Professional Documents

Culture Documents

July 3, J 1923. ' 1,461,013: H. D. Hodge

July 3, J 1923. ' 1,461,013: H. D. Hodge

Uploaded by

erwerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

July 3, J 1923. ' 1,461,013: H. D. Hodge

July 3, J 1923. ' 1,461,013: H. D. Hodge

Uploaded by

erwerCopyright:

Available Formats

July 3,j 1923.

'

1,461,013

H. D. HODGE

RIM FIRE AMMUNITI ON

Filed July 15 , 1920

14

'

f4,

1,461,013

Patented July 3, 1923.

*y UNITED STATES PATENT GFFICE.

HOWARD D. HODGE, v01?', NEW YORK, N. Y., ASSIGNOR T0 GEORGE RAMSEY, OF NEW

`

YORK, N. Y.

RIM-FIRE AMMUNITION.

i Application filed July 13, 1920.

To all whom it may concern.'

Be it known that I, HOWARD D. Hoven, a

citizen of the United States, and a resident

of the city of New York, in the county of

5 New York, State of New York, have in

ventedv certain new and useful Improve

ments in Rim-Fire Ammunition, of which

the following is a specification.

This invention relates broadly to ammu

10 nition and more specifically to rim lire cai'

Serial No. 395,898.

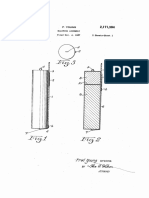

Figure l is a section through a rim iirc

shell illustrating one form of reinforcement

in accordance with my invention.

Figure 2 is an end View of the reinforcing

cup illustrated in Figure l and showing the

55

Hash-conveying grooves.

Figure 3 is a perspective View of the same

(il)

type of reinforcing cup.

Figure 4 illustrates a blank from which

the reinforcing cups may be formed.

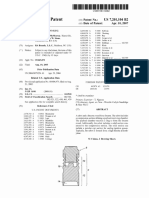

Figure 5 is a view showing a modification

.

' The principal object of the present inven having a series~of openings through which

`tion is to provide reinforcements for a rim the priming is adapted to fire directly into

~

re or similar cartridge to permit use of the powder chamber.

trdges.

15 such cartridges with high pressure powder

65

Figure 6 illustrates the preferred method

of securing the cup in position in a shell.

Figure 7 illustrates a cup of the type

Another object of the present invention

in existing weapons of standard types. _

is to provide reinforcements for n_stand

shown in Figure 5 secured by the method

ard rim re cartridge, without changing the illustrated in Figure 6.

20 compressibility of the rim carrying the

The rim fire type of shell is particularly

priming whereby the cartridge may be used adapted for cartridges of small diameter or

with powder having high ballistic efiiciency, caliber for the reason that the heads of such

75

, and, which use is impossible under present shells are so small as to render the adoption

and use of separate center fire primers inex

A further object of the present invention pedient and expensive. In small calibers the

is to provide reinforcement for a rim fire powder space is small and it is therefore

cartridge to obviate bursting of the rim un desirable that powder of high ballistic etti

der high powder pressures, and whereinthe ciency be used in'this type of ammunition

conditions and methods of construction..

25

where any considerable range is desired.

ness of the rim to the striker or firing pin Experience has shown that where powder

y reinforcement does not affect the sensitive

of the ordinary firearm.

'

pressures in rim fire cartridges have been

increased beyond that attained by black

powder the rims burst under such powder

with a pressure sustaining member adapted pressure long prior to the attaining of pres

to prevent excessive pressure from reaching sures that would be most effective and eiii

the duc-tile portion of the rim carrying the cient. Copper is commonly utilized as the

A still further object of the present 1n

_ vention is to provide a rim fire cartridge

35

priming.

most satisfactory material for rim fire car

90

A still further andL more specific obJect tridges for two reasons-:first:l the easily

of the present invention is to provide a> pres controlled ductility of the copper enables

sure sustaining cup adapted to be seated in

the head of a rim re cartridge to prevent

excessive powder pressure reaching _ the

. priming rim, and also to efficiently direct

40

the maker to select his method so that the

firing pin or striker will crush the primer

rim without severing the crushed portion

from the surrounding metal. Second: be

95

the'flame from the priming composition into cause other metals have been found to cause

