Professional Documents

Culture Documents

Illlllllllllllllllllllllllllllllll: United States Patent

Illlllllllllllllllllllllllllllllll: United States Patent

Uploaded by

WlopezaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Illlllllllllllllllllllllllllllllll: United States Patent

Illlllllllllllllllllllllllllllllll: United States Patent

Uploaded by

WlopezaCopyright:

Available Formats

I

llllllllllllllllllllllllllllllllllllllll

Illlllllllllllllllllllllllllllllll

1150051123754

United States Patent [19]

[11]

Patent Number:

Brown

[45]

Date of Patent:

[54]

[75]

RADlAL VANE DEVISTING SYSTEH l.\' A

SEPARATOR FOR REMOVING ENTRAIXED

DROPLETS FROM A GAS STREAM

Inventor:

5,112,375

May 12, 1992

FOREIGN PATENT DOCUMENTS

497034

Michael R. Brown, Tulsa. Okla.

3/1976

USSR. .............. ..

55/440

322967 12/1929

United Kingdom ..

55/440

2119674 11/1983

[73] Assignee: Natco, Tulsa. Okla.

L'.S.S.R. ............................... . 55/440

578935 11/1977

United Kingdom ................ .. 55/498

Primary ExaminerBernard Nozick

[21] App]. x0; 687,299

Attorney. Agent, or Firm-Head and Johnson

[22] Filed:

[57]

Apr. 18, 1991

ABSTRACT

A demisting system used to remove entrained liquid

[51]

[52]

Int. Cl.- ............................................ .. BOID 45/00

U.S. Cl. .................................................... .. 55/440

droplets from a gas stream employing radially arranged

[58]

Field of Search ......................... . 55/440. 434. 498

serpentine vanes. The radial arrangement of the vanes

provides ?ow paths in which the leading edges of the

[56]

References Cited

serpentine vanes are closer together than the trailing

edges so that a gas stream must undergo a series of

US. PATENT DOCUMENTS

direction and velocity changes. Centrifugal forces act

2,746,562

3.010.537

5/1956

11/1961

Ryall .................................. .. 183/67

Baker et

a1.

.......

t . . ..

3.352.778 11/1967

Brink. Jr. et al. .

210/23

3.813.855

6/1974

Hill et a1. ........ ..

55/440

4.017.275

4/1977

Hodgson et al.

.. 55/1

4.264.4ll

4/1981

Almond ....... ..

. 55/440

4.516.994

5/1985

Kocher ................................ . 55/337

20

'2

\\

to cause liquid droplets to impinge on the surface of the

183/34

vanes. Surface tension holds the liquid on the vanes as it

collects and gravity causes the collected liquid to drain

downward and out of the demisting system.

2 Claims, 3 Drawing Sheets

2e

\

\\\

'0

'2

\\s\\\x\

l6

\

t

I?

l4

We,

.

000

o

/

o

O0 0

no

In

no

u

14

/"~

1-

I.

EH0.'

=

o

:llll l

Z

7 1

l

22

l |

l

26

I

H

\24

I8

'

U.S. Patent

May 12, 1992

Sheet 1 of 3

10

\

\\\

T

\\\\\\\\\\

5,112,375

U.S. Patent

May 12, 1992

Sheet 2 of 3

mm

5,112,375

US. Patent

May 12, 1992

i i

Sheet 3 of 3

66

[I

F 1 1

/8

2 il zll .

4}__

k" __14

62C

so

ill

/34

32

68

5,1 12,375

5,112. 375

directional and velocity changes. Centrifugal forces

RADIAL VANE DEMISTING SYSTEM IN A

SEPARATOR FOR REMOVING ENTRAINED

DROPLETS FRO.\I A GAS STREA.\1

exerted on the heavier liquid cause the entrained liquid

droplets to impinge on the vane surface. Surface tension

holds the liquid onto the vane surface as it collects and

drains downward.

