Professional Documents

Culture Documents

E-DQ450DBZmanual de Aplicacion de Ajuste de Top Drive2011.8.31

E-DQ450DBZmanual de Aplicacion de Ajuste de Top Drive2011.8.31

Uploaded by

miguelzambrano92Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Schlumb - MWD LWD BasicDocument119 pagesSchlumb - MWD LWD Basicmiguelzambrano92No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Motor C32 CaterpillarDocument5 pagesMotor C32 CaterpillarRamón José Aponte Franco100% (2)

- 6-55. If The Built-Up Beam Is Subjected To An Internal Moment ofDocument5 pages6-55. If The Built-Up Beam Is Subjected To An Internal Moment ofPaula SilvaNo ratings yet

- Component Location Index: Fig. 1: Locating Gauges ComponentsDocument44 pagesComponent Location Index: Fig. 1: Locating Gauges ComponentsFernando Fernandes100% (1)

- A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedDocument8 pagesA E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedMiller Andres Ladino Fernandez100% (1)

- Acerca de MWD and LWDDocument5 pagesAcerca de MWD and LWDmiguelzambrano92No ratings yet

- E-DQ450 DBZmanual+de+aplicacion+de+top+drDocument75 pagesE-DQ450 DBZmanual+de+aplicacion+de+top+drmiguelzambrano92No ratings yet

- Snubbing Superior Service Telefono Snubbing TrinidadDocument4 pagesSnubbing Superior Service Telefono Snubbing Trinidadmiguelzambrano92No ratings yet

- Throttle BulletinDocument6 pagesThrottle BulletinRussell WhearNo ratings yet

- Owner's Manual and Installation Instructions: Air-Cooled Recreational Vehicle GeneratorsDocument52 pagesOwner's Manual and Installation Instructions: Air-Cooled Recreational Vehicle GeneratorsThao Nguyen XuanNo ratings yet

- Chapter 5 Rev 3 Tramming CirucitsDocument4 pagesChapter 5 Rev 3 Tramming CirucitsAnonymous 340A7vnwV1No ratings yet

- MS-01-05.pdf, PFA Tube Fitting & PFA Tubing PDFDocument4 pagesMS-01-05.pdf, PFA Tube Fitting & PFA Tubing PDFBDX Project INSTNo ratings yet

- LWH Novotechnik LWHDocument4 pagesLWH Novotechnik LWHGerardo Espinosa EspinosaNo ratings yet

- Gas Laws 2Document33 pagesGas Laws 2Iris LeuterioNo ratings yet

- Conveyor Support ComponentsDocument14 pagesConveyor Support ComponentsAnonymous IwqK1NlNo ratings yet

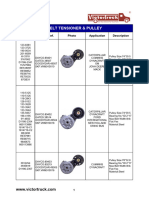

- ΤΕΝΤΟΤΗΡΕΣ ΚΑΤΑΣΚΕΥΑΣΤΩΝDocument49 pagesΤΕΝΤΟΤΗΡΕΣ ΚΑΤΑΣΚΕΥΑΣΤΩΝkanados1973No ratings yet

- Lec 40Document33 pagesLec 40khaledaj1977No ratings yet

- International Standard: Hot-Rolled Steel Sheet of Structural QualityDocument6 pagesInternational Standard: Hot-Rolled Steel Sheet of Structural QualityKalpesh0% (1)

- WorkBee Screw Assembly Manual 2019Document40 pagesWorkBee Screw Assembly Manual 2019CsíkJúliusNo ratings yet

- Specific Latent Heat Power PointDocument14 pagesSpecific Latent Heat Power PointAdamNo ratings yet

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDocument10 pagesVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoNo ratings yet

- Helicoil ThreadDocument4 pagesHelicoil ThreaddesignNo ratings yet

- Lincoln p203 PumpDocument4 pagesLincoln p203 PumphalimNo ratings yet

- Fiat Croma Owner HandbookDocument258 pagesFiat Croma Owner HandbookCharles Neal0% (1)

- Approved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)Document21 pagesApproved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)BeantickNo ratings yet

- Automotive TestingDocument4 pagesAutomotive Testingtahera aqeelNo ratings yet

- O & IO-540 Oper Manual 60297-10 PDFDocument118 pagesO & IO-540 Oper Manual 60297-10 PDFCatalin CiocarlanNo ratings yet

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen69% (16)

- Storing Aircraft TiresDocument2 pagesStoring Aircraft Tiresnosh1983No ratings yet

- Production Engineering I (Meng 3191) : Lecture On: Chip FormationDocument52 pagesProduction Engineering I (Meng 3191) : Lecture On: Chip FormationFasil Getachew100% (1)

