Professional Documents

Culture Documents

Bioluminescence ATP

Bioluminescence ATP

Uploaded by

Yessica Castillo OlivaresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bioluminescence ATP

Bioluminescence ATP

Uploaded by

Yessica Castillo OlivaresCopyright:

Available Formats

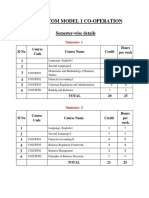

TI

UM

SCIE

N

R

NO

UM POLO

AR

ACTA

Acta Sci. Pol., Technol. Aliment. 7(4) 2008, 53-60

USING THE BIOLUMINESCENCE

AND MICROBIOLOGICAL CONTACT METHODS

IN SUSTAINING A PROPER HYGIENIC LEVEL

IN FOOD PROCESSING PLANTS

Dorota Cais-Sokoliska, Jan Pikul

Pozna University of Life Sciences

Abstract. The efficiency of bioluminescence applied to monitor the state of hygiene in a

dairy processing plant was assessed in relation to the results of conventional microbiological methods. The used blotting tests were Envirocheck Contact DC with Agar CASO

medium with added neutralizers. The analysed object was the surface of a beam stirrer in

a fermentation tank. Swabs were collected following tank washing and disinfection after

the completion of 15 production cycles. A high degree of correlation r = 0.91 was obtained at the reliability of comparison = 0.906. The analysis of probability of distribution confirmed the feasibility of bioluminescence. Boundary values (112 and 171 RLU)

were determined for bioluminescence for three object cleanliness ranges, based on microbial counts (cfu/cm2). Over 13% surfaces were classified as conditionally clean (Alert).

Key words: bioluminescence, ATP, hygiene

INTRODUCTION

In compliance with the Ordinance of the European Committee no. 1441/2007 of 5

December 2007 enterprises of the agri-food sector, including the dairy industry, are

required to provide for foodstuffs to meet the respective microbiological criteria and to

ensure the maintenance of respective hygienic criteria for the processes of their production. The application of microbiological criteria should constitute an integral part of the

implementation of procedures based on HACCP principles and other hygiene control

procedures. In order to ensure the acceptability of the operating production process,

agri-food sector enterprises have to meet respective process hygiene criteria. These

criteria determine the contamination index value, which when exceeded shows that

corrective actions are required in order to maintain process hygiene at a level imposed

by the food legal regulations. In the assessment of process hygiene criteria it is admissi-

Corresponding author Adres do korespondencji: Dr in. Dorota Cais-Sokoliska, Dairy Technology Department of Pozna University of Life Sciences, Wojska Polskiego 31, 60-624 Pozna,

Poland, e-mail: cais@up.poznan.pl

54

D. Cais-Sokoliska, J. Pikul

ble to analyse the presence of alternative microorganisms in relation to respective

microbiological limits, as well as investigate parameters other than microbiological

ones. They are particularly applicable in the monitoring of hygienic condition of production lines on a daily basis. The determination of correlations between conventional

microbiological methods and results recorded using modern ones will facilitate the

application of rapid cleanliness tests for analysed objects as an effective tool in the

monitoring of the hygiene condition [Bautista et al. 1992, Griffiths 1995, Squirrell et al.

2002, Cooper et al. 2007].

In food industry plants monitoring methods are most frequently used to determine

hygienic quality. Conventional methods of microbiological analysis, such as the swabbing, wash-and-rinse, direct or blotting methods are time-consuming and laborious.

Since the result of conventional analyses is obtained 48 or 72 h after swab collection, it

is impossible to undertake corrective actions, as in practice the production cycle has

been initiated much earlier. Safety assurance is facilitated when the cleanliness status of

analysed objects is monitored by modern methods using physico-chemical properties of

microorganisms, advances in genetics and findings concerning cell biochemistry [Griffiths 1996, Hawronskyj and Holah 1997, Cho and Yoon 2007]. An important advantage

of these methods is the practically immediate result and easy performance [Deshpande

2001]. The shorter the time interval between the measurement and the result, the more

effective the monitoring method in the food safety assurance system [Knaflewska and

Popiech 2007, Rosmaninho et al. 2007, Sharma and Anand 2002]. However, the key

factor in the appropriate use of these methods is to be able to properly interpret recorded

results [Lappalainen et al. 2000, Larson et al. 2003].