DISCLOSL'RE STATEMENT

SUMMARY OF THE INVENTION

Copies are enclosed ofthe US. patents listed on PTO

Form 144-9. which were found in a patentability search

of the ?eld.

The Ryall patent discloses a device in which com

A series of radially aligned. spaced apart serpentine

demisting vanes are positioned between inner and outer

perforated cylinders to form a demisting element. This

demisting element is contained within a vertical separa

pressed air containing droplets is directed onto a suit

able surface to cause separation ofthe liquid phase from

the gas phase by condensation of the vapors.

tor such as a cylindrical upright vessel. The gas stream

enters the demisting element through an interior perfo

rated cylinder and is directed radially outward through

The Baker et al patent discloses a device wherein

large liquid droplets are removed by centrifugal separa

the demisting vanes. The gas enters the serpentine ar

rangement of vanes where centrifugal force causes the

entrained liquid droplets to impact on the vane surfaces.

tion; smaller droplets are removed by a ?rst ?lter

means: and a baffle containing agglomerating tube as

sembles which separates the device into two chambers

The liquid droplets coalesce and drain into a liquid

reservoir. The dry gas then exits the demisting element

through the outer perforated cylinder and exits the

separator.

and functions to coalesce small liquid droplets into

larger liquid droplets.

The Brink et al patent is directed to novel shaped

?bers used in a ?ltering apparatus and does not disclose

a radial placement of serpentine vanes as disclosed in

the present application.

BRIEF DESCRIPTION OF THE DRAWINGS

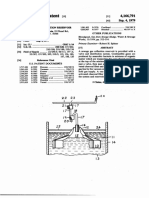

FIG. 1 is an enlarged cross-sectional side view of the

The Hill et al patent discloses serpentine vanes

mounted in parallel. However. this device does not

disclose radial placement and thus does not have a pres

sure drop due to the expanding distance between the

demisting element.

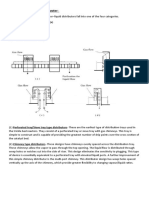

FIG. 2 is a top sectional view of some of the serpen

tine vanes taken along the line 2-2 of FIG. 3 without

the spacing rods being shown.

vanes which causes a decease in gas velocity as dis

closed in the present application.

3O

The Hodgson et a] patent discloses a device contain

ing a vortex tube which uses centrifugal action to throw

'

FIG. 3 is partially cut away side elevational view of

the separator vessel of this disclosure.

FIG. 4 is a bottom view with a partial cut-away sec

tion of the demisting element taking alone the line 44

liquid droplets outwardly to drain into a central cham

ber via a gap between two sections of the vortex tube.

The gas passes upwardly through a ?rst mist extractor .

and then through elongated vertical obstacles where

the liquid droplets are scrubbed out against these sur

faces.

of FIG. 3.

DESCRIPTION OF THE PREFERRED

EMBODIMENT

FIG. 1 illustrates a preferred embodiment of the de

misting system ofthis disclosure. generally indicated by

The Kochner patent discloses a vertical vessel incor

porating a method of mist extraction in which a flat 40 the numeral 8. The demisting system includes an ar

rangement of radial. spaced apart serpentine vanes. The

principle object of this invention is to provide an im

piece of metal twisted into a spiral shape is positioned

inside an inlet tube. This structure causes an incoming

mixture to impinge forcefully against the tube wall. The

proved demisting system for removing entrained liquid

smaller liquid droplets coalesce into larger droplets and

droplets from a gas stream. This novel gas demisting

45 system is well suited for use in vertical separators which

are often preferred in high gas/oil ratio applications or

drop through a ?lter element.

BACKGROUND OF THE DISCLOSURE

1. Field of the Invention

This invention relates to an improved arrangement of

demisting vanes for liquid/gas separators in which the

entrained liquid droplets in va gas stream are removed.

where space limitation might exist. However. this gas

demisting system could be used in other environments

where entrained liquid droplets are desired to be re

moved from a gas stream.

