Professional Documents

Culture Documents

Nitric Acid Synthesis Nitric Acid Synthesis

Nitric Acid Synthesis Nitric Acid Synthesis

Uploaded by

Marianne Eka ViariCopyright:

Available Formats

You might also like

- As Series - Installation Operation and Maintenance Manua1 - 1Document35 pagesAs Series - Installation Operation and Maintenance Manua1 - 1Ramesh BhosleNo ratings yet

- Nitric Acid Production PDFDocument87 pagesNitric Acid Production PDFmohamedNo ratings yet

- Phthalic AnhydrideDocument60 pagesPhthalic AnhydrideSatyam SharmaNo ratings yet

- Phthalic AnhydrideDocument60 pagesPhthalic AnhydrideAnonymous Ksq1dyPRh0% (2)

- Surfactants CONDEADocument55 pagesSurfactants CONDEAMohamed HalemNo ratings yet

- Production of Nitric Acid PDFDocument20 pagesProduction of Nitric Acid PDFPanji Aji Wibowo100% (5)

- Chapter 3Document30 pagesChapter 3biniyam aberaNo ratings yet

- Sulfuric Acid (7,8,9)Document17 pagesSulfuric Acid (7,8,9)Tamoghna BhattacharjeeNo ratings yet

- Uhde Envi NOxtechnologyfor NOXand N2 OabatementacontributiontoreducingemissionsfromnitricacidplantsDocument14 pagesUhde Envi NOxtechnologyfor NOXand N2 OabatementacontributiontoreducingemissionsfromnitricacidplantsAbhijitNo ratings yet

- HNO3 ProductionDocument9 pagesHNO3 ProductionAlex GenezNo ratings yet

- Chemical Technology Subject Code: CH2001 Module II-Lecture 3 Nitric AcidDocument12 pagesChemical Technology Subject Code: CH2001 Module II-Lecture 3 Nitric AcidU SANKAR TEJONo ratings yet

- Uhde GMBHDocument18 pagesUhde GMBHonejako12100% (1)

- Oxidation of Inorganic and Organic CompoundsDocument17 pagesOxidation of Inorganic and Organic CompoundswaqasNo ratings yet

- IntroductionDocument26 pagesIntroductionNoranierahNohoNo ratings yet

- Nitric AcidDocument15 pagesNitric AcidFACEtube100% (1)

- Other Bulk Chemicals ProductionDocument54 pagesOther Bulk Chemicals Productionmuhammad izzulNo ratings yet

- Nitric Acid and Aluminium-Sodium: Report OnDocument31 pagesNitric Acid and Aluminium-Sodium: Report OnDisha GardiNo ratings yet

- Nitrogen OxidesDocument30 pagesNitrogen OxidesskywalkerNo ratings yet

- B442vs2 1Document10 pagesB442vs2 1Dario BonillaNo ratings yet

- Description of Nitric Acid Manufacturing ProcessDocument3 pagesDescription of Nitric Acid Manufacturing ProcessSameer PandeyNo ratings yet

- CementCO2coststudyIEAGHG 2006Document6 pagesCementCO2coststudyIEAGHG 2006Marco HernandezNo ratings yet

- Acido Nitrico A17 293 PDFDocument50 pagesAcido Nitrico A17 293 PDFjaspreetNo ratings yet

- Catalyst AssignmentDocument5 pagesCatalyst AssignmentBorith pangNo ratings yet

- Nitric AcidDocument37 pagesNitric AcidBryce DayapNo ratings yet

- Nitric AcidDocument28 pagesNitric AcidAshkan AbbasiNo ratings yet

- Nitric Acid, HN: O O O ODocument5 pagesNitric Acid, HN: O O O Oحاتم غيدان خلفNo ratings yet

- Manufacturing of Nitric Acid - 1Document17 pagesManufacturing of Nitric Acid - 1Sohail KhanNo ratings yet

- Nitric Acid: Chemical Process IndustriesDocument13 pagesNitric Acid: Chemical Process Industries78623No ratings yet