- Applications of Newton's Laws: Equilibrium: Physics 513Document13 pagesApplications of Newton's Laws: Equilibrium: Physics 513Hannah GuillermoNo ratings yet

- The Benefits of Utilizing Series Counterflow Variable Speed Screw ChillersDocument11 pagesThe Benefits of Utilizing Series Counterflow Variable Speed Screw ChillersAntonio LebrunNo ratings yet

- Zkke With Ezdr HoistDocument64 pagesZkke With Ezdr HoistAnand PatelNo ratings yet

- Structural Design of Offshore Ships: Offshore Standard DNV-OS-C102Document44 pagesStructural Design of Offshore Ships: Offshore Standard DNV-OS-C102sanwang12345No ratings yet

E-DQ450DBZmanual de Aplicacion de Ajuste de Top Drive2011.8.31

E-DQ450DBZmanual de Aplicacion de Ajuste de Top Drive2011.8.31

Uploaded by

miguelzambrano92Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-DQ450DBZmanual de Aplicacion de Ajuste de Top Drive2011.8.31

E-DQ450DBZmanual de Aplicacion de Ajuste de Top Drive2011.8.31

Uploaded by

miguelzambrano92Copyright:

Available Formats

Contents

1. Safety cautions.................................................................................................................1

1.1 Precautions for installation and dismantling..................................................................1

1.2 Safety operation prompts for electricity........................................................................2

1.3 Safety operation prompts for hydraulic pressure...........................................................2

2. Installation preparation....................................................................................................3

2.1 Personnel allocation.......................................................................................................3

2.2 Checking of device........................................................................................................3

2.3 Installation planning......................................................................................................3

2.4 Well site arrangement....................................................................................................4

3. Installation of top drive and device..................................................................................4

3.1 Installation of electric control room...............................................................................4

3.2 Installation of drillers console......................................................................................4

3.3. Console replacement (in necessity)..............................................................................5

3.4 Installation of cable........................................................................................................5

3.4.1 Installation preparation...............................................................................................5

3.4.2 Installation of mast guide wheel bracket..................................................................10

3.4.3 Connections of top drive auxiliary power and control cable....................................12

3.4.4 Connection of main motor cable for top drive..........................................................16

3.4.5 Connections of 600VAC incoming cable and driller control cable..........................19

3.5 Installation of guide rail and top drive.........................................................................22

3.5.1 Installation of guide rail lifting lug...........................................................................22

3.5.2 Installation of guide rail hanging plate assembly.....................................................23

3.5.3 Installation of guide rail and top drive......................................................................27

3.6 Commissioning of balanced system............................................................................43

3.7 Installation of tilting oil cylinder.................................................................................44

4. Check.............................................................................................................................45

5. Running commissioning................................................................................................45

5.1 Commissioning of guide rail pulley.............................................................................45

5.2 Power transmission of electric control system............................................................45

5.3 Commissioning of main motor fan..............................................................................46

5.4 Commissioning of main motor....................................................................................46

5.5 Commissioning of hydraulic system............................................................................46

II

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

1. Safety cautions

Besides to introduce the contents of main body, this manual has also included the

following contents, such as 'note', 'caution' and 'warns'. They are marked and used for

prompting the possible danger which may cause in operation, the symbolic meanings are

as follows:

Note: Supplement for relevant safety items

Caution: Prompting for accident which may caused

Warning: Prompting for accident which may caused easily

Only qualified and experienced personnel are allowed to conduct installation and

commissioning to top drive unit. Prior to operation please read and follow this

specification and related technical documents carefully.

The personnel who accepted the training about drilling operation and drilling safety

are allowed to conduct the installation, commissioning and close to the system device. Be

sure to keep in mind that uses the proper protective articles such as gloves and safety

wares.

Note: All safety knowledge for operators can not be covered in the manual, so,

it needs to be judged and deal with by operators about safety problems not

involving.

Note: All installations should be carried out as per related standards and

specifications and confirmed by principals in charge of technique and safety.

Caution: Before installation and operation of hydraulic system device, cut off

electric power and compressed air source, close inlet/outlet valves and release the

pressure in accumulator.

Warning: Never try to install and maintain the top drive without professional

knowledge and training; otherwise, it may lead to the personal injury or equipment

accident.

1.1 Precautions for installation and dismantling

As per related regulations, pay attention to following items before installation and

dismantling:

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

1) The entire person on duty must put on safety wears such as gloves and safety

helmet according to the related regulation.

2) Cut off the power before dismantling and never try to operate live-wire work.

3) Fasten the safety belt when working high above the ground, tools and parts

should be fastened by safety rope or put into workbasket to avoid falling.

4) Stop installation and dismantling in strong windy, thundering, rainy and snowy

day.

