedNo ratings yet

- Flat Woven Webbing SlingsDocument2 pagesFlat Woven Webbing SlingsYosses Sang NahkodaNo ratings yet

- BS En795 - 1997 - 111115Document5 pagesBS En795 - 1997 - 111115EDDIE_LIM52No ratings yet

- Rigger and Signalman Handbook 2nd Revision 2019Document20 pagesRigger and Signalman Handbook 2nd Revision 2019andrewhw100% (1)

- Instructions For The Safe Use Of: ShacklesDocument2 pagesInstructions For The Safe Use Of: ShacklesAmeerUlHaqNo ratings yet

- User Manual Wire Rope SlingDocument4 pagesUser Manual Wire Rope SlingRashid Ghani100% (1)

- ShackleDocument2 pagesShackleRizwan Ahmed100% (1)

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocument6 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakNo ratings yet

- Technical-Guides Shackle Inspection Spa 2003Document1 pageTechnical-Guides Shackle Inspection Spa 2003israel11288No ratings yet

- Nbsir81 2265 PDFDocument110 pagesNbsir81 2265 PDFArunNo ratings yet

- Wire Rope Sling - Rejection CriteriaDocument1 pageWire Rope Sling - Rejection CriteriaKhairulz Anuar100% (1)

- Taglineuse PEERREVIEWDOCDocument56 pagesTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Casar End ConnectionsDocument75 pagesCasar End ConnectionsMuhammadFaridNo ratings yet

- Webbing Slings, Roundslings and Lifting NetsDocument10 pagesWebbing Slings, Roundslings and Lifting NetsYosses Sang NahkodaNo ratings yet

- TG4-11 May 2011Document15 pagesTG4-11 May 2011Abdul Hadhi100% (1)

- BS en Iso 3691-6-2013Document38 pagesBS en Iso 3691-6-2013yamen sayedNo ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Periodic Inspection Sling GBDocument2 pagesPeriodic Inspection Sling GBjeanmichelqNo ratings yet

- Slings-Chains+wir RopesDocument30 pagesSlings-Chains+wir RopestonyNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFDocument15 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFopreamihNo ratings yet

- Universal Beams PDFDocument2 pagesUniversal Beams PDFbrodieNo ratings yet

- FTC-13-099 Closed End Old Brass Zipper 4.5 ABCDocument5 pagesFTC-13-099 Closed End Old Brass Zipper 4.5 ABCLuis EduardoNo ratings yet

- Rigging KNOTSDocument13 pagesRigging KNOTSDexter FernandezNo ratings yet

- Common Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentDocument11 pagesCommon Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentEngr Arfan Ali DhamrahoNo ratings yet

- Splicing Optical Fiber CableDocument25 pagesSplicing Optical Fiber Cableafareenkhan100% (1)

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocument14 pagesCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNo ratings yet

- Hook Pallet Capacity CalculationDocument2 pagesHook Pallet Capacity CalculationrustamriyadiNo ratings yet

- Tutorial Manual Safi PDFDocument53 pagesTutorial Manual Safi PDFrustamriyadiNo ratings yet

- Lifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightDocument10 pagesLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightrustamriyadiNo ratings yet

- Rectangular Tank Calc - STDDocument24 pagesRectangular Tank Calc - STDrustamriyadiNo ratings yet

- Shape 2000Document217 pagesShape 2000rustamriyadiNo ratings yet

- Beam DesignDocument6 pagesBeam DesignrustamriyadiNo ratings yet

- Mech-Intro 13.0 WS07.1 SStherm PDFDocument14 pagesMech-Intro 13.0 WS07.1 SStherm PDFrustamriyadiNo ratings yet

- Mech-HT 13.0 L05 SteadyStateDocument9 pagesMech-HT 13.0 L05 SteadyStaterustamriyadiNo ratings yet

- SPMT BrochureDocument15 pagesSPMT BrochureAnonymous qT66pyKNo ratings yet

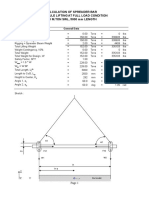

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- AnsysDocument26 pagesAnsysrustamriyadiNo ratings yet

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- Weld KcalculationDocument1 pageWeld KcalculationrustamriyadiNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationrustamriyadi100% (2)

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- ISOCHEM PRICECLIST 2019-2020 Mail PDFDocument109 pagesISOCHEM PRICECLIST 2019-2020 Mail PDFM Pandeeswari67% (3)