_ the powder charge.

deterioration in the most commonly used

Other and further objects of the present and most satisfactory priming' compositions,

invention will in part be obvious and will in namely, those using fulminate of mercury as

part be pointed out hereinafter in the speci one of the constituent ingredients. At

fication by reference to the accompanying tempts to reinforce rim fire cartridges have

5

drawings forming a part of the specifica

heretofore. been made by thickening the

tion and wherein like parts are represented metal. This led to misfires due to the tend

by like characters throughoutthe several ency of the thicker metal to flow the ful-_

figures thereof. `

100

minate priming inwardly without detonat

105

'1,461,013

ing the same when the rim was struck by the

tiring pin, and also due to the fact that theI

lirearxns in use are equippedwith liring

mechanism `capable of crushing, without

cuttingvor breaking, the sensitive soft rim

against the head of this shell in such 'man

ner that the priming composition is con

fined between the'walls of the rim #l and the

side wall of the reinforcing cup 5' so that

when the striker or iii-ing pin compresses the

in common use, but. not capable of crushing rim there 'is no possibility of the priming

the. hea-vier rim.

The same troubles have

70

composition breaking away from the rim

been encountered. by use of stronger metals

and thereby causing a mislire, As shown in -

nate of mercury.

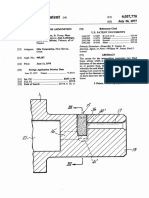

ing opening 6 from which leads a plurality

of radial liring grooves 7 so that `when the

such as brass-and as previously set forth:L Figures l, 2 and 3, the reinforcing cup com

and furthermore brass is one of the metals prises a substantially cylindrical walled cup 75

which causes rapid deterioration of fulmi having the head thereof provided with a lir

,

The present invention overcomes the fore

15

25

35

40

50

55

going di'tliculties by leaving the sensitiveness priming is exploded the flame and incandes

of the priming Vrim entirely undisturbed cent gases travel through the grooves -and

and by providing means to prevent the ex tiring opening into the powder chamber S

cessive powder pressure from reaching the within thel reinforcing cup 5. By this con

weaksensitive rim. This invention is pref struction the flame of the priming is direct

erably carried out by providing the base of ed to the center of one end of the powder

the standard rim fire shell with an interior chamber .along the longitudinal axis thereof

pressure cup constructed to permit the prim so that all the advantages of a center fire

ing to fire the powder charge and to receive cartridge are secured by this rim lire shell.

Aand support the gas pressures developed' by The reinforcing' cup may be formed from

the burning powder and prevent such pres a blank 9, such as is illustrated in Figure

sures from reaching the rim. In practice el, in such manner as to provide the cup `with

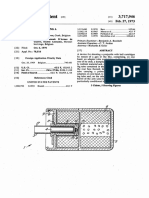

the pressure receiving members may be a plurality of spring segments l0 which tend

formed of suitable cups` preferably copper, to tightly' grip the interior wall'of the shell

which are inserted in the shells, after the l. The preferred method of securing the

rimis` filled with priming composition and retaining cup within the shell is illustrated

which are maintained in position by slightly in Figures G and T and comprises an en

distorting the reinforcing cup to expand a largement, as at 12, formed on the retaining

very slight port-ion thereof1 under the shoul cup and adapted vto engage the shoulder 14

This enlargement

der of the primer rim. This construction adjacent the firing rim

90

96

obviates any possibility of the reinforcing may

compressible

be conveniently

memberformed

l5, such'as

by providing

a paid ot 100

cup leaving the shell when the shell is fired.