1.2 Safety operation prompts for electricity

Pay attention to following items before operation of equipment and electrical

system:

1) Read the 'electrical system manual' carefully and knows well the electrical wiring

diagram.

2) Pay attention to protect pressurization grade and insulating property of tools.

3) Cut off the power switch before all operation had finished, and hang the

signboard of 'non-switch on'.

4) Prior to disconnecting electrical connection, verify that wire (cable) and

connecting terminal are properly labeled to ensure proper reconnection.

5) After installation had finished and confirmed qualified, connect power cable to

make sure person and equipment safety.

1.3 Safety operation prompts for hydraulic pressure

Pay attention to following items before operation of equipment and hydraulic

system:

1) Read the 'hydraulic system manual' carefully, and know well the schematic

diagram of hydraulic system.

2) Slowly release system pressure by using load release valve in system, and make

sure no pressure in pipe.

3) Before pipe disassembly, mark all connection positions so as to ensure correct

reconnection.

4) Close the valves in the system before dismantling the hydraulic pipeline, prepare

the proper container, cotton yarn and greasy blockage to avoid hydraulic fluid outflow to

pollute the equipment and environment when open the pipeline.

2

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

5) Due to the temperature of hydraulic device and hydraulic fluid is high, so they

need to be cooled for a long time to recover the normal temperature.

2. Installation preparation

2.1 Personnel allocation

Before top drive installation, assign principals for technique and safety, convene

specialized conference to determine installation technical proposal, make sure all

operators participating in installation have a clear idea of installation plan and relevant

safety precautions.

Any temporary technical alteration at installation field must be confirmed by

principals of technique and safety.

2.2 Checking of device

Check all devices as per related packing lists before top drive installation, ensure all

devices and its attachments are in good condition. All oils and tools etc auxiliary

materials are prepared well to avoid interruption because of insufficient preparation.

2.3 Installation planning

Draw up detailed installation planning before top drive and its assorted device

installation. The working items involved in top drive installation is: before erecting mast,

weld lug top plate under crown block, and then connect lug with lug top plate by bolts to

make sure connection is firmly.

Working procedures

Equipment

allocation

Device placement (electric control Crane truck (>40t)

room, drillers console, guide rail and

top drive etc )

Mast preparation

Crane, air winch

(rotary hose and hanging cables)

Installation of guide rail and top drive Crane truck (>40t)

Air winch

Pipeline connection of top drive

Air winch

System commissioning and operation Drilling rig and

training

auxiliary device

Personnel

allocation

3~5

Expected timeconsuming

3h

3~5

4h

3~5

3h

3~5

2h

4h

16h

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

2.4 Well site arrangement

Think over well site arrangement before top drive and its assorted devices

installation. The detail contents are as follows:

1) Place the electric control room at left &rear side of mast.

2) Put the drillers console into drillers house.

3) Place guide rail and top drive at front side of mast which away from ramp of

3~5m.

3. Installation of top drive and device

3.1 Installation of electric control room

Level up the ground, and then lift it from transport vehicle and place it on leveled

position as per hoisting requirements.

Cable outlet of electric control room should be towards to mast, easy to place cable.

Note: The ground must be leveled up to reduce house deformation and extend

its service life. And make operator feel more comfortable.

Knock earthing wire (coppered steel bar about 1.5m) into ground as per

requirements (the earthing wire must contact with moisture under ground).Connect

earthing wire with one end of earthing cable and make sure earth wire and cable core

connected reliably. The other end of earthing cable connected with electric control room

and fixed firmly by cable connector reliably.

Caution: Ground connection of electric control room must be sufficient and

reliable; general has 2 locations for earthing to make sure safety of personnel and

equipment.

3.2 Installation of drillers console

The drillers console should be placed at the location easy to operate in drillers

house.

Connect air source pipeline, adjust inlet pressure and make it not exceeding

0.8MPa.Adjust pressure reducing valve on drillers console, observe air bleeder at rear of

console and reduce slowly inlet pressure until air bleeder exhausting slightly.

Note: The drillers console adopts positive pressure anti-explosion, fill into

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

clean compressed air and keep a certain pressure (about 200Pa~3000Pa) before

using. Ensure the output pressure of pressure reducing valve accords with

requirements before ventilating.

Caution: Compressed air must be clean and dry, air source treatment device

works normally to avoid the moisture in air affecting the normal working of

electrical system.

Warning: Exceeding moisture or low pressure in compressed air can lead the

system works abnormally.

3.3. Console replacement (in necessity)

Install short console on racking board, the installation position should be easy to

operate and make sure top drive can get through racking board successfully. Pay attention

to fix the mounting holes which at the rear of console reliably and avoid falling.

3.4 Installation of cable

3.4.1 Installation preparation

1) Lay out VFD house as per cable length. And select reasonable and shapely cable

arrangement according to layout of drill floor at well site.