The demisting system 8 includes an inner and an

outer perforated cylinder 10 and 16. Between these

More speci?cally, the liquid droplets impact the demist

cylinders radially arranged, spaced apart serpentine

ing vanes and are drained from the demisting element.

2. Description of the Related Art

In the oil and gas and chemical process industries,

vanes 12 are positioned. Spacing rods 14 hold serpentine

vanes 12 in a spaced relationship. A top plate 20 closes

the top of the demisting system, and a vane support ring

22 supports the vanes in their spaced apart relationship.

Vane support ring 22 has a central opening 24 and at

least one smaller diameter opening 26 spaced from cen

free liquid is separated from pressurized gas in separa

tors" and scrubbers." These devices are pressure con

taining vessels with internal structure designed to pro

mote phase separation. The heart of a separator is the

tral opening 24.

The inner perforated cylinder 10 is spaced from and

encircles the leading edges 28 of serpentine vanes 12.

mist extractor which can be one of many different

kinds.

Some demisting elements of the prior art utilizes ser

pentine vanes arranged in parallel to remove entrained

liquid droplets from a ?owing gas stream. This is re

ferred to as a conventional cross flow separator.

Other similar chevron type demisters are common

within the industry. The demisting elements are ar

ranged so that the gas stream must undergo a series of

The outer perforated cylinder 16 is spaced from and

encircles the trailing edges 30 of serpentine vanes 12.

65

Top plate 20 encloses the top of the demisting system

and extends outward and attaches, such as by welding,

to the outer perforated cylinder 16. Vane support ring

22 is located on the bottom ofthe demisting element and

5.1 12,375

extends outwardfor attachment. such as by welding. to

a vertical tubular wall 32 of separator vessel. generally

indicated by the numeral 34 as shown in FIG. 3.

Attention is now directed to FIG. 3 which illustrates

a side. elevational view ofa separator vessel 34 with the

demisting system 8 installed therein. Vessel 34 has a gas

inlet 50 located on the side thereof. Gas containing

entrained liquid droplets enters vessel 34 and is directed

downwardly on second flat surface 48. Liquid droplets

coalescing on ?rst angled surface 38 either flow down

wardly on the surface by the force of gravity or are

blown to another surface on the serpentine'vanes by the

gas stream. Once the liquid drains down the vane sur

faces. it collects on top of the vane support ring 22 and

?ows to the drain means 18.

As the gas stream flows outward. its average velocity

in a circular manner by a gas divert 62. As gas flows in

is slowed due to the increasing width of the pathways.

a circular manner in the interior of the vessel some of 10 The demisting element's design provides for the gas

the entrained liquid droplets impact with and collect on

the interior ofthe vessel wall. Gravity forces act on the

liquid and it drains into a liquid reservoir 64. The gas

?ows upwards into the demisting system 8 through

opening 24in plate 22. The gas flows radially outwardly

between vanes 12 and out through perforated cylinder

16. The gas. having a substantial portion of entrained

liquid extracted therefrom. exits demisting system 8 as it

passes through the outer perforated cylinder 16 and

passes out of vessel 34 via gas outlet 66 located in the

vessel top.

Attention is now directed to FIG. 2 for more detailed

description ofthe serpentine vane arrangement. FIG. 2

is a top view ofthe serpentine vanes 12. The vane inner

and outer ends 28. 30 are spaced from both the inner

perforated cylinder 10 and the outer perforated cylinder

16. Each serpentine vane 12 is a ?at plate bent to form

integral rib structures. A space between the vanes form

serpentine pathways arranged in a radial pattern. The

resulting pathways have a narrower width near the .

leading edges 28 of the vanes than near the vanes trail

ing edges 30.