- 2017 Chemistry NotesDocument27 pages2017 Chemistry NotesOpalNo ratings yet

- Masina Whirlpool Awt 2250Document2 pagesMasina Whirlpool Awt 2250mark pavlovic100% (3)

- Accurate Analysis of Glycerol and Glycerides in Biodiesel Oil Using EN 14105 (2011) and Robust Metal MXT ColumnsDocument4 pagesAccurate Analysis of Glycerol and Glycerides in Biodiesel Oil Using EN 14105 (2011) and Robust Metal MXT ColumnsAstiJayatriIINo ratings yet

- Dot Point Txtbook ChemDocument24 pagesDot Point Txtbook ChemDavid ChinNo ratings yet

- GC and GCMS Basic TheoryDocument92 pagesGC and GCMS Basic TheoryJuliansyahNo ratings yet

- Effect of PH On GFP DenaturationDocument10 pagesEffect of PH On GFP DenaturationDominic YapNo ratings yet

- Analysing Amino Acids in Galanin Graph Theoretical ApproachDocument5 pagesAnalysing Amino Acids in Galanin Graph Theoretical ApproachEditor IJRITCCNo ratings yet

- Iw PDFDocument6 pagesIw PDFinggrianti wiratamaNo ratings yet

- Product Range Edition 2010-01: Rubber ChemicalsDocument20 pagesProduct Range Edition 2010-01: Rubber Chemicalsersin_uckunNo ratings yet

- 1 s2.0 S1751616123004368 MainDocument11 pages1 s2.0 S1751616123004368 MainMihai MihaiNo ratings yet

- DPR Vignesh September-2014Document1,423 pagesDPR Vignesh September-2014alpanakaurNo ratings yet

- ACS Omega - Article - Zavradashvili Et Al. 2019Document12 pagesACS Omega - Article - Zavradashvili Et Al. 2019Tengiz KantariaNo ratings yet

- Topic:-Nomenclature: 1. Give IUPAC Name ofDocument16 pagesTopic:-Nomenclature: 1. Give IUPAC Name ofkannan2030No ratings yet

- Polymers: Current Technologies in Depolymerization Process and The Road AheadDocument17 pagesPolymers: Current Technologies in Depolymerization Process and The Road AheadMishell Andrea Macías MonserrateNo ratings yet

- JEE Advanced Practice Papers Keys.Document13 pagesJEE Advanced Practice Papers Keys.Mahesh BabuNo ratings yet

- Bougainvillea Spectabilis Extract As An Alternative Pen Ink 11STEM NewtreatmentDocument91 pagesBougainvillea Spectabilis Extract As An Alternative Pen Ink 11STEM NewtreatmentIVA LEI PARROCHANo ratings yet

- Data For Oil Used in TransformerDocument31 pagesData For Oil Used in TransformerPlanning EngineeringNo ratings yet

- Plant Cells and Plant Structure: AS Biology Unit 2 - Topic 4Document33 pagesPlant Cells and Plant Structure: AS Biology Unit 2 - Topic 4Escape VelocityNo ratings yet

- Biochemistry Midterm Carbohydrates: ClassificationsDocument21 pagesBiochemistry Midterm Carbohydrates: ClassificationsArah Lyn ApiagNo ratings yet

- HF 2017Document116 pagesHF 2017renefbgNo ratings yet

- Refining of Palm Kernel OilDocument75 pagesRefining of Palm Kernel Oilhagung100% (3)

- US4997682 PvaDocument4 pagesUS4997682 PvaPaulo GomesNo ratings yet

- Project 3 DecDocument68 pagesProject 3 DecÄløk SähúNo ratings yet

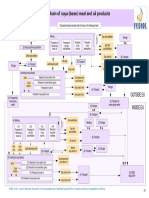

- Flow Chart of The Production Chain of Soya (Bean) Meal and Oil Products For Feed Application in The EUDocument25 pagesFlow Chart of The Production Chain of Soya (Bean) Meal and Oil Products For Feed Application in The EUadesuyan yomiNo ratings yet

- 42 Actualizaciones en Sida No56Document28 pages42 Actualizaciones en Sida No56Gonzalo WallsNo ratings yet

- Chemical Hazard Risk AssessmentDocument1 pageChemical Hazard Risk AssessmentMark CastilloNo ratings yet

- Chemical Kinetic Isotope EffectDocument43 pagesChemical Kinetic Isotope Effecttumman lal SahuNo ratings yet

- Weksler TermometrosDocument94 pagesWeksler TermometrosjhobanybernalNo ratings yet