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-1 lay out reasonable cable line

orientation as per well site.

3) Place top drive house as per well site layout.

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-2 hoisting top drive house to reasonable position steadily

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

4) The top drive house should be placed on a smooth foundation.

Fig. 3.4-3 top drive house is placed on smooth ground

5) Hang service loop of top drive as per the height of cable hanging board.

The cable of top drive mainly consists of main cable (main motor cable) and control

cable (auxiliary cable).

During installing the top drive, the cables need to be connected as follows:

Top drive main motor cable: a service loop (26m), a mast cable (41m) and 4

ground cables (30m), 3 sections in all.

8

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Top drive auxiliary power cable: a service loop (61m), a ground cable (30m), 2

sections in all.

Top drive control cable: a service loop (61m), a ground cable (30m), 2 sections in

all.

600VAC incoming cable: three pieces of ground cable (15m), one section in all.

Driller control cable: a control cable (60m), a PROFIBUS-DP cable (60m), one

section in all.

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

3.4.2 Installation of mast guide wheel bracket

The mast guide wheel bracket including two parts: one part is hanging board

assembly for fixing cable flange plates at servicing section of top drive main motor cable

and mast section, and fastening corresponding connectors; the other part is wiring lug

assembly for fixing servicing sections of auxiliary power supply cable and control cable.

The arrangement of mast guide wheel bracket indicates the place of cable guide

wheel bracket. This arrangement is more ideal, the reasons are listed as follows:

When the height of mast is 39.6~44.2m and the top drive is lowered to the

position 22.9~25.9m above the drill floor, the height of bracket shall not make the cable

has strain and damage the cable.

When the top drive dropped on the drill floor, the height of bracket shall not

make the cable lowered on the floor.

The cable from electric control room should get to mast guide wheel bracket

through ground linearly.

And on above the drillers cabin.

Caution: The operation of suspension equipment is lesser at this position. Place

mast guide wheel bracket at this position, probability of cable damage is really tiny.

The place of mast guide wheel bracket is determined by following several factors:

The height of mast

Location and type of locating plate

The length of removable devices (drill string, compensator, sheave and rotating

swivel)

The length of cable, besides otherwise requested.

Location of power unit

Placement of mast guide wheel bracket

1. Lift the mast guide wheel bracket on to drill floor by crane or other hoisting

equipment.

2. Lift the guide wheel bracket to desired location of mast by auxiliary winch (air

winch) or cathead line.

3. Assemble the cable guide wheel bracket onto locating plate.

Caution: The type of locating plate determines installation hardware. Analyze

10

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

and discuss this installation hardware during rig dimensions measuring and before

installation.

1. The top drive cable hanging plate should be installed on the crossbeam of

mast right side and away from drill floor about 23.5m.

2. Install cable hanging plate at the right side of crossbeam of mast, make it

close to back crossbeam as far as possible, and form a safety space away from rotary

hose to prevent cable and rotary hose from rubbing and getting caught in.

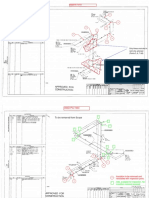

Fig. 3.4-4 cable hanging plate is installed at the right side of mast

(traveling) cable...........................................rotary hose

11

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

3.4.3 Connections of top drive auxiliary power and control cable

There are no breakpoints and trough connections at mast section and traveling

section of auxiliary power and control cable.

Connect all cables in turn from mast end (racking board):

Install mast guide wheel bracket on the mast.

Hang the centre sections of cable traveling section and mast section onto mast

guide wheel bracket, cable connector line without flange plate should be down.

Place ground cable and connect with cable mast section (connect with connector

in electric control room before commissioning and after all installation had been

finished).

One end of cable connecting line without flange plate should connect with

ground cable, and other end connected with cable connector of main body.

At last, test top drive slowly for several times after installation of electric loop for

top drive had been finished, and adjust it properly if necessary.

12

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Ensure the length of traveling control cable, and install cable wiring lug.

13

Fig. 3.4-5 ensure the length of traveling control cable

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

14

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

3.4-6

Fig. 3.4-7 lift wiring lug to drill floor

15

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-8 lift it to preset position by air winch and then fix it

3.4.4 Connection of main motor cable for top drive

Connect all cables in turn from mast end (racking board):

Install mast guide wheel bracket on the mast.

Hang the traveling cable onto mast guide wheel bracket, cable connector line

with longer connector should be down.

Hang the mast cable onto mast guide wheel bracket, place on ground in order

after extending downwards, the end without flange should be down.

Place ground cable and connect with mast cable (connect with connector in

electric control room before commissioning and after all installation had been finished).

Connect one end of traveling cable with mast cable, the other end connected with

cable connector of main body.