The aim of the study was to assess the efficiency of washing and disinfection processes and to define the scope of application for bioluminescence in the assessment of

hygienic status in a dairy processing plant prior to the commencement of production

within the framework of hygiene and sanitary control at the plant.

MATERIAL AND METHODS

Collection of samples. The experiment was performed at a dairy plant in northwestern Poland, producing fermented dairy drinks. The analyses were conducted on the

surface of a beam stirrer mounted within a fermentation tank. The object selected for

analyses was manufactured from high-alloy austenitic steel type 316L. It is stainless

chromium-nickel steel, cold rolled, annealed, etched, smooth and lustreless. Analyses

were conducted after the completion of each of the 15 production cycles. The selected

object was characterized by a high microbiological load.

Cleanliness of adjacent surfaces in the object was analysed after washing and disinfection processes by microbiological blotting tests and by bioluminescence. Swab samples were collected from clean and dry surfaces at least 2 h after and not later than 4 h

after the completion of washing and disinfection procedures. The same surface was

selected for each analysis.

Microbiological analysis. Blotting tests Envirocheck Contact DC by Merck KGaA

(Darmstadt, Germany) were used to assess the efficiency of washing and disinfection of

surfaces of technological line equipment at a dairy processing plant. The test is a rectangular plastic plate of approx. 9 cm2, covered on both sides with a layer of agar me-

Acta Sci. Pol.

Using the bioluminescence and microbiological contact methods ...

55

dium, and placed in a sterile vial. In the Envirocheck Contact DC test one side of the

strip is covered by CASO trypticase soy agar (TSA). It is an agar medium with casein

peptone and soy flour peptone for the determination of microbiological load before

washing and disinfection. The other side of the strip is covered with CASO Agar with

an addition of neutralizers such as Ploysorbate 80 (Tween 80), sodium thiosulfate, lecithin and histidine. Tween 80 neutralizes hexachlorophene and mercury compounds,

sodium thiosulfate neutralizes halogen derivatives, lecithin neutralizes chlorhexidines,

histidine in combination with Tween 80 and lecithin neutralizes aldehydes and substituted phenols. Quaternary ammonium salts are also neutralized by a combination of

Tween 80 and lecithin. The application of neutralizers facilitates the growth of bacteria,

which development was only inhibited as a result of washing and disinfection and

which still remain capable of growing. The Agar CASO medium with neutralizers is

used to investigate microbiological load on the surface following washing and disinfection.

Prior to use blotting tests were stored at 12 3C. The smearing procedure was performed according to the manufacturers recommendations. The cap on the tube was

unscrewed and the Envirocheck slide was removed from the tube, taking care not to

touch the agar surfaces. The slide was checked before use for any sign of dehydration or

contamination. The terminal end of the paddle was held with two fingers against the

surface to be tested. The spike was pressed down to bend the paddle, while still holding

the slide by the cap. With a firm and even pressure one medium was pressed against the

surface to be tested. Care was taken not to smear the agar over the test area. The procedure was repeated with the other side of the paddle on an area adjacent to the initial test

site. The slide was replaced back into the tube and closed tightly.

Tests, after being pressed to the analysed surface and replaced back to their tubes,

were transported to the incubation site within max. 6 h, in the dark and at a temperature

up to 5C. Tubes with tests were placed vertically in a WTB Binder microbiological

incubator (Tuttlingen, Germany) at 37C for 48 h. Microbial counts were given in

cfu/cm2 area.

Bioluminescence method. Cleanliness status by bioluminescence was assessed

based on results of ATP measurements with a luminometer FireFly Charm Sciences Inc.

(Malden, USA) and swabs PocketSwab Plus Charm Science Inc. (Lawrence, USA). The

measurement procedure was performed following the instructions of the manufacturers

of the meter and swabs. The total testing time including the reading did not exceed 45 s.

The result was given in relative light units (RLU).

Statistical analysis. Results of bioluminescence and those of the conventional

microbiological method were compared following the division of object surfaces into

those classified as clean, i.e. Pass ( 5 0.44 x Sd), conditionally clean, i.e. Alert (5

0.44 x Sd < and 8 0.44 x Sd) or unacceptable, i.e. Fail (> 8 0.44 x Sd) for the total

number of object samples n = 15. Pearsons linear correlation coefficients were calculated in order to determine the degree of proportional correlations between values of the

conventional microbiological method and those obtained by bioluminescence. On this

basis regression lines were plotted and the coefficient of determination was calculated,

constituting the basis for the size of the correlation. Coefficients of determination express the size of common variance for the two analysed variables. Statistical calculations were performed using a data analysis software system STATISTICA (version 7.1)

by StatSoft (2005).

