Professional Documents

Culture Documents

Micrologix™ Analog Input/Output: Installation Instructions

Micrologix™ Analog Input/Output: Installation Instructions

Uploaded by

David LucioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micrologix™ Analog Input/Output: Installation Instructions

Micrologix™ Analog Input/Output: Installation Instructions

Uploaded by

David LucioCopyright:

Available Formats

Installation Instructions

MicroLogix Analog Input/Output

Module

(Catalog Number 1762-IF2OF2)

Inside

For More Information................................................................................2

Description ................................................................................................3

Installation ................................................................................................4

Mounting...................................................................................................5

System Assembly......................................................................................7

Field Wiring Connections..........................................................................8

Input Type Selection ................................................................................ 8

Output Type Selection ............................................................................. 8

Wiring ..................................................................................................... 9

I/O Memory Mapping .............................................................................13

Specifications .........................................................................................18

Hazardous Location Considerations .......................................................22

Environnements dangereux ....................................................................23

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

For More Information

For

Refer to this Document

Information on installing, wiring, and

operating a MicroLogix 1200

Programmable Controller

MicroLogix 1200 Programmable 1762-UM001A-US-P

Controllers User Manual

Installation guide for the MicroLogix

1200 Programmable Controller.

MicroLogix 1200 Programmable 1762-IN006A-ML-P

Controllers Installation

Instructions

Installation guide for the MicroLogix

1200 Memory Module and Real Time

clock.

MicroLogix 1200 Memory

1762-IN001A-US-P

Module and/or Real Time Clock

Installation Instructions

Installation guide for the 1762-IA8

Discrete Input Module

1762-IA8 120V ac Input Module 1762-IN002A-US-P

Installation Instructions

Installation guide for the 1762-OW8

Discrete Output Module

1762-OW8 Relay Output

1762-IN003A-US-P

Module Installation Instructions

Installation guide for the 1762-IQ8

Discrete Input Module

1762-IQ8 DC Input Module

Installation Instructions

More information on proper wiring and Industrial Automation Wiring

grounding techniques.

and Grounding Guidelines

Pub. No.

1762-IN004A-US-P

1770-4.1

If you would like a manual, you can:

download a free electronic version from the internet:

www.ab.com/micrologix or www.theautomationbookstore.com

purchase a printed manual by:

contacting your local distributor or Rockwell Automation representative

visiting www.theautomationbookstore.com and placing your order

calling 1.800.963.9548 (USA/Canada)

or 001.330.725.1574 (Outside USA/Canada)

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

Description

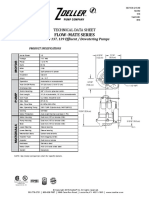

10

1a

Item Description

7

1a

upper panel mounting tab

1b

lower panel mounting tab

power diagnostic LED

module door with terminal

identification label

bus connector

with male pins

bus connector cover

flat ribbon cable with bus

connector (female)

terminal block

DIN rail latch

pull loop

10

input type selector switch

6

1b

4

1a

6

2

1b

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

Installation

1762 I/O is suitable for use in an industrial environment when installed in

accordance with these instructions. Specifically, this equipment is intended for

use in clean, dry environments (Pollution degree 2(1)) and to circuits not

exceeding Over Voltage Category II(2) (IEC 60664-1).(3)

Prevent Electrostatic Discharge

ATTENTION Electrostatic discharge can damage integrated circuits or

semiconductors if you touch bus connector pins. Follow these

guidelines when you handle the module:

Touch a grounded object to discharge static potential.

Wear an approved wrist-strap grounding device.

Do not touch the bus connector or connector pins.

Do not touch circuit components inside the module.

If available, use a static-safe work station.

When not in use, keep the module in its static-shield box.

Remove Power

ATTENTION Remove power before removing or installing this module.

When you remove or install a module with power applied, an

electrical arc may occur. An electrical arc can cause personal

injury or property damage by:

sending an erroneous signal to your systems field devices,

causing unintended machine motion

causing an explosion in a hazardous environment

causing permanent damage to the modules circuitry

Electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create

electrical resistance.

(1) Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

(2) Over Voltage Category II is the load level section of the electrical distribution system. At this level transient

voltages are controlled and do not exceed the impulse voltage capability of the products insulation.

(3) Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

Mounting

ATTENTION Do not remove protective debris strip until after the module and

Minimum Spacing

Side

MicroLogix

1200

1762 I/O

Top

1762 I/O

Maintain spacing from

enclosure walls, wireways,

adjacent equipment, etc.

