Professional Documents

Culture Documents

MX Pressure Booster Maximat MX1 PDF

MX Pressure Booster Maximat MX1 PDF

Uploaded by

Narendra Reddy BhumaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MX Pressure Booster Maximat MX1 PDF

MX Pressure Booster Maximat MX1 PDF

Uploaded by

Narendra Reddy BhumaCopyright:

Available Formats

EXTINGUISHING WATER SYSTEMS

PRESSURE BOOSTER

with feed tank maximat MX1

VdS

Zertifiziert nach

ISO 9001

C oo l d ow n.

F ir e P ro te ct io n by

Pressure booster

with feed tank

maximat MX1

Product

Application

Your advantages

When using this extinguishing

water system the water supply

line is wet (filled with extinguishing water) indirectly

connected by means of an open

feed tank with free outlet to

the drinking water supply.

In case of emergency when

actuating the hose connection

valve of a wall hydrant (extinguishing water request) the

pressure booster is activated

and the wall hydrant station

supplied with the necessary

water quantity with continuous pressure. In case of

extinction the DVGW-certified

float valve guarantees big outflow rates with low loss of

pressure as well as low pressure

fluctuations and thus establishes

the indirect connection from

the drinking water supply to

the fire extinguishing system.

After termination of the

extinguishing water request

(closure of the hose connection

valve), the pump resets automatically to the armed state.

The pressure booster with feed

tank maximat MX1 is applicable

as well in the scope of new

installation as for system separation of existing extinguishing

water plants acc. to DN 14462

and DIN 1988-60.

long-life cycle due to high-quality

materials

the modular construction allows

high flexibility in the installation

phase with minimum required

space. The access is limited to one

side. Therefore optimal space

exploitation

suitability in terms of fire protection

by VdS approved and in terms of

drinking water by DVGW certified

float valve and steel container.

Thereby application also possible

in fire load areas.

simple expert acceptance due to VdSapproved and DVGW-certified components

The aerodynamic construction of

the float valve assures high flow

rates with low loss of pressure

damaging vibrations and pressure

surges in the piping are avoided by

means of the high mass inertia of

the floater and the application of a

shut-off flap as inflow control fittings

an especially developed control

cabinet for this case of operation

with potential-free contacts and

control and retransmission possibilities

to the building control system

high maintainability due to easy

accessibility of all armatures and

control elements

Typical application areas without

frost risk are:

-

high-rise buildings

places of public assembly

hospitals

shops

blocks of offices

schools

Application in areas, which are

threatened by frost, is possible

in conjunction with maximat

FSX-LWT

The construction of the plant is

effected each object-related in

consideration of the piping

network isometry, the resulting

mathematical proof and all

further technical requirements

Function

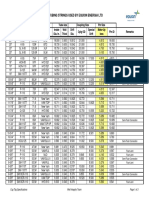

Technical data

Scope of delivery

container unpressurized, welded out of steel

for 600L net volume: L1745 x B616 x H1120 mm

Float valve VdS-approved and DVGW-certified with KV

Wert (l/min) 1000 nominal pressure PN10

VdS-approval-no.: G-4880060/G-4960035

DVGW-registration-no.: DW-0903AQ2013

Open, sand blasted, interiorly coated with tar epoxy

feed tank out of steel with free outlet, with noncircular overflow (unlimited) of family A in the colour

RAL 3000 with a hand-over point acc. to EN 1717

Service

Cover with steel cap in the color RAL 3000

compact construction, ready-for-use tubed and wired

VdS-approved and DVGW-certfied float valve and

stop valve

3-bar electrode for filling level control

The construction of the plant is effected each object-related

in consideration of the piping network isometry, the

resulting mathematical proof and all further technical

requirements

Special vanishing as well as other container dimensions

and special geometries on request

Your Minimax service takes over all works for inspection,

maintenance and repair

nominal voltage P2 [kW]

3 x 380-415 V

1,1

3 x 380-415 V

1,5

In [A]

4,5

4,5

Q nenn [m3/h]

3

3

Q max [m3/h]

4,5

4,5

H nenn [m]

53

57

H null [m]

73

79

nominal width

DN25 (PN16)

DN25 (PN16)

MX 1-18-4,2

MX 1-18-5,2

MX 1-18-6,5

3 x 380-415 V

3 x 380-415 V

3 x 380-415 V

4

4

5,5

8

8

11,2

18

18

18

23

23

23

42

52

65

58

71

83

DN50 (PN16)

DN50 (PN16)

DN50 (PN16)

MX 1-24-5,1

MX 1-24-6,3

MX 1-24-7,3

3 x 380-415 V

3 x 380-415 V

3 x 380-415 V

5,5

7,5

7,5

11,2

15,2

15,2

24

24

24

29

29

29

51

63

73

73

88

102

DN50 (PN16)

DN50 (PN16)