16

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-9 lifting main cable

17

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-10 installation and fixation of main cable

18

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-11 butt main cable on cable hanging plate

3.4.5 Connections of 600VAC incoming cable and driller control cable

(1) When connect 600AC incoming cable, electric control room is connected by

quick connector, however, VFD/MCC house adopts quick connector or copper bar to

connect as per actual condition.

(2) Connect driller control cable. The socket joint mode should be carried out during

connecting its control cable and PROFIBUS-DP cable with electric control room end and

drillers control cabinet respectively by quick connector.

Note: During cable connection, pay attention to color code of cable (A-phrase

stands for black, B-phrase is white and C-phrase is red), socket joint mode can be

done when the color is same.

Caution: Connect connectors which connected with electric control room after

devices are installed completely, to avoid occurring electric shock accident during

installation.

19

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Embed ground wire

20

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.4-12 lay out reasonable cable line orientation

Welding lifting lug top plate on crown block (if necessary)

3.5 Installation of guide rail and top drive

Installation procedures of guide rail and top drive are as follows:

Connecting lifting lug

Install hanging plate assembly (after erecting mast)

Iinstall guide rail and top drive

3.4-5

Install fixed beam 1

21

Install fixed beam 2

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

3.5.1 Installation of guide rail lifting lug

If the crown block has no preset hanging padeye matched with top drive, install

guide rail lifting lug at the top of mast during installing guide rail and top drive for first

time.

Weld the lifting lug top plate of guide rail on the crown block bottom beam of mast

top firmly, or fix it on top plate by bolts. Whole weight of guide rail and top drive main

body are borne by bolts. And ensure the welding seam can bear all weight of guide rail

and main body of top drive.

Caution: Pay attention to direction during connecting lifting lug. The correct

direction is shown as follows. If the crown block has already installed the hanging

padeye and the direction is inconsistent, and then adjust it by increasing shackles.

Caution: Magnaflux inspection should be carried out for welding position of

guide rail lifting lug top plate to make sure it firmly and reliably, prevent accidents

during drilling.

22

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-1 suspending padeye of top drive guide rail

3.5.2 Installation of guide rail hanging plate assembly

After welding suspending padeye (in necessity), install bow shackle, hanging plate

and connecting plate to finish the installation of hanging plate assembly.

Adjust the position of connecting pinhole of connecting plate and hanging plate as

per mast height. As shown in Fig. 3.5-2.

23

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-2 pinhole position confirmation

24

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-3 locating bolt installation

Note:

Install

four locating

bolts

and

thread split pins during connecting plate Lifting hanging

plate

connected with hanging plate. Install shear pin

and

safety

pin

into

two

pins

connected

connecting plate with hanging plate. As shown

in Fig. 3.5-3.

After connecting hanging plate, install 2

shackles: grade 35 and grade 30 respectively.

Install hanging plate assembly on the relevant

padeye of crown block before mast lifting.

If it is installed after mast lifting, the

installation

sequence

is

following:

after

installation of connecting plate and hanging plate,

hoist it at rear of drill floor by crane, and lift

hanging plate assembly to the back of traveling

block by cooperation of air winch and traveling

block. And then thread a wire rope with a length

of 4m and a diameter of 20mm into hole at upper end of traveling block, lift both ends of

Fig. 3.5-4 lifting hanging plate assembly

rope rings

at lifting padeye of connecting plate by 2 shackles (3.25T or 4.75T) and make the top of

hanging plate assembly is higher than traveling block about 1m (adjust it as per the height

of operator) to hang it at padeye of crown block through shackle of hanging plate

assembly. As shown in Fig. 3.5-4.

25

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-5 shackle installation sequence

Caution: The small shackle

should be above and big one under

hanging plate assembly. As shown

in Fig. 3.5-5.

3.5.3 Installation of guide rail and

top drive

26

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

1) Move the guide rail and top drive at front of ramp away from it for 1.5~2m.

2) Install section V, guide rail:

a. Lift 2 hoising points of section V, guide rail onto drill floor by crane, as shown in

fig. 3.5-6.

b. Threading 2 connecting pins into top of section V, guide rail, and lift it to the

position of top connecting pin by air winch.

c. and then loose the lifting shackle nearby the upper end of section V, guide rail,

and lift up it by cooperation of air winch and crane.

d. hang the steel wire rope of 5m on lower bail ring of traveling block,

Fig.3.5-6 lifting section V, guide rail

and both ends of wire rope are threaded into relevant lifting holes of guiding plate of

section V, guide rail through shackle of 15T, and make top of section V is higher than

traveling block top about 600mm.The upper end had the function of assisting and

stabilizing section V, guide rail through air winch. As shown in Fig. 3.5-7.