Allow 50.8 mm (2 in.) of

space on all sides for

adequate ventilation, as

shown:

1762 I/O

all other equipment near the module is mounted and wiring is

complete. Once wiring is complete and the module is free of

debris, carefully remove protective debris strip. Failure to

remove strip before operating can cause overheating.

Side

Bottom

NOTE

ATTENTION

1762 expansion I/O may be mounted horizontally only.

During panel or DIN rail mounting of all devices, be sure that

all debris (metal chips, wire strands, etc.) is kept from falling

into the module. Debris that falls into the module could cause

damage when power is applied to the module.

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

DIN Rail Mounting

The module can be mounted using the following DIN rails: 35 x 7.5 mm

(EN 50 022 - 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latch. Press the

DIN rail mounting area of the module against the DIN rail. The latch will

momentarily open and lock into place.

Use DIN rail end anchors (Allen-Bradley part number 1492-EA35 or

1492-EAH35) for environments with vibration or shock concerns.

End Anchor

End Anchor

NOTE

For environments with extreme vibration and shock concerns,

use the panel mounting method described below, instead of

DIN rail mounting.

Panel Mounting

Use the dimensional template shown below to mount the module. The preferred

mounting method is to use two M4 or #8 panhead screws per module. M3.5 or #6

panhead screws may also be used, but a washer may be needed to ensure a good

ground contact. Mounting screws are required on every module.

For more than 2 modules: (number of modules - 1) x 40.4 mm (1.59 in.)

40.4

(1.59)

MicroLogix 1200

Expansion I/O

MicroLogix 1200

Expansion I/O

MicroLogix 1200

Expansion I/O

100 90

(3.94) (3.54)

MicroLogix 1200

14.5

(0.57)

40.4

(1.59)

Publication 1762-IN005A-US-P

NOTE:

Hole spacing tolerance:

0.4 mm (0.016 in.).

MicroLogix Analog Input/Output Module

System Assembly

The expansion I/O module is attached to the controller or another I/O module by

means of a ribbon cable after mounting as shown below.

NOTE

WARNING

Use the pull loop on the connector to disconnect modules. Do

not pull on the ribbon cable.

EXPLOSION HAZARD

In Class I, Division 2 applications, the bus connector must

be fully seated and the bus connector cover must be

snapped in place.

In Class I, Division 2 applications, all modules must be

mounted in direct contact with each other as shown on

page 6. If DIN rail mounting is used, an end stop must be

installed ahead of the controller and after the last 1762 I/O

module.

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

Field Wiring Connections

Grounding the Module

This product is intended to be mounted to a well-grounded mounting surface

such as a metal panel. Additional grounding connections from the modules

mounting tabs or DIN rail (if used) are not required unless the mounting surface

cannot be grounded. Refer to Industrial Automation Wiring and Grounding

Guidelines, Allen-Bradley publication 1770-4.1, for additional information.

Input Type Selection

Select the input type, current or voltage, using the switch located on the modules

circuit board and the input type/range selection bits in the Configuration Data

File (see page 16). You can access the switch through the ventilation slots on the

top of the module. Switch 1 controls channel 0; switch 2 controls channel 1. The

factory default setting for both switch 1 and switch 2 is Current. Switch positions

are shown below.

Switch Location

ON

Voltage (OFF)

Current (ON) Default

Switch 1 = Channel 0

Switch 2 = Channel 1

Output Type Selection

The output type selection, current or voltage, is made by wiring to the

appropriate terminals, Iout or Vout, and by the type/range selection bits in the

Configuration Data File (see page 16).

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

Wiring

System Wiring Guidelines

Consider the following when wiring your system:

The analog common (COM) is not connected to earth ground inside the

module. All terminals are electrically isolated from the system.

Channels are not isolated from each other.

Use Belden 8761, or equivalent, shielded wire.

Under normal conditions, the drain wire (shield) should be connected to the

metal mounting panel (earth ground). Keep shield connection to earth ground

as short as possible.

To ensure optimum accuracy for voltage type inputs and outputs, limit overall

cable impedance by keeping all analog cables as short as possible. Locate the

I/O system as close to your voltage type sensors or actuators as possible.

The 1762-IF2OF2 module does not provide loop power for analog inputs. Use

a power supply that matches the input transmitter specifications.

Terminal Block Layout

IN 0 +

IN 0 IN 1 +

IN 1 V out 0

I out 0

V out 1

I out 1

COM

COM

ATTENTION

Commons connected

internally.

Analog outputs may fluctuate for less than a second when

power is applied or removed. This characteristic is common to

most analog outputs. While the majority of loads will not

recognize this short signal, it is recommended that preventive

measures be taken to ensure that connected equipment is not

affected.