The reinforcing cup andthe shell are pref suitable rubber mounted upon the end of a

erably -formed by drawing the cup from a suitable plunger 1G, preferably metal, which

sheet of .metal so as to provide spring seg may be used in seating the reinforcing cups*

ments on the side of the cup, which spring in the shells. 7 hen such a device is inserted

segments exert an outward pressure against in the cup, with the shells seated on a Hrm

the inside wall of the shell when the cup is in anvil, pressure on the plunger 16 will cause

105

position. It has been found in practice with

central fire cartridges that .the opening lead

ing from the primer to the powder _chamber

may be so proportioned, and in practice is,

as to be large enough to permit the?lame

from the primer to penetrate and suitably

11()

the compressible member 16 to expand lat

erally thereby slightly stretching the rein

forcing cup suliiciently to expand the same

under the shoulder 14 as lspecified the shell

heilig retained in- a suitable holder, not

shown,.during this operation.> lVhe're such

ignite the powder charge at the same time interlocking constructions are provided be

to be sm all enough to prevent the combustion tween the reinforcing cup and the shell it

gas pressure from bursting the primer cup. may be desirable to form reinforcing cups

I desire to utilize this principle in connec with continuous side walls, as shown in~ Fig

tion with my ~invention so that-the openings ure 5. and thereby omitting the spring seg

leading from the primeiwwill be su'liciently ments. As a modification of the liring open

large to insure efficient >operation of the ings a series of small holes 17 may be pro

priming at the same time be sufficiently small vided infthe _reinforcing cup and leading

to> prevent the passage of sufficient gas pres fromthe priming directly to the powder

sure to unduly increase back pressure in the chamber 8.v4 ln allcasesit is desirable that

priming rim during the normal firing of the tiring openings be so proportioned in size

the cartridge.

60

85

115

120

as to enablethe priming to effectively ignite

Referring now to the drawings the stand the powder charge but.4 at the saine time be

ard rim fire shell 1 is provided with the usual sufficiently small to prevent excessive back

125

composition priming Q which is secured by pressure acting upon the firing rim, as has

adhesion with the walls of the firingwrim 4. been previously specified. It is'to be noted

The reinforcing cupe lits the interior of that the high pressure in the 'powder cham

65

the standard rim lire shell l and is seated ber to reach the rim must be transmitted

130

1,461,013

through the small openings and through forced tightly into said priming retaining

the annular chamber which was filled by rim by the force of the powder gases.

65

4. In a rim re cartridge, a shell adapted

gas has passed into the priming chamber to to form a suitable powder chamber, a prim

increase the pressure therein up to the burst ing retaining rim of relatively soft thin ma

the priming composition. Before sufficient

ing point of the rim the projectile has left terial, a priming composition within said

10

the muzzle of the gun and the gas in the cup

is released to atmosphere.

Realizing that my invention may be em

bodied in structures other than the specific

construction herein disclosed, it, is my desire

i that the said disclosed construction be con

15

sidered merely as illustrative and not in

the limiting sense.

Having thus described my invention whatl

I claim is:

l. In a rim fire cartridge, a shell adapted

to form a- suitable powder chamber, a prim

rim, and a re-inforcing cup mounted with 70

in the head of said shell and having a por

tion extending within said rim sufficiently

to interlock said cup with said shell and

allow sufHcient space for the priming, said

cup being provided with small flame open 75

ings to permit the priming material to fire

the powder charge within the shell when

the priming is ignited.

5. In a rim fire cartridge, a shell adapted

to form a suitable powder chamber, a prim 80

ing retaining rim of relatively soft thin ma

ing retaining` rim of relatively soft thin terial, a priming composition within said

20

25

material, a priming composition within said

rim, and a re-inforcing cup mounted within

the head of said shell and having a portion

extending within said rim sufficiently to in

terlock said cup with said shell, said- cup

being provided with flame openings to per

mit the priming material to fire the powder

charge within the shell when the priming is

rim, and a re-inforcing cup mounted with

in the head of said shell and having a con

vex beaded portion formed to comprise a 85

small rim extending within said priming

retaining rim sufficiently to interlock said

cup with said shell, said cup being provided

with flame openings to permit the priming

material to fire the powder charge within

ignited, and said openings being sufficiently the shell when the priming is ignited, said

90

small to retard the backward flow of gas convex beaded portion being constructed to

pressure from the burning powder, there

be forced tightly into said priming retain

by preventing excessive powder pressures ing rim by the force of the powder gases.

from reaching the rim of the shell.