- Lec2 Nitric AcidDocument8 pagesLec2 Nitric AcidChaitanya PottiNo ratings yet

- Nitric Acid IndustryDocument6 pagesNitric Acid IndustryMuhammad AslamNo ratings yet

- Chapter II by Tarik-1Document56 pagesChapter II by Tarik-1Gebremeskel GebreslassieNo ratings yet

- CPCL HydrocrackerDocument177 pagesCPCL HydrocrackerKaustav Nayak100% (3)

- Nitric Acid HNO3Document12 pagesNitric Acid HNO3hamza A.laftaNo ratings yet

- Nitric Acid: Lecture By: Engr. Mina ArshadDocument27 pagesNitric Acid: Lecture By: Engr. Mina ArshadDanish BaigNo ratings yet

- The Ammonia Manufacturing ProcessDocument85 pagesThe Ammonia Manufacturing Processdabit imageNo ratings yet

- Thermal Nox Vs Fuel Nox - Strategies For Combustion ModificationsDocument10 pagesThermal Nox Vs Fuel Nox - Strategies For Combustion ModificationsAsela PathirathnaNo ratings yet

- Nitric Acid Manufacturing ProcessDocument7 pagesNitric Acid Manufacturing ProcessLenin PrabhuNo ratings yet

- F CVEN9857 - Biological Nutrient Removal MMDocument80 pagesF CVEN9857 - Biological Nutrient Removal MMWeixuan ZhangNo ratings yet

- Nitrogen PDFDocument43 pagesNitrogen PDFKhambampati GuruprasadNo ratings yet

- 3.4 Nitrogen and Its CompoundsDocument28 pages3.4 Nitrogen and Its CompoundsJoseph odhiambo100% (1)

- 8.8 Nitric AcidDocument7 pages8.8 Nitric AcidAshkan AbbasiNo ratings yet

- NO Abatement With H2O2 (Ecom) (USPeroxide ) (2s) PDFDocument2 pagesNO Abatement With H2O2 (Ecom) (USPeroxide ) (2s) PDFScribdManíacoNo ratings yet

- Hydrogen Introduction, Comppounds, SynthesisDocument39 pagesHydrogen Introduction, Comppounds, SynthesisSkye EdmnetNo ratings yet

- Nitric Acid Manufacturing: Class Lecture by Engr. Ghulam AbbasDocument11 pagesNitric Acid Manufacturing: Class Lecture by Engr. Ghulam Abbaskami9709No ratings yet

- Nitric Acid Ppt-1Document21 pagesNitric Acid Ppt-1Mathewos Sada100% (1)

- Air Pollution FinalDocument131 pagesAir Pollution FinalfaheemabbasNo ratings yet

- Selective Catalytic Reduction of Nox: Kushagra Abhishek 11/Ch/25Document13 pagesSelective Catalytic Reduction of Nox: Kushagra Abhishek 11/Ch/25Kushagra AbhishekNo ratings yet

- 44 NOx ReductionDocument24 pages44 NOx ReductionJsueNo ratings yet

- Haber Bosch ProcessDocument44 pagesHaber Bosch ProcessyudiapnNo ratings yet

- Nitric Acid and Hydrogen Cyanide ProcessDocument6 pagesNitric Acid and Hydrogen Cyanide ProcessArgelis CamachoNo ratings yet

- Pollution Acid Plants: NitricDocument7 pagesPollution Acid Plants: NitricduongchitrungNo ratings yet

- Processing of Columbite Tantalite Ores and Concentrates For Niobium and Niobium CompoundsDocument21 pagesProcessing of Columbite Tantalite Ores and Concentrates For Niobium and Niobium CompoundsOscar BenimanaNo ratings yet

- HNO3 Production PDFDocument25 pagesHNO3 Production PDFWaseem Razzaq100% (1)

- Sources and Control Methods: CE/AE 524B Air Pollution J. (Hans) Van LeeuwenDocument28 pagesSources and Control Methods: CE/AE 524B Air Pollution J. (Hans) Van LeeuwenSteve Johnson100% (1)

- Catalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3Document5 pagesCatalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3AnanthakishnanNo ratings yet