Technologia Alimentaria 7(4) 2008

56

D. Cais-Sokoliska, J. Pikul

RESULTS

Microbiological analyses conducted using blotting tests showed counts ranging from

0.8 to 5.3 cfu per 1 cm2 area of the investigated object. In turn, the simultaneous application of swabs, next placed in a luminometer, showed the presence of 17 to 116 RLU

on the surface of the object. The basis for the determination of a correlation between

both methods was to calculate the coefficient of determination (R2 = 0.93) and to analyse the probability density function (Table 1). High values of correlations were recorded for analysed variables, as it is evidenced by the reliability of correlation =

0.906, i.e. close to 1. The reliable correlation of results obtained using blotting tests and

by bioluminescence is shown by the low value p < 0.001. These data were recorded

irrespective of the division of cleanliness scores of the same objects in successive production cycles.

Table 1. The analysis of correlation between bioluminescence results (RLU) and microbial counts

(cfu/cm2), = 0.05, df = 1.13, n = 15

Mean

log cfu Sd

Mean

log RLU Sd

Pass

0.17 0.25

1.73 0.23

Alert

0.68 0.06

2.06 0.01

Mean

0.24 0.25

1.77 0.23

R2

0.93

59.48

0.906

< 0.001

df degrees of freedom.

R2 coefficient of determination.

F density function.

density probability.

Sd standard deviation.

p value statistically significant.

The determination of the correlation between results of bioluminescence and conventional microbiological assays was facilitated by the conducted analysis of probability

of normal distribution (Fig. 1). Almost 95% obtained results were found in the ellipse of

covariance defined by its matrix. They were results of great importance for the determination of correlation (weight 10). Only 20% results were found outside the regression

area defined at 95%. No deviations were found from the linear distribution of correlations of both variables. The calculated correlation coefficient of both methods was high

(r > 0.91).

Experimental values recorded using blotting tests and boundary values calculated on

their basis classified 87% experimental results to the class of adequate cleanliness (Pass)

and 13% results as the admissible warning class (Alert; Table 2). The maximum result

classified to the appropriate cleanliness level was the value of 3.3 cfu/cm2. The difference

between this value and the lowest result in the admissible range was 1.1 cfu/cm2. In turn,

this difference was equivalent to only 6 RLU recorded by bioluminescence. Thus, based

on the linear distribution, the RLU range was predicted in relation to the independent

variable characterized by microbial count (cfu/cm2). Obtained ranges of prediction values

for the admissible level of cleanliness were consistent with experimental data.

Acta Sci. Pol.

57

Using the bioluminescence and microbiological contact methods ...

log RLU = 1.57 + 0.81 log cfu/cm2

r = 0.91

2.1

2.0

1.9

1.8

log RLU

1.7

1.6

1.5

1.4

1.3

1.2

1.1

0.2

0.1

0.0

0.1

0.2

0.3

log cfu/cm

0.4

0.5

0.6

0.7

0.8

Fig. 1. Relative probability of normal distribution of results recorded using

conventional microbiological testing and bioluminescence (weight = 10)

190

Alert

Pass

limit value

experimental results

170

150

RLU

130

110

90

70

50

30

10

1

10

11

12

13

14

15

Fig. 2. Prediction and experimental ranges of object cleanliness based on

bioluminescence results

A detailed analysis of measurement data recorded using bioluminescence and their

prediction confirmed a lack of discrepancy between results obtained in the 15 successive cycles of the experiment (Fig. 2). Two of the 15 measurements taken with a luminometer were higher than the boundary value between the Pass and Alert ranges (112

RLU) and at the same lower than the boundary value between the Alert and Fail classes

Technologia Alimentaria 7(4) 2008

58

D. Cais-Sokoliska, J. Pikul

(171 RLU). No result recorded in the experiment would indicate that the object surface

was inadequately clean and thus requiring its repeated washing and disinfection.

