Professional Documents

Culture Documents

Green Chemistry

Green Chemistry

Uploaded by

Luis Francisco Pérez De LunaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Green Chemistry

Green Chemistry

Uploaded by

Luis Francisco Pérez De LunaCopyright:

Available Formats

12 PRINCIPLES OF GREEN CHEMISTRY

Developed by Paul Anastas and John Warner*, the following list outlines an early conception of what would

make a greener chemical, process, or product.

1

Prevention

It is better to prevent waste than to treat or clean up waste after it has been created.

Atom Economy

Synthetic methods should be designed to maximize the incorporation of all materials used in the

process into the final product.

Less Hazardous Chemical Syntheses

Wherever practicable, synthetic methods should be designed to use and generate substances that

possess little or no toxicity to human health and the environment.

Designing Safer Chemicals

Chemical products should be designed to affect their desired function while minimizing their

toxicity.

Safer Solvents and Auxiliaries

The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made

unnecessary wherever possible and innocuous when used.

Design for Energy Efficiency

Energy requirements of chemical processes should be recognized for their environmental and

economic impacts and should be minimized. If possible, synthetic methods should be conducted at

ambient temperature and pressure.

Use of Renewable Feedstocks

A raw material or feedstock should be renewable rather than depleting whenever technically and

economically practicable.

Reduce Derivatives

Unnecessary derivatization (use of blocking groups, protection/ deprotection, temporary

modification of physical/chemical processes) should be minimized or avoided if possible, because

such steps require additional reagents and can generate waste.

Catalysis

Catalytic reagents (as selective as possible) are superior to stoichiometric reagents.

Design for Degradation

Chemical products should be designed so that at the end of their function they break down into

innocuous degradation products and do not persist in the environment.

Real-time analysis for Pollution Prevention

Analytical methodologies need to be further developed to allow for real-time, in-process monitoring

and control prior to the formation of hazardous substances.

Inherently Safer Chemistry for Accident Prevention

Substances and the form of a substance used in a chemical process should be chosen to minimize

the potential for chemical accidents, including releases, explosions, and fires.

*Anastas, P. T.; Warner, J. C. Green Chemistry: Theory and Practice, Oxford University Press: New York, 1998,

p.30. By permission of Oxford University Press

WHAT IS GREEN CHEMISTRY?

The concept of greening chemistry is a relatively new idea which developed in the business and regulatory

communities as a natural evolution of pollution prevention initiatives. In our efforts to improve crop protection,

commercial products, and medicines, we also caused unintended harm to our planet and humans.

By the mid-20th century, some of the long-term negative effects of these advancements could not be ignored.

Pollution choked many of the world's waterways and acid rain deteriorated forest health. There were measurable

holes in the earth's ozone. Some chemicals in common use were suspected of causing or directly linked to

human cancer and other adverse human and environmental health outcomes. Many governments began to

regulate the generation and disposal of industrial wastes and emissions. The United States formed the

Environmental Protection Agency (EPA) in 1970, which was charged with protecting human and environmental

health through setting and enforcing environmental regulations.

Green chemistry takes the EPA's mandate a step further and creates a new reality for chemistry and engineering

by asking chemists and engineers to design chemicals, chemical processes and commercial products in a way

that, at the very least, avoids the creation of toxics and waste.

Green Chemistry is not politics, green Chemistry is not a public relations ploy, green chemistry is not a pipe

dream.

We are able to develop chemical processes and earth-friendly products that will prevent pollution in the first

place. Through the practice of green chemistry, we can create alternatives to hazardous substances we use as our

source materials. We can design chemical processes that reduce waste and reduce demand on diminishing

resources. We can employ processes that use smaller amounts of energy. We can do all of this and still maintain

economic growth and opportunities while providing affordable products and services to a growing world

population.

This is a field open for innovation, new ideas, and revolutionary progress, this is the future of chemistry.

This is green chemistry.

WHAT IS GREEN CHEMISTRY?

Green chemistry is a way to design chemicals and processes so they are safer, healthier, and more sustainable. It seeks to

prevent pollution at its source by creating chemicals that are not toxic. This eliminates exposure to toxic chemicals for

workers, consumers, and the environment. It also encourages using renewable feedstock, reducing energy use, and

optimizing other factors that are better for human health and the environment.