Caution: The model of lifting shackle should be specified one. The installation of top

drive main body and guide rail must be separate when the wire rope lifted the single.

The air winch can be loosened after 2 sections of guide rail had been installed.

27

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-7 section V installation

28

Fig.3.5-8 lift section , guide rail to drill floor

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-9 treading pins between section and section V of guide rail

Fig. 3.5-10 lift up traveling block after treading pins

29

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

3) Install section , guide rail:

a. at first lift section , guide rail onto drill floor, is shown in fig. 3.5-8.

b. adjust section by traveling block, make the centre of connecting padeye

aligned with lower hole of waist-type hole of section , and then thread connecting pins.

As shown in Fig. 3.5-9.

c. loosen the hoisting shackle nearby the upper end of section , lift up traveling

block, at the same time, lift guide rail up through traveling block by crane to make

connecting pins sliding into upper end of waist type hole of section automatically.

Under the action of dead weight, section wiggles, when it swings to a certain position,

locking core locked with locking block, and then automatic positioning of guide rail

achieved. As shown in fig. 3.5-10 and fig. 3.5-11.

30

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-11section locked with section V for positioning with dead weight after swinging

4) Install section, guide rail:

-5

The methods for installing section , andare similar to ones of section .

Fig. 3.5-12 installation of section of guide rail

5) Accomplish guide rail installation:

-5

31

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Lift traveling block after connection of 5 sections of guide rail finished, connect

guide rail section with hanging plate assembly through 2 connecting pins, as shown in

fig. 3.5-13 and Fig. 3.5-14.

Caution: Fix top drive pulley on section of guide rail before guide rail

installation.

Threading pins, shear

pins and safety pins

Fig. 3.5-13 connection between section

V, guide rail and hanging plate

Fig. 3.5-14 guide rail installation completion

32

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Caution: Install shear pin into connecting pins connected between guide rail

and hanging plate.

6) Installation of top drive main body:

Install main body of to drive after guide rail installed.

a. Lift main body of top drive onto drill floor by crane, as shown in Fig. 3.5-15.

Fig. 3.5-15 lift main body of top drive onto drill floor

33

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

b. Lift top drive bail ring by hook via steel wire rope, at same time lift top drive to

vertical position, as shown in fig. 3.5-16.

Fig. 3.5-16 hook up bail ring by hook directly

34

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

c. adjust traveling block height properly, make top drive main body and pulley are at

same height, and then install connecting bolts between them, i.e. lock main body onto

guide rail, is shown in fig. 3.5-17.

35

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-17 accomplish the bolts connection between top drive main body and pulley

Caution: The connecting bolts between main body and pulley of top drive

should be reliable and fastening.

Install oil cylinder connecting elevator link of balanced device on auxiliary hook of

hook. Install connecting cable and rotary hose of balanced device and main body of top

drive, as shown in fig. 3.5-18 and fig. 3.5-19.

Install balanced system before hydraulic system charging. The balanced system

includes two same hydraulic cylinders and its accessories (inc. hydraulic power

accumulator and related pipelines), one end of cylinder connected with bail ring, the

other end connected with hook ear ring, or connected on traveling block directly. The

power accumulator supplies energy by hydraulic oil and keep a preset pressure. Its value

preset by balance circuit of main manifold of hydraulic control system.

36

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Structural drawing of balanced system

Installation of balanced system:

1) Install ear rings.

Connect 2 elevator links of top drive with ear rings at both sides of hook.

2) Extend the piston of balance hydraulic cylinder:

Start top drive, turn mode valve of balance system from RUN to RIG-UP. The

piston rod of hydraulic cylinder extends completely now.

3) Install connecting clasps and pins.

Place the elevator link into connecting clasp groove of piston rod, thread pins, and

then turn the mode of balanced mechanism to RUN.

37

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-18 balanced device installation

38

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-19 installation of connection cable and rotary hose

d. Align the top drive with well bore centre, and install reverse torque beam, as

39

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

shown in fig. 3.5-20.

Fig. 3.5-20 adjust wellbore centre and install reverse torque beam

e. Install upper fixed beam.

40

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

Fig. 3.5-21 installation of upper fixing beam

41

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

f. Add the hydraulic oil for top drive by manual pump after installation.

Fig. 3.5-22 hydraulic oil adding

g. Remove 4 locating pins of top drive pulley and guide rail at last, so the

installation of top drive had been finished.

Caution: Install top drive cable and rotary hose before adjusting the wellbore

centre.

42

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

3.6 Commissioning of balanced system

Caution: Commissioning should be carried out after all parts and components

had been installed.

During working of balance mechanism, oil supply pressure of balanced cylinder is

1600 psi and its load bearing is about 15860kg.The procedures for adjusting load bearing

are following:

1) Turn the mode switch to RUN, spin pressure reducing valve to lowest

counterclockwise.

