Professional Documents

Culture Documents

Me 06 0005 0012

Me 06 0005 0012

Uploaded by

Esteban Vanegas AlvarezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me 06 0005 0012

Me 06 0005 0012

Uploaded by

Esteban Vanegas AlvarezCopyright:

Available Formats

ME-06-0005-0012(B)

05-25

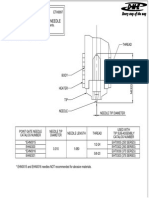

Catalog # BGMTIP

INSTALLATION DATA

FOR BLACK&GOLD METRIC TOP INTERCHANGEABLE

INTERLOCKS

Please read carefully before installing components.

M4-0.7

8.0 DEEP(MIN)

E0.02

CENTRAL

RF0.1

R0.20.1

14.00

LF

FEMALE POCKET

FEMALE POCKET

+0.02

BF

+0.01

+0.02

WP

+0.01

CENTRAL

+0.02

+0.01

CENTERAL

20.00

0.50.1x45

(2)

20.00

TM & TF

+0.02

C

+0.01

R0.1

+0.02

WP

+0.01

CENTRAL

MALE POCKET

+0.02

+0.01

+0.02

+0.01

+0.02

+0.01

CENTERED

R5.00.1

20.00

D0.2

MALE POCKET

+0.02

BM

- 0.01

R0.20.1

14.00

M4-0.7

12.0 DEEP(MIN)

BGT02020F/BGT020020M

RM0.1

LM

RECOMMENDED POCKET

SURFACE FINISH IS 1.6 mm [63min]Ra

+0.02

+0.01

ME-06-0005-0012(B)

05-25

Catalog # BGMTIP

INSTALLATION DATA

FOR BLACK &GOLD METRIC TOP INTERCHANGEABLE

INTERLOCKS

Please read carefully before installing components.

Installation Instructions:

1. Four D-M-E Top Interlocks must be used in each mold application. When in operation, the

interlocks contact the edges of the machined pocket to maintain parting line alignment. The

cap screws are only utilized to retain the interlocks to the mold base.

2. To maintain alignment, it is recommended that the mold base assembly be clamped together

and machined in assembly to insure proper parting line alignment.

3. Machine the interlock pockets accurately in assembly. Locate each interlock pocket on the

centerline of the mold. The location is critical to avoid misalignment problems which could

result from uneven thermal expansion of the separate mold halves.

4. Mount the female interlock on the half of which will have the highest operating temperature.

Normally, this will be the A side of the mold. This procedure is critical to insure that the

male interlock does not grow larger than the female interlock if uneven mold temperatures

are present. Place the female interlocks so the relief slot are at the bottom of the pocket for

easy interlock removal. Place the male interlock with the release side facing the pocket

bottom.

5. Place both male and female interlocks into the pockets while the mold is clamped together

then thread in and tighten screws.

6. Torque the mounting SHCS to:

x 7.8 N x m [ 5.7 FT x LBS] for M4-0.7 SHCS

x 16 N x m [ 11.7 FT x LBS] for M5-0.8 SHCS

x 27 N x m [ 19.8 FT x LBS] for M6-1 SHCS

x 65 N x m [ 47.7 FT x LBS] for M8-1.25 SHCS

x 130 N x m [ 95.5 FT x LB S] for M10-1.5 SHCS

7. After installation, open and close the mold on the bench to insure proper alignment.

8. For shuttle molds repeat steps 2 to 7 for each interchangeable B side.

WP

CATALOG #

BGT02020F

BGT03526F

BGT04530F

BGT05536F

BGT07536F

BGT10045F

BGT02020M

BGT03526M

BGT04530M

BGT05536M

BGT07536M

BGT10045M

POCKET

WIDE

BM

MALE

POCKET

WIDTH

BF

FEMALE

POCKET

WIDTH

RF / RM

POCKET

RADIUS

R

POCKET

RADIUS

+/-0.1

+/-0.1

POCKET

DEPTH

+0.02

+0.01

+0.02

+0.01

+0.02

+0.01

+0.02

+0.01

35.00

45.00

55.00

75.00

100.00

15.00

15.00

20.00

20.00

20.00

SEE POCKETS DIMENSIONS SHOWN ON DRAWING FOR BGT02020F/BGT02020M .

