Professional Documents

Culture Documents

Untitled Extract Pages1

Untitled Extract Pages1

Uploaded by

MOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled Extract Pages1

Untitled Extract Pages1

Uploaded by

MCopyright:

Available Formats

Predicting the Remaining Life of

Vacuum Interrupters in the Field

Applying the Magnetron Atmosphere Condition Assessment (MAC) test in a field environment

INTRODUCTION

Historical perspective

Historically, air-magnetic and oil interrupters were the only types of

interrupters used on circuit breakers rated at 2.4 kV and higher. The air

interrupters predominated the lower voltages in this range from 2.4 kV

up to 25 kV. Above 25 kV, oil interrupters were the more commonly used

primarily because of their ability to interrupt higher arc energies.

Thus there are a number of features that have led to its wide acceptance as

a superior interrupting technology. These features include the following:

It is a relatively compact and sealed unit.

The travel required to open is very short with distances that vary

with age and manufacturer. The actual travel distance varies with VI

geometry and voltage level; however, typical distances range from

approximately 8 mm (0.314 in) to 12 mm (0.472 in).

Air-magnetic interrupters

Air-magnetic interrupters degrade somewhat each time they are opened

under load, and they degrade significantly if they are interrupted under

fault. The contacts can be repaired or replaced if required; however, the

maintenance of these types of circuit breakers was not always properly

scheduled sometimes resulting in failures.

It has the longest expected service life of any interrupting method.

When a VI experiences one of their relatively rare failures, the

resulting damage is sometimes much less than air-magnetic

interrupters. However, they still can fail spectacularly causing great

damage.

In addition to the maintenance problem, the arc-chutes are very large and

heavy. Some of the arc chutes on these breakers are also somewhat fragile

and can be broken if not properly handled.

Oil interrupters

Oil interrupters are also very heavy. More importantly, the interrupter

itself is submerged in oil and is difficult to reach for inspection. Testing

methods such as contact micro-ohmmeter tests, insulation resistance

tests, power factor tests, and the like are quite reliable in determining

the condition of the interrupter. However, like air-magnetic interrupters,

these units were not always maintained as they should be.

In addition to maintenance and size problems, stricter environmental

requirements make using these types of interrupters subject to increased

regulation and higher cost of maintenance.

What accounts for the amazing popularity of the vacuum

interrupter?

Partially as a response to many of the issues with air-magnetic and oil

interrupters, widespread use of vacuum interrupter (VI) technology and

SF-6 technology in electric power distribution systems started over thirty

years ago. In the intervening years, the VI has become the choice for the

vast majority of circuit breakers applied between 1000 volts and 36,000

volts.

Figure 2. Internal view of a typical vacuum interrupter.

Why do vacuum interrupters work?

The VIs high interrupting capacity is based on the physical principle

discovered by Louis Karl Heinrich Friedrich Paschen (1865-1947).

Paschen did original experimental research and discovered that the

dielectric strength of a gas is a function of the gas pressure (p), the distance

between the two electrodes (d), and the type of gas. This relationship is

given in Equation 1.

Paschens Equation 1.

Note that a and b are constants that are derived for dry air.

Figure 1. External view of a

typical vacuum interrupter.

The VI (See Figures 1 and 2) is light-weight, sealed from the atmosphere,

and has a very long predicted useful life. Since VI technology was first used

in the industry, typical predictions have been 20 or 30 years.

Figure 3. Paschens curve for dry air.

You might also like

- High Voltage Circuit BreakerDocument29 pagesHigh Voltage Circuit BreakerDave Chaudhury100% (2)

- Bosch Alternators Service ManualDocument13 pagesBosch Alternators Service ManualLando FulsarNo ratings yet

- Repair Autocom CDP VCIDocument5 pagesRepair Autocom CDP VCIAdi Catanescu100% (2)

- INT Switchgear Developments For IMEDocument7 pagesINT Switchgear Developments For IMEcarlos vidalNo ratings yet

- North Bengal International University Department of Electrical & Electronic Engineering Course No.: Eee 4341 Course Title: Power System ProtectionDocument23 pagesNorth Bengal International University Department of Electrical & Electronic Engineering Course No.: Eee 4341 Course Title: Power System ProtectionEsha JahinNo ratings yet

- CA Vd4 40ka (En) M 1vcp000001 CatalogDocument86 pagesCA Vd4 40ka (En) M 1vcp000001 Catalogdorin serbanNo ratings yet

- Edoc Magnetron Atmospheric ConditionDocument7 pagesEdoc Magnetron Atmospheric ConditionEl Comedor BenedictNo ratings yet

