Professional Documents

Culture Documents

Scope of Engine RebuildEMD

Scope of Engine RebuildEMD

Uploaded by

Sreenath S KallaaraCopyright:

Available Formats

You might also like

- Emd-Bearing Inspection and Qualification of Engine Main BearingsDocument30 pagesEmd-Bearing Inspection and Qualification of Engine Main BearingsIvanNo ratings yet

- 2011 Harley-Davidson Touring Models Parts Catalog PDFDocument314 pages2011 Harley-Davidson Touring Models Parts Catalog PDFAiddie Ghazlan0% (1)

- Alco Century 628'sDocument5 pagesAlco Century 628'sstaustell92100% (1)

- EMD M.I. 100 Bore Alignment QualificationDocument24 pagesEMD M.I. 100 Bore Alignment QualificationMayor Paz GonzálezNo ratings yet

- Overhaul ManualDocument2,175 pagesOverhaul Manualernesto rodriguez100% (5)

- Emd Mi259Document20 pagesEmd Mi259Mike Finazzi100% (3)

- Shredder - Model 1975 NEWELL 80/104Document60 pagesShredder - Model 1975 NEWELL 80/104Alan Ross100% (1)

- Engine Base & BlockDocument47 pagesEngine Base & Blockkr_abhijeet7235658750% (2)

- Nfpa 10: Fire ExtinguishersDocument10 pagesNfpa 10: Fire ExtinguishersSreenath S KallaaraNo ratings yet

- Chaparral Models 1968 1974Document4 pagesChaparral Models 1968 1974Paul MartinNo ratings yet

- Land Rover - Defender - TD5 - R380 Manual Gearbox PDFDocument79 pagesLand Rover - Defender - TD5 - R380 Manual Gearbox PDFemanrosent100% (1)

- Demag End CarriagesDocument16 pagesDemag End CarriagesZain UddinNo ratings yet

- PartsDiagram KZ650SR - D1 D2 PDFDocument90 pagesPartsDiagram KZ650SR - D1 D2 PDFLeandro MoyanoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Locomotive 1 Service Manual: Fuel System and Engine Starting DescriptionDocument9 pagesLocomotive 1 Service Manual: Fuel System and Engine Starting Descriptionyuri peña quispeNo ratings yet

- MI - 5386 - Relays PDFDocument4 pagesMI - 5386 - Relays PDFSudarshan DhumalNo ratings yet

- Emd-Mi549 RadiadoresDocument7 pagesEmd-Mi549 RadiadoresVictor Raul Tobosque MuñozNo ratings yet

- MI - 1097 Air Dryer System Grahm WhiteDocument48 pagesMI - 1097 Air Dryer System Grahm WhitemathieuNo ratings yet

- MD C38emiDocument5 pagesMD C38emiPauloNo ratings yet

- EMD 645 Parts Catalog 302 Part 1Document164 pagesEMD 645 Parts Catalog 302 Part 1KarlaFernanda Roque Rodriguez0% (1)

- MI 432 Rev C - D12 Main GeneratorDocument28 pagesMI 432 Rev C - D12 Main GeneratorJesse BarnettNo ratings yet

- Nstruction: Scheduled Maintenance Program Turbocharged GP & SD Model Locomotives (645F3, F3A & F3B Engines)Document16 pagesNstruction: Scheduled Maintenance Program Turbocharged GP & SD Model Locomotives (645F3, F3A & F3B Engines)amir barekati100% (1)

- Modernization Recommendation Improving Ride Quality of Locomotlves Quipped With GP Single Shoe TrucksDocument5 pagesModernization Recommendation Improving Ride Quality of Locomotlves Quipped With GP Single Shoe Trucksamir barekatiNo ratings yet

- Emd-Mi926 Filtracion de AceitesDocument7 pagesEmd-Mi926 Filtracion de AceitesVictor Raul Tobosque MuñozNo ratings yet

- MI - 1748 Rev FDocument21 pagesMI - 1748 Rev FSudarshan Dhumal100% (2)

- Emd AftercoolerDocument1 pageEmd Aftercoolerjaskaran singhNo ratings yet

- Maintenance Mstruction: DescriptionDocument11 pagesMaintenance Mstruction: Descriptionamir barekatiNo ratings yet

- Testing The Alco HaulicsDocument3 pagesTesting The Alco Haulicsstaustell92No ratings yet

- Emd-Mi1577 Freno de Mano GP49Document4 pagesEmd-Mi1577 Freno de Mano GP49Victor Raul Tobosque MuñozNo ratings yet

- AMITDocument25 pagesAMITThe Fun ExplosionNo ratings yet

- Emd-Mi580 Manometros de TemperaturasDocument3 pagesEmd-Mi580 Manometros de TemperaturasVictor Raul Tobosque MuñozNo ratings yet

- US Army - Locomotive, Davenport Besler TM 55-1279Document90 pagesUS Army - Locomotive, Davenport Besler TM 55-1279Dexster Smith100% (1)

- WDP 3aDocument2 pagesWDP 3aRUDHRESH KUMAR SNo ratings yet

- Irtmm 2019 Chapter 3Document31 pagesIrtmm 2019 Chapter 3Abhishek SinghNo ratings yet

- 190 Vol 1Document875 pages190 Vol 1mathieuNo ratings yet

- Ge 7s12 PDFDocument25 pagesGe 7s12 PDFnangkarak8201100% (2)

- Tier 4 EVO Engine ToolingDocument95 pagesTier 4 EVO Engine ToolingTim Marvin100% (1)

- Locomotives in IndiaDocument18 pagesLocomotives in IndianelanandNo ratings yet

- MI 276 Rev B - Conversion of Turbochargers For Opposite Engine RotationDocument15 pagesMI 276 Rev B - Conversion of Turbochargers For Opposite Engine RotationJesse BarnettNo ratings yet

- MI 9687 - Modernization Recommendation - Paragon Fuel Pump Replacement KitsDocument6 pagesMI 9687 - Modernization Recommendation - Paragon Fuel Pump Replacement KitsJesse BarnettNo ratings yet

- Emd Mi259 PDFDocument20 pagesEmd Mi259 PDFJesse BarnettNo ratings yet

- MI - 20033 GT46AC Schedule Maint. ProgramDocument24 pagesMI - 20033 GT46AC Schedule Maint. ProgramRafael Dutil LucianaNo ratings yet

- Mi 1748 TDocument6 pagesMi 1748 Tamir barekatiNo ratings yet

- Locomotive Major Components InentoryDocument40 pagesLocomotive Major Components InentoryMetzger Tamba KendemaNo ratings yet

- MR 14002-Extended Light Load Specific TurbochargerDocument16 pagesMR 14002-Extended Light Load Specific TurbochargerVictor Noschang100% (1)

- 190 Vol 2Document604 pages190 Vol 2mathieuNo ratings yet

- Inspection & Qualification Guide: Revision BDocument54 pagesInspection & Qualification Guide: Revision Bamir barekatiNo ratings yet

- Emd Mi315Document6 pagesEmd Mi315Jesse BarnettNo ratings yet

- Emd-Mi3706 Generador AuxiliarDocument16 pagesEmd-Mi3706 Generador AuxiliarVictor Raul Tobosque MuñozNo ratings yet

- R1A4016R B12A1H1A A: Q Series PumpsDocument40 pagesR1A4016R B12A1H1A A: Q Series Pumpseaglego00No ratings yet

- Noble Corporation: Noble Analyst Day Singapore May 17-18, 2011Document27 pagesNoble Corporation: Noble Analyst Day Singapore May 17-18, 2011Andi ayuNo ratings yet

- DLW VaranasiDocument18 pagesDLW VaranasiPriyesh Kumar Singh100% (2)

- Overhaul (Top End) : Manual de Operación y MantenimientoDocument3 pagesOverhaul (Top End) : Manual de Operación y MantenimientomanuelNo ratings yet

- Emd-Mi928 Sistema de LubricacionDocument6 pagesEmd-Mi928 Sistema de LubricacionVictor Raul Tobosque Muñoz100% (1)

- Locomotive TrucksDocument9 pagesLocomotive TrucksjalilemadiNo ratings yet

- DLW Varanasi 2Document8 pagesDLW Varanasi 2Jalaj ChaudharyNo ratings yet

- Emd 567d 645 Parts Book AbbyDocument388 pagesEmd 567d 645 Parts Book AbbyJose100% (1)