Synthetic Webbing & Round Sling Acceptance Criteria

Synthetic Webbing & Round Sling Acceptance Criteria

Uploaded by

rustamriyadiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synthetic Webbing & Round Sling Acceptance Criteria

Synthetic Webbing & Round Sling Acceptance Criteria

Uploaded by

rustamriyadiCopyright:

Available Formats

SYNTHETIC WEBBING & ROUND SLING INSPECTION

Inspection Criteria (BS EN 696,697,699 & LEEA Approved Code of Practice Safe Use of Lifting Equipment 5th Ed)

1. Safe Working Load Marking

6. Cuts in Stitching

2. Identity Number

7. Discoloration (Chemical attack & Sun Effect)

3. Color Inspection Code

8. Burn Mark on Outer Surface

4. Broken Load Bearing Internal Yarn

9. Knots

5. Cuts and Abrasion to External Cover

Chemical Resistance

Nylon

Polyester

Polypropylene

Acids

No

Yes

Yes

Alkalis

Yes

No

Yes

Solvent

Yes

Yes

No

Color Code Plastic Sleeve Fitted

Type of Fiber

Color

Nylon

Green

Polyester

Blue

Polypropylene

Red/ Brown

Color Code According to BS EN 1492-1

WLL 1 T

WLL 2 T

WLL 3 T

WLL 4 T

WLL 5 T

WLL 6 T

WLL 8 T

WLL >10 T

Sample Picture of Rejected Fiber Slings

Surface and Edge Cut

All of the fibers in the synthetic sling contribute to the

strength of the sling. 1mm cut it reduce 40% strength

from the MBL (Minimum Breaking Load)

To prevent:

Always protect synthetic sling from being cut by corners

and edges by using wear Pads or other devices.

Page1 of 3

Sample Picture of Rejected Fiber Slings

Holes/ Snags/ Pulls

Punctures or areas where fibers stand out from the rest of

the sling surface.

To Prevent:

Avoid slings contact whit protrusions, both during lift and

while transporting or storing

Abrasion

Areas of the sling that look and feel fuzzy indicate that the

fibers have been broken by being subject to contact and

movement against a rough surface. Affected areas are

usually stained.

To prevent:

Never drag slings along the ground.

Never pull slings from under loads that are resting on the

slings.

Heat / Chemical Damage

Heat and Chemical damage can look similar and they both

have the effect the damaging sling and compromising the

slings strength. Look for discoloration and/ or fibers that

have been fused together and often feel hard or crunchy.

To prevent:

Never used Nylon or Polyester slings where they can be

exposed to temperatures in excess 1000 C.

Never used Nylon or Polyester slings in or around

chemicals without confirming that the slings material

compatible with the chemical being used.

Knots

Knots compromising the strength of the slings by not

allowing all fiber to contribute the lift as designed. Knots

may reduce sling strength to 50% from MBL.

Page2 of 3

Sample Picture of Rejected Fiber Slings

Broken/ Worn Stitching

The stitch patterns in the fiber slings have been engineered

to produce the most strength out of the slings. Is the

stitching not fully intact, the strength of the slings may be

affected.

To Prevent:

Never pull slings from the beneath loads where stitch

pattern can get hung up or snagged.

Illegible of Missing Tags

The information provided by sling tag is important for

knowing what sling to use and how it will function.

If you cant find or read all of the information on the sling

tag, BS Standard require that the slings shall be taken out

of services.

To prevent:

Avoid paint or chemical contact with tags.

Page3 of 3

You might also like

- Davit CalcDocument4 pagesDavit CalcrustamriyadiNo ratings yet

- Lifting Lug STD Design 5tDocument3 pagesLifting Lug STD Design 5trustamriyadi50% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Opito Rigger TrainingDocument61 pagesOpito Rigger TrainingTasia Di100% (1)

- Wstda-Ws-1: ©2015 Web Sling & Tie Down AssociationDocument39 pagesWstda-Ws-1: ©2015 Web Sling & Tie Down AssociationAditya GuptaNo ratings yet

- BS EN 360 (2002) - Retractable Type Fall ArrestorDocument14 pagesBS EN 360 (2002) - Retractable Type Fall ArrestorGistek MarcoNo ratings yet

- Web-Sling-Recommended-Operating-and-Inspection-GuidelineDocument12 pagesWeb-Sling-Recommended-Operating-and-Inspection-GuidelineibrahimNo ratings yet

- Manual For Wire RopesDocument25 pagesManual For Wire RopesAnand Agrawal0% (1)