Green chemistry has been around for decades. In 1998, Paul Anastas and John Warner published twelve principles of green

chemistry, which created goals for chemists and manufacturers to consider when they create new chemicals or processes.

MOVING TOWARDS GREEN CHEMISTRY

While it would be ideal for all chemicals to be created using the green chemistry principles, it will not happen overnight.

Some existing products and processes already use many green chemistry principles but others use few or none. If green

chemistry principles are incorporated into both existing and new product designs, we will greatly reduce the impacts

chemicals have on human health and the environment.

You might also like

- The CIMA Advanced Diploma in Islamic Finance (CADIF)Document406 pagesThe CIMA Advanced Diploma in Islamic Finance (CADIF)digitalbooks100% (3)

- Demand Worksheet PDFDocument2 pagesDemand Worksheet PDFDipti NagarNo ratings yet

- MT 304 - Gas Liquid Absorption: CL 333 Chemical Engineering Lab-III (2021)Document13 pagesMT 304 - Gas Liquid Absorption: CL 333 Chemical Engineering Lab-III (2021)Shivansh SinghNo ratings yet

- Polymer Handbook 4th EditionDocument1 pagePolymer Handbook 4th EditionJanika KetratnkulNo ratings yet

- Corrosive SoilDocument25 pagesCorrosive Soilsherasiya sherasiyaNo ratings yet

- BT 0413 BioseparationTechnologyLaboratoryDocument21 pagesBT 0413 BioseparationTechnologyLaboratoryvijaygovindarajNo ratings yet

- BIG3 LLC v. Qatar Investment AuthorityDocument33 pagesBIG3 LLC v. Qatar Investment AuthorityBeverly TranNo ratings yet

- Progress 1Document8 pagesProgress 1Nguyên NguyễnNo ratings yet

- Lesson 3 AssignmentDocument5 pagesLesson 3 AssignmentUmesh SharmaNo ratings yet

- 12 Years A SlaveDocument2 pages12 Years A SlaveismanNo ratings yet

- QCVN 09-2008 BTNMT National Technical Regulation On Underground Water QualityDocument8 pagesQCVN 09-2008 BTNMT National Technical Regulation On Underground Water QualitytungNo ratings yet

- C H O + A O + B NH C C H NO + D H O+eCO: InstructionsDocument4 pagesC H O + A O + B NH C C H NO + D H O+eCO: InstructionsJohn Paul Jandayan33% (3)

- Mass Transfer QuizzesDocument10 pagesMass Transfer QuizzesNate JamesNo ratings yet

- Lectura - EnzimasDocument13 pagesLectura - EnzimasMirella Bravo Benites0% (1)

- Assignment 2 3Document3 pagesAssignment 2 3Sandeep Challa0% (1)

- Langmuir Adsorption IsothermDocument2 pagesLangmuir Adsorption IsothermaliNo ratings yet

- CP302 MassTransfer 02 OKDocument38 pagesCP302 MassTransfer 02 OKDeneshVijayNo ratings yet

- HimmelblauDocument17 pagesHimmelblauadilla nitaaNo ratings yet

- Modern Theory of CorrosionDocument98 pagesModern Theory of CorrosionMujahid HaddadNo ratings yet

- QB PDFDocument18 pagesQB PDFShivani0% (1)

- Introduction of Bet Theory:: Brunauer-Emmett-Teller (BET) Theory Aims To Explain TheDocument10 pagesIntroduction of Bet Theory:: Brunauer-Emmett-Teller (BET) Theory Aims To Explain TheRajeshKumarJainNo ratings yet

- Syllabus For Master of Science in Chemistry: The Assam Kaziranga University, JorhatDocument52 pagesSyllabus For Master of Science in Chemistry: The Assam Kaziranga University, JorhatDibyajyoti SaikiaNo ratings yet

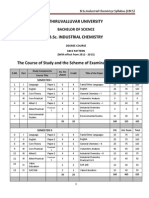

- B.sc. Industrial ChemistryDocument79 pagesB.sc. Industrial ChemistryOmar Abd Elsalam0% (1)

- A General Review of Thermodynamic Concepts: KMU220 Chemical Engineering Thermodynamics IDocument24 pagesA General Review of Thermodynamic Concepts: KMU220 Chemical Engineering Thermodynamics ISaud Hashmi100% (1)

- Chapter 4 - Membrane CharacterizationDocument17 pagesChapter 4 - Membrane CharacterizationNurfarahain ZolkeflyNo ratings yet