- Scheduled Maintenance Program Turbocharged F, GP, &SD Model Locomotives (645E3 Thru 645E3C Engines)Document16 pagesScheduled Maintenance Program Turbocharged F, GP, &SD Model Locomotives (645E3 Thru 645E3C Engines)amir barekatiNo ratings yet

- WDG4 RDSO Failure Code Book PDFDocument130 pagesWDG4 RDSO Failure Code Book PDFSAIKIRAN100% (1)

- Emd Core Mui Injector Identification Guide 2020Document6 pagesEmd Core Mui Injector Identification Guide 2020Alex GonzalezNo ratings yet

- Volvo p1800s Stromberg 175 Instruction BookDocument8 pagesVolvo p1800s Stromberg 175 Instruction Bookvanapeer100% (2)

- CM20170915 60253 59723 PDFDocument2 pagesCM20170915 60253 59723 PDFvarun m100% (1)

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Document20 pagesUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniNo ratings yet

- Agricultural-Tractors New Holland T5000 - Models, Technical Data and CharacteristicsDocument2 pagesAgricultural-Tractors New Holland T5000 - Models, Technical Data and Characteristicsyan_dunrossNo ratings yet

- Electro-Motive Division General M O T O R S C0Rpof2AtlonDocument6 pagesElectro-Motive Division General M O T O R S C0Rpof2Atlonamir barekatiNo ratings yet

- Class C:: Electrical EquipmentDocument10 pagesClass C:: Electrical EquipmentSreenath S KallaaraNo ratings yet

- Trash Wood Paper Liquids Grease: - Gasoline - Oil - Grease - Other SolventsDocument10 pagesTrash Wood Paper Liquids Grease: - Gasoline - Oil - Grease - Other SolventsSreenath S KallaaraNo ratings yet

- 9.0 Equipment and SuppliesDocument2 pages9.0 Equipment and SuppliesSreenath S KallaaraNo ratings yet

- S1 Me Course HandoutDocument74 pagesS1 Me Course HandoutSreenath S KallaaraNo ratings yet

- E S O W: Levator Tatement F ORK 1.0 Service LocationDocument11 pagesE S O W: Levator Tatement F ORK 1.0 Service LocationSreenath S KallaaraNo ratings yet

- 7.0 Call Back ServiceDocument2 pages7.0 Call Back ServiceSreenath S KallaaraNo ratings yet

- Thermodynamic Cycles PDFDocument5 pagesThermodynamic Cycles PDFSreenath S KallaaraNo ratings yet

- Casting Cost EstimationDocument3 pagesCasting Cost EstimationSreenath S KallaaraNo ratings yet

- Srarter Motor PDFDocument24 pagesSrarter Motor PDFSreenath S KallaaraNo ratings yet

- MOD 2 Ans BankDocument27 pagesMOD 2 Ans BankSreenath S KallaaraNo ratings yet

- VolvoDocument10 pagesVolvoSreenath S KallaaraNo ratings yet

- Types Principle Nonslip Diffrential Diffrential HousingDocument14 pagesTypes Principle Nonslip Diffrential Diffrential HousingSreenath S KallaaraNo ratings yet

- Chapter-1: 1.1 History of Indian RailwayDocument13 pagesChapter-1: 1.1 History of Indian RailwaySreenath S KallaaraNo ratings yet

- Load Box Test-Sanyal DaDocument1 pageLoad Box Test-Sanyal DaSreenath S KallaaraNo ratings yet

- MP 0 2600 26 Sept 09Document8 pagesMP 0 2600 26 Sept 09Sreenath S KallaaraNo ratings yet

- Irimee TRGDocument15 pagesIrimee TRGSreenath S KallaaraNo ratings yet

- Hoisting System (Sistema de Elevacion)Document8 pagesHoisting System (Sistema de Elevacion)Ferna DiazNo ratings yet

- 4GZ Aty Sesv1722 PDFDocument280 pages4GZ Aty Sesv1722 PDFenrique100% (1)

- Buku Manual Yamaha MioDocument376 pagesBuku Manual Yamaha MioAngodi Maniz0% (1)

- Honeywell VisionPro 8000 Install InstructionsDocument12 pagesHoneywell VisionPro 8000 Install InstructionskoolermanNo ratings yet

- Lap WindingDocument13 pagesLap WindingSyah RoniNo ratings yet

- Air Compressor TermsDocument9 pagesAir Compressor TermsUniversal CollabNo ratings yet

- MS3282EMW04 Shaft AlignmentDocument25 pagesMS3282EMW04 Shaft AlignmentTaufikNo ratings yet

- Product Data: 39T Central Station Air-Handling UnitsDocument100 pagesProduct Data: 39T Central Station Air-Handling UnitsJesus CantuNo ratings yet

- Hari Modified ProjectDocument46 pagesHari Modified ProjectraamanNo ratings yet

- Bhushan Ics+bcsDocument24 pagesBhushan Ics+bcsmukesh_kht1No ratings yet

- Module 5 - Pipe Cutting and JoiningDocument14 pagesModule 5 - Pipe Cutting and JoiningKrizia InteligandoNo ratings yet

- Manual Taller Ssangyong KyronDocument297 pagesManual Taller Ssangyong Kyrondarkgothchi50% (2)

- Injector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesDocument2 pagesInjector Sleeve Installation On 2008-2017 Detroit Diesel DD15 & 16 Diesel EnginesIonut-alexandru IordacheNo ratings yet

- Manual Partes PowerlinkDocument34 pagesManual Partes PowerlinkMiguel Henriquez TizkaNo ratings yet

- Tablero Controlador FIRETROL FTA1300Document2 pagesTablero Controlador FIRETROL FTA1300Accesorios y SistemasNo ratings yet

- Rain+Birdt: DAS-ASVF Series Valve Installation and OperationDocument3 pagesRain+Birdt: DAS-ASVF Series Valve Installation and OperationcobasajamasNo ratings yet

- Service Repair Manual: English All Language: Geographic Region: Serial Number RangeDocument108 pagesService Repair Manual: English All Language: Geographic Region: Serial Number RangeChua Yong0% (2)

- Modelo 4030hcuDocument5 pagesModelo 4030hcuaalazaro29No ratings yet

- Operating Instructions: D 2866 E D 2866 TE D 2866 LE D 2866 LXEDocument64 pagesOperating Instructions: D 2866 E D 2866 TE D 2866 LE D 2866 LXEMohamed MohamedNo ratings yet

- TIC-Wireline Tools and Equipment Catalog - 部分225Document1 pageTIC-Wireline Tools and Equipment Catalog - 部分225zbhdzpNo ratings yet

- Dosatron DI210pxDocument4 pagesDosatron DI210pxChevronelleNo ratings yet

- Effects of OverheatingDocument46 pagesEffects of OverheatingSajjad Hossain ShuvoNo ratings yet

- Customer Service Department: Komatsu Utility Europe Pag. 1 Di 41 WETT001304Document41 pagesCustomer Service Department: Komatsu Utility Europe Pag. 1 Di 41 WETT001304juanitoNo ratings yet

Scope of Engine RebuildEMD

Scope of Engine RebuildEMD

Uploaded by

Sreenath S KallaaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope of Engine RebuildEMD

Scope of Engine RebuildEMD

Uploaded by

Sreenath S KallaaraCopyright:

Available Formats

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

Page 1 of 61

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

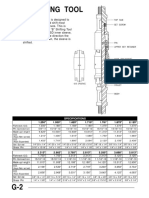

SPECIAL TOOLS AND

INSTRUCTIONS

PRE-CLEANING OF THE ENGINE

Special lifting bar.

Spray guns

8193041

Hot water HP

equipment.

COMPLETE DISASSEMBLING OF ENGINE

Injector pry bar

8041183

The methods can differ from one to another workshop, however the following sequence can be

adopted following the E.M.M in reverse sequence.

Water

pumpboltwrench

9519601

The engine weight is approximately 15,700 kg (without turbocharger) or 16,500kg (with

turbocharger). A 20-ton crane can handle the engine by means of a lifting bar with two hooks, which

will sling on two lifting eyes available on the engines ends.