- Inspection of Wire Rope ProcedureDocument4 pagesInspection of Wire Rope ProceduremochisitampanNo ratings yet

- Cranes and Derricks, 4th Edition .Page400Document1 pageCranes and Derricks, 4th Edition .Page400danilolbg2903No ratings yet

- Bentley Limcon v3.63Document4 pagesBentley Limcon v3.63rustamriyadiNo ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Seminar Report On Amoled TechnologyDocument22 pagesSeminar Report On Amoled TechnologyRanjana Upadhayay88% (8)

- Synthetic Web Sling InspectionDocument11 pagesSynthetic Web Sling Inspectionamin110110No ratings yet

- LEEA Correspondence Courses: Assignment 1.10Document6 pagesLEEA Correspondence Courses: Assignment 1.10ikponmwonsaNo ratings yet

- Short Link Chain For Lifting Purposes - SafetyDocument26 pagesShort Link Chain For Lifting Purposes - SafetyAHMED LUOSHNo ratings yet

- Crane Safety On Construction Sites: Standards, Regulations, CertificationsDocument22 pagesCrane Safety On Construction Sites: Standards, Regulations, Certificationsedcamil100% (1)

- HookDocument5 pagesHookHarris ShehzadNo ratings yet

- Slinging Tubulars, Scaffold, BeamsDocument3 pagesSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNo ratings yet

- Suspended Platform System Conform UlDocument19 pagesSuspended Platform System Conform UlEmerson OliveiraNo ratings yet

- Lifting+Matters+Q4+2019 Final WEB LRDocument44 pagesLifting+Matters+Q4+2019 Final WEB LRMeleti Meleti MeletiouNo ratings yet

- LEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFDocument72 pagesLEEA ACADEMY STEP NOTES - Foundation - Aug2018 - v1.8 Print PDFSelva GanapathiNo ratings yet

- No. 8 - Chain & Chain SlingsDocument11 pagesNo. 8 - Chain & Chain SlingsAhmed AtefNo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- OSHA's New Rules For Crane-Suspended Personnel PlatformsDocument4 pagesOSHA's New Rules For Crane-Suspended Personnel PlatformswitwatersrandNo ratings yet

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Document2 pages0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNo ratings yet

- Inspection ChecklistsDocument43 pagesInspection Checklistsmuhammad.younisNo ratings yet

- RiggingDocument129 pagesRiggingInnocent BhaikwaNo ratings yet

- ANSI Requirements For Overhead and Gantry CranesDocument7 pagesANSI Requirements For Overhead and Gantry CranesRizki SadikinNo ratings yet

- Crane Safety Training ModuleDocument29 pagesCrane Safety Training ModuleBergensur100% (3)

- Timber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Document6 pagesTimber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Shery TentionNo ratings yet

- Wire Rope Slings: General InformationDocument16 pagesWire Rope Slings: General Informationegy pureNo ratings yet

- Certex Wire Rope Slings LR Rev3Document34 pagesCertex Wire Rope Slings LR Rev3jogi oscar sinagaNo ratings yet

- Wire Rope Slings Wire Rope SlingsDocument6 pagesWire Rope Slings Wire Rope SlingsegyinspectoryahooNo ratings yet

- Guidance To The Verification of Sockets and Davits.: Document Reference LEEA 061Document18 pagesGuidance To The Verification of Sockets and Davits.: Document Reference LEEA 061GaniyuNo ratings yet

- Iso 10325 2018Document9 pagesIso 10325 2018Julio Andrés Casal Ramos0% (1)

- Osha 29 CFR 1926.1400Document13 pagesOsha 29 CFR 1926.1400Aly MurrietaNo ratings yet

- Wire Rope Sling Tech InfoDocument6 pagesWire Rope Sling Tech InfoDaud PirriNo ratings yet

- Wire Rope InspectionDocument21 pagesWire Rope Inspectionrois100% (2)

- Wire Rope Slings: Recommended Guideline For Proof Test Procedures ForDocument22 pagesWire Rope Slings: Recommended Guideline For Proof Test Procedures Fordonnyars1979No ratings yet

- List of Wire Rope SlingsDocument1 pageList of Wire Rope SlingskvsagarNo ratings yet

- Wire Rope SlingsDocument5 pagesWire Rope SlingsEr Faiyaz AhmedNo ratings yet

- Flat Woven Webbing SlingsDocument2 pagesFlat Woven Webbing SlingsYosses Sang NahkodaNo ratings yet