- Nitric Oxide: Jump To Navigation Jump To SearchDocument86 pagesNitric Oxide: Jump To Navigation Jump To SearchChaeyoung SonNo ratings yet

- Unit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Document22 pagesUnit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Green JeskNo ratings yet

- Nox Abatement TechnologiesDocument16 pagesNox Abatement TechnologiesMohita JaiswalNo ratings yet

- Nitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's EncyclopediaDocument49 pagesNitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's Encyclopediapoly6icsNo ratings yet

- Material Balance Reaction - Compound FormingDocument15 pagesMaterial Balance Reaction - Compound FormingIlham Muhamad YusufNo ratings yet

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- 5.0. Beam Design-Steel PlateDocument19 pages5.0. Beam Design-Steel PlateFarly Vergel100% (1)

- Bpharm 3 Sem Pharmaceutical Organic Chemistry 2 Bp301t 2020Document1 pageBpharm 3 Sem Pharmaceutical Organic Chemistry 2 Bp301t 2020ABHISHEK YADUVANSHINo ratings yet

- Density (Calculation)Document28 pagesDensity (Calculation)Taufik PamisNo ratings yet

- Chemistry Investigatory Project (Final)Document17 pagesChemistry Investigatory Project (Final)RaK AmVs アムブNo ratings yet

- Mechanics Explained in Seven Pages: Excerpt From The No Bullshit Guide To Math and Physics by Ivan SavovDocument8 pagesMechanics Explained in Seven Pages: Excerpt From The No Bullshit Guide To Math and Physics by Ivan Savovjamey_mork1No ratings yet

- June 2016 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument12 pagesJune 2016 (IAL) MS - Unit 1 Edexcel Physics A-LevelDaianna PeirisNo ratings yet

- Ravicitation DuplicateDocument1,163 pagesRavicitation Duplicateganapathy2010svNo ratings yet

- GM 13Document1 pageGM 13Awad SalibNo ratings yet

- Sandmeyer Isatin Synthesis 2010 PDFDocument4 pagesSandmeyer Isatin Synthesis 2010 PDFSamrat MazumdarNo ratings yet

- (SiC-En-2013-22) Molding Compounds Adhesion and Influence On Reliability of Plastic Packages For SiC-Based Power MOS DevicesDocument13 pages(SiC-En-2013-22) Molding Compounds Adhesion and Influence On Reliability of Plastic Packages For SiC-Based Power MOS Devicesnuaa_qhhNo ratings yet

- Liquid Gold and Processes Within Our Bodies: Technology Workshop Craft Home Food Play Outside CostumesDocument6 pagesLiquid Gold and Processes Within Our Bodies: Technology Workshop Craft Home Food Play Outside Costumesx spaceNo ratings yet

- Soil Physical Properties - 03!02!2023Document68 pagesSoil Physical Properties - 03!02!2023Gabby ChebetNo ratings yet

- 9-Effective Permeability and RelativeDocument20 pages9-Effective Permeability and Relativeاحمد ابوبكر اشقيفهNo ratings yet

- 325w Poly Solar Panel SpecsDocument4 pages325w Poly Solar Panel SpecsEmmanuel santosNo ratings yet

- Chapter - 5 Minerals and Energy ResourcesDocument23 pagesChapter - 5 Minerals and Energy ResourcesRohan PatelNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and CompanyDocument8 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and CompanyEdin Krdžalić EdoNo ratings yet

- Chemistry of Fire, Triangle of Fire Etc.Document48 pagesChemistry of Fire, Triangle of Fire Etc.HDF ltoncreastNo ratings yet

- Salkowski Test ConclusionDocument3 pagesSalkowski Test Conclusionclint xavier odangoNo ratings yet

- Seminar Nr.5: Llogaritja e Themeleve Te Tipit Pilota Nen Vibrime VertikaleDocument5 pagesSeminar Nr.5: Llogaritja e Themeleve Te Tipit Pilota Nen Vibrime VertikaleTENo ratings yet

- 11.1 Physics 2 StaticDocument8 pages11.1 Physics 2 StaticAlex24680verizonnetNo ratings yet