- Chemical Kinetics PDFDocument162 pagesChemical Kinetics PDFsharmimiameerasanadyNo ratings yet

- Process Development For Metal SoapsDocument98 pagesProcess Development For Metal SoapsAlex RichardNo ratings yet

- Reaction Kinetic Studies. Catalytic Dehydrogenation of Sec-Butyl Alcohol To Methyl Ethyl KetoneDocument6 pagesReaction Kinetic Studies. Catalytic Dehydrogenation of Sec-Butyl Alcohol To Methyl Ethyl Ketonehaniehkosar0% (1)

- Lecture - Young-Laplace and Kelvin EquationsDocument8 pagesLecture - Young-Laplace and Kelvin EquationsquoctriNo ratings yet

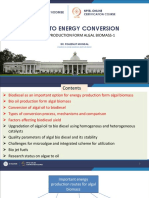

- 39 Algal Oil Production 1Document21 pages39 Algal Oil Production 1Sai Srivathsava UdathuNo ratings yet

- Green SolventsDocument10 pagesGreen Solventsdchy100% (1)

- FTIRDocument6 pagesFTIRAnubhav ShuklaNo ratings yet

- Industrial ChemistryDocument168 pagesIndustrial ChemistryAbdullah Sabry AzzamNo ratings yet

- A Complete Review On Effluent Testing and Treatment in Pharmaceutical IndustryDocument14 pagesA Complete Review On Effluent Testing and Treatment in Pharmaceutical IndustrysallurajNo ratings yet

- 08 Monoglyceride eDocument14 pages08 Monoglyceride eAlf FloNo ratings yet

- Ethylene Glycol PFD ProcessDocument1 pageEthylene Glycol PFD ProcessKim HanaNo ratings yet

- IITB Chemical Engineering CarriculumDocument20 pagesIITB Chemical Engineering CarriculumpuneetNo ratings yet

- 13 Reaction Kinetics (S)Document32 pages13 Reaction Kinetics (S)Mr TanNo ratings yet

- Mass Transfer OperationsDocument77 pagesMass Transfer OperationsNhã UyênNo ratings yet

- Unit Operations Tutorial 2015-2016Document13 pagesUnit Operations Tutorial 2015-2016hazimraad0% (1)

- Adsorption SlidesDocument24 pagesAdsorption Slidesdivyachauhan050No ratings yet

- Saperation 1: Ass. Prof. Adnan Ripin Faculty of Chemical and Energy Engineering Universiti Teknologi MalaysiaDocument79 pagesSaperation 1: Ass. Prof. Adnan Ripin Faculty of Chemical and Energy Engineering Universiti Teknologi MalaysiaNurul AinNo ratings yet

- Principle of Mass Transfer P1 PDFDocument77 pagesPrinciple of Mass Transfer P1 PDFSahar NasrallahNo ratings yet

- Lab 3Document16 pagesLab 3Paen Zulkifli100% (1)

- Lab Report 10 Organic Chemistry UVA 2411Document6 pagesLab Report 10 Organic Chemistry UVA 2411Alia LieNo ratings yet

- An Industrial Wastewater Contains 10 MG L ChlorophenolDocument5 pagesAn Industrial Wastewater Contains 10 MG L ChlorophenolsumitNo ratings yet

- Mechanical Biological & Chemical (MBC) Treatment Plant: Collection of Waste WaterDocument4 pagesMechanical Biological & Chemical (MBC) Treatment Plant: Collection of Waste Watervinay ChalagundlaNo ratings yet

- CHAPTER 4 Energy BalanceDocument35 pagesCHAPTER 4 Energy BalanceZafirahAhmadFauziNo ratings yet

- Stoichiometry of Microbial Growth and Product FormationDocument30 pagesStoichiometry of Microbial Growth and Product FormationMark GerardNo ratings yet

- Environmental Chemistry PDFDocument3 pagesEnvironmental Chemistry PDFRijit ChakrabortyNo ratings yet

- Report Compiled 1Document14 pagesReport Compiled 1Opeyemi KehindeNo ratings yet

- Chapter 3. Nano Technology in Industrial Wastewaters TreatmentDocument121 pagesChapter 3. Nano Technology in Industrial Wastewaters TreatmentSophie LvNo ratings yet