Closer examination of the gas flow entails a descrip

tion of one of the pathways. A pathway is the passage

outlined by two adjacent demisting vanes as illustrated

in FIG. 2. Each vane has rib structures formed by a ?rst

?at surface 36. a ?rst angled surface 38 connected to the

?rst ?at surface 36 having a ?rst side 40 and a second

side 42. a second ?at surface 48 connected to the ?rst

angled surface 38. a second angled surface 72 connected

to the second ?at surface 48. and a'third flat surface 74

connected to the second angled surface 72. and so forth.

forming a series of vertical integral rib structures. Each

vane thus has a plurality of rib structures.

stream velocity at trailing edge 30 of serpentine vane 12

to be slow enough to prevent re-entrainment. Re

entrainment occurs when the gas velocity is suf?ciently

high enough to cause some ofthe liquid droplets drain

ing down the serpentine vanes to be blown off the trail

ing edge ofthe serpentine vanes and re-enter the exiting

gas stream.

The liquid removed from the gas stream by the de

misting system exits via opening 26. A drain pipe 68 is

connected to second opening 26in vane support ring 22.

The drain pipe 68 extends from the bottom of vane

support ring 22 into a liquid reservoir 64. The lower end

of drain pipe 68 is submerged in liquid reservoir 64 so

that gas does not by-pass serpentine vanes 12 within

vessel 34. The liquid drains from the vessel via second

outlet 76. Liquid level is controlled to prevent cycling

and is maintained above the bottom of drain pipe 68 but

below horizontal shelf 70. The method of controlling

the liquid level is not illustrated since such is well

known to practitioners in the gas demising art.

A horizontal shelf 70 is located immediately above

liquid reservoir 64. The horizontal shelf has a passage so

that liquid draining from the interior ofthe vessel walls

can drain into liquid reservoir 64. The purpose of shelf

70 is to shield a large part of the surface area of liquid

reservoir 64 to prevent gas entering vessel 34 from

blowing against liquid in the liquid reservoir 64 and to

thereby reduce re-entrained liquid into the gas.

The effectiveness of the demisting system is reduced

when gas velocity passing through serpentine vanes 12

is so high as to tear the fluid ?lm offtrailing edge 30 of

the vanes. causing re-entrainment. Effectiveness is also

reduced at low ?ow rates when very low gas velocity

through the vane pathways produce insuf?cient centrif

In operation of the demisting system gas enters

through central opening 24 in the vane support ring 22.

The gas then passes through openings 52 in the inner

perforated cylinder 10 which are of suf?cient size and

through serpentine vanes 12. Thus, the demisting sys

located on the inner perforated cylinder 10 in such a

tem functions best within upper and lower gas flow rate

ugal forces to cause impingement of the liquid onto

serpentine vanes 12. This allows droplets to channel .

manner as to create a suf?cient pressure drop to evenly 50 limits. The size of a mist extractor is determined as that

distribute the gas stream containing entrained liquid

which will keep the velocity below the magnitude

droplets across serpentine vanes 12.

The gas stream enters the serpentine pathway as illus

trated by arrows 54. The gas is evenly distributed across

produces suf?cient centrifugal force needed for separa

droplets entrained in the gas stream causing the liquid

droplets to impact against ?rst side 40 of ?rst angled

2. Improved Separation Ef?ciency: This disclosure

which produces re-entrainment, but at least that which

tion. If applicable, a turndown limit may be placed on

all the pathways. For illustration purposes the gas ?ow 55 the ?ow capacity to prevent failure due to low gas

velocity.

through one of the pathways will be examined. First.

the gas containing entrained liquid droplets enters the

This disclosure provides a demisting system for use in

pathway located between two leading edges 28 of the

relatively large vertical separators offering these three

?rst flat surfaces 36 oftwo adjacent serpentine vanes 12.

bene?ts over conventional cross flow separators:

The ?rst angled surface 38 causes the gas stream to

1. Physical Size Reduction: This system is able to

suddenly change direction. At each change in direction

reduce vessel length from that required for a con

in the pathway, centrifugal forces act on the liquid

ventional cross ?ow separator.

surface 38.

65

The gas flows around corner 44 forming a low pres

sure zone 46 near second flat surface 48. The liquid

droplets coalesce, and gravity causes the liquid to drain

provides a system that enhances removal of the

smaller liquid droplets. This advantage is due to the

high initial velocity occurring at the leading edges

of the serpentine vanes which decrease as the gas

stream approaches the trailing edges of the vanes.

