Professional Documents

Culture Documents

Design Brief Design & Projects Department:: Product Options

Design Brief Design & Projects Department:: Product Options

Uploaded by

Poschina CiprianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Brief Design & Projects Department:: Product Options

Design Brief Design & Projects Department:: Product Options

Uploaded by

Poschina CiprianCopyright:

Available Formats

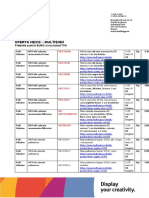

D e s i g n & P r o j e c ts D e pa r t m e n t :

Design Brief

Company name:

Date sent:

Contact name:

Account Ref:

Contact tel:

Quote deadline:

Contact email:

Delivery deadline:

Product Options

Please tick below all product groups you intend to use in your design. Please also complete a

separate specification design sheet for each product group selected. These will be provided.

Modular Panel

Pop-up

Physique

Linear Extrusion

Arena 4 Gantry

Plan Layout

Display Space

Scale:

Page 1 of 2

Width (m)

Depth (m)

# Open Sides

Max. Height (m)

Additional Details

For advice on completing the design brief, and for product group specification sheets

please contact our team direct on +44 (0)1536 272265 or

email: design@ultimadisplays.co.uk.

Completed design forms may also be faxed direct on: +44 (0)1536 205 648.

Conditions of Use

We will prepare a quotation based on your design specification which must include details of how the quoted items

or display will be used. Lead-time, Location of the display or unit, venue environment, frequency of usage,

transportation, load-bearing requirements etc. must be considered as part of your specification.

When requesting a quote/design our Design & Projects team will provide you with the appropriate specification

guide for your proposed design.

We can only guarantee a design is fit-for-purpose based on the information you supply, and we may request

further details of the project for the purposes of completion of the quote as necessary.

If necessary, our quotation will include a drawing of your proposed designs. Subsequent revisions to designs may

be subject to a fee, which will be advised before any further work is undertaken. If required, a full colour rendering

may also be supplied for a nominal fee. Up to 100 of this fee is refundable with your order.

Lead-times for the completion of designs and or quotes will be confirmed on submission of your brief on request.

The lead-time will depend on the complexity of the design and current workload. Please complete our design forms

as fully as possible in order to minimise turnaround time.

All quotations and accompanying documentation must be signed-off as acceptable before commencement of the

manufacture and build of your required solution and accompanied by a Purchase Order.

All quotation numbers must be included on any resulting orders to ensure the item ordered is exactly as quoted

and to secure the agreed price. Failure to quote this number may increase lead-time. Please ensure you get

confirmation from our Design & Projects team of any subsequent changes you may wish to make to your original

quote, along with the revision number.

Quotations and sign-offs must be completed for all custom orders over 400.00.

Delivery lead-times will ONLY be agreed when we are in receipt of your order along with any sign-off that is

required. Any delay in these processes may affect the delivery lead-time.

Page 2 of 2

Linear - Specification notes (page 1)

Please fill in where appropriate.

Linear is made from lightweight aluminium and is finished in anodised silver. Linear is extremely strong and versatile; this allows us with

the aid of CAD software to design everything from small display kits all the way to large display stands. It sometimes may be necessary for

transport reasons to limit the linear extrusion length used in our designs; please state below if this is required. In a design you may wish to

hang heavy items from the linear; If possible please state the approx weight per item. i.e. 1x Plasma 40Kg; 2x LCD Screen 20kg (ea).

Max length of sections:

(mm) Heavy items:

Graphics:

The Linear system can take a number of different graphic options, most common

attachment method we design our system to use is (option Brigid substrate);

usually 5mm foam board and (option Cmagnetic / steel tape) usually a pop-up

style media. (Please note for option C, steel tape is supplied but not fitted)

Your max graphic size:

(Graphic Option B)

(Graphic Option C)

(mm)

Graphic Infill sizes can be calculated using the following example diagrams:

Custom Linear Design

Linear custom kit / stand designs are created in the Design & Projects department, and the average quote/design turnaround time is two

business days; but this depends on the complexity of the design and the information thats supplied. Please advise us if you have any special requirements so we can make sure that the designs are correctly catered for your customer.