2) Test the pressure at the location 15.2 (see schematic drawing), the pressure should

be zero.

3) Test the pressure at oil inlet of balance cylinder, observe the top drive position on

hook.

Adjust pressure reducing relief control valve clockwisely, observe pressure gauge at

oil inlet 15.2 (see schematic drawing) until the top drive separated from hook, at this

time, adjust pressure back of 25 psi to make top drive bail ring seat go back to hook.

Test for bouncing

If the function of bouncing runs normally, the load balanced mechanism bore is

15860kg and the pressure at the location 15.2 is about 1800 psi. Increased 200psi

pressure is provided by No. 18 relief valve (schematic drawing).The procedures for

adjusting pressure are as follows:

1) Turn the knob mode to RUN active mode, open bouncing switch, measure

the pressure at the locations of 15.2 and 15.2, adjust relief valve (No. 18) to the lowest

position counterclockwisely.

2) Adjust No. 18 relief valve clockwisely to make the pressure at location 15.2

increased slowly until the bail ring separated from hook (at this time the elevator will

take a stand by top drive).

Caution: Adjust relief valve 18 slowly and make the pressure at the location

15.2 steady.

3.7 Installation of tilting oil cylinder

Link tilt device mainly consists of tilting oil cylinder, elevator link clamp seat, oil

43

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

cylinder supporting plate, oscillating bearing and nipple etc, action of whole mechanism

can be realized by controlling of hydraulic mechanism.

Installation and commissioning of link tilt device:

1) Connect link tilt oil cylinder tail with rotating head.

2) Make tilting oil cylinder extended slowly until to max. position.

3) Fix U-type screw clamp seat onto elevator link, move the top drive elevator link

to the position of 35manually, adjust U-type screw to make the pin hole of U-type clamp

seat aligned with one of link tilt oil cylinder, and then connect and fix them.

4) Retraction should be carried out by operating tilting oil cylinder, observe whether

there are blockages and loosing at all active locations. Retract tilting oil cylinder

completely and measure if caster angle of top drive elevator link is ideal.

44

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

4. Check

After top drive installation, check it thoroughly for commissioning to make sure all

installations had finished as per requirements in manual and all transport fixers had been

removed.

The inspection should be done by technical principal installing top drive.

The inspection should be carried out according to Installation and check list of top

drive device which given in attached list. The check list just has the directive function, so

if there are some contents missing, the inspector should judge and deal with them by

themselves.

Warning: The cable connector must be socketed and connected at marking

position, and then lock it by locking screw to avoid false connection, and cable and

connector damage.

Caution: The cable connector must be connected firmly, there are seal rings in

female joint, so check the seal ring during installation, and then lock them to avoid

false connection, water inflow, or cable and connector damage.

5. Running commissioning

Running commissioning should be carried out after installation inspection without

incorrect installation and omission. It should be processed according to following

procedures strictly.

5.1 Commissioning of guide rail pulley

Lift and lower down the top drive device slowly within guide rail overall length to

observe whether the top drive slides normally, and if the top drive cable and hydraulic

pipeline are normal.

5.2 Power transmission of electric control system

Ensure the sequence of line incoming is correct before starting up, power on the

electric control system, check whether the PLC/MCC system, instrument and indicators

of power system and monitoring system work normally.

5.3 Commissioning of main motor fan

Commissioning of main motor fan should be carried out as per following procedures

45

DQ450DBZ DIRECT DRIVE TOP DRIVE

INSTALLATION AND COMMISSIONING MANUAL

and make sure the fan works normally.

1) Ensure the operation knobs of main motor are in stop position.

2) Start up fan manually to make sure the rotating direction.

3) Check fan delivery.

5.4 Commissioning of main motor

Start main motor, operate it at low speed, observe rotating direction and make sure

the motor rotating direction accord with the direction indicated on the operation panel.

5.5 Commissioning of hydraulic system

Fill oil into oil tank to proper level, make pump housing be full of oil by opening oil

drain valve of hydraulic pump, start hydraulic pump motor, observe whether pump

rotating direction, pressure and turning are normally, and then test all actions as per

functions of hydraulic system one by one to see whether the actions can be achieved.