- Application of Grounded Metallic Enclosing Mesh For Expanding Rated Voltage of Dry-Type TransformerDocument8 pagesApplication of Grounded Metallic Enclosing Mesh For Expanding Rated Voltage of Dry-Type TransformerMahali Nizar SafriNo ratings yet

- ABB VD4 Catalogue EngDocument56 pagesABB VD4 Catalogue EngPuiu TiganasuNo ratings yet

- 2 - 2 Circuit Breaker DesignDocument3 pages2 - 2 Circuit Breaker DesignMrNo ratings yet

- Circuitbreakers 15121504Document35 pagesCircuitbreakers 15121504MOHSIN_IIUINo ratings yet

- CircuitDocument45 pagesCircuit1981todurkarNo ratings yet

- Untitled Extract Pages2Document1 pageUntitled Extract Pages2MNo ratings yet

- SourabDocument31 pagesSourabImam HossainNo ratings yet

- IEC 62271200 HV Switchgear and Controlgear EEPDocument3 pagesIEC 62271200 HV Switchgear and Controlgear EEPMohammed MadiNo ratings yet

- SF6 Vs VCB - MVDocument9 pagesSF6 Vs VCB - MVHeather CarterNo ratings yet

- Magnetron Atmospheric ConditionDocument8 pagesMagnetron Atmospheric Conditionfede.lozano30No ratings yet

- Circuit Breaker Types and TestingDocument30 pagesCircuit Breaker Types and TestingAnuj GuptaNo ratings yet

- ABB Vacuum BreakerDocument40 pagesABB Vacuum BreakerVikrantNo ratings yet

- Standards and Specifications (Chap-9)Document12 pagesStandards and Specifications (Chap-9)Mehdi Rabbani100% (1)

- ABB 11KV Vmax VCB CatalogueDocument40 pagesABB 11KV Vmax VCB CatalogueDan Juson60% (5)

- CIRED20007 - Paper 267Document4 pagesCIRED20007 - Paper 267bpd21No ratings yet

- Selection of 400kV Circuit Breakers and IsolatorsDocument5 pagesSelection of 400kV Circuit Breakers and Isolatorsgagandeeppruthi21No ratings yet

- Circuit Breakers PresentationDocument48 pagesCircuit Breakers Presentationmuaz_aminu1422100% (2)

- 04 Siemens PTD 3ah Vacuum Versus Sf6 Circuit BreakersDocument6 pages04 Siemens PTD 3ah Vacuum Versus Sf6 Circuit Breakerssaniya_mirza4No ratings yet

- Design & Testing of ZnO Lightening ArresterDocument19 pagesDesign & Testing of ZnO Lightening ArrestersureshnfclNo ratings yet

- Bep 2Document4 pagesBep 2RK KNo ratings yet

- Ehv EquipmentsDocument5 pagesEhv EquipmentskjfensNo ratings yet

- Digital Testing of Voltage CircuitDocument23 pagesDigital Testing of Voltage CircuitpraneethNo ratings yet

- VD4 CB 13.8 KVDocument120 pagesVD4 CB 13.8 KVAshraf AbdelsalamNo ratings yet

- Switchgear Lab ManualDocument40 pagesSwitchgear Lab ManualZeeshan Ahmed100% (2)

- (10.2.1.2) Vacuum Type Circuit BreakersDocument4 pages(10.2.1.2) Vacuum Type Circuit BreakersHassan AbdoNo ratings yet

- 1.vacuum Circuit Breaker Working and ApplicationsDocument6 pages1.vacuum Circuit Breaker Working and ApplicationsadarshNo ratings yet

- HV BushingDocument3 pagesHV BushingEdison SelvarajNo ratings yet

- Lectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1Document6 pagesLectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1William PinzonNo ratings yet

- Ca Unisafe (En) A 1vcp000250-1003Document32 pagesCa Unisafe (En) A 1vcp000250-1003boukhaadraNo ratings yet

- Eep-IEC 62271200 HV Switchgear and ControlgearDocument4 pagesEep-IEC 62271200 HV Switchgear and Controlgearabdulyunus_amirNo ratings yet

- Fundamentals of HV Circuit-BreakersDocument22 pagesFundamentals of HV Circuit-BreakersBastian OspinaNo ratings yet

- Faqs Vacuum Circuit Breaker VD4Document2 pagesFaqs Vacuum Circuit Breaker VD4maruf048No ratings yet