DISCUSSION

Bautista et al. [1992], when assessing the hygienic status of surfaces using the conventional method and by bioluminescence, showed that in 74% analysed surfaces the

results obtained by the traditional method and by bioluminescence were consistent. In

36% surfaces RLU results indicated that the surfaces were not sufficiently clean, although it was not confirmed using the conventional method. Prior to washing the authors on 20 surfaces measured 4 2191 RLU, while after washing they detected 2 285

RLU. In turn, Aycicek et al. [2006] found that 97.5% examined surfaces could be considered clean on the basis of results recorded by both the conventional method and bioluminescence. The other 2.5% investigated objects turned out to be clean based on

ATP-bioluminescence results, although microbial count assessed by the conventional

method did not show it. The percentage of objects assessed as clean by the authors on

the basis of bacterial counts and which turned out to be dirty based on RLU data was

74.6%. At the same time the authors when examining 14 different objects, e.g. steel and

plastic, showed a wide spectrum ranging from 1435 to 90959 measured RLU. The suitability of bioluminescence in the assessment of cleanliness status was shown by Cooper

et al. [2007] within the range of 83% to 100% prior to washing and 90% to 100% after

surface washing. The authors decided that on average 84% surfaces they examined were

clean based on RLU data, but only 66% based on the conventional microbial count

method. Cho and Yoon [2007] used in their model studies the high dependence of microbial counts and results of RLU measurements to determine detection levels with

a luminometer. A high correlation was also found for results of bioluminescence and the

conventional method reported by Larson et al. [2003]. When examining 219 surfaces of

4 cm 4 cm those authors detected 2.97 log cfu and at the same time recorded on average 2.61 log RLU at p = 0.45. The value of measured RLU ranged from 0.8 to 4.6 log

RLU, which corresponded to 15 44 000 RLU. The correlation coefficient calculated

by the authors of the study was r = 0.82.

Table 2. Bioluminescence results corresponding to calculated and experimental values of microbiological testing determining cleanliness levels of the analysed object

Cleanliness levels

for object

Results of microbiological

method, cfu/cm2

Bioluminescence results, RLU

cfu/cm2

experimental values

experimental values

Pass

4.42

0.8-3.3

17-98

112

Alert

4.42 < x 7.42

4.4-5.3

114-116

112 < x 171

Fail

> 7.42

> 171

prediction

Pass clean, Alert conditionally clean, Fail unacceptable.

Acta Sci. Pol.

Using the bioluminescence and microbiological contact methods ...

59

CONCLUSION

A high correlation was determined in this experiment between results of blotting

tests and those recorded by bioluminescence. However, the introduction of bioluminescence testing using a luminometer requires a pre-determination of cleanliness ranges

based on results of conventional microbiological tests. This results from the necessity to

calculate boundary values of dependent variables, RLU, on the basis of the independent

variable, i.e. results of microbial count determinations on the analysed surface. Ranges

of the hygienic status of the surface, defined as clean, conditionally clean and inadequately clean based on RLU, should be completely convergent with ranges determined

as a result of prediction, as it was the case in the experiment. Analyses conducted using

a luminometer showed that it is possible to monitor the presence of microorganisms as

an indicator of surface cleanliness in a dairy processing plant.

REFERENCES

Aycicek H., Oguz U., Karci K., 2006. Comparison of results of ATP bioluminescencie and traditional hygiene swabbing methods for the determination of surfach cleanliness at a hospital

kitchen. Int. J. Hyg. Environ.-Health 209, 203-206.

Bautista D.A., Mcintyre L., Laleye L., Griffiths M.W., 1992. The application of ATP bioluminescence for the assessment of milk quality and factory hygiene. J. Rapid Methods Autom. Microbiol. 1(3), 179-193.

Cho M., Yoon J. 2007. The application of bioluminescence assay with culturing for evaluating

quantitative disinfection performance. Water Res. 41, 741-746.

Cooper R., Griffith C., Malik R., Obee P., Looker N., 2007. Monitoring the effectiveness of

cleaning in four British hospitals. Am. J. Infect. Control 35(5), 338-341.

Deshpande S.S., 2001. Principles and applications of luminescence spectroscopy. Crit. Rev. Food

Sci. Nutr. 41, 155-224.

Griffiths M.W., 1995. Bioluminescence and the food industry. J. Rapid Methods Autom. Microbiol. 4, 65-75.

Griffiths M.W., 1996. The role of ATP bioluminescence in the food industry: new light on old

problems. Food Technol. 50, 62-72.