Pre-cleaning will remove oil, grease and heavy dirt contained in all surfaces and components and

make further disassembling easier for the personnel.

Several methods can be used, but spraying a suitable manufacturers industrial cleaner detergent

(alkaline liquid) all over the surfaces and leaving it 10 - 15 minutes, then spraying it with hot water at

high pressure, will remove most of the substances referred to above.

Bolts, screws and other attachments showing heavy rust must be sprayed with suitable rust

removers (liquid cans) in order to get them easier to unscrew during disassembling.

2.1

2.2

Remove the two starting motors ship the motors to the repair shop.

Remove the protecting devices (engine protector, hot oil shutdown and over speed trip

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

housing and mechanism)- ship the devices to the specialised repair shops.

Remove the governor and linkages ship the unit to the repair shop.

Remove fuel filters/valves and injectors-ship the units to the repair shop.

Remove the 2 water pumps and after-coolers together with piping and housing ship to the

specialised repair shops.

Remove the lube oil filters, lube oil pumps (two), turbo pump, filter and valves, and strainer

housing together with attached piping ship them to the repair shops.

Remove exhaust manifold, exhaust screen and exhaust joints ship to repair shops.

Remove front and rear gear train covers and accessory housings- ship to repair shop.

Remove all gears at the front and rear of the engine-ship to the repair shop (except the

spring drive turbo gear).

Remove the camshafts ship to the repair shop.

Remove the stub shafts - ship to the repair shop

Remove the accessory drive coupling, flywheel and vibration damper ship to repair shop.

Remove conn rod and main bearings (baskets and main caps kept in matched units with

serial numbers registered).

Remove complete power packs ship for further disassembling into components.

Split crankcase and oil pan and remove crankshaft ship to the repair shop.

Remove miscellaneous piping, tubes, hoses, flanges etc ship to the repair shops.

Page 2 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

File 690 to lift after

cooler

Exhaust manifold

torque tool kit

8463512, 8463513

and 8463514

Turbo charger lifting

eye bolt 8496116

Main BRG cap tool

8487487

Test valve wrench

8032587

Lifting clamp

8417858

Piston hold eng tool

8417859

Conn rod clamp

8417881

Crab nut wrench set

9551713

E.M.M all sections

from o thru.

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

Page 3 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REBUILD/RE-QUALIFICATION OF ENGINE COMPONENTS

All components of the engine will be inspected, deeply cleaned, measured, magnafluxed (where

applicable) and repaired or replaced accordingly. In this project some components will be replaced

by new or utex components supplied to the re-manufacturer to be assembled later.

All repair kits, single parts, gaskets, seals etc will be supplied during individual repair of each

component.

Instructions, dimensions, limits and clearances are supplied on the E.M.M. or MIs where applicable.

These instructions are remarked on the column tools/instructions.

List of chemicals

used for deep

cleaning engines.

The crankcase will be immersed into a suitable tank in a solution of caustic soda and hot water. All

water and oil piping attached must be flushed with the solution to remove all scale, sediments and

dirt. After deep cleaning the crankcase will be flushed with clean water and dried with compressed

air. All surfaces must show a shinning grey colour after being clean. Alternative methods using

steam, spray of detergents etc. can also be used as long as the final appearance is the same.

Liquid detergent

sprayers.

High pressure hot

water equipment.

Gasket surfaces must be brushed to remove traces of old gasket material stuck to the surfaces. Old

traces of paint should be brushed off. Holes, threads and rusty surfaces must be brushed or wiped

and have a clean aspect for further inspections.

Rotating wire

brushes of several

diameters from

small to very large.

Straight ruler with 3

CRANK CASE AND OIL PAN RE-MANUFACTURING / RE-QUALIFICATION

a) DEEP CLEANING

3.1

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

b) VISUAL INSPECTIONS

Top deck covers for distortions.

All gasket surfaces for any defects that prevent good sealing later on.

All A frames for distortions.

Base rail to air box welds (if cracks are suspected confirm by Magna Flux).

Hand holes cover surfaces for sufficient sealing area.

Gussets and bracings in oil pan for damages.

Water manifold pipes for damages.( intensive corrosion )

Head frames for damages or distortions.

NOTE: All areas with defects must be marked with visible coloured markers and reported in

suitable documents, which contains the serial number of the component.

3.1

Page 4 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

meters min.

Feeler gage 0,1mm

Magnifying glasses.

150 to 200 watts

inspection lamp.

Yellow or white

marker.

c) MAGNA FLUX INSPECTIONS

As per amperage rating defined on MI-318 all following areas must be subject to magnetic

particle inspection. The iron dust in powder cans with spray gun must be from a

recognised source (Magnaflux company or equivalent). Suitable ultra violet lamp must

also be used during inspection of.

Mainframe serration.

Cylinder head retainers inside and outside diameter welds.

CRV tubes to retainer welds.

CRV tubes to crankcase side sheets.

Air box stress plate to end plate welds.

Cam pad welds.

Injector pad welds.

Cylinder head water discharge holes.

Top deck weld joints.

MI 318

Magnaflux unit or

D.C welding

machine for 500

AMP rating

minimum.

Magnaflux iron

powder and SAE 10

oil.

Ultra violet lamp.

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Page 5 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

End bar to top deck welds.

End bar support welds.

Exhaust manifold elbow welds

Oil pan piping application welds.

Oil pan mounting pads.

NOTES: all areas showing defects are marked with coloured markers for further correction. All

areas that have been repaired by grinding and welding must again be Magnafluxed to confirm that

repairs have been properly done.

3.1

d) HYDRAULIC PRESSURE TEST

If during visual and Magnaflux inspections no cracks are found it is necessary to perform a

hydraulic pressure test. Water/ fuel can be used compressed at 100psi pressure either by

mechanical or manual pumps. All water and oil passages are sealed in one extremity and

hydraulic pressure fluid injected at the opposite side of the passages. No leaks can be

acceptable. If leaks of fluid are found these areas must be marked to be ground/welded/plugged

or any other suitable repair method. New hydraulic test must be performed after repair.

e) DIMENSIONAL INSPECTION

Main bearing bore dimensions (EMM page 1-5 and MI 100)

Main bearing cap serration (MI-100)

Main frame member serration

Main bearing studs with die method

Upper pilot and lower liner bores diameters and concentricity (EMM 1-100) with liner insert

installed (MI-315). (note: if this dimension is not correct, insert must be removed and

concentricity checked again without insert).

Upper pilot and lower liner bores perpendicular to crankshaft centre line

Base rail parallel to line bore (crankshaft centre line)

End plates perpendicular to line bore

Cylinder head seats wear step (MI-316 and 317)

Keyways on crankcase and oil pan for spacing and size

Set of sealing

covers (to fabricate)

Set of rubber seals.

100 psi capacity

electric or manual

pump.

Tools and gages

preferred on EMM,

MI-100, MI-315, MI316, MI-317

Go no go gages

according to the list

on the text for

threads.

Line boring fixtures

for horizontal or

vertical boring.

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Page 6 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

Exhaust deck wear step versus top deck thickness

Hand hole cover flanges for wear and thickness

Hand hole cover diameters

Cylinder heads water outlet orifices for wear step

Exhaust deck to cam pads dimensions

Crab bolts with die nut method

All bolt holes by thread chasing method

Note: to be considered go / no go gages for threads of 1 -12 1 -12 1-14 1-8 -16

5/8-18 3/8-24 3/8-16 -20 and -20

Dowel holes on oil pan mounting feet for roundness and size

Stubshaft dowel holes for roundness and size

Base rail hole sizes for possible alignment purposes between crankcase and oil pan.

Note: preferentially dimensions must be marked and a document filled in indicating the

deviations found versus the factorys standard and instructions for further machining (or build up

welding stock to increase thickness).

3.1

f)

CRACK CORRECTION BY WELDING

All cracks found in any area must be corrected according to instructions contained in MI-318.

Suitable grinders and a variety of grinding bits, (carbide), with different shapes and sizes, will be

properly chosen, to cut the material around the crack and prepare the area for further welding.

Electrodes, amperages and welding machines must comply with MI-318 in all parameters

according to the place where the defect exists.

Exhaust elbows (complete) P/N 8344765 will be supplied to replace elbows that cannot be

salvaged.