6. In a rim fire cartridge, a shell adapted 96

2. In a rim fire cartridge, a shell adapted to form a suitable powder chamber, a prim

,to form a suitable powder chamber, a prim ing retaining' rim of relatively soft thin ma

ing retaining rim of relatively soft thin ma terial, a priming composition within said

terial, a priming composition within said rim, and a re-inforcing cup mounted within

rim, and a re-inforcing cup mounted within the head of said shell and having a por

the head. of said shell and having a por tion formed to comprise a small rim extend

40

45

tion formed to comprise a small rim ex ing within said priming retaining rim suf'

tending within said priming retaining rim ficiently to interlock said cup with said

sufficiently to interlock said cup with said _shell and allow sufficient space for the prim

shell, said cup being provided with flame ing, said cup being provided with small

openings to permit the priming material to flame openings to permit the priming ma

100

105

fire the powder charge within the shell when terial to fire the powder charge within the

the priming is ignited; and said openings shell when the priming is ignited..

being sufficiently small to retard the back

7. In a rim fire cartridge` a shell adapted

ward flow of gas pressure from the burn

to form a suitable powder' chamber, a prim

ing powder, thereby preventing excessive ing retaining rim of relatively soft thin ma

110

powder pressures from reaching the rim of' terial, a priming composition within said

50~

the shell.

rim, and a re-inforcing cup mounted within

3. In a rim fire cartridge, a shell adapted the head of said shell and having a convex

to form a suitable powder chamber, a prim beaded portion formed to comprise a small 115

ing retaining rim of relatively soft thin ma rim extending within said priming retain

terial, a priming composition within said ing rim sufficiently to interlock said cup with

rim, and a re-inforcing cup mounted with

in the head of said shell and having a con

said shell and allow sufficient space for the

priming, said cup being provided with

vex beaded portion extending within said small flame openings to permit the priming

rim sufficiently to interlock said cup with material to fire the powder charge within

said shell` said cup being provided with the shell when the priming is ignited. said

60

flame openings to permit the priming ma convex beaded portion being constructed to

terial to fire the powder charge within the be forced tightly into said priming retain

shell when the priming is ignited, said con ing rim by the force of the powder gases.

vex beaded portion being constructed to be

HOWARD D. HODGE.

120

You might also like

- Carl-Gustaf M4 Training MhowDocument134 pagesCarl-Gustaf M4 Training Mhowwmsenevirathneuk100% (1)

- Gundrilling HandbookDocument49 pagesGundrilling HandbookJealse100% (3)

- Gundrilling HandbookDocument49 pagesGundrilling HandbookBooks for the lot100% (1)

- Module 2 in Forensic BallisticsDocument9 pagesModule 2 in Forensic Ballisticscriminologyalliance100% (2)

- Weaponeer Forums - STEN MK II BuildDocument221 pagesWeaponeer Forums - STEN MK II Buildcrbspoa93% (15)

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- Cement BasketDocument4 pagesCement Basketराजकुमार यादवNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- Umted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997Document6 pagesUmted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997zeichsteinNo ratings yet

- United States Patent (10) Patent No.: US 8,251,371 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNo ratings yet

- United States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985Document5 pagesUnited States Patent (19) : Wood (45) Date of Patent: Jan. 8, 1985mohammadreza91No ratings yet

- LLLLLLLLLLL: United States Patent (191Document9 pagesLLLLLLLLLLL: United States Patent (191Mark EdowaiNo ratings yet

- US898276Document5 pagesUS898276Jacob LukaNo ratings yet

- United States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993Document13 pagesUnited States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993fghdfjerNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- 'Fr'Edlyqqj/G' Inventor.: Aug. 29, 1939. F - Young 2,171,384Document5 pages'Fr'Edlyqqj/G' Inventor.: Aug. 29, 1939. F - Young 2,171,384kahj juliNo ratings yet

- Us 5153374Document5 pagesUs 5153374ererNo ratings yet

- Us7201104 PDFDocument7 pagesUs7201104 PDFThamuze UlfrssonNo ratings yet

- Us 4394836Document4 pagesUs 4394836ererNo ratings yet

- Bassick Mfg. Co. v. R. M. Hollingshead Co. Rogers v. Alemite Corporation, 298 U.S. 415 (1936)Document8 pagesBassick Mfg. Co. v. R. M. Hollingshead Co. Rogers v. Alemite Corporation, 298 U.S. 415 (1936)Scribd Government DocsNo ratings yet