When requesting you design / quote; please inform us of which graphics solution you require as it can drastically change the design depending on you choice. It also very important that you tell us the maximum size you can print you graphics too; as this can also have a

major affect on the design.

Linear - Specification notes (page 2)

Linear Post

The Linear post extrusion is offered in three main profile shapes, round, square & oval. The round has three versions, 75mm fourway, 75mm eight-way & 50mm four-way. The 75mm square and 75mm oval post extrusion is only offered with a four-way option.

Each post end can accept any of the fittings below.

Male end

Open end

Base end

Lock end

This version has all

the parts required to

link end to end with

a post of the same

extrusion.

This version has an

open end and can accept either a male end

or plastic top cap.

This version has a base fitment

that accepts of any linear base

and also allows fitment of M10

bolts such as the linear coin slot

screw as used on linear Kit 11.

This version has a lock fitted; this allows the post

to be linked to other posts; though this depends on

the profile used i.e. you wont be able to link to a

round or oval vertical post, but the square profile

post in a vertical position will take any profile type.

Linear Beam Extrusion

The Linear beam extrusion is available in three main profile types, 45mm double channel, 40mm single channel & 125mm twin span;

which has two channels. These beams can be used in either vertical or horizontal positions, and similar to the post come with a number of different end fitting options. They are most commonly used to link two posts together as seen in linear kit 1. Like the linear

posts each end can have a fitment; the ends are as follows: male end, open end & lock end (see post descriptions above).

45mm Beam extrusion

This extrusion has a channel to the top and bottom of the profile, these channels allow either connection of a lock or fitment of a substrate (lengths are available from 100-2000mm). 45mm beams can also be bent in to a curve to allow more complex designs; and we

offer the following standard radiuses 500, 750, 1000, 1250, 1500, 2000mm. These curved beams are available in different cut lengths

depending on the radius. We also offer custom radius curved beams; but we apply a one off charge for creating a manufacturing jig.

40mm Beam Extrusion

The 40mm beam shares many of the features as the 45mm version, but with only one channel this can limit the applications where

this beam can be used. The design will dictate which beam is possible and if we are creating a design for you we will use the most

suitable beam. Please note there is currently no end cap for this extrusion.

125mm Twin-span Extrusion

The 125mm beam again shares the features of the 45mm version and is basically two 45mm beams joined together in one profile.

This allows for up to four end fitments on one profile, for example you can have two locks to each profile end; this would allow you to

increase span length possible, and or the weight that this section could hold. Please note this extrusion isnt available curved and

currently has no end cap.

Linear Corner Re-enforcer

If increased strength is required for a particular configuration we also offer a corner re-enforcer; it slides into the channel of two profiles and locks them in place tightly; the locking process works in similar way to standard linear lock. Please note that if your design

uses infill style graphics; allowances will need to be made in your substrate when the corner re-enforcers are used.

Linear & Table Tops

Linear table tops are available in all the standard thermo-formed laminate finishes, and include fitting attachments (not fitted to the

linear unless a project charge is applied). Linear table tops can be almost any shape and are only limited in size buy the size of the

thermo-forming material. There is a one off charge for CNC setup that will only apply to the first time these items are ordered. Please

note any charges will be added as a separate line on your quote.

Lead-time for bespoke linear kits & systems

Please allow a minimum of three weeks lead time from enquiry to despatch, we advise that you also allow enough time to fully check

& test you order. From the offset please inform us of your delivery deadline; if your request is urgent; please speak to our design

team so we can check schedule space and stock; and we will advise you if your deadline is achievable.

Please note; schedule space can not be reserved until we are in receipt of an order and quotation sign-off. If all required information

isnt returned before the manufacturing date the schedule space will be reallocated and will not be re-scheduled until we are in receipt of these outstanding items.