Hawronskyj J.-M., Holah J., 1997. ATP a universal hygiene monitor. Trends Food Sci. Technol.

8(3), 79-84.

Knaflewska J., Popiech E., 2007. Quality assurance systems in food industry and health security

of food. Acta Sci. Pol., Technol. Aliment. 6(2), 75-84.

Lappalainen J., Loikkanen S., Havana M., Karp M., Sjoberg A.-M., Wirtanen G., 2000. Microbial

testing methods for detection of residual cleaning agents and disinfectants errors in the food

industry. J. Food Prot. 63(2), 210-215.

Larson E.L., Aiello A., Gomez-Duarte C., Lin S.X., Lee L., Della-Latta P., Lindhardt C., 2003.

Bioluminescence ATP monitoring as a surrogate marker for microbial load on hands and surfaces in the home. Food Microbiol. 20, 735-739.

Rosmaninho R., Santos O., Nylander T., Paulsson M., Beuf M., Benezech T., Yiantsios S., Andritsos A., Karabelas A., Rizzo G., Muller-Steinhagen H., Melo L.F., 2007. Modified stainless

steel surfaces targeted to reduce fouling: Evaluation of fouling by milk components. J. Food

Eng. 80, 1176-1187.

Sharma M., Anand S.K., 2002. Biofilm evaluation as an essential component of HACCP for

food/dairy processing industry a case. Food Control 13, 469-477.

Technologia Alimentaria 7(4) 2008

60

D. Cais-Sokoliska, J. Pikul

Squirrell D.D., Price R.L., Murphy M.J., 2002. Rapid and specific detection of bacteria using

bioluminescence. Anal. Chem. Acta. 457, 109-114.

WYKORZYSTANIE BIOLUMINESCENCJI

I MIKROBIOLOGICZNEJ METODY KONTAKTOWEJ

W UTRZYMANIU ODPOWIEDNIEGO POZIOMU HIGIENY

W ZAKADACH PRZEMYSU SPOYWCZEGO

Streszczenie. Ocen skutecznoci stosowania metody bioluminescencji w monitorowaniu

higieny w zakadzie przetwrstwa mleka prowadzono w odniesieniu do wynikw tradycyjnych metod mikrobiologicznych. Uyto testw kontaktowych Envirocheck Contact

DC z podoem Agar CASO z dodatkiem neutralizatorw. Obiektem bya powierzchnia

mieszada belkowego w zbiorniku fermentacyjnym. Wymazy pobierano po procesie mycia i dezynfekcji zbiornika po zakoczeniu 15 cykli produkcyjnych. Uzyskano wysoki

stopie korelacji r = 0,91 przy wiarygodnoci porwnania = 0,906. Analiza prawdopodobiestwa rozkadu potwierdzia przydatno stosowania metody bioluminescencji.

Ustalono wartoci graniczne (112 i 171 RLU) metody bioluminescencji dla trzech zakresw czystoci obiektu na podstawie liczby drobnoustrojw (cfu/cm2). Powierzchni zaklasyfikowanych jako czystych warunkowo (Alert) byo ponad 13%.

Sowa kluczowe: bioluminescencja, ATP, higiena

Accepted for print Zaakceptowano do druku: 20.11.2008

For citation Do cytowania: Cais-Sokoliska D., Pikul J., 2008. Using the bioluminescence and

microbiological contact methods in sustaining a proper hygienic level in food processing plants.

Acta Sci. Pol., Technol. Aliment. 7(4), 53-60.

Acta Sci. Pol.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- SPSS Statistics - 210303Document25 pagesSPSS Statistics - 210303Ana Maria Parra100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Instant Download Ebook PDF Burns and Groves The Practice of Nursing Research Appraisal Synthesis and Generation of Evidence 8th Edition PDF ScribdDocument48 pagesInstant Download Ebook PDF Burns and Groves The Practice of Nursing Research Appraisal Synthesis and Generation of Evidence 8th Edition PDF Scribdlillie.mitchell825100% (46)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Gea1000 Finals CheatsheetDocument2 pagesGea1000 Finals CheatsheetAxel JavasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- KTN FixedEffectsDocument10 pagesKTN FixedEffectskobeadjordanNo ratings yet

- Khelfaoui, Mounia - Sedkaoui, Soraya - Sharing Economy and Big Data Analytics-IsTE - John Wiley & Sons, Inc. (2020)Document259 pagesKhelfaoui, Mounia - Sedkaoui, Soraya - Sharing Economy and Big Data Analytics-IsTE - John Wiley & Sons, Inc. (2020)Can ArmutcuNo ratings yet