Publication 1762-IN005A-US-P

10

MicroLogix Analog Input/Output Module

Differential Sensor Transmitter Types

IN 0 (+)

Analog Sensor

IN 0 (-)

IN 1 (+)

IN 1 (-)

Analog Load

I out 0

I out 1

V out 0

V out 1

COM

COM

NOTE

Grounding the cable shield at the module end only usually

provides sufficient noise immunity. However, for best cable

shield performance, earth ground the shield at both ends, using

a 0.01F capacitor at one end to block AC power ground

currents, if necessary.

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

11

Sensor/Transmitter Types

2-Wire Transmitter

Power +

Supply (1)

Transmitter

Module

IN +

IN COM

3-Wire Transmitter

Power +

Supply(1)

Transmitter

Supply

Signal

Module

IN +

IN COM

4-Wire Transmitter

Power +

Supply(1)

Transmitter

Supply

+

-

Signal

Module

+

-

IN +

IN COM

(1) All power supplies rated N.E.C. Class 2.

Labeling the Terminals

A write-on label is provided with the module. Mark the identification of each

terminal with permanent ink, and slide the label back into the door.

Publication 1762-IN005A-US-P

12

MicroLogix Analog Input/Output Module

Wiring the Finger-Safe Terminal Block

ATTENTION

Be careful when stripping wires. Wire fragments that fall into

a module could cause damage when power is applied. Once

wiring is complete, ensure the module is free of all metal

fragments.

When wiring the terminal block, keep the finger-safe cover in place.

1. Route the wire under the terminal pressure plate. You can use the stripped end

of the wire or a spade lug. The terminals will accept a 6.35 mm (0.25 in.)

spade lug.

2. Tighten the terminal screw making sure the pressure plate secures the wire.

Recommended torque when tightening terminal screws is 0.904 Nm (8 in-lbs).

3. After wiring is complete, remove the debris shield.

NOTE

If you need to remove the finger-safe cover, insert a screw

driver into one of the square wiring holes and gently pry the

cover off. If you wire the terminal block with the finger-safe

cover removed, you will not be able to put it back on the

terminal block because the wires will be in the way.

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

13

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Wire Type

Solid

Stranded

Wire Size

#14 to #22 AWG

#16 to #22 AWG

Cu-90C (194F)

Cu-90C (194F)

Terminal Screw Torque

0.904 Nm (8 in-lbs)

0.904 Nm (8 in-lbs)

I/O Memory Mapping

Addressing

The addressing scheme for 1762 Expansion I/O is shown below.

Data File

0 or 1

File Type

Input (I) or Output (O)

Slot Number (1)

Word

X1:x.0/0

Bit

Data File # 0 = Output

Data File # 1 = Input

Slot Delimiter

Bit Delimiter

Word Delimiter

(1) I/O located on the controller (embedded I/O) is slot 0. I/O added to the controller (expansion I/O) begins with

slot 1.

Publication 1762-IN005A-US-P

14

MicroLogix Analog Input/Output Module

Input Data File

For each module, slot x, words 0 and 1 contain the analog values of the inputs.

The module can be configured to use either raw/proportional data or

scaled-for-PID data. The input data file for each configuration is shown below.

Word

Raw/Proportional Format

0

1

2

3

4

5

15

0

0

14

13

12

Bit Position

11 10 9

8

7

6

Channel 0 Data 0 to 32760

Channel 1 Data 0 to 32760

reserved

reserved

reserved

UI

0

OI

0

UI

1

OI

1

reserved

UO

0

OO

0

SO

1

UO

1

SO

0

OO

1

2

0

0

1

0

0

0

0

0

reserved

SI

1

SI

0

reserved

Word

Scaled-for-PID Format

0

1

2

3

4

5

15

0

0

UI

0

14

0

0

OI

0

13

UI

1

12

OI

1

Bit Position

10 9

8

7

6

5

Channel 0 Data 0 to 16,380

Channel 1 Data 0 to 16,380

reserved

reserved

SO

reserved

1

U0 O0 U0

reserved

0

0

1

11

SO

0

O0

1

reserved

1

0

0

0

0

0

SI

1

SI

0

reserved

The bits are defined as follows:

SIx = General status bits for input channels 0 and 1.

SOx = General status bits for output channels 0 and 1. This bit is set when an

error (over- or under-range) exists for that channel, or there is a general

module hardware error.

OIx = Over-range flag bits for input channels 0 and 1.

OOx = Over-range flag bits for output channels 0 and 1. These bits can be used

in the control program for error detection.

UIx = Under-range flag bits for input channels 0 and 1.