5,l12,375

The reduced ?ow velocity helps prevent re

entrainment at the vanes trailing edges.

6

bottom end. the cylinders providing an attnular

area therebetween and having a common cylindri

3. Wider Turndown Ratio: The gas flow rate can be

reduced to lower values than in conventional cross

cal axis;

a top plate closing said top ends of both said cylin

ders:

a bottom plate having a central opening therein of

flow designs without causing re-entrainment.

The gas flow area upon which a vane section size is

determined is the area perpendicular to the flow at

trailing edge 30 of the vanes. In a conventional cross

flow or transverse flow pattern. the area of the demist

diameter substantially that of said inner cylinder,

the bottom plate being secured to said bottom ends

of said cylinders. the opening therein providing a

gas inlet passageway into said inner perforated

ing element is obtained by calculating the minimum

allowable inside diameter and then making the vane's

cylinder:

vertical height sufficient to obtain the desired flow areav

a plurality of vertically and radially arranged vanes

In the presented disclosure. the flow area is the cylindri

positioned in said annular area between said inner

and outer perforated cylinders and between said

cal imaginary surface circumscribing vane trailing

edges 30. Therefore the circumferential dimension is

top and bottom plates wherein each vane has a

much greater than the vane width in a conventional

plurality of spaced apart flat inline portions past

cross-?ow design. Therefore. vane height in the radial

placement of this disclosure is much less than the vane

which a gas flow stream flows, the flat inline por

height in a conventional cross flow or transverse design.

This advantage allows the design ofa shorter vessel at 20

reduced cost compared with systems requiring taller

vessels.

The claims and the speci?cation described the inven

tion presented and the terms that are employed in the

claims draw their meaning from the use of such terms in

the speci?cationv The same terms employed in the prior

art may be broader in meaning than speci?cally em

ployed herein. Whenever there is a question between

the broader de?nition of such terms used in the prior art

tions being in a radial plane of said common cylin

drical axis, and a plurality of angled ?at portions

each extending at an angle to and integrally formed

with said inline portions such that entrained drop

lets impact against such angled portions:

the inline and angled portions being repeated be

tween each vane inner end and outer end. the inner

end of each vane being adjacent and spaced from

said inner perforated cylinder providing an open

annular area between said inner perforated cylin

der and said vanes and the outer end of each vane

and the more speci?c use of the terms herein. the more

being adjacent and spaced from said outer perfo

speci?c meaning is meant.

rated cylinder providing an open annular area be

tween said outer perforated cylinder and said

vanes. the vanes providing a plurality of generally

While the invention has been described with a certain

degree of particularity. it is manifest that many changes

radially extending contoured flow paths for gas

passing through said inner perforated cylinder and

may be made in the details of construction and the ar

rangement of components without departing from the

spirit and scope of this disclosure. It is understood that

outwardly through said outer perforated cylinder.

the invention is not limited to the embodiments set forth

the vanes forming surfaces for the collection of

herein for purposes of exempli?cation. but is to be lim

ited only by the scope of the attached claim or claims.

including the full range of equivalency to which each

element thereof is entitled.

What is claimed is:

l. A gas demister for separating entrained droplets

droplets therein which drain downwardly onto

said bottom plate. the bottom plate having a drain

age opening therein through which liquid collected

from entrained droplets passes out ofthe demisting

system.

2. A gas demister according to claim 1 wherein said

from a gas stream. comprising:

drainage opening in said bottom plate communicates

an inner and a concentric outer perforated cylinder. 45 with said open annular area between said outer perfo

the cylinders being upright and of substantially

rated cylinder and said vanes.

identical length. each cylinder having a top and a

1!