- Fabrication of Steel PipeworkDocument10 pagesFabrication of Steel PipeworkjoseritoNo ratings yet

- Analysis of Reasons Causing Riser Feeding FailureDocument8 pagesAnalysis of Reasons Causing Riser Feeding Failuremarcotulio123No ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- Freeman v. AsmusDocument11 pagesFreeman v. AsmusScribd Government DocsNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- A New Retievables Wire Line Cemnting ToolDocument8 pagesA New Retievables Wire Line Cemnting ToolPutri MarantikaNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- 11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555Document5 pages11111111mumnlllgglotgggglgggggnn - : United States Patent (19) (11) Patent Number: 5,613,555mohammadreza91No ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Document23 pagesUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuNo ratings yet

- Sept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1Document6 pagesSept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1kikkuri13No ratings yet

- Us 2345069Document4 pagesUs 234506916f628aNo ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- 6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061Document4 pages6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061mohamed hemdanNo ratings yet

- Foundry Theory N1 Book 2Document168 pagesFoundry Theory N1 Book 2dakalo.tshivhase1No ratings yet

- Chanard Incendiary 1919 US1306747Document6 pagesChanard Incendiary 1919 US1306747Dreamk990No ratings yet

- Us4540334 PDFDocument9 pagesUs4540334 PDFJigar SutharNo ratings yet

- Deç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946Document3 pagesDeç. 7, 1948. F, A, Gaspar ' - 2,455,469: Filed Oct. 1, 1946david19775891No ratings yet

- Sept. 24, 1929. W. Siders: Filed Nov. 5. 1925Document3 pagesSept. 24, 1929. W. Siders: Filed Nov. 5. 1925monem2014No ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Us2181099 PDFDocument4 pagesUs2181099 PDFAt ChecoNo ratings yet

- Us6517602 PDFDocument18 pagesUs6517602 PDFEidelsayedNo ratings yet

- Patented Dec. I7, I90".: ' WH NesseszDocument3 pagesPatented Dec. I7, I90".: ' WH NesseszPayal MinochaNo ratings yet

- Dec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LDocument5 pagesDec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LcheesewizzNo ratings yet

- Neral Capítulo.9 PDFDocument24 pagesNeral Capítulo.9 PDFtrinoNo ratings yet

- R. Meredith, U.S. Patent 2,274,631Document5 pagesR. Meredith, U.S. Patent 2,274,631Erivaldo ConstantNo ratings yet

- Us 4037770Document3 pagesUs 4037770ererNo ratings yet

- MFPW PE - 002 & PE - 007Document16 pagesMFPW PE - 002 & PE - 0072K18/PE/007 ANIKET GUPTANo ratings yet

- Cementing Patent 2Document3 pagesCementing Patent 2Lara CitlalliNo ratings yet

- Sam W Hoke Torch PatentDocument5 pagesSam W Hoke Torch PatentRichard.nlNo ratings yet

- Olin BWP Primer Patent - US3062146Document5 pagesOlin BWP Primer Patent - US3062146orpheus1972No ratings yet

- 'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679Document5 pages'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679ShameekaNo ratings yet

- 枪炮声抑制器 PDFDocument11 pages枪炮声抑制器 PDFJin SongNo ratings yet

- Annular Mill1Document4 pagesAnnular Mill1rahulNo ratings yet

- (A Oe Émgoueogmo: +2 (ll/l4fl2Document6 pages(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNo ratings yet

- Cumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2Document3 pagesCumblned Muffle and Mud Guard For Mgtor Ve'Rhbles.: Patented July 22, 2%2monem2014No ratings yet

- Us 3407511Document5 pagesUs 3407511AhmadmartakNo ratings yet

- Us2475875 PDFDocument4 pagesUs2475875 PDFchecolonoskiNo ratings yet

- Us 3717946Document4 pagesUs 3717946ererNo ratings yet

- Patented Oct. 18, 1932: Black Powder Compositions by Incorporating Ing Co-Pending Application of Bringing AboutDocument2 pagesPatented Oct. 18, 1932: Black Powder Compositions by Incorporating Ing Co-Pending Application of Bringing AbouterwerNo ratings yet