UOx = Under-range flag bits for output channels 0 and 1. These bits can be

used in the control program for error detection.

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

15

Output Data File

For each module, slot x, words 0 and 1 contain the channel output data.

Raw/Proportional Format

Word

Bit Position

15

Channel 0 Data 0 to 32,760

Channel 1 Data 0 to 32,760

14

13

12

11

10

Scaled-for-PID Format

Word

Bit Position

15

14

Channel 0 Data 0 to 16,380

Channel 1 Data 0 to 16,380

13

12

11

10

Publication 1762-IN005A-US-P

16

MicroLogix Analog Input/Output Module

Configuration Data File

The configuration of the format for analog inputs and outputs is made at going to

run (GTR). Changes made to the configuration file while in run mode have no

effect.

The configuration table for analog inputs and outputs is shown in the table below.

0

1

Bit Position

15

reserved

Word

Configuration Data File

14

13

12

reserved

Data Format Input

Channel 1

Type/Range Select

Input Channel 1

reserved

reserved

reserved

reserved

10

Type/Range Select

Input Channel 0

2

4

11

Data Format Input

Channel 0

Data Format

Output Channel 0

Type/Range Select

Output Channel 0

reserved

Data Format

Output Channel 1

Type/Range Select

Output Channel 1

reserved

reserved

reserved

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

17

Bit 15 and Bits 7 through 0 - Reserved

These bits are reserved and are not checked by the module.

Data Format (Bits 14 through 12)

These bits indicate the format of the data as shown in the following table. Other

combinations of these bits are not supported and result in an error.

Bit Settings

Data Format

14

13

12

Raw/Proportional

Scaled for PID

other

Not Supported

Type/Range Select (Bits 11 through 8)

These bits indicate the type and range as in the following table. Other

combinations of these bits are not supported and result in an error.

Bit Settings

11

10

other

Data Format

Voltage Mode 0 to 10V dc

Current Mode 4 to 20 mA

Not Supported

Publication 1762-IN005A-US-P

18

MicroLogix Analog Input/Output Module

Specifications

General Specifications

Specification

Value

Dimensions

90 mm (height) x 87 mm (depth) x 40 mm (width)

height including mounting tabs is 110 mm

3.54 in. (height) x 3.43 in. (depth) x 1.58 in. (width)

height including mounting tabs is 4.33 in.

Approximate Shipping Weight

(with carton)

240g (0.53 lbs.)

Storage Temperature

-40C to +85C (-40F to +185F)

Operating Temperature

0C to +55C (-32F to +131F)

Operating Humidity

5% to 95% non-condensing

Operating Altitude

2000 meters (6561 feet)

Vibration

Operating: 10 to 500 Hz, 5G, 0.030 in. max. peak-to-peak

Shock

Operating: 30G

Bus Current Draw (max.)

40 mA at 5V dc

105 mA at 24V dc

Analog Normal Operating Range

Voltage: 0 to 10V dc

Current: 4 to 20 mA

Full Scale(1) Analog Ranges

Voltage: 0 to 10.5V dc

Resolution

12 bits (unipolar)

Repeatability(2)

0.1%

Input and Output Group to System

Isolation

30V ac/30V dc rated working voltage(3)

(N.E.C. Class 2 required)

(IEC Class 2 reinforced insulation)

Current: 0 to 21 mA

type test: 500V ac or 707V dc for 1 minute

Module Power LED

On: indicates power is applied.

Recommended Cable

Belden 8761 (shielded)

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

Specification

19

Value

Vendor I.D. Code

Product Type Code

10

Product Code

75

Agency Certification

C-UL certified (under CSA C22.2 No. 142)

UL 508 listed

CE compliant for all applicable directives

Hazardous Environment Class

Class I, Division 2, Hazardous Location, Groups A, B, C, D (UL

1604, C-UL under CSA C22.2 No. 213)

Noise Immunity

NEMA standard ICS 2-230

Radiated and Conducted Emissions

EN50081-2 Class A

Electrical /EMC:

The module has passed testing at the following levels:

ESD Immunity (IEC1000-4-2)

4 kV contact, 8 kV air, 4 kV indirect

Radiated Immunity (IEC1000-4-3)

10 V/m, 80 to 1000 MHz, 80% amplitude modulation, +900

MHz keyed carrier

Fast Transient Burst (IEC1000-4-4)

2 kV, 5 kHz

Surge Immunity (IEC1000-4-5)

1 kV galvanic gun

Conducted Immunity (IEC1000-4-6)

10V, 0.15 to 80 MHz(4)

(1) The over- or under-range flag comes on when the normal operating range (over/under) is exceeded. The

module continues to convert the analog input up to the maximum full scale range.