50

55

You might also like

- Urea - Aspen TutrialDocument19 pagesUrea - Aspen TutrialAmanda BittencourtNo ratings yet

- Two Phase SeparatorDocument67 pagesTwo Phase SeparatorRaden MasNo ratings yet

- Inlet Nozzles MomentumDocument9 pagesInlet Nozzles Momentum404FileNotFound100% (1)

- Login Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationDocument8 pagesLogin Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationFilipNo ratings yet

- United States PatentDocument5 pagesUnited States PatentPraveen SinghNo ratings yet

- United States PatentDocument6 pagesUnited States PatentAlex IonNo ratings yet

- United States Patent (191: Lown (45) Nov. 11, 1980Document4 pagesUnited States Patent (191: Lown (45) Nov. 11, 1980HamedJamshidiNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Us 2409624Document6 pagesUs 2409624Giovanni BlancoNo ratings yet

- United States Patent: SchwartzmanDocument4 pagesUnited States Patent: SchwartzmanJames LindonNo ratings yet

- United States PatentDocument7 pagesUnited States PatentDouglas TondelloNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,610,957 B2Document8 pagesUlllted States Patent (10) Patent N0.: US 7,610,957 B2lfilippiniNo ratings yet

- Description: US2012085239 (A1) 2012-04-12Document10 pagesDescription: US2012085239 (A1) 2012-04-12nthung114No ratings yet

- Multiple Downcomer Fractional Distillation Tray and ProcessDocument9 pagesMultiple Downcomer Fractional Distillation Tray and Processziz37No ratings yet

- United States Patent: Attorney-Pastoriza and KellyDocument4 pagesUnited States Patent: Attorney-Pastoriza and KellyEnrico FermiNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Description: (OCR Text May Contain Errors)Document3 pagesDescription: (OCR Text May Contain Errors)SachinNo ratings yet

- Us 5472145Document4 pagesUs 5472145mhtofighiNo ratings yet

- United States Patent (191: Allum Et Al. (11) Patent NumberDocument12 pagesUnited States Patent (191: Allum Et Al. (11) Patent NumberdnddownloaderNo ratings yet

- Depósito de Gases ResidualesDocument5 pagesDepósito de Gases ResidualesLuis BejaranoNo ratings yet

- Separador BifásicoDocument42 pagesSeparador BifásicoAldoDeLaCerda100% (1)

- Us 3378330Document5 pagesUs 3378330James LindonNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- US6390148 Valvula de LlenadoDocument8 pagesUS6390148 Valvula de LlenadoFreddy SalinasNo ratings yet

- Oil and Gas SeparationDocument70 pagesOil and Gas SeparationKyle S Jones100% (5)

- Negative Pressure Sanitary Installation Equipped With A Purifier of Gaseous FluidsDocument8 pagesNegative Pressure Sanitary Installation Equipped With A Purifier of Gaseous FluidsCarlos Javier Mendoza MendozaNo ratings yet

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 pagesJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNo ratings yet

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Document3 pagesJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNo ratings yet

- Cardone Industries Et. Al. v. BBB IndustriesDocument22 pagesCardone Industries Et. Al. v. BBB IndustriesPriorSmartNo ratings yet

- ВведениеDocument47 pagesВведениеЕлнур ИкимбаевNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,188,675 B2Document13 pagesUnited States Patent: (12) (10) Patent No.: US 7,188,675 B2lfilippiniNo ratings yet

- United States Court of Appeals Third Circuit.: No. 13825. No. 13826Document10 pagesUnited States Court of Appeals Third Circuit.: No. 13825. No. 13826Scribd Government DocsNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- Journal of The Air Pollution Control AssociationDocument7 pagesJournal of The Air Pollution Control AssociationMhackSahuNo ratings yet

- 01 - Dr. Simon Tseytlin Tseytlin ConsultingDocument16 pages01 - Dr. Simon Tseytlin Tseytlin ConsultingРоман ЖуковNo ratings yet

- United States Patent (191: Larsson Et AlDocument7 pagesUnited States Patent (191: Larsson Et Alarses20026695No ratings yet

- Centrifugal CompressorDocument7 pagesCentrifugal Compressorrohan112358No ratings yet