- BS En795 - 1997 - 111115Document5 pagesBS En795 - 1997 - 111115EDDIE_LIM52No ratings yet

- Rigger and Signalman Handbook 2nd Revision 2019Document20 pagesRigger and Signalman Handbook 2nd Revision 2019andrewhw100% (1)

- Instructions For The Safe Use Of: ShacklesDocument2 pagesInstructions For The Safe Use Of: ShacklesAmeerUlHaqNo ratings yet

- User Manual Wire Rope SlingDocument4 pagesUser Manual Wire Rope SlingRashid Ghani100% (1)

- ShackleDocument2 pagesShackleRizwan Ahmed100% (1)

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesDocument6 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting MachinesnoormanmubarakNo ratings yet

- Technical-Guides Shackle Inspection Spa 2003Document1 pageTechnical-Guides Shackle Inspection Spa 2003israel11288No ratings yet

- Nbsir81 2265 PDFDocument110 pagesNbsir81 2265 PDFArunNo ratings yet

- Wire Rope Sling - Rejection CriteriaDocument1 pageWire Rope Sling - Rejection CriteriaKhairulz Anuar100% (1)

- Taglineuse PEERREVIEWDOCDocument56 pagesTaglineuse PEERREVIEWDOCMohamed Said0% (1)

- Casar End ConnectionsDocument75 pagesCasar End ConnectionsMuhammadFaridNo ratings yet

- Webbing Slings, Roundslings and Lifting NetsDocument10 pagesWebbing Slings, Roundslings and Lifting NetsYosses Sang NahkodaNo ratings yet

- TG4-11 May 2011Document15 pagesTG4-11 May 2011Abdul Hadhi100% (1)

- BS en Iso 3691-6-2013Document38 pagesBS en Iso 3691-6-2013yamen sayedNo ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Periodic Inspection Sling GBDocument2 pagesPeriodic Inspection Sling GBjeanmichelqNo ratings yet

- Slings-Chains+wir RopesDocument30 pagesSlings-Chains+wir RopestonyNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFDocument15 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories, Non-Fixed Load Lifting Attachments - Version 2 PDFopreamihNo ratings yet

- Universal Beams PDFDocument2 pagesUniversal Beams PDFbrodieNo ratings yet

- FTC-13-099 Closed End Old Brass Zipper 4.5 ABCDocument5 pagesFTC-13-099 Closed End Old Brass Zipper 4.5 ABCLuis EduardoNo ratings yet

- Rigging KNOTSDocument13 pagesRigging KNOTSDexter FernandezNo ratings yet

- Common Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentDocument11 pagesCommon Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentEngr Arfan Ali DhamrahoNo ratings yet

- Splicing Optical Fiber CableDocument25 pagesSplicing Optical Fiber Cableafareenkhan100% (1)

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocument14 pagesCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNo ratings yet

- Hook Pallet Capacity CalculationDocument2 pagesHook Pallet Capacity CalculationrustamriyadiNo ratings yet

- Tutorial Manual Safi PDFDocument53 pagesTutorial Manual Safi PDFrustamriyadiNo ratings yet

- Lifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightDocument10 pagesLifting Calculation Pipe-Pipe Jn680 Turret Access Structure, Bluewater 110 Ton WeightrustamriyadiNo ratings yet

- Rectangular Tank Calc - STDDocument24 pagesRectangular Tank Calc - STDrustamriyadiNo ratings yet

- Shape 2000Document217 pagesShape 2000rustamriyadiNo ratings yet

- Beam DesignDocument6 pagesBeam DesignrustamriyadiNo ratings yet

- Mech-Intro 13.0 WS07.1 SStherm PDFDocument14 pagesMech-Intro 13.0 WS07.1 SStherm PDFrustamriyadiNo ratings yet

- Mech-HT 13.0 L05 SteadyStateDocument9 pagesMech-HT 13.0 L05 SteadyStaterustamriyadiNo ratings yet

- SPMT BrochureDocument15 pagesSPMT BrochureAnonymous qT66pyKNo ratings yet

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- AnsysDocument26 pagesAnsysrustamriyadiNo ratings yet

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- Weld KcalculationDocument1 pageWeld KcalculationrustamriyadiNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationrustamriyadi100% (2)

- Spreader 150T - PL100 A36Document8 pagesSpreader 150T - PL100 A36rustamriyadiNo ratings yet

- ISOCHEM PRICECLIST 2019-2020 Mail PDFDocument109 pagesISOCHEM PRICECLIST 2019-2020 Mail PDFM Pandeeswari67% (3)