(2) Repeatability is the ability of the input module to register the same reading in successive measurements for

the same input signal.

(3) Rated working voltage is the maximum continuous voltage that can be applied at the terminals with respect

to earth ground.

(4) Conducted Immunity frequency range may be 150 kHz to 30 MHz if the Radiated Immunity frequency range is

30 MHz to 1000 MHz.

Publication 1762-IN005A-US-P

20

MicroLogix Analog Input/Output Module

Input Specifications

Specification

Value

Number of Inputs

2 differential (unipolar)

A/D Converter Type

Successive approximation

Common Mode Voltage

Range(1)

27 V

Common Mode Rejection(2)

> 55 dB at 50 and 60 Hz

Non-linearity (in percent full

scale)

0.1%

Typical Overall Accuracy(3)

0.5% full scale at 0 to 55C

Input Impedance

Voltage Terminal: 200K

0.3% full scale at 25C

Current Terminal: 250

Current Input Protection

32 mA

Voltage Input Protection

30 V

Channel Diagnostics

Over or under range or open circuit condition by bit reporting for

analog inputs.

(1) For proper operation, both the plus and minus input terminals must be within 27V of analog common.

(2) Vcm = 1 Vpk-pk AC

(3) Vcm = 0 (includes offset, gain, non-linearity and repeatability error terms)

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

21

Output Specifications

Specification

Value

Number of Outputs

2 single-ended (unipolar)

D/A Converter Type

Resistor string

Resistive Load on Current

Output

0 to 500 (includes wire resistance)

Load Range on Voltage Output > 1K

Reactive Load, Current Output < 0.1 mH

Reactive Load, Voltage Output < 1 F

Typical Overall Accuracy(1)

1% full scale at 0 to 55C

Output Ripple

range 0 to 500 Hz

(referred to output range)

< 0.1%

Non-linearity (in percent full

scale)

< 0.5%

Open and Short-Circuit

Protection

Continuous

Output Protection

32 mA

0.5% full scale at 25C

(1) Includes offset, gain, non-linearity and repeatability error terms.

Publication 1762-IN005A-US-P

22

MicroLogix Analog Input/Output Module

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to

use in hazardous locations.

WARNING

EXPLOSION HAZARD

Substitution of components may impair suitability for

Class I, Division 2.

Do not replace components or disconnect equipment unless

power has been switched off.

Do not connect or disconnect components unless power has

been switched off.

This product must be installed in an enclosure.

In Class I, Division 2 applications, the bus connector must

be fully seated and the bus connector cover must be

snapped in place.

In Class I, Division 2 applications, all modules must be

mounted in direct contact with each other as shown on

page 6. If DIN rail mounting is used, an end stop must be

installed ahead of the controller and after the last 1762 I/O

module.

All wiring must comply with N.E.C. article 501-4(b).

Publication 1762-IN005A-US-P

MicroLogix Analog Input/Output Module

23

Environnements dangereux

Cet quipement est conu pour tre utilis dans des environnements de Classe 1,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

sapplique une utilisation dans des environnements dangereux.

MISE EN GARDE DANGER DEXPLOSION

La substitution de composants peut rendre cet quipement

impropre une utilisation en environnement de Classe 1,

Division 2.

Ne pas remplacer de composants ou dconnecter

l'quipement sans s'tre assur que l'alimentation est

coupe.

Ne pas connecter ou dconnecter des composants sans

s'tre assur que l'alimentation est coupe.

Ce produit doit tre install dans une armoire.

Pour les applications de Classe I, Division 2, le connecteur

de bus doit tre correctement install et son couvercle

enclench.

Pour les applications de Classe 1, Division 2, tous les

modules doivent tre installs en contact direct les uns avec

les autres, comme indiqu page 6. Si on utilise le montage

sur rail DIN, une bute doit tre place l'avant de

l'automate et aprs la dernire unit d'E/S 1762.

Publication 1762-IN005A-US-P

MicroLogix is a trademark of Rockwell Automation.

Belden is a trademark of Belden, Inc.