- TECE2Document8 pagesTECE2ahmedNo ratings yet

- ASTM B406-96 Transverse Rupture Strength of Cemented CarbidesDocument3 pagesASTM B406-96 Transverse Rupture Strength of Cemented CarbidesTyson BoyceNo ratings yet

- Exercise 4.3Document3 pagesExercise 4.3Anonymous w7ujq3cH2FNo ratings yet

- Interaction of Light With MatterDocument6 pagesInteraction of Light With MatteraarthijayakumarNo ratings yet

- Solutions For Topic 6 - Circular Motion and Gravitation: End-Of-Topic QuestionsDocument2 pagesSolutions For Topic 6 - Circular Motion and Gravitation: End-Of-Topic QuestionsHansal Pravin KachharaNo ratings yet

- CHP 5 TranspirationDocument9 pagesCHP 5 TranspirationAryan KumarNo ratings yet

- Haloalkanes and HaloarenesDocument20 pagesHaloalkanes and HaloarenesNiranjan RajaNo ratings yet

- SuperalloyDocument5 pagesSuperalloyJayanthi Arumugam JayanthiNo ratings yet

Nitric Acid Synthesis Nitric Acid Synthesis

Nitric Acid Synthesis Nitric Acid Synthesis

Uploaded by

Marianne Eka ViariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitric Acid Synthesis Nitric Acid Synthesis

Nitric Acid Synthesis Nitric Acid Synthesis

Uploaded by

Marianne Eka ViariCopyright:

Available Formats

4/28/2008

Nitric acid synthesis

Nitric acid

Production world wide: 65 million t/a

Applications: fertilizers, explosives, organic synthesis, polymers

(e g nylon)

(e.g.

AN ammonium nitrate

CN calcium

l i

nitrate

i

CAN calcium ammonium nitrate

ASN ammonium sulfate nitrate

NP nitrophosphates

4/28/2008

History of Nitric Acid Production

Middle Ages

Produced from salpeter, KNO3

19th century

Produced from Chile salpeter, NaNO3

20th century

Catalytic oxidation of ammonia with air

CF Industries: Urea and UAN

plants at Donaldsonville

Synthesis of nitric acid by oxidation of ammonia

Main challenge in the production of nitric acid is the selectivity for

catalytic

t l ti oxidation

id ti off ammonia

i tto nitric

it i oxide.

id Sid

Side reactions

ti

are

decomposition into N2 and H2 or H2O and formation of N2O.

Direct oxidation of NH3 to NO2 is thermodynamically unfavorable under

the process conditions.

Therefore, the reaction mixture needs cooling

g before non-catalytic

y

conversion of NO to NO2.

Finally, NO2 is absorbed in water to give HNO3.

4/28/2008

Reactions and thermodynamics

NH3 + 2 O2

HNO3 + H2O

H298= -330 kJ/mol

(1)

4 NH3 + 5 O2

NO + 6 H2O

H298= -907

907 kJ/mol

(2)

2 NO + O2

2 NO2

H298= -1261 kJ/mol

(3)

3 NO2 + H2O

2 HNO3 + NO

H298= -1261 kJ/mol

(4)

Side reaction:

4 NH3 + 3 O2

2 N2 + 6 H2O

H298= -1261 kJ/mol

(5)

Equilibrium constants at 900oC:

K(5) = 1015

K(4) =1011

A catalyst with high selectivity for ammonia

oxidation to NO is necessary.

Thermodynamic consideration

4/28/2008

The Ostwald process

Three main steps:

Oxidation of NH3

4 NH3 + 5 O2 4 NO + 6 H2O

Oxidation of NO

2 NO + O2 2 NO2

Absorption of NO2 in H2O

3 NO2 + H2O 2 HNO3 + NO

Ostwald process plant

52-65 %

4/28/2008

Typical process data (Ostwald plant)

KRUPP-UHDE process-dual pressure azeotropic HNO3

4/28/2008

Catalysts for nitric acid production

Pt-Rh alloy (containing 10 wt% Rh) in the form of wire gauze

(Dupont, 1934)