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- ShopSabre RC SeriesDocument7 pagesShopSabre RC SerieskairotdfNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Problem Set 3Document2 pagesProblem Set 3cheche datingalingNo ratings yet

- NADCA Tolerances 2009Document44 pagesNADCA Tolerances 2009Tom Hagerty100% (1)

- Trough and Waffle Moulds: For In-Situ Ribbed FloorsDocument12 pagesTrough and Waffle Moulds: For In-Situ Ribbed Floorsror77No ratings yet

- Company Profile DCTCDocument14 pagesCompany Profile DCTCvalerie05No ratings yet

- Beaufighter Plans and Pricing 2008Document8 pagesBeaufighter Plans and Pricing 2008khail007No ratings yet

- Build Your Own Garage Manual: More Than 175 PlansFrom EverandBuild Your Own Garage Manual: More Than 175 PlansRating: 4 out of 5 stars4/5 (2)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Hexis hx20000 Colors PDFDocument2 pagesHexis hx20000 Colors PDFPoschina CiprianNo ratings yet

- 7 Eleven StockDocument15 pages7 Eleven StockChandra SekharNo ratings yet

- Wal-Mart's Operations ManagementDocument6 pagesWal-Mart's Operations ManagementMithilesh WaghmareNo ratings yet

- Excellence in HemmingDocument12 pagesExcellence in Hemmingmlucian73No ratings yet

- Welding Fixture DescriptionDocument4 pagesWelding Fixture DescriptionCrunkyNo ratings yet

- Shear Stud CapacityDocument12 pagesShear Stud CapacityMurali2130No ratings yet

- Jr. Quality Control Monthly Report On August 2019: Prepared byDocument9 pagesJr. Quality Control Monthly Report On August 2019: Prepared byMichael Angelo LumauigNo ratings yet

- Parker TechSeal ParFab Design Guide TSD 5420Document44 pagesParker TechSeal ParFab Design Guide TSD 5420Christopher GarciaNo ratings yet

- Grating CatalogueDocument16 pagesGrating CataloguePrashant Dhotre100% (1)

- W201 - PCF MFG - Technical AgreementDocument17 pagesW201 - PCF MFG - Technical AgreementSandip PatilNo ratings yet

- ToolingStandard PDFDocument16 pagesToolingStandard PDFKodhansNo ratings yet

- Applications: Selective Laser Sintering Is The Ideal Solution ForDocument8 pagesApplications: Selective Laser Sintering Is The Ideal Solution FordpksobsNo ratings yet

- NADCA Tolerances 2009Document44 pagesNADCA Tolerances 2009Pedjman GhaderiNo ratings yet

- Design For Manufacture (DFM) Tips For Die Cast PartsDocument5 pagesDesign For Manufacture (DFM) Tips For Die Cast PartsJimmy ManuelNo ratings yet

- Grate-Lock Grating: Solid Deck Planking & LAMBDA-LOK™Document20 pagesGrate-Lock Grating: Solid Deck Planking & LAMBDA-LOK™asifaliabidNo ratings yet

- Lintech Shortform 2011 CatalogDocument80 pagesLintech Shortform 2011 CatalogElectromateNo ratings yet

- Simpson Strong-Tie - Wood Construction Connectors - 2011Document216 pagesSimpson Strong-Tie - Wood Construction Connectors - 2011arquitrol100% (1)

- Manufacturing Guidelines: Layout Examples DXF Layer Guide MaterialsDocument21 pagesManufacturing Guidelines: Layout Examples DXF Layer Guide MaterialsErdnee UlaanNo ratings yet

- Lindab - Construction - Documentation - Rainline BIM For Archicad ManualDocument18 pagesLindab - Construction - Documentation - Rainline BIM For Archicad ManualTudosa TomaNo ratings yet

- Fume Hood Placement Laboratory SetupDocument11 pagesFume Hood Placement Laboratory Setupreny7caspeNo ratings yet

- Nadca 402 4aDocument44 pagesNadca 402 4awholenumberNo ratings yet

- Leadscrews Ballscrews Splines CtenDocument236 pagesLeadscrews Ballscrews Splines CtenTony BeltranNo ratings yet

- Hi SpanDocument54 pagesHi Spangdoyle7282No ratings yet

- So 3 ManualDocument44 pagesSo 3 ManualMiguel Gc100% (1)