Publication 1762-IN005A-US-P - March 2000

PN 40071-073-01(A)

2000 Rockwell International Corporation. Printed in the U.S.A.

H'*i!AC

You might also like

- LJ-V7000 Series: User's ManualDocument448 pagesLJ-V7000 Series: User's ManualDavid Lucio100% (1)

- Manual Skoda Octavia 1,6 74kWDocument164 pagesManual Skoda Octavia 1,6 74kWCornea Horatiu Sebastian100% (2)

- 1762 Ob16Document16 pages1762 Ob16SANKPLYNo ratings yet

- Compact 32-Point Solid-State 24V DC Source Output Module: Installation InstructionsDocument24 pagesCompact 32-Point Solid-State 24V DC Source Output Module: Installation InstructionsThanh BaronNo ratings yet

- Devicenet 1732 Armorblock I/O, Series A: Installation InstructionsDocument16 pagesDevicenet 1732 Armorblock I/O, Series A: Installation InstructionsMariano DavicoNo ratings yet

- Ult REL Output Analog Modules 1734-In002 enDocument24 pagesUlt REL Output Analog Modules 1734-In002 enGabriel Constantin NastaseNo ratings yet

- Micrologix™ Analog Input/Output: Installation InstructionsDocument24 pagesMicrologix™ Analog Input/Output: Installation Instructionscamus1125No ratings yet

- GuardPLC Digital Input Output Module PDFDocument20 pagesGuardPLC Digital Input Output Module PDFTarun BharadwajNo ratings yet

- 1769 Iq32tDocument20 pages1769 Iq32tHilder Ramirez PuellesNo ratings yet

- 1769 Ob32tDocument24 pages1769 Ob32tHilder Ramirez PuellesNo ratings yet

- Manual Módulo Interfaz Cortina de Seguridad Banner 62822Document12 pagesManual Módulo Interfaz Cortina de Seguridad Banner 62822Guillermo GarciaNo ratings yet

- SLC 500™ Analog Input Modules: Installation InstructionsDocument20 pagesSLC 500™ Analog Input Modules: Installation InstructionsneoflashNo ratings yet

- Redundancy Module Quint-Diode/40: 1. Short DescriptionDocument6 pagesRedundancy Module Quint-Diode/40: 1. Short Description54045114No ratings yet

- Micrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsDocument24 pagesMicrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsRexNo ratings yet

- Controllogix Voltage/Current Input Module: Installation InstructionsDocument20 pagesControllogix Voltage/Current Input Module: Installation InstructionsMarco RojasNo ratings yet

- Manual Armoblock ABDocument24 pagesManual Armoblock ABJermy Abraham CarrascoNo ratings yet

- Ethernet Interface 1761 Net EniDocument40 pagesEthernet Interface 1761 Net EniDaniel Castrellon MedellinNo ratings yet

- 1764-24AWA - 24BWA - 28BXB Install (1764-In001A-MU-P Mar 2000) - SuperseededDocument122 pages1764-24AWA - 24BWA - 28BXB Install (1764-In001A-MU-P Mar 2000) - SuperseededjishyNo ratings yet

- Mini Mcr-Sl-I-I: Standard Signal - 3-Way Isolating AmplifierDocument7 pagesMini Mcr-Sl-I-I: Standard Signal - 3-Way Isolating AmplifieremersonalessandroNo ratings yet

- GuardPLC Digital Output Module PDFDocument16 pagesGuardPLC Digital Output Module PDFTarun BharadwajNo ratings yet

- GuardPLC Digital Input ModuleDocument16 pagesGuardPLC Digital Input ModuleTarun BharadwajNo ratings yet

- Siga Io ModulesDocument6 pagesSiga Io ModulesAnonymous s6f1tisKjSNo ratings yet

- Compact 1769-ASCII Module: Installation InstructionsDocument40 pagesCompact 1769-ASCII Module: Installation InstructionsMaximilianoAlvarezNo ratings yet

- A1SD75P 1 2 3 S3 UserManual Hardware IB 66732 EDocument16 pagesA1SD75P 1 2 3 S3 UserManual Hardware IB 66732 EJuliana BertonNo ratings yet

- POINT I/O Common Terminal Module and Voltage Terminal ModuleDocument16 pagesPOINT I/O Common Terminal Module and Voltage Terminal Moduleluisllumiquinga97No ratings yet

- C264 en o C80Document828 pagesC264 en o C80Natarajan SubramanyanNo ratings yet

- 1756 Ib32Document16 pages1756 Ib32Daniel BacicNo ratings yet

- POINT I/O Wiring Base Assembly: Environment and EnclosureDocument2 pagesPOINT I/O Wiring Base Assembly: Environment and EnclosureThanh BaronNo ratings yet

- Hoja de Datos PLC 1762:L4Document35 pagesHoja de Datos PLC 1762:L4Martin GuzmanNo ratings yet

- C264 en o C80 PDFDocument828 pagesC264 en o C80 PDFAnonymous g0InJ4BLBNo ratings yet