Welders must be qualified to perform all possible welding jobs in any position. Welders must

exhibit a suitable factory certificate or be trained on the job by and EMDs instructor.

g) PLUG WELDING AND THREAD INSERTS

Holes with diameter above must be plug welded and re-taped if they are found defective.

MI-318 tools.

Rotating grinder

with several spare

grinding bits.

AC/AC or AC/DC

welding equipment.

Electrodes as per

MI 318.

Air compressed

hammers of several

sizes.

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Page 7 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

Holes with diameter bellow and including can be repaired by thread inserts.

h) BUILD UP STOCK BY WELDING

An area such as main bearing bores, cylinder bores, and head retainer seats etc. if found with

insufficient stock to be machined can be welded in minimum possible amounts to gain such

stock. Suitable techniques must be used to control deformation of the surfaces being welded.

i)

j)

3.1

HEAT STRESSES AND CONTROL OF DEFORMATION

The crankcase and oil pan can deform if extensive welding is necessary. By shot peening

during the process or/and into a suitable oven at proper temperature. The material stresses and

deformation must be avoided.

MACHINING OF CRANKCASE AND OIL PAN

Milling, boring, re-surfacing etc. are operations to be performed in crankcases and oil pans

calling for precision on the 0,001 range.

Some operations such as re-surfacing must cover the entire surface to be machined and some

others will cover individual spots or specific surfaces limited in areas of defects.

Specific machining requirements are as follows:

Main bearing cap serration

Note: caps cannot be welded and stock must be gained by serration re-machining.

Line bore just one or several bores

Weld shim to end plate of oil pan and match crankcase to oil pan

Base rail parallel to line bore after line bore is done

Upper pilot bores concentricity and/or perpendicular to line bore

Same for lower liner inserts before and after installation of new inserts

Head seats re-machined after build up welding

Keyways re-machined at correct sizes and spacing

Note: when this repair is necessary, it is mandatory to re-machine the top deck.

Holes and new threads to be done on a case by case basis

Exhaust decks re-machining if thickness is maintained within limits of drawing.

Hand hole cover flanges machined for correct diameter and thickness

Main frame serrations machined to maintain spacing and parallelism.

Hammer bits of

several sizes

according to areas

to shot peen.

Guaranteed

precision of

machines and

instruments up to

0,0005with proper

calibration within 6

months validity.

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

3.1

Crab stud support re-machining ( spherical seats )

End bars machined

Piston cooling pipes flanges machined

Crank shaft thrust faces re-machined

Re-machine the first end plate hole

O.S Hsg internal drain hole modification

Cam drive holes in end plate to be re-applied

Drill and tap hole for crankcase/oil pan protector modification

End plate dowel holes to be drilled oversized (or plug welded) and re-located

Crab bolt threads to be chased.

CRV bores to be re-bored if plug welded

CRV faces

Stubshaft dowel holes

Modify head frame to convert square into rounded corners

Notes on machining:

The tasks above described will be executed partly or totally according to the inspection criteria

dictated before welding and re-machining.

The surface finishes are clearly shown on manufacturers blue print therefore the tooling and cutting

speeds need to comply with the superficial texture of the faces varying from rough surfaces for

sealing purposes till almost polished faces of fine texture such as main bearing bores.

Critical fixing points such as main bearings and crab bolts on the heads require 100% inspection on

threads, studs and nuts to guarantee the tightness of these elements.

OIL PAN RE-MANUFACTURING

3.2

The works will be done together with the crankcase as described in 3.1

The oil pan will be matched with its specific crankcase and it may require the dowel holes to be plug

welded and re-drilled to fit the alignment of end plates and parallel to crankshaft centreline after line

boring. Serial numbers on both crankcase and oil pan will be registered during matching in an

Page 8 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

appropriate document which belongs to the engines remanufacture documents.

3.2

Note: Both crankcase and oil pan will be washed again in the end of the machining process and

finally inspected including Magnaflux all areas welded to repair rejects. Special EMD primer will be

used inside and outside of both components before shipping them for the assembly phase.

CRANKSHAFT

3.3

The crankshaft must pass by a process if inspection before a decision is taken to accept it and reuse it or to reject it for further rehabilitation or scrap.

INSPECTION OF CRANKSHAFTS

3.3 .1

a) CLEANING

Oil gallery plugs are removed

Crankshaft is immersed in a hot caustic solution to degrease quickly

Oil galleries are rodded with a wire brush

Oil galleries are flushed with hot caustic solution

Crankshaft is removed from tank and power washed

Crankshaft is dried with compressed air and lubricated lightly for rust prevention

b) MAGNAFLUX

Using proper equipment and methods as per MI314 several critical areas of the crankshaft

must be inspected.

All journals

All fillets

Oil holes

Counter weights

Page 9 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

3.3.1

TITLE, WORK DESCRIPTION AND COMMENTS

c) DIMENSIONAL CHECKS

Main and rod journal diameters

Main thrust faces

Rod thrust faces

Main run out between segments and adjacent journals

Pilot diameters

Note: all defects must be marked and a document produced indicating serial number of the

crankshaft.

CRITERIAS TO ACCEPT OR REJECT CRANKSHAFTS

According to Magnaflux and dimensional inspections the following procedures must be adopted.

3.3.2

a) Cracks Any crack in any area reject the crankshaft for further usage.

b) Dimensions-Comparing maximum and minimum dimensions with EMM page 6-16

and 6-17 any dimensions out of limits reject the crankshaft.

c) Defects Scratches or similar defects cannot change the polished surfaces

of the journals. Deep superficial defects that cannot be eliminated by hand polish

will reject the crankshaft.

REHABILITATION OR REPLACEMENT OF CRANKSHAFTS

3.3.3

If a crankshaft is rejected and if the re-manufacturer is not equipped with proper chrome plating

facilities, another new or qualified crankshaft must be ordered to replace the one rejected.

Page 10 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

SALVAGE OF REJECTED CRANKSHAFTS

There are several methods, however the process described bellow, complies with the O.E.M.

criteria.

a) PRE-GRIND

The areas showing defects, cracks or lack of dimensions must be ground to an undersize

diameter that cannot exceed 0.030 in order to eliminate defects. In order to reduce costs, it is

suggested to grind manually to a thickness not deeper than 0.002 to 0.005 and Magnaflux

again. Once the crack is removed and a sound core is found the grinding operation can stop.

3.3.4

b) DISASSEMBLE THE CRANKSHAFT INTO TWO SEGMENTS

In cases where one half can be saved and the other half be rejected the Crankshaft can be split

into two halves. A new or qualified segment can be attached to the segment that has been

saved and the segment flanges re-dowelled with conical Dowels (special) to form another

complete Crankshaft. In these circumstances it mandatory to perform a complete re-balance of

the Crankshaft in addition to the tasks performed if the whole crankshaft was originally saved.

c) MAGNAFLUX INSPECTIONS

Every time it becomes necessary to grind the journals or fillets or thrust areas to eliminate

cracks it is mandatory to Magnaflux the areas that were ground to ensure that the crack has

disappeared completely.

d) SHOT PEENING

Fillets will be shot peened to improve fatigue life

e) GLASS BEAD PROJECTION AT HIGH PRESSURE

The whole Crankshaft, (or each segment separately before re-assembly) will pass by Glass

Beads splashing in order to offer a suitable texture for the chrome plating process.

f) CLEAN WITH SOLVENTS

Gasoline or any spirits will help to de-grease and remove the Glass Bead residue.

Page 11 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

g) PRE-BRAKE

It improves the stress relief after pre-grinding and evaporates any residual oil, grease or

volatiles in the steel pores. Time and temperature to be closely controlled during the process.

h) PLATING PREPARATION

Lead tape will be applied at the fillets to provide sharp split between the chromed journal and

the steel fillet and also to reduce the hydrogen absorbed by the fillet. Remaining areas not to be

plated will be waxed.

