Professional Documents

Culture Documents

Analysis of Casting Defects at TKT High-Tech Cast Pvt. LTD

Analysis of Casting Defects at TKT High-Tech Cast Pvt. LTD

Uploaded by

yashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of Casting Defects at TKT High-Tech Cast Pvt. LTD

Analysis of Casting Defects at TKT High-Tech Cast Pvt. LTD

Uploaded by

yashCopyright:

Available Formats

Analysis of casting defects at tkt high-tech cast pvt. ltd.

ANALYSIS OF CASTING DEFECTS AT TKT

HIGHTECH CAST PVT. LTD.

By

THAKER YASH P.

SHAH ABHISHEK S.

VYAS MAHARSHI J.

PATEL RAKESH J.

Under the Guidance of

Mr. Kunal B. Thakkar

Director

TKT High-tech cast pvt. ltd.

A Report Submitted to

TKT High-tech cast pvt. ltd.

Nov-Dec 2015

M/S TKT high-tech cast pvt. ltd.

Plot No.6 Survey No. 254/1, Opp. Chharodi Railway station, SanandViramgam highway Taluka-Sanand Dist- Ahmedabad Pin-382170

Analysis of casting defects at tkt high-tech cast pvt. ltd.

ABSTRACT

In the foundry and casting industries there are so many interception

they have to face. The main crux they are facing is casting defects. Due to

the casting defects the rejection rate of the manufacturing batch is raise

which drag the organization to the detriment. The losses perhaps harm the

firm abundant, like deterioration of the raw material, the wastage of time

and manpower too. The rejected products due to casting defects may

restrain the additional space in organization and also take some excerpt

manpower to handle the scrap due to the casting defects. It also leads to

delay the dispatching process. In conclusion the casting defects engender

contrariness for avocation of organization.

Therefore, here first of all we are finding the casting defects in our

current working industry TKT HIGHTECH CAST PVT. LTD. And we

enquiring the difficulties of casting defects and the type of casting defects

which are the industry facing presently.

Analysis of casting defects at tkt high-tech cast pvt. ltd.

LIST OF DEFECTS

01. Ingate Shrinkage

02. Sand fusion

03. Mismatch

04. Cold shut or cold lap

05. Blow holes

06. Core tilting or core shift

07. Slag Defect

08. Scabbing

Analysis of casting defects at tkt high-tech cast pvt. ltd.

1. Ingate Shrinkage

Fig :- Ingate Shrinkage

Possible causes

The density of a die casting alloy in the molten state is less than its

density in the solid state. Therefore, when an alloy changes phase

from the molten state to the solid state, it always shrinks in size.

This shrinkage takes place when the casting is solidifying inside a

die casting die. At the centre of thick sections of a casting, this

shrinkage can end up as many small voids known as shrinkage

porosity.

If the shrinkage porosity is small in diameter and confined to the

very centre of thick sections it will usually cause no problems.

However, if it is larger in size, or joined together, it can severely

weaken a casting. It is also a particular problem for castings which

need to be gas tight or watertight.

Using too thin sprue can also cause the shrinkage defect.

Proposed Solution

Slight modification in design, using slightly thick sprue can

minimize this defect.

Analysis of casting defects at tkt high-tech cast pvt. ltd.

2. Sand fusion

Fig:-Sand fusion

Possible causes

Clay-bonded sand

Lustrous carbon content too low

Proportion of low-melting-point substances too high

Moulding plant

Uneven mould compaction

Gating and pouring practice

Uneven distribution of inflowing metal with resultant over-heating

Temperature of liquid metal too high

2.3 Proposed solution

Mould compaction should be even so that it doesnt

loose its porosity after loading.

Make sure proportion of water content in mould making is

maintained

Analysis of casting defects at tkt high-tech cast pvt. ltd.

3. Mismatch defect

Fig:-Mismatch

Possible causes

A mismatch is caused by the cope and drag parts of the mould not

remaining in their proper position.

This is caused by loose box pins, inaccurate pattern dowel pins or

carelessness in placing the cope on the drag.

Proposed solution

Make sure cope and drag part match properly in molding machine

Loose patent pins should be checked regularly

Analysis of casting defects at tkt high-tech cast pvt. ltd.

4. Cold lap or cold shut

Fig:- cold lap or cold shut

Possible Causes

Lack of fluidity in molten metal

Faulty design

Faulty gating

High moisture content in mold sand

Proposed solution

Maintain pouring time.

Maintain pouring temperature.

Make sure not to use damaged patent.

Analysis of casting defects at tkt high-tech cast pvt. ltd.

5. Blowhole

Fig:-Blowhole

Possible causes

Inadequate core venting

Excessive release of gas from core

Excessive moisture absorption by the cores

Low gas permeability of the core sand

Clay-bonded sand

Moisture content of sand too high, or water released too quickly

Gas permeability of the sand too low

Sand temperature too high

Bentonite content too high

Too much gas released from lustrous carbon producer.