DN50 (PN16)

MX

MX

MX

MX

3

3

3

3

V

V

V

V

7,5

7,5

11

11

15,2

15,2

21,4

21,4

36

36

36

36

40

40

40

40

42

49

56

63

71

78

90

98

DN65

DN65

DN65

DN65

MX 1-48-4,9

MX 1-48-5,6

MX 1-48-6,8

3 x 380-415 V

3 x 380-415 V

3 x 380-415 V

11

11

15

21,4

21,4

26,5

48

48

48

58

58

58

49

56

68

65

78

92

DN80 (PN16)

DN80 (PN16)

DN80 (PN16)

MX 1-72-5,4

MX 1-72-6,2

MX 1-72-6,8

3 x 380-415 V

3 x 380-415 V

3 x 380-415 V

15

18,5

18,5

26,5

31,5

31,5

72

72

72

85

85

85

54

62

68

80

90

98

DN100 (PN16)

DN100 (PN16)

DN100 (PN16)

MX 1-96-4,0

MX 1-96-4,7

MX 1-96-6,1

3 x 380-415 V

3 x 380-415 V

3 x 380-415 V

15

18,5

22

26,5

31,5

38,5

96

96

96

120

120

120

40

47

61

68

82

102

DN100 (PN16)

DN100 (PN16)

DN100 (PN16)

1-36-4,2

1-36-4,9

1-36-5,6

1-36-6,3

Das Unternehmen

ist gem

ISO 14001:2004

zertifiziert.

x

x

x

x

380-415

380-415

380-415

380-415

Minimax Mobile Services GmbH & Co. KG

Minimaxstrae 1 D-72574 Bad Urach

Tel.: +49 7125 154-0 Fax: +49 7125 154-100

E-Mail: info@minimax.de www.minimax.de

(PN16)

(PN16)

(PN16)

(PN16)

Minimax Brandschutzcenter Hamburg

Competence Center Lschwassertechnik

Osterrade 23 D-21031 Hamburg

Tel.: +49 40 251966-20 Fax: +49 40 251966-19

E-Mail: loeschwassertechnik@minimax.de

PB10LWTe

description

MX 1-3-5,3

MX 1-3-5,7

Dezember 2008

Range of pressure booster of MX1

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Decision Making (PUMA) - Engineering ManagementDocument17 pagesDecision Making (PUMA) - Engineering ManagementWilson ChengNo ratings yet

- MSDS PDFDocument5 pagesMSDS PDFdang2172014No ratings yet

- MX Filling and Drainage Station Maximat FSX LWT PDFDocument2 pagesMX Filling and Drainage Station Maximat FSX LWT PDFNarendra Reddy BhumaNo ratings yet

- MX Filling and Drainage Station FuE1 PDFDocument2 pagesMX Filling and Drainage Station FuE1 PDFNarendra Reddy BhumaNo ratings yet

- MX Filling and Drainage Station Maximat DN50 FuE PDFDocument2 pagesMX Filling and Drainage Station Maximat DN50 FuE PDFNarendra Reddy BhumaNo ratings yet

- Viking Bladder TanksDocument11 pagesViking Bladder Tanksrasnowmah2012No ratings yet

- PB32We - 04 FSX PDFDocument2 pagesPB32We - 04 FSX PDFAnonymous 3q9fOpWt9vNo ratings yet

- MX Deluge Valve Set PDFDocument2 pagesMX Deluge Valve Set PDFNarendra Reddy BhumaNo ratings yet

- Catalogo PDFDocument8 pagesCatalogo PDFantonio_avanci100% (1)

- Valve and Actuator CatalogueDocument60 pagesValve and Actuator Catalogueashfaq-matte-79930% (1)

- Valves ActuatorsCAT0408Document60 pagesValves ActuatorsCAT0408Rami ReddyNo ratings yet

- Altecnic Expansion Vessel GuideDocument13 pagesAltecnic Expansion Vessel GuidePedro Quintal100% (1)

- Viking 062293Document8 pagesViking 062293Lukman ZakariyahNo ratings yet

- WDS Specification SheetDocument2 pagesWDS Specification SheetWattsNo ratings yet

- Detail Spec 220914Document2 pagesDetail Spec 220914AzifahNo ratings yet

- VRCA Relief ValveDocument8 pagesVRCA Relief Valvenenad135No ratings yet

- Catalogue-8bt1 - en Ovo Je U ProjektuDocument16 pagesCatalogue-8bt1 - en Ovo Je U ProjektuAnonymous mcCJYBoNo ratings yet

- Catalogue Nxplus C enDocument72 pagesCatalogue Nxplus C enSheik HussainNo ratings yet

- Becker EmergShtdwnValve BrochureDocument8 pagesBecker EmergShtdwnValve BrochureAnonymous b9ylgFXNo ratings yet