- Data Analysis On BigMart SalesDocument17 pagesData Analysis On BigMart SalesBhiraj Sonawane67% (3)

- TOPIC 4 - Curve Fiiting and InterpolationDocument23 pagesTOPIC 4 - Curve Fiiting and InterpolationBryan YuNo ratings yet

- Madras University Business Statistics SyllabusDocument1 pageMadras University Business Statistics SyllabusHarini kNo ratings yet

- Development of Prediction Models For Horizontal and Vertical MergersDocument13 pagesDevelopment of Prediction Models For Horizontal and Vertical MergersEnaNukovićNo ratings yet

- Simple Linear Regression Analysis Group 3Document13 pagesSimple Linear Regression Analysis Group 3Danna Krysta Gem LaureanoNo ratings yet

- Exploring Salient Features Influencing Repeat Visit Intention of Young Costumers in Shopping-MallsDocument16 pagesExploring Salient Features Influencing Repeat Visit Intention of Young Costumers in Shopping-MallsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The MIT PressDocument17 pagesThe MIT PressAlejandra MartinezNo ratings yet

- Effect of Resource Alignment On Organizational Performance of Listed Energy and Petroleum Companies in KenyaDocument7 pagesEffect of Resource Alignment On Organizational Performance of Listed Energy and Petroleum Companies in KenyaThe IjbmtNo ratings yet

- Quiz Feedback - CourseraDocument5 pagesQuiz Feedback - Courseraanon_744716350% (1)

- Revell 2009.evol - EarlyviewDocument11 pagesRevell 2009.evol - EarlyviewOzan KorkmazNo ratings yet

- NMC Codebook v4 0Document68 pagesNMC Codebook v4 0suraci2No ratings yet

- Quantitative Business (EBC2025), 2020-2021: Statistical FormulasDocument3 pagesQuantitative Business (EBC2025), 2020-2021: Statistical FormulasPaolina NikolovaNo ratings yet

- B Com Model 1 Co OperationDocument37 pagesB Com Model 1 Co OperationHvffNo ratings yet

- Xlri Ba BrochureDocument16 pagesXlri Ba BrochureSudipto PaulNo ratings yet

- Imark™ Microplate Absorbance Reader Instruction ManualDocument48 pagesImark™ Microplate Absorbance Reader Instruction ManualdnajenNo ratings yet

- Erectile Function After Partial Penectomy For Penile CancerDocument8 pagesErectile Function After Partial Penectomy For Penile CancerTai rascunhos TaiNo ratings yet

- Examination Assignment: Matriculation NumberDocument6 pagesExamination Assignment: Matriculation NumberDIKSHANT GHIMIRENo ratings yet

- Covid 19 and Corporate Performance in The Energy IndustryDocument5 pagesCovid 19 and Corporate Performance in The Energy IndustrySang PhamNo ratings yet

- Application-Logistic-RegressionDocument12 pagesApplication-Logistic-Regressionreach2ghoshNo ratings yet

- Factors Influencing Family Business Decision For Borrowing Credit From Commercial Banks - Evidence in Tra Vinh Province, Viet NamDocument4 pagesFactors Influencing Family Business Decision For Borrowing Credit From Commercial Banks - Evidence in Tra Vinh Province, Viet NamFrans SimanjuntakNo ratings yet

- Sonic LogDocument10 pagesSonic LogSukawan ZakyNo ratings yet

- Linear RegressionDocument12 pagesLinear RegressionsonalNo ratings yet

- Fraud Prevention: Relevance To Religiosity and Spirituality in The WorkplaceDocument9 pagesFraud Prevention: Relevance To Religiosity and Spirituality in The WorkplaceJannah ZahraNo ratings yet

- Full Chapter Quantification Validation and Uncertainty in Analytical Sciences 1St Edition Max Feinberg Serge Rudaz PDFDocument47 pagesFull Chapter Quantification Validation and Uncertainty in Analytical Sciences 1St Edition Max Feinberg Serge Rudaz PDFmargaret.coble262100% (2)

- Introduction To Python For Data Science - SyllabusDocument5 pagesIntroduction To Python For Data Science - SyllabusRaja KarthikNo ratings yet