- Utilisation of Electrical Energy: Circuit Protection For Distribution and InstallationDocument28 pagesUtilisation of Electrical Energy: Circuit Protection For Distribution and InstallationceastlandNo ratings yet

- Circuit BreakersDocument30 pagesCircuit BreakersGame Lone DocNo ratings yet

- SwitchgearDocument7 pagesSwitchgearShahid JamalNo ratings yet

- PressuremonitoringtechniquesofVI CIRED2011 0234 FinalDocument5 pagesPressuremonitoringtechniquesofVI CIRED2011 0234 FinalshrinivasangtkNo ratings yet

- Circuit Breakers: Presented by Ajay.S 11EE02Document28 pagesCircuit Breakers: Presented by Ajay.S 11EE02Ahmad Kalbounah0% (1)

- ABB Medium Voltage Vacuum Circuit-Breakers VD4Document120 pagesABB Medium Voltage Vacuum Circuit-Breakers VD4Alfiansyah Dharma Setia Djaketra100% (1)

- EDOC-Practical Considerations in Surge ProtectionDocument15 pagesEDOC-Practical Considerations in Surge ProtectionEl Comedor BenedictNo ratings yet

- Circuit Breaker: o o o o oDocument11 pagesCircuit Breaker: o o o o oSry Santos100% (1)

- GSMIDocument4 pagesGSMIAnthony LoriaNo ratings yet

- VCB NotesDocument9 pagesVCB NotesDakshinaMoorthyNo ratings yet

- Switchgear - WikipediaDocument42 pagesSwitchgear - Wikipediahafiztanha450No ratings yet

- Circuit Breakers Lecture Notes 3Document124 pagesCircuit Breakers Lecture Notes 3Varun NarisettyNo ratings yet

- Switchgear and Protective DevicesDocument17 pagesSwitchgear and Protective DevicesAnonymous 5O6HavcVNo ratings yet

- CIGRE 2012: 21, Rue D'artois, F-75008 PARISDocument6 pagesCIGRE 2012: 21, Rue D'artois, F-75008 PARISfgdfgdfNo ratings yet

- Module - 5: Circuits BreakersDocument25 pagesModule - 5: Circuits BreakersGyanaranjan pandaNo ratings yet

- CIRED 2019 All Full Papers - CIRED 2019 - 340Document4 pagesCIRED 2019 All Full Papers - CIRED 2019 - 340Abdul MoizNo ratings yet

- Seminar Report On Ultra ConductorDocument18 pagesSeminar Report On Ultra ConductorNavneet Singh100% (1)

- Induction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryFrom EverandInduction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryRating: 5 out of 5 stars5/5 (2)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Dfvbnmmhyy 40 PDFDocument1 pageDfvbnmmhyy 40 PDFMNo ratings yet

- Dfvbnmmhyy 13 PDFDocument1 pageDfvbnmmhyy 13 PDFMNo ratings yet

- Fvsfv5455454 VVDVSVDVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVV VVVVVVVVVVVVV DSVSD VSDDocument1 pageFvsfv5455454 VVDVSVDVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVV VVVVVVVVVVVVV DSVSD VSDMNo ratings yet

- Dfvbnmmhyy 40 PDFDocument1 pageDfvbnmmhyy 40 PDFMNo ratings yet

- Untitled Extract Pages1Document1 pageUntitled Extract Pages1MNo ratings yet

- Substation Wiring Schematics - Autodesk CommunityDocument4 pagesSubstation Wiring Schematics - Autodesk CommunityMNo ratings yet

- Untitled Extract Pages5Document1 pageUntitled Extract Pages5MNo ratings yet

- Untitled Extract Pages3Document1 pageUntitled Extract Pages3MNo ratings yet

- Untitled Extract Pages5Document1 pageUntitled Extract Pages5MNo ratings yet

- The Problem: Vacuum Interrupters in The FieldDocument1 pageThe Problem: Vacuum Interrupters in The FieldMNo ratings yet

- Untitled Extract Pages2Document1 pageUntitled Extract Pages2MNo ratings yet

- Model No.: Weight 977Document1 pageModel No.: Weight 977MNo ratings yet

- Applications: Southwire's Booster Cable Is Useful For Interconnection Between Batteries When Jump Starting Is RequiredDocument2 pagesApplications: Southwire's Booster Cable Is Useful For Interconnection Between Batteries When Jump Starting Is RequiredMNo ratings yet

- Applications: Stranded Bare or Tinned Copper Conductors. 105°C, 50 VoltsDocument2 pagesApplications: Stranded Bare or Tinned Copper Conductors. 105°C, 50 VoltsMNo ratings yet