Pt shows

h

hi

high

h selectivity

l ti it ttowards

d NO fformation

ti

Rh addition enhances mechanical strength of Pt gauze and

decreases the volatility of Pt during the high temperature/high

pressure reaction

Several gauze configurations: knitted

gauzes lower N2O emission and

increase mechanical strength

Catalyst deactivation

Catalysts are deactivated by poisoning, fouling and loss of active Pt

Pt metal losses cause a reduction in mechanical strength of the

catalyst gauze (limiting the lifetime of the catalyst) and a gradual

increase of the Rh content on the catalyst surface

Increased Rh leads to decreased activities and a higher production

of N2O and N2, at the expense of NO

In situ Pt recovery process

Use of a woven gauze 90-10%Pd-Au gauze just after the oxidation gauze

to capture the Pt species

PtO2 (g) + Pd

Pt-Pd (alloy) + O2

Up to 80% recovery of Pt

4/28/2008

Process conditions for NH3 oxidation

Optimal conditions for ammonia oxidation to NO are

high temperature (1073 to 1223 K)

short residence time 10-3 - 10-4 s

low pressure 1 to 6.5 bar in dual-pressure plants and

ammonia-to-air ratio in the feed should be 1:9 (i.e. 10 vol.%

NH3)

3 to 50 layers of gauzes stacked in the reactor (burner)

Elementary reaction steps in NH3 oxidation

NH3 + NH3

O2 + 2 2 O

NH3 + O NH2 + OH

NH2 + O NH + OH

NH + O N + OH

N + O NO +

NO NO +

N + N N2 + 2

OH + OH H2O + O +

NH + O NO + H

NH + 2O NO + OH

NO N + O

NH2 + NO N2 + H2O + 2

NO + N N2 + O +

NO + N N2O +

N2O N2O +

At low temperatures (473

( 473 K): NN

coverage dominates the catalyst

surface leading to N2.

At higher temperatures O-coverage

increases and more oxidized

products are formed.

Under industrial conditions the

oxygen-coverage is dominant,

leading to NO.

4/28/2008

Formation of nitric acid by absorption

Mass transport and film diffusion determine overall reaction kinetics.

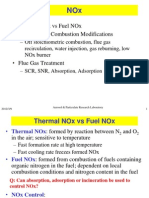

Environmental concerns in nitric acid production

5.5 kg N2O (green house gas) per tonne of nitric acid produced

Total emissions of N2O from nitric acid manufacture in Europe

can be estimated in 130 kt/a, which is equivalent to 40 Mtonne

of CO2.

4/28/2008

Current developments

Oxide-based combustion catalysts

Lower cost than Pt catalysts

Lower N2O emissions

Lower specific activity 2 orders of magnitude

Sintering, reduction of the oxides because of NH3

Co3O4 doped with Ce, La, selectivity of NH3 to N2O <0.5%

Single metal oxides or mixed oxides (perovskites and spinels) based on

Co, Fe, Bi, Mn, Cr, and Ni.

Combined beds consisting of Pt gauzes and oxides have been successfully

proposed for industrial applications.

You might also like

- As Series - Installation Operation and Maintenance Manua1 - 1Document35 pagesAs Series - Installation Operation and Maintenance Manua1 - 1Ramesh BhosleNo ratings yet

- Nitric Acid Production PDFDocument87 pagesNitric Acid Production PDFmohamedNo ratings yet

- Phthalic AnhydrideDocument60 pagesPhthalic AnhydrideSatyam SharmaNo ratings yet

- Phthalic AnhydrideDocument60 pagesPhthalic AnhydrideAnonymous Ksq1dyPRh0% (2)

- Surfactants CONDEADocument55 pagesSurfactants CONDEAMohamed HalemNo ratings yet

- Production of Nitric Acid PDFDocument20 pagesProduction of Nitric Acid PDFPanji Aji Wibowo100% (5)

- Chapter 3Document30 pagesChapter 3biniyam aberaNo ratings yet

- Sulfuric Acid (7,8,9)Document17 pagesSulfuric Acid (7,8,9)Tamoghna BhattacharjeeNo ratings yet