- Abb Rdcu 12cDocument14 pagesAbb Rdcu 12cMarco MedinaNo ratings yet

- Relay Block PDFDocument5 pagesRelay Block PDFJapheth K. KiptooNo ratings yet

- MPD-1000 Bug-ODocument59 pagesMPD-1000 Bug-OROMERJOSENo ratings yet

- 1734 Oe2cDocument16 pages1734 Oe2ctony.pearce1No ratings yet

- PanelView 300 Micro Terminals Installation Instructions - ° ×°Ö ÄÏ PDFDocument116 pagesPanelView 300 Micro Terminals Installation Instructions - ° ×°Ö ÄÏ PDFjaimeasisa100% (1)

- Inj-24 Series Qig E4 0Document8 pagesInj-24 Series Qig E4 0Liliana ZamoraNo ratings yet

- SLC 500™ 32-Channel Digital I/O Modules: (Catalog Numbers 1746-IB32, - IV32, - OB32, - OB32E and - OV32)Document20 pagesSLC 500™ 32-Channel Digital I/O Modules: (Catalog Numbers 1746-IB32, - IV32, - OB32, - OB32E and - OV32)Rim GrissaNo ratings yet

- Controllogix™ DC (10-31.2V) Input Module: Installation InstructionsDocument18 pagesControllogix™ DC (10-31.2V) Input Module: Installation InstructionsRichard ReyesNo ratings yet

- 1732e In004 - en eDocument20 pages1732e In004 - en eisaacsavioNo ratings yet

- 1756 Ob32Document20 pages1756 Ob32downpourguyNo ratings yet

- Q Amp CX UserguideDocument102 pagesQ Amp CX UserguideGOLDEN MUSIC DISCO MOVILNo ratings yet

- Bu6010 GB 0300Document44 pagesBu6010 GB 0300Kadirou BigstarNo ratings yet

- Instructions AND Parts Manual: Modular Drive SystemDocument55 pagesInstructions AND Parts Manual: Modular Drive SystemMarcos Ribeiro100% (1)

- 039 Siga-Ct1Document4 pages039 Siga-Ct1zezohome100% (1)

- Compact High-Density Analog Current Input: Catalog Number 1769-IF16CDocument28 pagesCompact High-Density Analog Current Input: Catalog Number 1769-IF16CpaplusNo ratings yet

- 1500 Micro LogixDocument100 pages1500 Micro LogixMisael CastilloNo ratings yet

- Compact High-Density Analog Voltage Input: Catalog Number 1769-IF16VDocument28 pagesCompact High-Density Analog Voltage Input: Catalog Number 1769-IF16VHelio rodrigues da silva cabeçaNo ratings yet

- TID00323-MANUAL MODULO 1794 OA16-1794-in103 - En-PDocument24 pagesTID00323-MANUAL MODULO 1794 OA16-1794-in103 - En-PNatalia BeltránNo ratings yet

- MDS Ipm Bugo MDS 1002Document57 pagesMDS Ipm Bugo MDS 1002Taz Juan GNo ratings yet

- ECX 400 SeriesDocument16 pagesECX 400 SeriesGeneral Electronic Facility LandsideNo ratings yet

- Sigma Status Unit Man-1089Document13 pagesSigma Status Unit Man-1089MikeNo ratings yet

- Compact I/O High-Speed Counter: Installation InstructionsDocument32 pagesCompact I/O High-Speed Counter: Installation InstructionsYosed Leonardo Santos GomezNo ratings yet

- Point I/O Devicenet Adapter: Installation InstructionsDocument28 pagesPoint I/O Devicenet Adapter: Installation InstructionsCarlosOtinianoNo ratings yet

- LexiumDocument32 pagesLexiumIbrahima DiawNo ratings yet

- Ismart Operation ManualDocument138 pagesIsmart Operation ManualMoreno CancunNo ratings yet

- IOLC1Document13 pagesIOLC1Adithya A RNo ratings yet

- Man-1092 Synhro RepeterDocument12 pagesMan-1092 Synhro RepetersvirkomartinkoNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Flow-Mate Series: Technical Data SheetDocument2 pagesFlow-Mate Series: Technical Data SheetDavid LucioNo ratings yet

- Prototrak & Trak CNC: Service and Troubleshooting ManualDocument85 pagesPrototrak & Trak CNC: Service and Troubleshooting ManualDavid LucioNo ratings yet

- SpeedControl V90 S7-1200 DOC enDocument23 pagesSpeedControl V90 S7-1200 DOC enDavid LucioNo ratings yet

- ARYUNGDocument2 pagesARYUNGDavid LucioNo ratings yet

- 1762 Um002 - en PDocument144 pages1762 Um002 - en PDavid LucioNo ratings yet

- Micro - Compact Selection ToolDocument2 pagesMicro - Compact Selection ToolDavid LucioNo ratings yet