3.3.4

i) PLATING

Shaft will be brought to the bath temperature and reversed etched. Current density, bath

temperature, bath chemistry and time will be the parameters to closely control, in order to get

the correct thickness, hardness and adherence of the chrome layer. Maximum acceptable

chrome layer should be 0,015, to comply with max undersized diameter of 0.030.

j) LEAD TAPE REMOVAL AND SOLVENT DEGREASED

To eliminate wax and grease contained in the parts, clean with solvents or spirits.

k) POST BAKE

To eliminate hydrogen embrittlement, the temperature and time are closely controlled to obtain

the desired results.

l) FINAL GRIND

Many light cuts are mandatory. The surfaces being cut must be cooled by flooded fluid. The

peripheral speed of the grinder and the part must be closely controlled to obtain the desired

result.

m) MAGNAFLUX INSPECTION

To guarantee that after the final grind, the Crankshaft is free of defects.

Page 12 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Page 13 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

n) ASSEMBLY OF THE TWO HALVES

Should a new or qualified segment be joined to the original one, new dowel alignment is

necessary to connect the mating flanges. Oversized dowels are available.

3.3.4

o) BALANCING OF THE CRANKSHAFT (only if two different halves are matched together)

If an original Crankshaft is completely re-habilitated by chrome plating, it doesnt require rebalancing. If two halves are joined together delivered from two originally different segments, the

new Crankshaft formed, must be balanced.

p) POLISHING JOURNALS

After all above steps have been followed, all journals must be polished mirror like.

Note: after rehabilitation of the crankshaft, as described above and using the correct data for the

various parameters, the Crankshaft should be as good as new for continuous operation.

3.4

CAMSHAFTS

Magnifying lens for fine

inspection of defects.

The Camshafts will be inspected together with their respective stubshafts for signs of discoloration,

indicating possible operation with lack of lubrication. If sensible discoloration is found both areas

must be Magnafluxed and tested for hardness.

Precise V blocks and

precise table to check

run out and bending.

a) CLEANING

Wash with solvents and flush all dirt from the oil passages clean with dry compressed air and

wipe with clean cloths the cams and journals in order to make them shine.

b) INSPECTION (visual)

Cam lobes and journals shouldnt show pitting, chipping or excessive score marks. Cams

without wear steps and very light flat spots or pit marks can be re-used after hand polishing,

blending and eliminating sharp edges.

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

c) INSPECTION (dimensions)

Journals must be checked for diameters, tapers, runouts, squareness of flanges, concentricity

between stubshaft and journals.

The stubshafts that accompany each camshaft must also be checked for diameter, thrust

dimension, thrust wear etc. as per EMM 7-23 data.

3.4

d) ACCEPTANCE/REJECTION CRITERIA AND SALVAGE OF CAMSHAFT PARTS

Camshafts have two segments each, therefore it is possible to replace just one segment if

damaged.

Excessive wear on cam lobes or diameter of journals or significant defects on the wearing

surfaces compels rejection of the parts.

Under certain conditions camshaft segments can be saved, as long as journal diameters are not

bellow the minimum of 2.490 and Cam Lobes still have sufficient hardness left after re-grinding.

The segment has conditions to be saved by chrome plating the journals and re-profiling the

lobes, (with suitable template).

These costs must be balanced against the cost of a new (or qualified) segment.

POWER PACK

3.5

The power pack is removed from the engine as a unit which now needs to be further cleaned,

disassembled into sub-components which will be individually inspected to determine those that can

be re-qualified from those that require further rehabilitation and finally those that must be scrapped

and replaced by new or qualified ones.

a) LIGHT CLEANING OF THE POWER PACK

The power pack must be washed with solvent (spirits) sprayed around the top of the head,

through the liner ports and underneath in order to remove dirt, carbon and oil before splitting it

Page 14 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

in sub-components.

Alternatively the power pack can be immersed in a caustic solution or sprayed with steam to

achieve the same results.

3.5

b) DISASSEMBLING THE POWER PACK INTO SUB-COMPONENTS

All gaskets and attaching materials will be removed and scrapped. The disassembling

procedure must follow instructions of EMM section 5 step by step using the proper tools and

fixtures there contained. Each individual sub-component will be inspected as per instructions or

the next chapters as follows:

3.5.1

3.5.2

3.5.3

3.5.4

Cylinder head, valves and springs, bridges, lash adjusters and test valve.

Piston and carriers with piston pin.

Connecting rods fork and blade types.

Liner.

The inspection, special cleaning, tests and re-qualification criteria to replace, reuse or repair are

bellow described in detail.

3.5.1

CYLINDER HEAD, EXHAUST VALVES, SPRINGS, BRIDGES, ROCKER ARMS, LASH

ADJUSTERS AND CYLINDER TEST VALVES.

3.5.1.1 CYLINDER HEAD

After the exhaust valve and springs are removed from the bare head it will pass by a heavy cleaning

and inspection as follows:

a) CLEANING OF THE BARE HEAD (EMM 2-3)

With caustic solution and carbon remover chemicals to eliminate built in carbon and sludge hard

deposits on water and exhaust passages. Rinse in pressurised water and dry with compressed

air and rotating brush. Valve guides must be cleaned by brushing the inside diameter.

Page 15 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

b) INSPECTION (VISUAL)-(EMM 2-4)

Overheated head to liner grommets reject the head for further usage. Scratches or nicks on

the sealing area require re-machining. Valve seats with pits and burned must be re-machined.

c) INSPECTION (MAGNAFLUX) (EMM 2-4)

Any cracks found by metallic particle inspection reject the head.

d) DIMENSIONAL CHECK (EMM 2-4)

The injector hole area and flange thickness as well as fire face to flange dimensions must

comply with standards otherwise it rejects the head.

3.5.1

e) LEAK TEST (EMM 2-3)

At 100 psi air pressure on the head immersed in water at 75C and sealed all passages during

2 minutes no leaks can be detected otherwise it causes rejection.

Note: if a cylinder head passes the inspection without rejection it may require further repair in

specific areas such as:

Valve seat grinding

Injector hole rework

Valve guide replacement (if necessary)

resurfacing

3.5.1.2 EXHAUST VALVE

a) CLEANING

Using solvent to remove oil and soft carbon. glass bead and vapour blasting or alternative

wire brushing.

b) INSPECTION visual and die penetrant (Emm 2-9)

Micro finishing the valve stem better than 0.6 microns. No sign of cracks at the cup. Cracks

on the outside rim diameter. Wear at the stem groove area. Deep nicks or scuffs. All these

areas reject the valve.

Page 16 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

c) INSPECTION dimensional

All dimensions according to EMM 2-19

d) ACCEPTANCE AND SALVAGE OF VALVES

If inspections reveal defects as referred above valves must be scrapped. If only light pitting

or small nicks are found the valve can be salvaged. If stem diameters are smaller than

standards the stems can be chrome plated but costs need to be balanced against the cost

of a new valve. Valves that still have stem diameters acceptable and only small defects at

the rim face must be ground with special grinders.

3.5.1.3 VALVE SPRINGS (EMM 2-10)

3.5.1

a) CLEANING

With solvent and brushing.

b) INSPECTION (visual and dimensional) EMM 2-19

According to EMM instructions and data provided.

c) ACCEPTANCE OF VALVE SPRINGS

If a spring has its free length within tolerances and the pressure is still in the middle

between max and min it can be re-used as long as the remaining conditions are

acceptable. Otherwise springs must be rejected and replaced by new.

Note: valve springs and bridge springs are the same and must be qualified at the same

time. Valve locks must be replaced by new (always).

3.5.1.4 EXHAUST VALVE BRIDGES

The bridges (two per head) require further disassembling into parts before final inspection

and re-qualification. These parts are as follows:

Valve bridge body (to be inspected and re-qualified or rejected)

Spring with lock ring (tested together with valve springs EMM 2-10)

Page 17 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Hydraulic lash adjuster ( to be replaced by new).

a) CLEANING

Before disassembling into parts the whole bridge is clean in solvents (spirits)

Note: do not use caustic solution.

b) INSPECTION OF BRIDGE BODY (visual and dimensional)-EMM 2-12 (3.5.1.3item)

The disassembling process requires special tools and fixtures. The valve bridge body

must be measured in 9 (nine) areas according to EMM 2-12 and EMM 2-20.Any area

out of dimensions reject the bridge body.

3.5.1

d) CRITERIA TO ACCEPT/REJECT BRIDGE BODIES

If pin at the end of bridge is bent it can be straightened and re-used. If all dimensions

are within parameters of EMM 2-20 the bodies can be re-used. Spring seats and lock

rings which maintain the bridge springs in place must be replaced by new.