- Ldu 11 Eun 7696 en 25042005Document16 pagesLdu 11 Eun 7696 en 25042005Thiago FernandesNo ratings yet

- Modern HVDC Thyristor ValvesDocument6 pagesModern HVDC Thyristor ValvesAnonymous OpLDOPNo ratings yet

- Deltaflux CT s540 EDocument20 pagesDeltaflux CT s540 Eraquel.mc2No ratings yet

- Wellhead Control Panel1Document2 pagesWellhead Control Panel1kmsrini@yahoo.com100% (1)

- PFISTERER CableSystems 300kV PDFDocument12 pagesPFISTERER CableSystems 300kV PDFHashimAmrNo ratings yet

- STP PDFDocument7 pagesSTP PDFJames FernNo ratings yet

- ABB 11KV ZX1 Panel CatalogueDocument12 pagesABB 11KV ZX1 Panel Catalogueyac128No ratings yet

- Condenserless Liquid ChillersDocument12 pagesCondenserless Liquid ChillersBader ShrbajiNo ratings yet

- KCA Bladder Tanks en 2010Document11 pagesKCA Bladder Tanks en 2010M Kumar Marimuthu100% (1)

- DS 2471 ZX-Family enDocument2 pagesDS 2471 ZX-Family enAndrei HorhoianuNo ratings yet

- Es LFWDSDocument2 pagesEs LFWDSWattsNo ratings yet

- Differential Pressure DetectorsDocument4 pagesDifferential Pressure Detectorskdp_806212786No ratings yet

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFDocument20 pagesSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011No ratings yet

- Catalogue 8djh enDocument92 pagesCatalogue 8djh enbajricaNo ratings yet

- Potopna Crpka PEDROLLO VXC Vortex BrosuraDocument4 pagesPotopna Crpka PEDROLLO VXC Vortex Brosurajose03No ratings yet

- Catalog Celule Siemens 8DJHDocument80 pagesCatalog Celule Siemens 8DJHAlexandru HalauNo ratings yet

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouNo ratings yet

- Calpeda MXV BDocument6 pagesCalpeda MXV B2009tamerNo ratings yet

- Cast Resin TransformersDocument7 pagesCast Resin TransformersNandkumar Chinai100% (1)

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- System Sensor WFDTNRN Data SheetDocument4 pagesSystem Sensor WFDTNRN Data SheetJMAC SupplyNo ratings yet

- Production Control SystemsDocument12 pagesProduction Control SystemsTony EduokNo ratings yet

- Wellhead Control Panel (WHCP) : Product DescriptionDocument4 pagesWellhead Control Panel (WHCP) : Product DescriptionIrfan SiddiqueNo ratings yet

- Product Information Anti Surge Pipe Protection 2Document4 pagesProduct Information Anti Surge Pipe Protection 2AhmedRamadanNo ratings yet

- Fire Protection - Rev.06Document79 pagesFire Protection - Rev.06Anil MarturiNo ratings yet

- S T e C K IDocument14 pagesS T e C K Isurfin_bumpkinNo ratings yet

- 744 Double Interlock Preaction System Type D 8Document20 pages744 Double Interlock Preaction System Type D 8Nirmal KvNo ratings yet

- Tyco Alarm Check Valve AV-1 300 PDFDocument26 pagesTyco Alarm Check Valve AV-1 300 PDFRomyrNo ratings yet

- Water Meter ActarisDocument4 pagesWater Meter ActarisNavneet SinghNo ratings yet

- Catalogue Nxplus C enDocument68 pagesCatalogue Nxplus C enAnonymous 2feRXsn30No ratings yet

- Chilled Water Dist I But I OnDocument44 pagesChilled Water Dist I But I OnVineeth MuraleedharanNo ratings yet

- Sewage Lift StationDocument110 pagesSewage Lift Stationmohdnazir100% (1)

- DUNGS - Data SheetDocument12 pagesDUNGS - Data SheethamzadarbarNo ratings yet

- Chilled Water Distribution SystemDocument5 pagesChilled Water Distribution SystemThiru AnanthNo ratings yet

- 2012 Plumbing Design Guides PDFDocument29 pages2012 Plumbing Design Guides PDFIonut SomneaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- C29-JE-Y (ST) Y BD PDFDocument1 pageC29-JE-Y (ST) Y BD PDFNarendra Reddy BhumaNo ratings yet

- SiklaDocument487 pagesSiklaNarendra Reddy BhumaNo ratings yet

- Nibco 14 and 16 Gate ValvesDocument1 pageNibco 14 and 16 Gate ValvesNarendra Reddy BhumaNo ratings yet

- Rex E11-20180614 PDFDocument77 pagesRex E11-20180614 PDFNarendra Reddy BhumaNo ratings yet