- CSA Spec. C22.2, No. 51-95 (R2004) CSA File Listing: LL90458 Class 58 11 01Document2 pagesCSA Spec. C22.2, No. 51-95 (R2004) CSA File Listing: LL90458 Class 58 11 01MNo ratings yet

- Open and Short Circuit Analysis in Simple CircuitsDocument2 pagesOpen and Short Circuit Analysis in Simple CircuitsCOLD FIRENo ratings yet

- NEMA Code Letters For AC Motors EASA Electrical Engineering HandbookDocument2 pagesNEMA Code Letters For AC Motors EASA Electrical Engineering HandbookSyed IqbalNo ratings yet

- Lecture 5 - CMOS Transistor TheoryDocument44 pagesLecture 5 - CMOS Transistor Theorysadia santaNo ratings yet

- Attachment-S - Drive Control PhilosophyDocument14 pagesAttachment-S - Drive Control PhilosophyMpd mühendislikNo ratings yet

- Advantages Three Phase Over Single PhaseDocument2 pagesAdvantages Three Phase Over Single Phaseaman1686No ratings yet

- Assignment of Utilization of Electrical EnergyDocument3 pagesAssignment of Utilization of Electrical EnergyRahul SrivastavaNo ratings yet

- K Tec en 05 12 PDFDocument4 pagesK Tec en 05 12 PDFtdropulicNo ratings yet

- Electronics: Automatic Voltage RegulatorDocument7 pagesElectronics: Automatic Voltage RegulatorBeto_pciNo ratings yet

- AC Loco Question Bank For LP & ALP Ready Refreshing Their KnowledgeDocument1 pageAC Loco Question Bank For LP & ALP Ready Refreshing Their Knowledgejohn peter50% (2)

- 16 Samss 510Document11 pages16 Samss 510Mohammed Jaffar Adnan100% (1)

- Kinetrol Actuators and Add-On Control Units: AbbreviationsDocument6 pagesKinetrol Actuators and Add-On Control Units: Abbreviationszytura2019No ratings yet

- DMS-100 Equipment CablingDocument526 pagesDMS-100 Equipment CablingRastekHI100% (1)

- GSR Wiring DiagramsDocument43 pagesGSR Wiring DiagramsJamie WinklehoffenNo ratings yet

- Experiment 2 PDFDocument7 pagesExperiment 2 PDFRegar EfendiNo ratings yet

- Disco3 OwnerDocument18 pagesDisco3 OwnerJcarlos LópezNo ratings yet

- MGP 20 N 40 CLDocument6 pagesMGP 20 N 40 CLDaniel TamayoNo ratings yet

- Polycab January 2018 PDFDocument2 pagesPolycab January 2018 PDFjuga2013100% (1)

- Motor of VTOL AircraftDocument22 pagesMotor of VTOL Aircraftvimarsh joshiNo ratings yet

- Samsung MO1650xx Service ManualDocument29 pagesSamsung MO1650xx Service ManualBrent SmithNo ratings yet

- Single Electron TransistorDocument16 pagesSingle Electron Transistorimcoolsha999100% (3)

- Combined Instrument TrasformersDocument6 pagesCombined Instrument Trasformersraghavendran raghuNo ratings yet

- Over Current ProtectionDocument22 pagesOver Current Protectionnihkinwejkb100% (1)

- Master Instrument Corporation: Single-Phase Bridge Rectifier W005M THRU W10MDocument2 pagesMaster Instrument Corporation: Single-Phase Bridge Rectifier W005M THRU W10MLUCEZHITANo ratings yet

- ELEC4142 Power System Protection and Switchgear: The University of Hong KongDocument7 pagesELEC4142 Power System Protection and Switchgear: The University of Hong KongKT ChanNo ratings yet

- 6C33CDocument7 pages6C33CPeter KilburnNo ratings yet

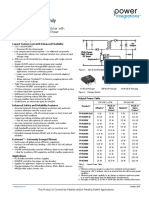

- Tinyswitch-4 Family: Energy-Efficient, Off-Line Switcher With Line Compensated Overload PowerDocument26 pagesTinyswitch-4 Family: Energy-Efficient, Off-Line Switcher With Line Compensated Overload PowerFrancisco MárcioNo ratings yet

- The Automatic Voltage RegulatorDocument2 pagesThe Automatic Voltage RegulatornewcreationofheartNo ratings yet

- Data Sheet PST 120 12Document1 pageData Sheet PST 120 12Christopher OchoaNo ratings yet