- Uhde Envi NOxtechnologyfor NOXand N2 OabatementacontributiontoreducingemissionsfromnitricacidplantsDocument14 pagesUhde Envi NOxtechnologyfor NOXand N2 OabatementacontributiontoreducingemissionsfromnitricacidplantsAbhijitNo ratings yet

- HNO3 ProductionDocument9 pagesHNO3 ProductionAlex GenezNo ratings yet

- Chemical Technology Subject Code: CH2001 Module II-Lecture 3 Nitric AcidDocument12 pagesChemical Technology Subject Code: CH2001 Module II-Lecture 3 Nitric AcidU SANKAR TEJONo ratings yet

- Uhde GMBHDocument18 pagesUhde GMBHonejako12100% (1)

- Oxidation of Inorganic and Organic CompoundsDocument17 pagesOxidation of Inorganic and Organic CompoundswaqasNo ratings yet

- IntroductionDocument26 pagesIntroductionNoranierahNohoNo ratings yet

- Nitric AcidDocument15 pagesNitric AcidFACEtube100% (1)

- Other Bulk Chemicals ProductionDocument54 pagesOther Bulk Chemicals Productionmuhammad izzulNo ratings yet

- Nitric Acid and Aluminium-Sodium: Report OnDocument31 pagesNitric Acid and Aluminium-Sodium: Report OnDisha GardiNo ratings yet

- Nitrogen OxidesDocument30 pagesNitrogen OxidesskywalkerNo ratings yet

- B442vs2 1Document10 pagesB442vs2 1Dario BonillaNo ratings yet

- Description of Nitric Acid Manufacturing ProcessDocument3 pagesDescription of Nitric Acid Manufacturing ProcessSameer PandeyNo ratings yet

- CementCO2coststudyIEAGHG 2006Document6 pagesCementCO2coststudyIEAGHG 2006Marco HernandezNo ratings yet

- Acido Nitrico A17 293 PDFDocument50 pagesAcido Nitrico A17 293 PDFjaspreetNo ratings yet

- Catalyst AssignmentDocument5 pagesCatalyst AssignmentBorith pangNo ratings yet

- Nitric AcidDocument37 pagesNitric AcidBryce DayapNo ratings yet

- Nitric AcidDocument28 pagesNitric AcidAshkan AbbasiNo ratings yet

- Nitric Acid, HN: O O O ODocument5 pagesNitric Acid, HN: O O O Oحاتم غيدان خلفNo ratings yet

- Manufacturing of Nitric Acid - 1Document17 pagesManufacturing of Nitric Acid - 1Sohail KhanNo ratings yet

- Nitric Acid: Chemical Process IndustriesDocument13 pagesNitric Acid: Chemical Process Industries78623No ratings yet

- Lec2 Nitric AcidDocument8 pagesLec2 Nitric AcidChaitanya PottiNo ratings yet

- Nitric Acid IndustryDocument6 pagesNitric Acid IndustryMuhammad AslamNo ratings yet

- Chapter II by Tarik-1Document56 pagesChapter II by Tarik-1Gebremeskel GebreslassieNo ratings yet

- CPCL HydrocrackerDocument177 pagesCPCL HydrocrackerKaustav Nayak100% (3)

- Nitric Acid HNO3Document12 pagesNitric Acid HNO3hamza A.laftaNo ratings yet

- Nitric Acid: Lecture By: Engr. Mina ArshadDocument27 pagesNitric Acid: Lecture By: Engr. Mina ArshadDanish BaigNo ratings yet

- The Ammonia Manufacturing ProcessDocument85 pagesThe Ammonia Manufacturing Processdabit imageNo ratings yet

- Thermal Nox Vs Fuel Nox - Strategies For Combustion ModificationsDocument10 pagesThermal Nox Vs Fuel Nox - Strategies For Combustion ModificationsAsela PathirathnaNo ratings yet

- Nitric Acid Manufacturing ProcessDocument7 pagesNitric Acid Manufacturing ProcessLenin PrabhuNo ratings yet