3.5.1.5 ROCKER ARM ASSEMBLIES. (EMM 2-15 and 2-16)

The arms (3 per head) require further disassembling into parts. Together with the arms it is

necessary to re-qualify the rocker arm supports (2 per head) and the rocker arm shaft ( one

per head) the whole assembly contains the following individual parts:

Rocker arm body ( to be re-qualified)

Roller assembly (to be replaced by new)

Adjusting screw assembly (to be replaced by new)

Supports and support caps ( to be re-qualified)

Shaft (to be re-qualified)

Bushings and bolts/nuts (to be replaced by new)

Page 18 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

a) CLEANING

All oil passages must be cleaned using solvents. No caustic solution acceptable. The

attached parts must be disassembled from the bodies, and those to be scrapped will be

separated from those to inspect and re-qualify.

b) INSPECTION (visual and dimensional)

To re-qualified or reject rocker arm bodies, supports and support caps as rocker arm shafts

instructions or EMM 2-15 and 2-16 must be followed and dimensions must comply with

EMM 2-20.

3.5.1.6.LASH ADJUSTERS

3.5.1

Due to special equipment tools and procedures involved as well as the cost for parts that

require replacement during repair, lash adjusters quality is very important and high risks of

failure exist it is considered of no value to attempt repairing them. Complete replacement by

new units is fundamental.

3.5.1.7. CYLINDER TEST VALVE

The complete test valve assembly is removed (unscrewed) from the cylinder head, cleaned

and inspected as per EMM 12-16 and 2-17. The valve may receive a proper re-conditioning

if leaking after being tested at 90psi air pressure. Reconditioning limits for the body are

available at EMM 2-17 and the whole valve must be scrapped and replaced by new, should

the valve require repairs.

PISTON, CARRIER AND PISTON PIN

3.5.2

The piston, carrier and connecting rod are removed from the power pack as a unit that is further

disassembled into the major components and sub-components.

Piston (to be re-qualified)

Carrier (to be re-qualified if its life is less than 15 years)

Page 19 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

Thrust washer (to be scrapped)

Piston pin (to be re-qualified if its life is less than 15 years)

Bearings (to be scrapped)

Note: connecting rods re-qualification will be dealt with in chapter 3.5.3.

3.5.2.1 PISTON

a) CLEANING

The piston requires a deep cleaning to remove under crown deposits according to MI-1759.

This cleaning procedure also removes the phosphate coating and prepares the piston

surfaces for new phosphate treatment or tin plated.

Note: If the piston is cracked or the grooves are damaged, deep cleaning doesnt become

necessary therefore inspections are prior to the deep cleaning.

3.5.2

b) VISUAL INSPECTION

After immersing the piston in an alkaline solvent solution to remove carbon deposits and

brushing it with steam or hot water and blow dry air, inspect it for excessive scoring of the

skirt as per EMM 3-7

c) MAGNAFLUX INSPECTION

To determine cracks in the crown or at the ring groove land.

d) DIMENSIONAL INSPECTION

Should a piston show any cracks it must be scrapped and dimensional inspection is not

necessary. Otherwise the basic dimensions of the piston must coincide with the standards

of EMM 3-14 in 6 areas of measurements. Should any dimension change beyond the limits

the piston is rejected.

e) SALVAGE OF PISTONS

Under certain conditions of excessive scores and oversized first groove the piston can be

re-machined to use oversized first compression ring and re-coated thru phosphatization or

tin plating.

Page 20 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

3.5.2.2 CARRIER

The carrier is a sturdy piece that has an indefinitely long life therefore light cleaning and

magnaflux inspections are the only two tasks required to re-qualify the carrier. Dimensional

checks are done in addition to the above tasks according to EMM 3-15 and any minor area

of defect will reject the carrier. Carriers older than 15 years should be scrapped.

3.5.2.3 PISTON PIN

External surface of the pin must be washed and brushed to remove any traces of oil, carbon

etc and rinsed in clean solvent and dried with compressed air. Tap hole with 7/8 14-28 tap.

3.5.2

a) Rejection of pins by serial number and specific defects. All pins over 15 years old must

be scrapped even if found in good condition. Pins p/n 9518958 from serial no.9760001 thru

97k0240 must be scrapped. Any minor defect noticed on Magnaflulx inspection especially

around the 0,375 drive hole on the side of the pin will force the pin to be scrapped.

Discolouration caused by possible overheat will scrap the pin too.

b) MAGNAFLUX INSPECTION

To detect longitudinal cracks the current is 2000 to 2500 amperes on the coil around the

pin. For transversal cracks the current is 1000 to 1500 amperes with the coil crossways.

Time is 5 seconds. Any small defect noticed will scrap the pin. Demagnetise the qualified

pin before re-usage.

CONNECTING RODS

3.5.3

The two types of rods have different criteria for re-qualification however the cleaning process is the

same. To remove rust oil, carbon and dirt it requires caustic, solvents, wire brush, rinsing and dry

air.

3.5.3.1 PROCESS OF FORK ROD RE-QUALIFICATION

Page 21 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

3.5.3

It is necessary to remove, debris and tap the following.

Fork rod dowel pins (1/2)

Fork basket dowel pin (0,3125)

Fork rod bore protrusions.

Fork rod counterbore.

Fork baskets serrations and bore

Tap the 5/8-18-28 hole

a) MAGNAFLUX FORK ROD

To find the transverse cracks in I beam, saddle and U slot and longitudinal cracks in saddle

and U section. If such defects are found scrap the rod.

b) MAGNAFLUX BASKET

To find longitudinal or transverse cracks. If defects are found scrap the basket.

c) DE-MAGNETIZE all rods that have not been scrapped.

d) DIMENSIONAL checks for all holes with go-no go gages if any hole doesnt qualify scrap

the rod.

e) DIMENSIONAL check of C bore width and depth.

If width is not within parameters scrap the rod. If depth is not within limits scrap the rod.

f) CHECK OF DIMENSIONS for twist, parallelism and overall length between centre lines.

If dimensions are not within parameters scrap the rod.

g) SALVAGE OF RODS

If some or all the conditions bellow are observed the fork rod can be salvaged by rework

(EMM 3-10).

Fork rod and basket bore exceed the maximum

Nicks, burrs or fretting on serrations

Damaged threads in bolt holes or loose dowels

Damaged or distorted basket

Out of parallel in excess of limits in length

Page 22 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Length of rod shorter than limits

Fork counterbore exceeds the maximum depth

h) RODS THAT CANNOT BE SALVAGED

There are cases that rods must be scrapped since it is not possible to salvage

Cracks revealed by magnaflux

Heat discolouration on fork or basket

Twisted, bent or out of parallel beyond repair

Length between bore centres beyond minimum rework limit

3.5.3.2 BLADE ROD RE-QUALIFICATION

The rod must be deburred at the pin end, I beam and shoulder

3.5.3

a) MAGNAFLUX BLADE ROD

To find transverse cracks in beam section and saddle parallel to piston pin and longitudinal

cracks in saddles.

b) DEMAGNETISE ALL RODS THAT HAVE NOT BEEN SCRAPPED

c)CHECKING OPEN OR CLOSED ENDS.

With a 7,692 mandrel diameter and feeler gage.

d) CHECKING SHOULDER THICKNESS

If less than 0,320 the rod must be scrapped.

e) CHECKING TWO HOLES ON PIN END

Diameter of 0, 890 if cannot meet standards after rework the rod is scrapped.

f) MICRO FINISHING OF SLIPPER SURFACE TO BE LESS THAN 6 MICRO INCHES.

g) LENGTH, TWIST AND PARALLEL QUALIFICATION

Page 23 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

Page 24 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

To be done with a special gage as per EMM section 3.

3.5.3

h) SALVAGE OF RODS

Blade rods can be reworked and re-qualified if the following conditions exist.

Scarred, pitted or deeply rusted at slipper surface.

Slipper closed or opened beyond limits.

Out of parallel along side of saddle length.

Length of rod between bore centres is less than minimum.

EMM page 1 to 10

of section 3.

Drawing file 686.

i) RODS THAT MUST BE SCRAPPED

Cracks found during Magnaflux inspection

Heat discolouration on slipper surface

Less than minimum flange thickness on slipper shoulder.