25.00

26.00

8.00

0.2

13.0

23.0

M5 x 20 LG M5 x 30 LG

25.00

30.00

8.00

0.3

15.0

30.0

M6 x 18 LG M6 x 30 LG

30.00

36.00

8.00

0.7

18.0

37.5

M8 x 25 LG M8 x 35 LG

35.00

36.00

8.00

0.7

18.0

52.0 M10 x 25 LG M10 x 40 LG

60.00

45.00

8.00

1.0

22.5

70.0 M10 x 25 LG M10 x 65 LG

SCREWS

LOCATIONS

+/-0.2

TM

MALE

SHCS

SIZE

TF

FEMALE

SHCS

SIZE

+/-0.2

LM

MALE

THREAD

LENGTH

LF

MALE

THREAD

LENGTH

M IN

M IN

12.0

11.0

15.0

17.0

17.0

13.0

13.0

15.0

17.0

17.0

NOTE: Dimensions are in mm.

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

MICHIGAN 48071 USA

US 800-656-6656

CANADA 800-387-6600

www.dme.net

You might also like

- EASA Essay Paper Module 10Document5 pagesEASA Essay Paper Module 10mohan78% (9)

- CS440-01 R223.1337en Spare Parts CatalogDocument32 pagesCS440-01 R223.1337en Spare Parts CatalogLuis Aguilera S92% (13)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Parts List Brother Pe700IIDocument25 pagesParts List Brother Pe700IILuis Armando Mendoza Lozoya100% (1)

- CR-10 BomDocument12 pagesCR-10 BomMarc AlamoNo ratings yet

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71589% (27)

- Flightline Marshaller Task Book: Extracted From The Civil Air Patrol Aircrew & Flightline Tasks Manual Dated 24 May 2004Document32 pagesFlightline Marshaller Task Book: Extracted From The Civil Air Patrol Aircrew & Flightline Tasks Manual Dated 24 May 2004Anonymous QRVqOsa5No ratings yet

- Solid MechanicDocument7 pagesSolid MechaniczinilNo ratings yet

- Me 06 0005 0011Document2 pagesMe 06 0005 0011Esteban Vanegas AlvarezNo ratings yet

- Mongoose PT Spare Parts (Less Control Panel)Document18 pagesMongoose PT Spare Parts (Less Control Panel)Anonymous gwldee5100% (2)

- Screenshot 2024-03-24 at 5.12.49 PMDocument65 pagesScreenshot 2024-03-24 at 5.12.49 PMchangaiz899No ratings yet

- Thomson Roundrail 1NC SpecsheetDocument2 pagesThomson Roundrail 1NC SpecsheetElectromateNo ratings yet

- MB07 Service&Repair ManualDocument54 pagesMB07 Service&Repair Manualenver456No ratings yet

- ArcMATE 120ic M20iADocument24 pagesArcMATE 120ic M20iABrendisNo ratings yet

- KS0198X Keyestudio 4DOF Robot Arm Kit For Arduino DIYDocument249 pagesKS0198X Keyestudio 4DOF Robot Arm Kit For Arduino DIYjoseNo ratings yet

- S07 Optional EquipDocument18 pagesS07 Optional EquipSales AydinkayaNo ratings yet

- CPLJDocument9 pagesCPLJFXNScottNo ratings yet

- 511147-200 SPM20CE sn00000 E.P REV2Document46 pages511147-200 SPM20CE sn00000 E.P REV2XXXNinjabeastNo ratings yet

- Kyocera 1737 Plus Parts ManualDocument37 pagesKyocera 1737 Plus Parts ManualPhạm Công ThứNo ratings yet

- 499738Document3 pages499738LUISPINTOUISNo ratings yet

- Service Bulletin: Instrument Panel AircraftDocument10 pagesService Bulletin: Instrument Panel AircraftvanNo ratings yet