- 2017 Chemistry NotesDocument27 pages2017 Chemistry NotesOpalNo ratings yet

- Masina Whirlpool Awt 2250Document2 pagesMasina Whirlpool Awt 2250mark pavlovic100% (3)

- Accurate Analysis of Glycerol and Glycerides in Biodiesel Oil Using EN 14105 (2011) and Robust Metal MXT ColumnsDocument4 pagesAccurate Analysis of Glycerol and Glycerides in Biodiesel Oil Using EN 14105 (2011) and Robust Metal MXT ColumnsAstiJayatriIINo ratings yet

- Dot Point Txtbook ChemDocument24 pagesDot Point Txtbook ChemDavid ChinNo ratings yet

- GC and GCMS Basic TheoryDocument92 pagesGC and GCMS Basic TheoryJuliansyahNo ratings yet

- Effect of PH On GFP DenaturationDocument10 pagesEffect of PH On GFP DenaturationDominic YapNo ratings yet

- Analysing Amino Acids in Galanin Graph Theoretical ApproachDocument5 pagesAnalysing Amino Acids in Galanin Graph Theoretical ApproachEditor IJRITCCNo ratings yet

- Iw PDFDocument6 pagesIw PDFinggrianti wiratamaNo ratings yet

- Product Range Edition 2010-01: Rubber ChemicalsDocument20 pagesProduct Range Edition 2010-01: Rubber Chemicalsersin_uckunNo ratings yet

- 1 s2.0 S1751616123004368 MainDocument11 pages1 s2.0 S1751616123004368 MainMihai MihaiNo ratings yet

- DPR Vignesh September-2014Document1,423 pagesDPR Vignesh September-2014alpanakaurNo ratings yet

- ACS Omega - Article - Zavradashvili Et Al. 2019Document12 pagesACS Omega - Article - Zavradashvili Et Al. 2019Tengiz KantariaNo ratings yet

- Topic:-Nomenclature: 1. Give IUPAC Name ofDocument16 pagesTopic:-Nomenclature: 1. Give IUPAC Name ofkannan2030No ratings yet

- Polymers: Current Technologies in Depolymerization Process and The Road AheadDocument17 pagesPolymers: Current Technologies in Depolymerization Process and The Road AheadMishell Andrea Macías MonserrateNo ratings yet

- JEE Advanced Practice Papers Keys.Document13 pagesJEE Advanced Practice Papers Keys.Mahesh BabuNo ratings yet

- Bougainvillea Spectabilis Extract As An Alternative Pen Ink 11STEM NewtreatmentDocument91 pagesBougainvillea Spectabilis Extract As An Alternative Pen Ink 11STEM NewtreatmentIVA LEI PARROCHANo ratings yet

- Data For Oil Used in TransformerDocument31 pagesData For Oil Used in TransformerPlanning EngineeringNo ratings yet

- Plant Cells and Plant Structure: AS Biology Unit 2 - Topic 4Document33 pagesPlant Cells and Plant Structure: AS Biology Unit 2 - Topic 4Escape VelocityNo ratings yet

- Biochemistry Midterm Carbohydrates: ClassificationsDocument21 pagesBiochemistry Midterm Carbohydrates: ClassificationsArah Lyn ApiagNo ratings yet

- HF 2017Document116 pagesHF 2017renefbgNo ratings yet

- Refining of Palm Kernel OilDocument75 pagesRefining of Palm Kernel Oilhagung100% (3)

- US4997682 PvaDocument4 pagesUS4997682 PvaPaulo GomesNo ratings yet

- Project 3 DecDocument68 pagesProject 3 DecÄløk SähúNo ratings yet

- Flow Chart of The Production Chain of Soya (Bean) Meal and Oil Products For Feed Application in The EUDocument25 pagesFlow Chart of The Production Chain of Soya (Bean) Meal and Oil Products For Feed Application in The EUadesuyan yomiNo ratings yet

- 42 Actualizaciones en Sida No56Document28 pages42 Actualizaciones en Sida No56Gonzalo WallsNo ratings yet

- Chemical Hazard Risk AssessmentDocument1 pageChemical Hazard Risk AssessmentMark CastilloNo ratings yet

- Chemical Kinetic Isotope EffectDocument43 pagesChemical Kinetic Isotope Effecttumman lal SahuNo ratings yet

- Weksler TermometrosDocument94 pagesWeksler TermometrosjhobanybernalNo ratings yet