- Relays, TimersDocument25 pagesRelays, TimersDavid LucioNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Jyri Pakarinen, David T. Yeh A Review of Digital Techniques For Modeling Vacuum-Tube Guitar AmplifiersDocument16 pagesJyri Pakarinen, David T. Yeh A Review of Digital Techniques For Modeling Vacuum-Tube Guitar AmplifiersMišo KovačNo ratings yet

- Test4-Reading Passage 3Document2 pagesTest4-Reading Passage 3vanpham248No ratings yet

- Homework #1 (Circuit Basics, Equivalents and Models) : MicroelectronicsDocument7 pagesHomework #1 (Circuit Basics, Equivalents and Models) : MicroelectronicsFuc Fuc LeiNo ratings yet

- Data Sheet Prolec - 1500 Kva - 22860V - 480-240VDocument2 pagesData Sheet Prolec - 1500 Kva - 22860V - 480-240VAlfrhNo ratings yet

- LG 55uf950t LB52VDocument111 pagesLG 55uf950t LB52VJeank RivadeneyraNo ratings yet

- 712 06Document136 pages712 06JorGe Luiz AmbarioNo ratings yet

- SUBSTATION OPERATOR - Job Description PDFDocument1 pageSUBSTATION OPERATOR - Job Description PDFhabte gebreial shrashrNo ratings yet

- Signature in Remote SensingDocument8 pagesSignature in Remote SensingKang XiaoNo ratings yet

- Jiang2003 PDFDocument9 pagesJiang2003 PDFtigerman manNo ratings yet

- MCQ RMT Final Unit1,2,3Document14 pagesMCQ RMT Final Unit1,2,3Deven MaliNo ratings yet

- Small Signal Diode: BAW56, BAV70, BAV99 225mW SMD Switching DiodeDocument4 pagesSmall Signal Diode: BAW56, BAV70, BAV99 225mW SMD Switching DiodeKwun Hok ChongNo ratings yet

- Electrical Load ScheduleDocument14 pagesElectrical Load ScheduleAtty AttyNo ratings yet

- High Low Impedance Busbar ProtectionDocument92 pagesHigh Low Impedance Busbar Protectionsugeng100% (1)

- Ease 2 Physics Grade 12Document20 pagesEase 2 Physics Grade 12Arisee PrasetyaNo ratings yet

- QuizDocument5 pagesQuizgeetikag_23No ratings yet

- Igcse Electrochemistry Review PDFDocument7 pagesIgcse Electrochemistry Review PDFbilly ogadaNo ratings yet

- Course Out-LineDocument24 pagesCourse Out-LinemandeNo ratings yet

- Induction Heating Basics PDFDocument39 pagesInduction Heating Basics PDFAlee LópezNo ratings yet

- Uccx8C4X Bicmos Low-Power Current-Mode PWM Controller: 1 FeaturesDocument55 pagesUccx8C4X Bicmos Low-Power Current-Mode PWM Controller: 1 FeaturesVishnu SharmaNo ratings yet

- Worksheet To Complement Echalk Resource: "Electricity Bills"Document3 pagesWorksheet To Complement Echalk Resource: "Electricity Bills"Prayogo DidiNo ratings yet

- 01 4ib 48010Document51 pages01 4ib 48010Charles RobiansyahNo ratings yet

- ME4542/ME4542-G: N and P-Channel 30-V (D-S) MOSFETDocument7 pagesME4542/ME4542-G: N and P-Channel 30-V (D-S) MOSFETfelipe ayalaNo ratings yet

- Programmable Logic ControllersDocument21 pagesProgrammable Logic ControllersDivya PandeyNo ratings yet

- Instruction - Resistance Heating Element ProjectDocument6 pagesInstruction - Resistance Heating Element Projectarg0nautNo ratings yet

- (Analogicas) Cp1w-Ad Da Mad Ts DRT SRT Pages From W471-E1-04Document70 pages(Analogicas) Cp1w-Ad Da Mad Ts DRT SRT Pages From W471-E1-04armani_crupierNo ratings yet

- For The Participants From The Belorussia, Russia and UkraineDocument4 pagesFor The Participants From The Belorussia, Russia and Ukraineaymmon8950No ratings yet

- ISD4004 12MEIR Winbond PDFDocument28 pagesISD4004 12MEIR Winbond PDFFredrickNo ratings yet

- ExerciseSet6 01Document3 pagesExerciseSet6 01Woldemariam Worku100% (1)