- Principles of Separation: Incoming Stream Spin Around Reaction Force From The Separator WallDocument10 pagesPrinciples of Separation: Incoming Stream Spin Around Reaction Force From The Separator Wallmohamad alamehNo ratings yet

- Metering Dispenser 1Document9 pagesMetering Dispenser 1Ronaldo SantosNo ratings yet

- CHAPTER 6 Separation & ProcessingDocument72 pagesCHAPTER 6 Separation & Processingfaitholiks841No ratings yet

- In The DrawingsDocument8 pagesIn The DrawingsLalit KumarNo ratings yet

- Catatan Bab 1 (1.5-1.10)Document12 pagesCatatan Bab 1 (1.5-1.10)Aulia RamadhanNo ratings yet

- United States Patent: KiernanDocument12 pagesUnited States Patent: KiernanharisupayNo ratings yet

- Oil& Gas SeparationDocument9 pagesOil& Gas SeparationHomam MohammadNo ratings yet

- 1 s2.0 S0255270107002231 MainDocument10 pages1 s2.0 S0255270107002231 MainJuanIgnacio1No ratings yet

- Umted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997Document6 pagesUmted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997zeichsteinNo ratings yet

- Surface Condenser Eng2Document5 pagesSurface Condenser Eng2MuhammadFikriNo ratings yet

- Trickle Bed Internals (Distribution Plate, Inlet Diffusers)Document9 pagesTrickle Bed Internals (Distribution Plate, Inlet Diffusers)MOHAMMED SHAKEIBNo ratings yet

- Steam EjectorsDocument6 pagesSteam EjectorsmayurjannuNo ratings yet

- Distillation DesignDocument30 pagesDistillation DesignAPURVA SUMAN 18CH10033No ratings yet

- Understanding EjectorDocument6 pagesUnderstanding Ejectormrazamudinishak100% (1)

- Stream Straightener For Fluid Flowing and Dispensing Nozzle: Latest Husky Corporation PatentsDocument9 pagesStream Straightener For Fluid Flowing and Dispensing Nozzle: Latest Husky Corporation PatentsMohib ShamshadNo ratings yet

- Enter Your Search Here: Liquid Ring Pump Lobe PurgeDocument4 pagesEnter Your Search Here: Liquid Ring Pump Lobe PurgeNARAYANA RAO PUPPALANo ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- Hydrodynamics of Gas-Liquid Reactors: Normal Operation and Upset ConditionsFrom EverandHydrodynamics of Gas-Liquid Reactors: Normal Operation and Upset ConditionsNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Information Handling Services, Mon Mar 10 09:50:18 2003Document70 pagesInformation Handling Services, Mon Mar 10 09:50:18 2003WlopezaNo ratings yet

- Section 7Document64 pagesSection 7WlopezaNo ratings yet

- Fire Protection: Cone and A Narrower Inner Cone Combine To Give Full Cone EffectDocument2 pagesFire Protection: Cone and A Narrower Inner Cone Combine To Give Full Cone EffectWlopezaNo ratings yet

- Final Exam 2021Document6 pagesFinal Exam 2021Hoàng NhậtNo ratings yet

- Lewis Structures Shapes Worksheets IntroDocument11 pagesLewis Structures Shapes Worksheets IntromijaggiNo ratings yet

- An Introduction To Inductively Coupled Plasma - Mass Spectrometry (ICP-MS)Document42 pagesAn Introduction To Inductively Coupled Plasma - Mass Spectrometry (ICP-MS)Billy Iberico Castro100% (1)

- Flow Conditioning PLatesDocument8 pagesFlow Conditioning PLatesGeethaNo ratings yet

- Plastic Deformation Capacity of Bolted T-Stubs: Theoretical Analysis and TestingDocument18 pagesPlastic Deformation Capacity of Bolted T-Stubs: Theoretical Analysis and TestingVincenzo PilusoNo ratings yet