- Phoenix PDFDocument32 pagesPhoenix PDFNarendra Reddy BhumaNo ratings yet

- TYCO ENDEFRFP+0713+LoRes PDFDocument456 pagesTYCO ENDEFRFP+0713+LoRes PDFNarendra Reddy BhumaNo ratings yet

- Sprinkler-Approval-Minimax - ENDocument1 pageSprinkler-Approval-Minimax - ENNarendra Reddy BhumaNo ratings yet

- Class 125 Iron Y-StrainerDocument1 pageClass 125 Iron Y-StrainerNarendra Reddy BhumaNo ratings yet

- Kidde-Fire Suppression System PDFDocument20 pagesKidde-Fire Suppression System PDFNarendra Reddy BhumaNo ratings yet

- Groove Machine PDFDocument2 pagesGroove Machine PDFNarendra Reddy BhumaNo ratings yet

- Heavy Duty BrochureDocument16 pagesHeavy Duty BrochureАлексей ГордиенкоNo ratings yet

- Iso9001 PDFDocument6 pagesIso9001 PDFblitzkrigNo ratings yet

- Smith ChartDocument28 pagesSmith ChartsniyaNo ratings yet

- BSD - M Odule 5Document38 pagesBSD - M Odule 5M MNo ratings yet

- Nirmal Products: Natural Gas Pre-Heaters Are Classified As Under: Direct Type Pre-HeatersDocument8 pagesNirmal Products: Natural Gas Pre-Heaters Are Classified As Under: Direct Type Pre-HeatersConcept -CEPLNo ratings yet

- Basic ElectronicsDocument10 pagesBasic ElectronicsKENZO LAREDONo ratings yet

- HCL Maubhandar, Project ReportDocument57 pagesHCL Maubhandar, Project ReportRahul Raj Yaduvanshi100% (1)

- Cable Tensionmeter-TN-001-T5 Operation and Service ManualDocument28 pagesCable Tensionmeter-TN-001-T5 Operation and Service ManualDade SobarnaNo ratings yet

- Kingdom of Saudi Arabia Royal Commission For Jubail and YanbuDocument152 pagesKingdom of Saudi Arabia Royal Commission For Jubail and YanbupramodpadmajaNo ratings yet

- MDocument209 pagesMAnirudh BiswasNo ratings yet

- Racecar Engineering 2005 06 PDFDocument99 pagesRacecar Engineering 2005 06 PDFfreddyonnimiNo ratings yet

- Odell - Nikon1V1 J1 - Guide v1.064 Excerpt PDFDocument33 pagesOdell - Nikon1V1 J1 - Guide v1.064 Excerpt PDFmasreogNo ratings yet

- EXTRAQC Manual July2013Document9 pagesEXTRAQC Manual July2013Hemerson PinheiroNo ratings yet

- LEM Active P SeriesDocument8 pagesLEM Active P Seriesjuan manuel sierra solisNo ratings yet

- Des 1008a PDFDocument3 pagesDes 1008a PDFFREE SOFTWARE DOWNLOADNo ratings yet

- BWY-803A Oil Temperature Thermometer ManualDocument13 pagesBWY-803A Oil Temperature Thermometer Manualdung_bk_vnNo ratings yet

- The Project Cycle and The Role of Eia and EmsDocument12 pagesThe Project Cycle and The Role of Eia and EmsAngela GarciaNo ratings yet

- CSG TBG Dimensions PDFDocument3 pagesCSG TBG Dimensions PDFElisa Maria Angulo VanegasNo ratings yet

- SlowspeedwatercooledDocument2 pagesSlowspeedwatercooledapi-311397395No ratings yet

- (Kinetico) MachBackwashingFilterownersmanualDocument48 pages(Kinetico) MachBackwashingFilterownersmanualGreg ReynekeNo ratings yet

- Intrusion Detection System Using Multivariate Control Chart Hotelling's T Based On PCADocument7 pagesIntrusion Detection System Using Multivariate Control Chart Hotelling's T Based On PCARumaisa KrubaNo ratings yet

- 7 1 - Area Between Two CurvesDocument2 pages7 1 - Area Between Two Curvesapi-251824010100% (1)

- Donor Coach MTDC02Document1 pageDonor Coach MTDC02Huzaifa UjjainNo ratings yet

- Datenblatt Bestmax Soft En01 ScreenDocument2 pagesDatenblatt Bestmax Soft En01 ScreenzaferbulNo ratings yet

- Microproject CPHDocument19 pagesMicroproject CPHaditi pawarNo ratings yet

- Cretical ReviewDocument18 pagesCretical ReviewGani mutiaraNo ratings yet

- SCM Rfid, Gis and Gps FinalDocument45 pagesSCM Rfid, Gis and Gps FinalSubair ThekepurathvalappilNo ratings yet

- Asha Sharma ResumeDocument3 pagesAsha Sharma ResumeRachit SharmaNo ratings yet