Twisted, bent, out of parallel damaged beyond repair.

Length of rod between bore centres is less than minimum rework limits.

CYLINDER LINER

3.5.4

Before washing the liner in a caustic bath and/or scale remover from the water passages it is

necessary to use the tool file 686 to clean the water seal counterbore.

a) WASHING

Immerse liners in a tank containing an acid solution adequate for removing inside scale

deposits at the water passages without attacking the base cast iron. Prior to washing the

water deflector and seal must be removed to allow the circulation for the cleaning fluid.

b) VISUAL INSPECTION

All inner surfaces of the liner for scratches, hot spots, nicks, ridge at the combustion

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

chamber part and other cosmetic defects at outside and inside diameters. Any minor crack

found, scrap the liner. Signs of overheating and scratches longer than 1 at the working

area of the liner will scrap the liner.

3.5.4

c) DIMENSION CHECKS

With special indicator and handler will tale 2 readings 90 apart in several areas of the

inside diameter as per EMM 4-2 and compare with standards on EMM 4-5.

Should all measurements be within standards, check with a new piston the clearance at 6

bellow the top of the liner. If clearance is more than 0,5mm the liner can be matched

selectively with another piston that shows a clearance less than 0,5mm.

d) CHROME PLATED LINERS

If chrome plated liners cannot be re-qualified by dimensional checks and if no cracks are

found, they can be re-chromed after being reclaimed and sent to specialised companies for

salvage.

INJECTORS

3.6

The injectors removed from the engine will be packed into groups after light washing in solvents

with out disassembling them.

Groups of injectors contained in boxes will be shipped to outside of the country. Replacement

injector will be sent to the shop for final installation.

Note: the injectors are controlled by means of a set of levers, shafts and unions with adjusting

screws, nuts and springs, all these components will be individually inspected and qualified on item

3.23. injector control rods and governor control levers, following the column sequence.

Page 25 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

3.6

3.6.1 STANDARDIZATION OF INJECTORS

All injectors received P/N 5229250 (UTEX 8478046) or P/N 5229335 (UTEX 8478055) respectively

for engines type E3 or E3B will be standardized in just one type E3B. In these circumstances all

injectors to replace and be assembled on overhauled engines must be P/N 5229335 new or

8478055 UTEX.

3.6.2 RE-QUALIFICATION AND OVERHAUL OF INJECTORS

Out of the scope of this project but can be dealt separately upon request.

GOVERNOR

3.7

The governor removed as a complete unit will be emptied of oil and lightly washed in solvents

without disassembling. The units will be wrapped up in plastic with a light film of clean oil to be

preserved for shipment to the specialized shop. Replacement governors will be supplied for

installation in the engine.

Two types of governors will be received type E3 and E3B all associated levers, adjusting screws,

knobs, springs etc will be qualified separately under item 3.23 injector control rods and governor

control levers.

3.7.1 STANDARDIZATION OF GOVERNORS

All governors to be installed in the overhauled engines will be standardized in just one type either

P/N 9516898 or 9329963 rated to 900 RIM and 0,80 rack setting. The standardization will occur

during the unit exchange process.

3.7.2 RE-QUALIFICATION AND OVERHAUL OF GOVERNORS

Out of the scope of this project but can under request be dealt separately.

Page 26 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

ENGINE PROTECTOR

3.8

All protectors removed from the engines will be lightly washed with solvents and packaged for unit

exchange. The UTEX unit to be supplied for assembly in the overhauled engine may have two

distinct part numbers. P/N 9320130 new (9332828 UTEX) delta P for turbo engine P/N 40006305

new (40042768 UTEX) dual delta P for turbo engine.

The dual delta P protector is identical to the single delta P except for the addition of another

independent low water portion to sensing pressure rise through the right bank water pump.

If the dual delta P protector is supplied as a much better and efficient protector, the right bank

water pump requires the addition of the hardware (piping, fittings etc.) now only available on the left

bank water pump as well as suitable connections to the extra low water portion of the protector.

Cost study should compare prices of 9320130 and 40006305 to decide commercially the best

arrangement.

REPAIR OF ENGINE PROTECTOR

3.8 (a)

Alternatively being available a special tester for protectors (9339066) and the repair kit 9535869 it is

possible to repair and test the protector following instructions of MI-260.

WATER PUMPS

3.9

The water pumps and respective water inlet and outlet piping must be cleaned, disassembled,

inspected and reconditioned as per instructions or EMM section 10 pages 10-5 to 10-11.

a) PUMP DISASSEMBLY

Some special tools (9549072) are necessary together with normal wrenches to split the

pump into sum-components and parts.

All replaceable parts (water slinger, seal assembly, gaskets, ball bearings, brass bolts,

wear ring, thrust collar and drive ring). If the shaft is magnetic and not silver plated it must

Page 27 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

be disregarded and replaced by current shaft.

b) CLEANING

Rust, scale deposits, dirt etc must be cleaned thoroughly, to allow further inspections.

3.9

c) VISUAL AND DIMENSIONAL INSPECTION

Dimension of bearing bores in support housing (to be reworked)

Housing thrust face dimension (to be reworked)

Shaft dimensions (to be scrapped)

Defective threads (to use keenserts)

Gasket surfaces (to re-machine if corroded)

Impeller housing for cracks (scrap if defective)

d) UPGRADING

The pump may need to be transformed into self oiling to meet current specifications.

e) RE-ASSEMBLY

With repair kit and new parts to replace those scrapped the pumps will be re-assembled

respectively L (left) and R (right) per engine according to EMM 10-8. Some special tools

will be needed.

OIL PUMPS

3.10

The two oil pumps (main pump and scavenging pump) will be dealt separately despite being similar

in design and repair methods.

Whereas the main pump operates to distribute the oil in two distinct circuits (for general lubrication

and for piston cooling). The scavenging pump only circulates the oil through external circuit

Page 28 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

MAIN LUBE OIL PUMP

3.10.1

a) CLEANING

Just externally a light cleaning with solvents before disassembling.

b)DISASSEMBLING

Using special puller and following EMM 9-10 procedure.

c) CLEANING INDIVIDUAL PARTS

With solvents and compressed air.

d) INSPECTION VISUAL AND DIMENSIONAL

Pump bodies (front and rear) rework if scratches are found.

Spacer between pump chambers scrap if nicks and wear are visible.

All gears teeth in excess of 30% contact area pitted must be scrapped/

Defective threads may be repaired with keenserts

Gear bores wear cuts, grooves, nicks or scoring to be reworked

Drive shafts nicks to be reworked

Shafts thrust wear to be reworked

All bushings, seals etc to be replaced

e) ASSEMBLY

According to EMM 9-11 procedure and all tolerances of EMM 9-19and 9-20 regarding (any

tolerance out of limits must be corrected accordingly.)

Drive shaft to rear housing bushing clearance.

Sleeve to bushing clearance .

Idler shaft to gear bushing clearance.

Driven gears total thrust clearance.

Thrust face of body to bushing clearance.

Drive and driven gear back lash.

Radial clearance of drive gear to body.

Drive shaft thrust clearance.

Pump drive gear face runout.

Pump flange face runout.

Page 29 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

3.10.1

3.10.2

Pump flange pilot concentricity.

Pump drive gear to acc drive gear backlash.

SCAVENGING PUMP

a) CLEANING

Same procedure as for main pump item 3.10.1

b) DISASSEMBLING

Same as for item3.10.1

c) CLEANING INDIVIDUAL PARTS

Same as for item 3.10.1

d) INSPECTION visual and dimensional

The scavenging pump doesn't have the central spacer, which is used on the main pump

only. The remaining components are the same with the same criteria for re-qualification or

rejection.

e) ASSEMBLY

According to EMM 9-14 and 9-15 and check all clearances indicated as follows for item

3.10.1 (indicated in EMM 9-19 and 9-20)

Drive shaft to rear Hsg bushing clearance.

Sleeve to bushing clearance.

Idler shaft to gear bushing clearance.

Drive and Driven gears back lash.

Radial clearance of drive and driven gears.

Drive shaft thrust clearance.

Pump drive gear face runout.

Pump flange pilot concentricity.

Pump drive gear to acc drive gear backlash.