- The Norgren Guide To Specifying Pneumatic ActuatorsDocument34 pagesThe Norgren Guide To Specifying Pneumatic ActuatorssridveiNo ratings yet

- 2020 Year 11 Examination Physics Marking Guidelines: Part A AnswerDocument12 pages2020 Year 11 Examination Physics Marking Guidelines: Part A AnswerlEENo ratings yet

- Viscoelastic Vibration Toolbox PDFDocument107 pagesViscoelastic Vibration Toolbox PDFYongliang LiuNo ratings yet

- RCHK DP Physics: Topics 7,13: Atomic, Nuclear & Quantum Physics (HL)Document50 pagesRCHK DP Physics: Topics 7,13: Atomic, Nuclear & Quantum Physics (HL)Denning KWANNo ratings yet

- KinematicsDocument16 pagesKinematicstoxicjjNo ratings yet

- Force and MotionDocument15 pagesForce and MotionTeoh MilayNo ratings yet

- Homework 07 ProblemsDocument6 pagesHomework 07 ProblemsBrianna ChapaNo ratings yet

- 2022 Arxiv M2P2S6Document10 pages2022 Arxiv M2P2S6Arvind MauryaNo ratings yet

- Benzalkonii Chloridum: Benzalkonium ChlorideDocument2 pagesBenzalkonii Chloridum: Benzalkonium ChlorideMulayam Singh YadavNo ratings yet

- Oe4625 Dredge Pumps and Slurry Transport: Vaclav MatousekDocument32 pagesOe4625 Dredge Pumps and Slurry Transport: Vaclav MatouseknawajhaNo ratings yet

- DPT Circle-2: 07/VIII/03/FLA-05/CG-15/A/500Document2 pagesDPT Circle-2: 07/VIII/03/FLA-05/CG-15/A/500VM ViKasNo ratings yet

- NK Um Ar Sir: ClockDocument13 pagesNK Um Ar Sir: ClocktanuNo ratings yet

- Problems in Complex Variable TheoryDocument300 pagesProblems in Complex Variable TheoryfelipeplatziNo ratings yet

- Intermolecular ForcesDocument7 pagesIntermolecular Forcesphils_skoreaNo ratings yet

- Power Screws: ME 147P Machine Design IDocument23 pagesPower Screws: ME 147P Machine Design IJohn Karl De BelenNo ratings yet

- Projectile Motion Lab ReportDocument6 pagesProjectile Motion Lab Reportapi-439198935No ratings yet

- Soil NotesDocument28 pagesSoil Notessunleon31No ratings yet

- J. D. Watson and F. H. C. Crick - Molecular Structure of Nucleic Acids: A Structure For Deoxyribose Nucleic AcidDocument3 pagesJ. D. Watson and F. H. C. Crick - Molecular Structure of Nucleic Acids: A Structure For Deoxyribose Nucleic AcidYopghm698No ratings yet

- Acta Physica Polonica-2000Document8 pagesActa Physica Polonica-2000yayavaramNo ratings yet

- Experiment 102: KinematicsDocument9 pagesExperiment 102: KinematicsJaz DionisioNo ratings yet

- Subject Code: CHM 217 Subject Description: Quantum ChemistryDocument1 pageSubject Code: CHM 217 Subject Description: Quantum ChemistrycfmonarquiaNo ratings yet

- Magnetic Particle InspectionDocument172 pagesMagnetic Particle InspectionRamesh RNo ratings yet

- Gennady v. Nikolaev - Modern Electrodynamics and The Causes of Its Paradoxical Nature. Theories, Experiments, Paradoxes - 2003Document105 pagesGennady v. Nikolaev - Modern Electrodynamics and The Causes of Its Paradoxical Nature. Theories, Experiments, Paradoxes - 2003hanon975% (4)

- Offshore Petroleum Production SystemsDocument48 pagesOffshore Petroleum Production SystemsPungguh Ikhsan PNo ratings yet

- Gurson Model For Ductile FractureDocument27 pagesGurson Model For Ductile Fracturesaded05No ratings yet