- Adulph Frank, of Charlqtteh: Lilo. 792,511., Tetented (Limo 13, FigiltinDocument2 pagesAdulph Frank, of Charlqtteh: Lilo. 792,511., Tetented (Limo 13, FigiltinerwerNo ratings yet

- ,united States Patent Office: Patented Feb. 7, 1950Document4 pages,united States Patent Office: Patented Feb. 7, 1950erwerNo ratings yet

- Us 2700603Document1 pageUs 2700603erwerNo ratings yet

- Us 4570540Document3 pagesUs 4570540erwerNo ratings yet

- Chum/W: April 8, 194?. H. C. HebardDocument3 pagesChum/W: April 8, 194?. H. C. HebarderwerNo ratings yet

- How Do Forensic Investigators Analyze Ballistic Evidence?Document22 pagesHow Do Forensic Investigators Analyze Ballistic Evidence?prop andreomsNo ratings yet

- Cybergun Airsoft Catalog 2023Document83 pagesCybergun Airsoft Catalog 2023Adtime tama100% (1)

- US6662726Document17 pagesUS6662726Savage MasaruNo ratings yet

- HRG Instrumen OrhoDocument413 pagesHRG Instrumen Orhogus_margono-1100% (1)

- 556x45NATO Barrel Length Studies - PDF PDFDocument4 pages556x45NATO Barrel Length Studies - PDF PDFDavidArcherNo ratings yet

- Rang Boster No Leg Set Edit FFDocument11 pagesRang Boster No Leg Set Edit FFikangfadli190% (1)

- Accutek At25 At32 At380Document4 pagesAccutek At25 At32 At380Justin0% (1)

- 6 Rifle MarksmanshipDocument25 pages6 Rifle MarksmanshipAngelica TañedoNo ratings yet

- Cheytac M200 Manual (Airsoft)Document16 pagesCheytac M200 Manual (Airsoft)HengkiPram0% (1)

- Sail Hunting Fall Winter 2011Document42 pagesSail Hunting Fall Winter 2011Peter RuigrokNo ratings yet

- Sig Sauer M17XDocument5 pagesSig Sauer M17XTwobirds Flying PublicationsNo ratings yet

- Tabela Recarga LymanDocument27 pagesTabela Recarga LymanmarcioNo ratings yet

- Magnum Research 1722Document17 pagesMagnum Research 1722Paul Zitterbart100% (1)

- z299 2 Ansi Saami ShotshellDocument121 pagesz299 2 Ansi Saami ShotshelljrnelsonNo ratings yet

- New M39Document20 pagesNew M39Justin Lane Hayes100% (2)

- Ammunition Handbook Ver 6 2021Document189 pagesAmmunition Handbook Ver 6 2021ibrahim sugar100% (3)

- 5e1db40f5caa2749a7501267 - STS - PROTECH - Gun Mount BrochureDocument2 pages5e1db40f5caa2749a7501267 - STS - PROTECH - Gun Mount BrochurePanthep PattongNo ratings yet

- 11 2019 Product BrochureDocument2 pages11 2019 Product BrochureTapes AndreiNo ratings yet

- GunnerDocument11 pagesGunnerBubba GaunceNo ratings yet

- The Rifleman SeriesDocument54 pagesThe Rifleman SeriesJoshua Gardner100% (7)

- Sportsmatch AOP 55 Scope MountDocument1 pageSportsmatch AOP 55 Scope MountRafał DzióbNo ratings yet

- Marcas de Bases PDFDocument195 pagesMarcas de Bases PDFManolo BermeoNo ratings yet

- STRONG-LG 20 - STRONG - The High-End Wooden Stock Air Rifle! - ManualDocument13 pagesSTRONG-LG 20 - STRONG - The High-End Wooden Stock Air Rifle! - Manualapi-3695814No ratings yet

- M240B Machine GunDocument4 pagesM240B Machine GunkaseykozNo ratings yet

- FIREARMDocument6 pagesFIREARMMicah JyraNo ratings yet

- Hornady 168grain A-Max TAP PRECİSİONDocument3 pagesHornady 168grain A-Max TAP PRECİSİONfcaskiiNo ratings yet

- M 3Document47 pagesM 3Fábio Santana SantosNo ratings yet