- Twin-Head 20211118 070802Document14 pagesTwin-Head 20211118 070802自动化工程师DIYNo ratings yet

- 3306 Di Engine Especificaciones de BielaDocument3 pages3306 Di Engine Especificaciones de Bielacristhian_tbb100% (5)

- pm30 Operators ManualDocument38 pagespm30 Operators ManualLucas BarriosNo ratings yet

- SS250Document70 pagesSS250jrsauveNo ratings yet

- Set Up Instructions - InvictaDocument12 pagesSet Up Instructions - InvictaRicardo XlvNo ratings yet

- L0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023Document25 pagesL0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023quality assuranceNo ratings yet

- 527337-001 OCR Bar Code Scanner PRTSDocument20 pages527337-001 OCR Bar Code Scanner PRTSAldo GarciaNo ratings yet

- Ec10d 1Document9 pagesEc10d 1Guido Leonardo EnriqueNo ratings yet

- Project Data: DesignDocument8 pagesProject Data: Designchaly37No ratings yet

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Document8 pagesContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreNo ratings yet

- Connecting Rods: Pantalla AnteriorDocument3 pagesConnecting Rods: Pantalla AnterioredgarNo ratings yet

- Cable: Torque SpecificationsDocument2 pagesCable: Torque SpecificationsCristian SNo ratings yet

- BT PDFDocument55 pagesBT PDFChristian CarrerasNo ratings yet

- Putting in To OperationDocument7 pagesPutting in To OperationsriyantoNo ratings yet

- Hartl-1060 3Document56 pagesHartl-1060 3xm7kffrwgyNo ratings yet

- Plastic Analysis in StaadDocument6 pagesPlastic Analysis in Staadpetronashscribdid100% (1)

- Multi OneDocument57 pagesMulti Onegn.falchNo ratings yet

- Ringspann ClampDocument5 pagesRingspann ClamphamishjbadamsonNo ratings yet

- Samsung Le32b550m2h Le37b550m2h Le40b550m2h Le46b550m2h Chassis n65cDocument194 pagesSamsung Le32b550m2h Le37b550m2h Le40b550m2h Le46b550m2h Chassis n65cr_cristiNo ratings yet

- Cub Cadet Parts Manual For Model 5264dl TractorDocument7 pagesCub Cadet Parts Manual For Model 5264dl Tractordavid100% (42)

- PL56042535Document36 pagesPL56042535John OuartNo ratings yet

- IM3000rev02 Spare PartsDocument4 pagesIM3000rev02 Spare Partsiletras9019No ratings yet

- Spare Parts: Circuit D'Eau Hydrabolt/Wib Assemblé - NssDocument28 pagesSpare Parts: Circuit D'Eau Hydrabolt/Wib Assemblé - Nssmarcos.esquivelNo ratings yet

- Yst MS50Document15 pagesYst MS50Muru SubramaniNo ratings yet

- 2005 MZ360BR2 7CTFDocument24 pages2005 MZ360BR2 7CTFDaniHuToscanoNo ratings yet

- Exploded Views and Parts List: Samsung ElectronicsDocument11 pagesExploded Views and Parts List: Samsung ElectronicsgibsonofficeNo ratings yet

- Biselador de 3 AntorchasDocument7 pagesBiselador de 3 AntorchasIrving Israel IrvingNo ratings yet

- GS70 - MSI-1771 Disassembly GuideDocument17 pagesGS70 - MSI-1771 Disassembly GuideCatalin FinkelsteinNo ratings yet

- A6E511201029M05Document7 pagesA6E511201029M05padapo3086No ratings yet

- Modicon Modernisation Guide - Quantum To X80 Evolution Cable Management Installation Kit, Jul'19 - MFR91487Document4 pagesModicon Modernisation Guide - Quantum To X80 Evolution Cable Management Installation Kit, Jul'19 - MFR91487Asim ButtNo ratings yet

- SP 20 SP 25 ManualDocument18 pagesSP 20 SP 25 ManualdiegoNo ratings yet

- Case Sealing Machine Model: Exc-103SdDocument24 pagesCase Sealing Machine Model: Exc-103Sdalberto francisco mendez cardonaNo ratings yet