- F CVEN9857 - Biological Nutrient Removal MMDocument80 pagesF CVEN9857 - Biological Nutrient Removal MMWeixuan ZhangNo ratings yet

- Nitrogen PDFDocument43 pagesNitrogen PDFKhambampati GuruprasadNo ratings yet

- 3.4 Nitrogen and Its CompoundsDocument28 pages3.4 Nitrogen and Its CompoundsJoseph odhiambo100% (1)

- 8.8 Nitric AcidDocument7 pages8.8 Nitric AcidAshkan AbbasiNo ratings yet

- NO Abatement With H2O2 (Ecom) (USPeroxide ) (2s) PDFDocument2 pagesNO Abatement With H2O2 (Ecom) (USPeroxide ) (2s) PDFScribdManíacoNo ratings yet

- Hydrogen Introduction, Comppounds, SynthesisDocument39 pagesHydrogen Introduction, Comppounds, SynthesisSkye EdmnetNo ratings yet

- Nitric Acid Manufacturing: Class Lecture by Engr. Ghulam AbbasDocument11 pagesNitric Acid Manufacturing: Class Lecture by Engr. Ghulam Abbaskami9709No ratings yet

- Nitric Acid Ppt-1Document21 pagesNitric Acid Ppt-1Mathewos Sada100% (1)

- Air Pollution FinalDocument131 pagesAir Pollution FinalfaheemabbasNo ratings yet

- Selective Catalytic Reduction of Nox: Kushagra Abhishek 11/Ch/25Document13 pagesSelective Catalytic Reduction of Nox: Kushagra Abhishek 11/Ch/25Kushagra AbhishekNo ratings yet

- 44 NOx ReductionDocument24 pages44 NOx ReductionJsueNo ratings yet

- Haber Bosch ProcessDocument44 pagesHaber Bosch ProcessyudiapnNo ratings yet

- Nitric Acid and Hydrogen Cyanide ProcessDocument6 pagesNitric Acid and Hydrogen Cyanide ProcessArgelis CamachoNo ratings yet

- Pollution Acid Plants: NitricDocument7 pagesPollution Acid Plants: NitricduongchitrungNo ratings yet

- Processing of Columbite Tantalite Ores and Concentrates For Niobium and Niobium CompoundsDocument21 pagesProcessing of Columbite Tantalite Ores and Concentrates For Niobium and Niobium CompoundsOscar BenimanaNo ratings yet

- HNO3 Production PDFDocument25 pagesHNO3 Production PDFWaseem Razzaq100% (1)

- Sources and Control Methods: CE/AE 524B Air Pollution J. (Hans) Van LeeuwenDocument28 pagesSources and Control Methods: CE/AE 524B Air Pollution J. (Hans) Van LeeuwenSteve Johnson100% (1)

- Catalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3Document5 pagesCatalytic Oxidation of NO To NO2 For Nitric Acid Production Over A Pt-Al2O3AnanthakishnanNo ratings yet

- Nitric Oxide: Jump To Navigation Jump To SearchDocument86 pagesNitric Oxide: Jump To Navigation Jump To SearchChaeyoung SonNo ratings yet

- Unit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Document22 pagesUnit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Green JeskNo ratings yet

- Nox Abatement TechnologiesDocument16 pagesNox Abatement TechnologiesMohita JaiswalNo ratings yet

- Nitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's EncyclopediaDocument49 pagesNitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's Encyclopediapoly6icsNo ratings yet

- Material Balance Reaction - Compound FormingDocument15 pagesMaterial Balance Reaction - Compound FormingIlham Muhamad YusufNo ratings yet

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- 5.0. Beam Design-Steel PlateDocument19 pages5.0. Beam Design-Steel PlateFarly Vergel100% (1)

- Bpharm 3 Sem Pharmaceutical Organic Chemistry 2 Bp301t 2020Document1 pageBpharm 3 Sem Pharmaceutical Organic Chemistry 2 Bp301t 2020ABHISHEK YADUVANSHINo ratings yet

- Density (Calculation)Document28 pagesDensity (Calculation)Taufik PamisNo ratings yet