Page 30 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

FRONT AND REAR COVERS AND HOUSINGS

3.11

The engine has basically five housings located at the front and rear ends requiring individual requalification since they form a group of structural members.

Accessory drive housing.

Camshaft drive housing.

Engine air filter housing (not attached to the engine on locomotive appl).

Governor drive housing.

Overspeed device housing.

Each one of the four remaining housing (since air filter HSG is not part of this project) must be

individually cleaned, inspected and rejected or reworked accordingly.

a) CLEANING

Caustic solution and brushing in order to remove all paint and old gasket material at the

sealing faces. The housing must show a clean to the touch appearance, grey and shining

material.

b) VISUAL AND MAGNAFLUX INSPECTIONS

All bolting holes must be inspected for roundness, threads condition and cracks and marked

for further correction by plug welding and re-drilling or tapping.

Surfaces with nicks, burrs etc must be blended at the sealing areas, Cracks that affect the

future strength of the members must be ground and welded/ machined.

Thickness, straightness etc must be confirmed. Any slight deformation must be corrected

and stress relieved by peening or normalization.

c) CRITERIA FOR REJECTION AND REPLACEMENT

Only when housings are damaged beyond repair they must t be replaced by new.

Page 31 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

GEAR TRAIN AND SPRING DRIVE GEAR

3.12

The gear train is the group of main gears that are located respectively at the front and at the rear of

the engine which transmit motion from the crankshaft up to all other major components timed with

the motion of the crankshft. The major gear assemblies are as follows:

Accessory drive gear.

Crankshaft gear.

Camshaft drive gears (two gears).

No.1 Idler gear.

No. 2 Idler gear (see also spring drive gear).

Spring drive gear (turbocharger drive).

Governor drive gear.

Auxiliary drive assembly.

Note: the no.2 idler gear and the turbocharger drive gear are assembled together into one single

assembly called spring drive gear containing a special hub with a group of springs separating the

two gears.

Each gear must be cleaned, inspected, magnafluxed, re-worked (if possible) or replaced (if

damaged beyond repair).

3.12.1 ACCESSORY DRIVE GEAR

3.12.1

The gear assembled is sub-divided into:

Gear

Solid disc

Spring housing disc

Dowelled hub

Oil slinger

Spring segments

Spring (to be scrapped)

Page 32 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

3.12.1

TITLE, WORK DESCRIPTION AND COMMENTS

a) CLEANING

Individual elements of the gear assembly will be cleaned with solvents and brushed to

remove oil, grease, dirt etc. till all parts are shiny clean.

b) INSPECTION

According to EMM 6-8 and 6-9 item by item individually.

c) CRITERIA TO ACCEPT/REJECT

Follow EMM 6-8 and 6-9 except for springs which must be scrapped and replaced by new.

d) RE-ASSEMBLY AND PHOSPHATE TREATMENT

Before re-assembly it is important that the gear, hub, discs and segments are hosphatised

and all bolts, nuts, washers etc be also new together with springs.

To assemble the accessory drive gear, follow EMM 6-8 and 6-9.

The final assembly of the acc drive gear in the front of the engine depends on the

crankshaft end configuration. If the configuration is standard the assembly procedure is

different to the bolt-on stubshaft. Most of the crankshafts are passing to bolt-on stubshaft

configuration and those that are still standard can be converted into bolt-on stubshaft type.

EMM 6-8 and 6-9 and mounting clearances of EMM 6-15 and 6-16 must be followed

integrally during assembly.

3.12.2 CRANKSHAFT GEAR

3.12.2

a) CLEANING

With solvents and compressed air.

b) DISASSEMBLING

The gear and oil slinger can be separated and inspected individually.

c) MAGNAFLUX INSPECTION

No sign of cracks can be found in any tooth of the gear. Fatigue indications, pits, excessive

wear can still reuse the gear as long as the backlash as per figure 7-6 of EMM is within

limits.

Page 33 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

3.12.2

TITLE, WORK DESCRIPTION AND COMMENTS

d) INSPECTION OF SLINGER AND OIL SEAL RETAINER

If bent or damaged beyond repair should be scrapped and replaced. The clearance

between slinger and oil seal must be 0,090 to 0,110 and if not obtained shims can be

added or removed to comply (shims P/N 8035526-0,010; 8035527 0,020 or 80355280,030 can be used to adjust the clearance accordingly).

e) RE-ASSEMBLY

The gear, slinger and oil retainer must be assembled as a unit to be installed afterwards at

the crankshaft and during the assembly of the gear train with gage file 768 the backlash is

out of limits the crankshaft gear must be removed and scrapped.

3.12.3- CAMSHAFT DRIVE GEARS (TWO)

3.12.3

a) CLEANING

With solvents and compressed air.

b) MAGNAFLUX AND VISUAL INSPECTIONS

No signs of cracks can be found in any tooth of the gears fatigue indications as well as pits

on the teeth can still be acceptable if backlash between gears is still acceptable as per

EMM 7-21 potting or gouging on teeth that mate with auxiliary drive gear indicates

misalignment of the auxiliary gear that need to be investigated and corrected during engine

assembly.

c) RE-ASSEMBLY

The camshaft gears will be installed at the gear train during engine assembly.

The counterweights to be attached to each one of the camshaft gears should be clean and

mounted with new bolts and washers, however they will only be installed after the whole

gear train at the rear of the engine is installed and timed relatively to the top dead centre.

Page 34 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

SEQUENCE

TITLE, WORK DESCRIPTION AND COMMENTS

3.12.4- NO.1 IDLER GEAR

3.12.4

a) CLEANING

With solvents and compressed air.

b) MAGNAFLUX AND VISUAL INSPECTION

As per inspection of Emm 7-5

c) CRITERIA TO ACCEPT/REJECT

If cracks, fatigue or damaged beyond rework it must be replaced by new.

d) RE-ASSEMBLY

As per instructions of EMM 7-6

Note: Alignment of no.1 idler gear and backlash depends on condition of stubshafts which

are inspected and qualified according to item 3.l13 of this project, therefore the assembly of

no. 1 idler gear is after the assurance that its stubshaft is duly qualified.

3.12.5- NO. 2 IDLER GEAR (SPRING DRIVE GEAR)

3.12.5

This gear is inserted into an assembly called spring gear, therefore the re-qualification or rejection

of one of the gears (two gears in the assembly) affects the qualification of the other.

The assembly consists of the following:

No.2 Idler gear with 58 teeth

Turbocharger drive gear with 74 teeth

Spring assembly mounted between the two above gears

The spring assembly can be object of inspection after cleaning with solvents as follows:

a) SPIDERS Magnaflux for cracks, fretting on ID, verify max.ID. of pilot, verify all threaded holes and

reject the whole assembly if these defects arise.

b) SNAPRINGMagnaflux for cracks and replace old model by current one.

Page 35 of 61

SPECIAL TOOLS AND

INSTRUCTIONS

REPORT: REPAIR AND REHABILITATION OF 16-645 E3/E3B IIRR PROJECT

Author: LIBERTO PIRES

Date: 11TH SEPTEMBER 2000

TITLE, WORK DESCRIPTION AND COMMENTS

SEQUENCE

3.12.5

c) SPRING SEAT ASSEMBLYMagnaflux for cracks at the swaged lip and must be tight on the plate (reject if a 0,002

feeler gage can pass between seat and plate.

d) SPRINGSMagnaflux for cracks and check for length.

e) SPRING RETAINER PLATESMagnaflux for cracks.

The two gears must be inspected using the same criteria as for all other gears of the engine gear

train.

Should anyone of the parts of the assembly be out of limits beyond repair the whole assembly must

be changed by a new or re-qualified one. The spring gears rejected should be packed for exchange.

The UTEX spring gear must be checked before assembly on the gear train no. 2 idler position

applying a torque of 1000 ft lb on one gear while the other is immobilised to check the binding and

freedom of action. The torque must be applied in both directions to analyse the total freedom of

action.

SPRING DRIVE GEAR

3.12.6

Same as above.

3.12.7 GOVERNOR DRIVE GEAR

3.12.7

The governor drive gear located at the front of the engine is an assembly of the following

components.

Governor drive gear and bushing

Stubshaft

Retainer plate

Governor drive flange

Each sub-component requires proper cleaning with solvents and brushing all components must be