Resin-bonded sand

Proposed solution

Bentonite content should be maintained

Use sand with high gas permeability

Make sure moisture content in sand is not too high

Analysis of casting defects at tkt high-tech cast pvt. ltd.

6. Core tilting or core shift

Fig:-Core tilting or Core shift

Possible causes

Improper core sitting.

Improper flow of molten metal while pouring.

Using damaged cores.

Proposed solution

Do not use damaged cores.

Make sure core sit is proper in mould

Analysis of casting defects at tkt high-tech cast pvt. ltd.

7. Slag Defect

Fig:-Slag Defect

Possible causes

Oxide content of the charge too high

High impurity levels of oxides and hydroxides in charge materials

Poor or slow dissolution of inoculants

Ladle lining too highly reactive

Poor deslagging of the molten metal

Proposed solution

Remove slag as much as possible at the time of melting.

make sure inoculants is dissolved completely and also maintain

amount of inoculant added per mould.

Analysis of casting defects at tkt high-tech cast pvt. ltd.

8. Scabbing

Fig:-Scabbing

Possible causes

Clay-bonded sand

Too little bentonite or poor bentonite quality in the moulding

sand

Proportion of fine quartz in the sand too high

Moulding sand too fine

Insufficient conditioning of bentonite

Too much salt in the sand

Gating and pouring practice

Sand heated up too severely by inflowing metal and long

exposure to radiated heat

Proposed solution

Maintain moisture content in moulding sand according to ambient

temperature.

Use proper amount of bentonite and also maintain quality of

bentonite.

10

Analysis of casting defects at tkt high-tech cast pvt. ltd.

REFERECES

1. John Fernihough, Matthias Dr. Hoebel, Maxim Dr. Konter

Method Of Removing Casting Defects Application numberEP20020405142

2. Ernst wiss Remedying Defects, Such As Blow Holes In Metal

Castings Application number-US884,346

3. Susumu Ihara, Hiroyuki Yoshimoto, Katsumi Mizuuchi, Hideo

Nishiumi, Takanobu Suzuki Method And Apparatus For

Detecting Internal Cavities In Casting Bars Application numberUS 05/864,910

4. Joseph M.VihtelicInvestment Casting With Improved As-Cast

Surface Finish Application number- US08/736,534

5. Hansen Method and equipment for feeding shrinkage voids in

metal castings Patent number- EP0738192B1

6. Pradeep kumar Mould modification for eliminating freckle defects

in roll casting Patent number- US3882942

7. Rajesh Rajkohle, J.G. Khan; Defects, Causes and Their Remedies

in Casting Process, A Review, International Journal Of Research

In Advent Technology, Vol-2,no-3, March- 2014, page no:03-09.

8. V.V.Mane, Amit Sata and M. Y. Khire New Approach to Casting

Defects Classification and Analysis Supported by Simulation

11

You might also like

- GAS PROBLEM in Steel Sand CastingsDocument7 pagesGAS PROBLEM in Steel Sand CastingsVasu RajaNo ratings yet

- Odoo HR PDFDocument17 pagesOdoo HR PDFRejoy Radhakrishnan100% (1)

- Fluids Lab ReportDocument19 pagesFluids Lab Reportdhruv100% (3)

- SMACNA SummariesDocument9 pagesSMACNA SummariesKhobeb MuslimNo ratings yet

- Blowhole Defect in Sand CastingDocument33 pagesBlowhole Defect in Sand CastingWalton BangladeshNo ratings yet

- Casting Defects and RemediesDocument9 pagesCasting Defects and Remediesraoz81100% (1)

- Casting DefectsDocument49 pagesCasting Defectsgopi.nryn100% (2)

- Alternative Casting TechDocument93 pagesAlternative Casting TechCherif Fayez100% (1)

- 5-Hot Tear PDFDocument9 pages5-Hot Tear PDFPeeka Prabhakara RaoNo ratings yet

- 3Document2 pages3ak pathakNo ratings yet

- Casting DefectDocument25 pagesCasting Defectravikataria02No ratings yet

- Casting RefDocument20 pagesCasting RefNavdeep GillNo ratings yet

- Conspec, Inc.: AssociatesDocument73 pagesConspec, Inc.: AssociatessamuelNo ratings yet

- Module 1Document289 pagesModule 1Vikrant SinghNo ratings yet

- Casting ProceduresDocument68 pagesCasting Proceduresshailja100% (1)

- Defectos Soluciones PDFDocument9 pagesDefectos Soluciones PDFCaballero RrzNo ratings yet

- Defects in CastingDocument29 pagesDefects in CastingbhimsignNo ratings yet

- Foundry Hand ToolsDocument83 pagesFoundry Hand ToolsKiran MunavalliNo ratings yet