- Chemistry Investigatory Project (Final)Document17 pagesChemistry Investigatory Project (Final)RaK AmVs アムブNo ratings yet

- Mechanics Explained in Seven Pages: Excerpt From The No Bullshit Guide To Math and Physics by Ivan SavovDocument8 pagesMechanics Explained in Seven Pages: Excerpt From The No Bullshit Guide To Math and Physics by Ivan Savovjamey_mork1No ratings yet

- June 2016 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument12 pagesJune 2016 (IAL) MS - Unit 1 Edexcel Physics A-LevelDaianna PeirisNo ratings yet

- Ravicitation DuplicateDocument1,163 pagesRavicitation Duplicateganapathy2010svNo ratings yet

- GM 13Document1 pageGM 13Awad SalibNo ratings yet

- Sandmeyer Isatin Synthesis 2010 PDFDocument4 pagesSandmeyer Isatin Synthesis 2010 PDFSamrat MazumdarNo ratings yet

- (SiC-En-2013-22) Molding Compounds Adhesion and Influence On Reliability of Plastic Packages For SiC-Based Power MOS DevicesDocument13 pages(SiC-En-2013-22) Molding Compounds Adhesion and Influence On Reliability of Plastic Packages For SiC-Based Power MOS Devicesnuaa_qhhNo ratings yet

- Liquid Gold and Processes Within Our Bodies: Technology Workshop Craft Home Food Play Outside CostumesDocument6 pagesLiquid Gold and Processes Within Our Bodies: Technology Workshop Craft Home Food Play Outside Costumesx spaceNo ratings yet

- Soil Physical Properties - 03!02!2023Document68 pagesSoil Physical Properties - 03!02!2023Gabby ChebetNo ratings yet

- 9-Effective Permeability and RelativeDocument20 pages9-Effective Permeability and Relativeاحمد ابوبكر اشقيفهNo ratings yet

- 325w Poly Solar Panel SpecsDocument4 pages325w Poly Solar Panel SpecsEmmanuel santosNo ratings yet

- Chapter - 5 Minerals and Energy ResourcesDocument23 pagesChapter - 5 Minerals and Energy ResourcesRohan PatelNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and CompanyDocument8 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and CompanyEdin Krdžalić EdoNo ratings yet

- Chemistry of Fire, Triangle of Fire Etc.Document48 pagesChemistry of Fire, Triangle of Fire Etc.HDF ltoncreastNo ratings yet

- Salkowski Test ConclusionDocument3 pagesSalkowski Test Conclusionclint xavier odangoNo ratings yet

- Seminar Nr.5: Llogaritja e Themeleve Te Tipit Pilota Nen Vibrime VertikaleDocument5 pagesSeminar Nr.5: Llogaritja e Themeleve Te Tipit Pilota Nen Vibrime VertikaleTENo ratings yet

- 11.1 Physics 2 StaticDocument8 pages11.1 Physics 2 StaticAlex24680verizonnetNo ratings yet

- TECE2Document8 pagesTECE2ahmedNo ratings yet

- ASTM B406-96 Transverse Rupture Strength of Cemented CarbidesDocument3 pagesASTM B406-96 Transverse Rupture Strength of Cemented CarbidesTyson BoyceNo ratings yet

- Exercise 4.3Document3 pagesExercise 4.3Anonymous w7ujq3cH2FNo ratings yet

- Interaction of Light With MatterDocument6 pagesInteraction of Light With MatteraarthijayakumarNo ratings yet

- Solutions For Topic 6 - Circular Motion and Gravitation: End-Of-Topic QuestionsDocument2 pagesSolutions For Topic 6 - Circular Motion and Gravitation: End-Of-Topic QuestionsHansal Pravin KachharaNo ratings yet

- CHP 5 TranspirationDocument9 pagesCHP 5 TranspirationAryan KumarNo ratings yet

- Haloalkanes and HaloarenesDocument20 pagesHaloalkanes and HaloarenesNiranjan RajaNo ratings yet

- SuperalloyDocument5 pagesSuperalloyJayanthi Arumugam JayanthiNo ratings yet