- ChBE3210 Spring2007 Exam2Document6 pagesChBE3210 Spring2007 Exam2Abishek KasturiNo ratings yet

- Liquid-Liquid Extraction Spray ColumnsDocument10 pagesLiquid-Liquid Extraction Spray Columnsalihamid hamediNo ratings yet

- Research 2 Duplex Pump: GradeDocument10 pagesResearch 2 Duplex Pump: GradeAli Requiso MahmudNo ratings yet

- Interphase Mass TransferDocument58 pagesInterphase Mass TransferParitosh Chaudhary0% (1)

- Material Safety Data Sheet Dibutyl PhthalateDocument4 pagesMaterial Safety Data Sheet Dibutyl PhthalateKameliza Saranghe Choi-siwon SujuelfNo ratings yet

- Functional and Physical Properties of Polymer NanocompositesFrom EverandFunctional and Physical Properties of Polymer NanocompositesAravind DasariNo ratings yet

- Case Study: Tubcloud Migration To Nextcloud 11Document7 pagesCase Study: Tubcloud Migration To Nextcloud 11vicenteNo ratings yet

- MC 2022-2306Document45 pagesMC 2022-2306Meynard OrtuaNo ratings yet

- U3 l5 4 Handout 4 Descriptions of Nomadic Peoples in Written RecordsDocument3 pagesU3 l5 4 Handout 4 Descriptions of Nomadic Peoples in Written Recordsapi-134134588No ratings yet

- Chapter1 FinalDocument21 pagesChapter1 FinalGelo MoralNo ratings yet

- BPMIndustryFramework V5 PDFDocument27 pagesBPMIndustryFramework V5 PDFDaveNo ratings yet

- Deuteronomy 26:1-11 Why Bother With Worship? IntroductionDocument3 pagesDeuteronomy 26:1-11 Why Bother With Worship? Introductionapi-26086913100% (1)

- Senoir Project-IrelandDocument12 pagesSenoir Project-Irelandapi-317313323No ratings yet

- Bitc Investor HandbookDocument118 pagesBitc Investor HandbookVishal AgarwalNo ratings yet

- Birla Organization StructureDocument19 pagesBirla Organization StructureSouravsapPPNo ratings yet

- Educ 6 Module 1Document12 pagesEduc 6 Module 1Christian Jay Ramos MarcosNo ratings yet

- 21st Outline Week 5Document6 pages21st Outline Week 5JochelleNo ratings yet

- Soc. of Clim. Ch. Soc. of Clim. CHDocument4 pagesSoc. of Clim. Ch. Soc. of Clim. CHUtkarsh KhannaNo ratings yet

- MythologyDocument6 pagesMythologysharlymarieNo ratings yet

- The Potency and Future of Indonesia'S Natural Fibres As Raw Materials For Various IndustriesDocument7 pagesThe Potency and Future of Indonesia'S Natural Fibres As Raw Materials For Various IndustriesGina FirgiantiNo ratings yet

- Annual Report 2016Document44 pagesAnnual Report 2016Chu NamNo ratings yet

- 24-27 Usenet and NewsgroupsDocument2 pages24-27 Usenet and Newsgroupsyarichek.zviagintsevNo ratings yet

- A Research On Affordable HousingDocument3 pagesA Research On Affordable HousingEditor IJTSRDNo ratings yet

- Magsaysay v. AganDocument2 pagesMagsaysay v. Agand2015memberNo ratings yet

- TCW Lesson Globalization of ReligionDocument18 pagesTCW Lesson Globalization of Religionyonki minNo ratings yet

- MGT610 MIDTERM SOLVED MCQS by JUNAIDDocument33 pagesMGT610 MIDTERM SOLVED MCQS by JUNAIDtalha8389711100% (1)

- After Creating Masters, Passing Entries & Analysing The Reports Let's See The Banking FeaturesDocument15 pagesAfter Creating Masters, Passing Entries & Analysing The Reports Let's See The Banking FeaturesMadhuri ShirkarNo ratings yet

- Mysticism in Shaivism and Christianity PDFDocument386 pagesMysticism in Shaivism and Christianity PDFproklos100% (2)

- Danh Vo Paris Press ReleaseDocument18 pagesDanh Vo Paris Press ReleaseTeddy4321No ratings yet

- GluttonyDocument2 pagesGluttonyFrezel BasiloniaNo ratings yet