- Technical ManualDocument36 pagesTechnical Manualneeshakothari31No ratings yet

- Mold Standards & ClassificationsDocument3 pagesMold Standards & ClassificationsKamleshVasavaNo ratings yet

- C 2011Document243 pagesC 2011xicmenNo ratings yet

- 4079 Form-Scaff Columns V9 FA WEBDocument16 pages4079 Form-Scaff Columns V9 FA WEBFiona steelNo ratings yet

- Limits & Fits - Types of Fits Explained & Tolerance Charts - FractoryDocument10 pagesLimits & Fits - Types of Fits Explained & Tolerance Charts - FractoryMangesh KetkarNo ratings yet

- Schletter Montage Und Projektierung enDocument32 pagesSchletter Montage Und Projektierung enKirsten HernandezNo ratings yet

- ShopSabre Is Series RouterDocument9 pagesShopSabre Is Series RouterkairotdfNo ratings yet

- Shaft ExtensionsDocument2 pagesShaft ExtensionsTally AnuNo ratings yet

- Metalform Max Span Purlins & Girts Design ManualDocument41 pagesMetalform Max Span Purlins & Girts Design Manuals_khan1997466No ratings yet

- Am ItDocument27 pagesAm Itakalbhor90No ratings yet

- Rhino To STL Best PracticesDocument5 pagesRhino To STL Best PracticesLotteDomine100% (1)

- Basic 2D Engineering Drawing Checklist: 1. A Name For The Component And/or ProjectDocument5 pagesBasic 2D Engineering Drawing Checklist: 1. A Name For The Component And/or ProjectShacheendra SharmaNo ratings yet

- PCRC Conc Lintels For Structural SupportsDocument24 pagesPCRC Conc Lintels For Structural SupportsZaky MessengerNo ratings yet

- Autodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationDocument15 pagesAutodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationGraham MooreNo ratings yet

- Danley Insert Plate ArmourMate BrochureDocument12 pagesDanley Insert Plate ArmourMate BrochuresuvraNo ratings yet

- Manual de Iluminación 2016Document346 pagesManual de Iluminación 2016keylaNo ratings yet

- Purlins & Girts: Biggest RangeDocument2 pagesPurlins & Girts: Biggest RangelombangrurusNo ratings yet

- FOR RELEASE: BFP Design Notes and Documentation PDFDocument39 pagesFOR RELEASE: BFP Design Notes and Documentation PDFHassan ZiaNo ratings yet

- Emhart Teknologies HeliCoil Thread Insert System CatalogueDocument36 pagesEmhart Teknologies HeliCoil Thread Insert System CatalogueThor InternationalNo ratings yet

- Thomson LeadScrews BallScrews BallSplines CatalogDocument230 pagesThomson LeadScrews BallScrews BallSplines CatalogElectromateNo ratings yet

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonNo ratings yet

- Somta User GuideDocument175 pagesSomta User GuideFrancois-No ratings yet

- 2900SF Asy 660005033 Rev2Document44 pages2900SF Asy 660005033 Rev2Иван Сергеевич ЛатошаNo ratings yet

- Thomson BSA Lead and Ball Screws CatalogDocument94 pagesThomson BSA Lead and Ball Screws CatalogElectromateNo ratings yet

- Jig AssignmentDocument26 pagesJig Assignmentkalu kioNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Hexis Ecotac Colors PDFDocument2 pagesHexis Ecotac Colors PDFPoschina CiprianNo ratings yet

- Oferta Hexis - Multisign: Preturile Sunt in EURO Si Nu Includ TVADocument9 pagesOferta Hexis - Multisign: Preturile Sunt in EURO Si Nu Includ TVAPoschina CiprianNo ratings yet

- License Certificate: Premium License (Unlimited Use Without Attribution)Document2 pagesLicense Certificate: Premium License (Unlimited Use Without Attribution)Poschina CiprianNo ratings yet

- Outdoor: Portable Display Solutions For Every Outdoor EventDocument20 pagesOutdoor: Portable Display Solutions For Every Outdoor EventPoschina CiprianNo ratings yet