- Arn - Matrix 150 PDFDocument37 pagesArn - Matrix 150 PDFAnitShizumaNo ratings yet

- 1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesDocument13 pages1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesAmirmasoudNo ratings yet

- Manual TransmissionDocument46 pagesManual Transmissionjrrodrigueza2No ratings yet

- YZ250F B7B2 - 2019 CompressedDocument63 pagesYZ250F B7B2 - 2019 CompressedRepuestos.Florencia M.FNo ratings yet

- Manual de Partes CAT 10K-423-843Document421 pagesManual de Partes CAT 10K-423-843Zonis Taller7No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Pillared Metal-Organic Frameworks: Properties and ApplicationsFrom EverandPillared Metal-Organic Frameworks: Properties and ApplicationsNo ratings yet

- Mold SaverDMEsav-msds 1Document7 pagesMold SaverDMEsav-msds 1Esteban Vanegas Alvarez100% (1)

- Abrasive Stones - General Purpose Type A and BDMEabstonesab-msdsDocument6 pagesAbrasive Stones - General Purpose Type A and BDMEabstonesab-msdsEsteban Vanegas AlvarezNo ratings yet

- SDS271 Diamond CompoundDocument7 pagesSDS271 Diamond CompoundEsteban Vanegas AlvarezNo ratings yet

- D-M-E Mold Straps: Important Safety InformationDocument1 pageD-M-E Mold Straps: Important Safety InformationEsteban Vanegas AlvarezNo ratings yet

- D-M-E In2 Innovative Interlocks: Mold Base MachiningDocument2 pagesD-M-E In2 Innovative Interlocks: Mold Base MachiningEsteban Vanegas AlvarezNo ratings yet

- Jumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsDocument2 pagesJumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsEsteban Vanegas AlvarezNo ratings yet

- S-Series Straight-Shot T-Series Straight-ShotDocument2 pagesS-Series Straight-Shot T-Series Straight-ShotEsteban Vanegas AlvarezNo ratings yet

- Heater Replacement Instructions For Point Gate and Thru Hole TipsDocument2 pagesHeater Replacement Instructions For Point Gate and Thru Hole TipsEsteban Vanegas AlvarezNo ratings yet

- Distibutor Tubes: Important Safety InformationDocument2 pagesDistibutor Tubes: Important Safety InformationEsteban Vanegas AlvarezNo ratings yet

- Installation Data For: 250 & 375 Series Point Gate NeedleDocument2 pagesInstallation Data For: 250 & 375 Series Point Gate NeedleEsteban Vanegas AlvarezNo ratings yet

- Me 100005 0227Document2 pagesMe 100005 0227Esteban Vanegas AlvarezNo ratings yet

- Me 06 0005 0011Document2 pagesMe 06 0005 0011Esteban Vanegas AlvarezNo ratings yet

- DMEInternalLatchLock DKL CAMFingerRemoval InstallationDocument5 pagesDMEInternalLatchLock DKL CAMFingerRemoval InstallationEsteban Vanegas AlvarezNo ratings yet

- Maintenance Guide: Things To Look ForDocument1 pageMaintenance Guide: Things To Look ForEsteban Vanegas AlvarezNo ratings yet

- 250 Series Extended Sprue Gate Nozzle Installation Data: Machining DetailsDocument2 pages250 Series Extended Sprue Gate Nozzle Installation Data: Machining DetailsEsteban Vanegas AlvarezNo ratings yet

- "N" "N" "N" "N" R0.125: Me-X741-Ps-421 (B)Document2 pages"N" "N" "N" "N" R0.125: Me-X741-Ps-421 (B)Esteban Vanegas AlvarezNo ratings yet

- Micro Probes Auto-Fixed Integral Heater: ME-0725-PS-216-B AFIP/IDDocument2 pagesMicro Probes Auto-Fixed Integral Heater: ME-0725-PS-216-B AFIP/IDEsteban Vanegas AlvarezNo ratings yet