46

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Schlumb - MWD LWD BasicDocument119 pagesSchlumb - MWD LWD Basicmiguelzambrano92No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Motor C32 CaterpillarDocument5 pagesMotor C32 CaterpillarRamón José Aponte Franco100% (2)

- 6-55. If The Built-Up Beam Is Subjected To An Internal Moment ofDocument5 pages6-55. If The Built-Up Beam Is Subjected To An Internal Moment ofPaula SilvaNo ratings yet

- Component Location Index: Fig. 1: Locating Gauges ComponentsDocument44 pagesComponent Location Index: Fig. 1: Locating Gauges ComponentsFernando Fernandes100% (1)

- A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedDocument8 pagesA E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedMiller Andres Ladino Fernandez100% (1)

- Acerca de MWD and LWDDocument5 pagesAcerca de MWD and LWDmiguelzambrano92No ratings yet

- E-DQ450 DBZmanual+de+aplicacion+de+top+drDocument75 pagesE-DQ450 DBZmanual+de+aplicacion+de+top+drmiguelzambrano92No ratings yet

- Snubbing Superior Service Telefono Snubbing TrinidadDocument4 pagesSnubbing Superior Service Telefono Snubbing Trinidadmiguelzambrano92No ratings yet

- Throttle BulletinDocument6 pagesThrottle BulletinRussell WhearNo ratings yet

- Owner's Manual and Installation Instructions: Air-Cooled Recreational Vehicle GeneratorsDocument52 pagesOwner's Manual and Installation Instructions: Air-Cooled Recreational Vehicle GeneratorsThao Nguyen XuanNo ratings yet

- Chapter 5 Rev 3 Tramming CirucitsDocument4 pagesChapter 5 Rev 3 Tramming CirucitsAnonymous 340A7vnwV1No ratings yet

- MS-01-05.pdf, PFA Tube Fitting & PFA Tubing PDFDocument4 pagesMS-01-05.pdf, PFA Tube Fitting & PFA Tubing PDFBDX Project INSTNo ratings yet

- LWH Novotechnik LWHDocument4 pagesLWH Novotechnik LWHGerardo Espinosa EspinosaNo ratings yet

- Gas Laws 2Document33 pagesGas Laws 2Iris LeuterioNo ratings yet

- Conveyor Support ComponentsDocument14 pagesConveyor Support ComponentsAnonymous IwqK1NlNo ratings yet

- ΤΕΝΤΟΤΗΡΕΣ ΚΑΤΑΣΚΕΥΑΣΤΩΝDocument49 pagesΤΕΝΤΟΤΗΡΕΣ ΚΑΤΑΣΚΕΥΑΣΤΩΝkanados1973No ratings yet

- Lec 40Document33 pagesLec 40khaledaj1977No ratings yet

- International Standard: Hot-Rolled Steel Sheet of Structural QualityDocument6 pagesInternational Standard: Hot-Rolled Steel Sheet of Structural QualityKalpesh0% (1)

- WorkBee Screw Assembly Manual 2019Document40 pagesWorkBee Screw Assembly Manual 2019CsíkJúliusNo ratings yet

- Specific Latent Heat Power PointDocument14 pagesSpecific Latent Heat Power PointAdamNo ratings yet

- Varela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFDocument10 pagesVarela (2011) - Control of Vibration Induce by People Walking On Large Span Composite Floor Decks PDFJosé Francisco AnunciaçãoNo ratings yet

- Helicoil ThreadDocument4 pagesHelicoil ThreaddesignNo ratings yet

- Lincoln p203 PumpDocument4 pagesLincoln p203 PumphalimNo ratings yet

- Fiat Croma Owner HandbookDocument258 pagesFiat Croma Owner HandbookCharles Neal0% (1)

- Approved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)Document21 pagesApproved For Construction: Only Areas Encircled in Red To Be Actioned (Points 5, 6, 7 &8)BeantickNo ratings yet

- Automotive TestingDocument4 pagesAutomotive Testingtahera aqeelNo ratings yet

- O & IO-540 Oper Manual 60297-10 PDFDocument118 pagesO & IO-540 Oper Manual 60297-10 PDFCatalin CiocarlanNo ratings yet

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen69% (16)

- Storing Aircraft TiresDocument2 pagesStoring Aircraft Tiresnosh1983No ratings yet

- Production Engineering I (Meng 3191) : Lecture On: Chip FormationDocument52 pagesProduction Engineering I (Meng 3191) : Lecture On: Chip FormationFasil Getachew100% (1)

- Applications of Newton's Laws: Equilibrium: Physics 513Document13 pagesApplications of Newton's Laws: Equilibrium: Physics 513Hannah GuillermoNo ratings yet

- The Benefits of Utilizing Series Counterflow Variable Speed Screw ChillersDocument11 pagesThe Benefits of Utilizing Series Counterflow Variable Speed Screw ChillersAntonio LebrunNo ratings yet

- Zkke With Ezdr HoistDocument64 pagesZkke With Ezdr HoistAnand PatelNo ratings yet

- Structural Design of Offshore Ships: Offshore Standard DNV-OS-C102Document44 pagesStructural Design of Offshore Ships: Offshore Standard DNV-OS-C102sanwang12345No ratings yet