- Install 5Document3 pagesInstall 5Poschina CiprianNo ratings yet

- My SEO AuditDocument12 pagesMy SEO AuditPoschina CiprianNo ratings yet

- Analysis Results For: CanonicalisationDocument4 pagesAnalysis Results For: CanonicalisationPoschina CiprianNo ratings yet

- BRANZ Facts Mid Rise 5 Steel CorrosionDocument3 pagesBRANZ Facts Mid Rise 5 Steel Corrosionlouis donyNo ratings yet

- 01192015114316IMYB - 2013 - Vol III - BauxiteDocument14 pages01192015114316IMYB - 2013 - Vol III - BauxitevishalNo ratings yet

- Internship ReportDocument71 pagesInternship ReportKrushnasamy SuramaniyanNo ratings yet

- Total Productive MaintenanceDocument53 pagesTotal Productive MaintenanceamitwadaskarNo ratings yet

- 14251A ch1Document32 pages14251A ch1jcarlos7411No ratings yet

- Computer Aided Process Planning (CAPP)Document30 pagesComputer Aided Process Planning (CAPP)brijkishor2017100% (1)

- Rowenta Cs W3Document2 pagesRowenta Cs W3rasgeetsinghNo ratings yet

- JDH Sample Warehouse Design ReportDocument18 pagesJDH Sample Warehouse Design ReportAin Nsf0% (2)

- Turtle Diagram - R & DDocument2 pagesTurtle Diagram - R & Dabdelmutalab100% (5)

- Fastener Design Manual, Part OneDocument30 pagesFastener Design Manual, Part OnesmithworkNo ratings yet

- Answer SchemeDocument13 pagesAnswer SchemeAmalina Zainal100% (1)

- 31Document5 pages31iskricaman7No ratings yet

- 4 Heat TreatmentokDocument22 pages4 Heat TreatmentokPramod AthiyarathuNo ratings yet

- Vander Voort, George F. Eds. Atlas of Time-Temperature Diagrams For Nonferrous AlloysDocument783 pagesVander Voort, George F. Eds. Atlas of Time-Temperature Diagrams For Nonferrous AlloysDaniel Navarro100% (4)

- Positive Material Identification-Summary: 8/4/2020 Spectro Test Txc03Document1 pagePositive Material Identification-Summary: 8/4/2020 Spectro Test Txc03norman moralesNo ratings yet

- Make To Order (MTO) and Make To Stock (MTS)Document2 pagesMake To Order (MTO) and Make To Stock (MTS)Deepak SangramsinghNo ratings yet

- 06-Equipment Selection and DesignDocument78 pages06-Equipment Selection and DesignS J100% (1)

- Casing PresentationDocument33 pagesCasing PresentationJua RulerNo ratings yet

- Vacuum Treatment of Melts With Charge Weights Up To 30 Tons: Vacuum Induction Degassing VID 400 - VID 3000Document8 pagesVacuum Treatment of Melts With Charge Weights Up To 30 Tons: Vacuum Induction Degassing VID 400 - VID 3000sureshkumar908No ratings yet

- 13 Dela Cruz - Chapters 5 and 6 Summaries PDFDocument12 pages13 Dela Cruz - Chapters 5 and 6 Summaries PDFMau Dela CruzNo ratings yet

- Foundry ProcessDocument54 pagesFoundry ProcessgovindarajaluvNo ratings yet

- ITM Assignment: Chanrdragupt Institute of Management, PatnaDocument10 pagesITM Assignment: Chanrdragupt Institute of Management, PatnanewsacanNo ratings yet

- Assignment 4 OmDocument8 pagesAssignment 4 OmShafik MasriNo ratings yet

- Historical Structural Steelwork HandbookDocument76 pagesHistorical Structural Steelwork Handbookjimmyoftheworld100% (1)

- Fine Boring & Jig BoringDocument12 pagesFine Boring & Jig Boringshiva100% (1)

- Role of Industry and Trade in Economic DevelopmentDocument22 pagesRole of Industry and Trade in Economic DevelopmentAmmar HassanNo ratings yet

- Sap Ewm - Erp Initial SetupDocument3 pagesSap Ewm - Erp Initial SetupVAIBHAV PARAB80% (5)