- Compass Repeater Price Sheet GA4 0912Document2 pagesCompass Repeater Price Sheet GA4 0912kongbengNo ratings yet

- Aircraft Structural Integrity ManagementDocument17 pagesAircraft Structural Integrity ManagementarkibDGTA0% (1)

- Zeppelin Hindenburg AirshipDocument14 pagesZeppelin Hindenburg AirshipMarcelo Alberto RechNo ratings yet

- Report - ANC18LA004 - 96208 - 11 - 13 - 2023 6 - 34 - 53 PMDocument8 pagesReport - ANC18LA004 - 96208 - 11 - 13 - 2023 6 - 34 - 53 PMThaís SilvaNo ratings yet

- 01 - 0071 Boeing 787 Dreamliner Lighting EquipmentDocument4 pages01 - 0071 Boeing 787 Dreamliner Lighting EquipmentotavarezNo ratings yet

- Rolls Royce 250 c30 Series Overhaul Manual Turbine Section Inspection - CheckDocument68 pagesRolls Royce 250 c30 Series Overhaul Manual Turbine Section Inspection - CheckAdi KistajiNo ratings yet

- ZYTLDocument9 pagesZYTLqlxiaoNo ratings yet

- Ec Enr 1.3 en GBDocument2 pagesEc Enr 1.3 en GBGovind Arun ShahNo ratings yet

- VINOY KRISHNA SIR S&TFullDocument34 pagesVINOY KRISHNA SIR S&TFullajaz53782No ratings yet

- Use of Controller-Pilot Data Link Communications (CPDLC) in The Brazilian Continental AirspaceDocument8 pagesUse of Controller-Pilot Data Link Communications (CPDLC) in The Brazilian Continental AirspaceMarcos Victor Pimentel de AlmeidaNo ratings yet

- Own Wordings. No Cheating in Any Form or Method.: Carl Kimbo BarrogoDocument35 pagesOwn Wordings. No Cheating in Any Form or Method.: Carl Kimbo BarrogoJb ManglinongNo ratings yet

- EventsDocument2 pagesEventsMustafa OğuzhanNo ratings yet

- Curriculum Vitae Akyar Nur KholiqDocument12 pagesCurriculum Vitae Akyar Nur Kholiqrio tanoneNo ratings yet

- SpaceX Vs The United StatesDocument79 pagesSpaceX Vs The United StatesAnonymous PrqvEf100% (1)

- Cessna172 FlightSimulationDataDocument25 pagesCessna172 FlightSimulationDataMehmet AliNo ratings yet

- Aerothon 2024 Rulebook AbstractDocument4 pagesAerothon 2024 Rulebook Abstractmaulikshah_23No ratings yet

- Loadsheet & Loadmessage Passenger Aircraft: TotalDocument1 pageLoadsheet & Loadmessage Passenger Aircraft: Totalnwadi nwaforNo ratings yet

- Preforming: Test and Simulation MethodsDocument35 pagesPreforming: Test and Simulation MethodsadeelyjNo ratings yet

- Instrument NavigationDocument4 pagesInstrument Navigation9t42sn2pz5No ratings yet

- Optimisation of Wind Turbine BladesDocument9 pagesOptimisation of Wind Turbine BladesmannoqamarNo ratings yet

- EASA Sunny SwiftDocument38 pagesEASA Sunny SwiftDani CuparNo ratings yet

- Ascent AeroSystems Spirit Brochure - Jul 2021Document6 pagesAscent AeroSystems Spirit Brochure - Jul 2021PhilNo ratings yet

- 0905PPCDocument39 pages0905PPCsamir samiraNo ratings yet

- Seminole Poh PDFDocument316 pagesSeminole Poh PDFCasper YanoNo ratings yet

- Afd 021019 1 1B 50Document100 pagesAfd 021019 1 1B 50Sab-Win DamadNo ratings yet

- Design Calculations For Cabana Roof StructureDocument4 pagesDesign Calculations For Cabana Roof Structuremsiddiq1No ratings yet

- The Hitler EscapeDocument13 pagesThe Hitler EscapeincroyablNo ratings yet