- Dental InvestmentsDocument133 pagesDental InvestmentsMohamed AliNo ratings yet

- Picture General Description Pros Cons Cost Surface Expendable Mold, Permanent PatternDocument1 pagePicture General Description Pros Cons Cost Surface Expendable Mold, Permanent PatternVlad TampizaNo ratings yet

- Mte New Workshop BmeDocument27 pagesMte New Workshop BmeSahil YadavNo ratings yet

- TSP Bits: by Jack Leave A CommentDocument8 pagesTSP Bits: by Jack Leave A CommentMuhammad Saqib JanNo ratings yet

- 01 Burnt-On SandDocument2 pages01 Burnt-On SandWert DasNo ratings yet

- VacuumDocument6 pagesVacuum03sri03No ratings yet

- 16 Foundry Resins: 16.1 Mold-And Core-Making ProcessesDocument13 pages16 Foundry Resins: 16.1 Mold-And Core-Making ProcessesJoão Victor VieiraNo ratings yet

- Riser Casting ReportDocument47 pagesRiser Casting Reportganesh0% (1)

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDocument11 pagesCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalNo ratings yet

- Assignment IDocument23 pagesAssignment I016 ARUNACHALAM S R MNo ratings yet

- Presentation Sand CastingDocument23 pagesPresentation Sand CastingAbdul RazzaqNo ratings yet

- V13N1 Inovative Lost Wax PDFDocument22 pagesV13N1 Inovative Lost Wax PDFznaky1100% (1)

- 50 Casting DefectsDocument49 pages50 Casting DefectsmohammadNo ratings yet

- Defects/imperfections in Welds - Porosity: IdentificationDocument4 pagesDefects/imperfections in Welds - Porosity: Identificationguru_terexNo ratings yet

- Kiln QuestionsDocument234 pagesKiln Questionsbasavaraju535100% (2)

- Casting Defects 6Document36 pagesCasting Defects 6AnuskaNo ratings yet

- WPT CastingDocument70 pagesWPT CastingHuzaifaNo ratings yet

- Recommendations & ConclusionDocument3 pagesRecommendations & ConclusionFaez Feakry100% (2)

- Assignment IDocument23 pagesAssignment I016 ARUNACHALAM S R MNo ratings yet

- 6.the Solution Approach To Flow Problems Using Tivar 88Document11 pages6.the Solution Approach To Flow Problems Using Tivar 88hadiNo ratings yet

- Common Metallurgical Defects in Grey Cast IronDocument9 pagesCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- F& F LAB MANUALDocument18 pagesF& F LAB MANUALJagdish Singh MehtaNo ratings yet

- Q 1Document11 pagesQ 1Ahmed AymanNo ratings yet

- Casting DefectsDocument38 pagesCasting Defectsዘረአዳም ዘመንቆረርNo ratings yet

- 5) Plug CementingDocument35 pages5) Plug Cementingeng20072007No ratings yet

- HTHP Gas Production Casing CementingDocument5 pagesHTHP Gas Production Casing Cementinganeka2No ratings yet

- Foundry ProcessDocument81 pagesFoundry ProcessGopalakrishnan Kuppuswamy100% (1)

- Investment Casting of Titanium Alloy ReportDocument17 pagesInvestment Casting of Titanium Alloy ReportAdvait BawdekarNo ratings yet

- Casting ProcedureDocument52 pagesCasting ProcedureRosa GhahremaniNo ratings yet

- Bit Technology: Bit Technology Additional Reading Available at The Spe ElibraryDocument9 pagesBit Technology: Bit Technology Additional Reading Available at The Spe ElibrarymvkellyNo ratings yet

- Micro Cavities PDFDocument4 pagesMicro Cavities PDFSiddharth GuptaNo ratings yet

- CH 11 PDFDocument13 pagesCH 11 PDFMuhammad FarhanNo ratings yet

- Green Sand, MouldingDocument92 pagesGreen Sand, MouldingKrishna Deo100% (1)

- Metal Casting: Saleens Famula Fahri Fauzan Charis Maulana Afrizal Pratama Akmal Fasya Fadhil Trisetyaatmaja Rama AdityaDocument17 pagesMetal Casting: Saleens Famula Fahri Fauzan Charis Maulana Afrizal Pratama Akmal Fasya Fadhil Trisetyaatmaja Rama AdityaFAHRI FAUZANNo ratings yet

- Wellbore Stability & Clay MineralogyDocument48 pagesWellbore Stability & Clay MineralogySapan100% (1)

- Unit 3Document42 pagesUnit 3Anup M UpadhyayaNo ratings yet

- Casting DefectsDocument21 pagesCasting DefectsImran KhanNo ratings yet

- Casing LeaksDocument8 pagesCasing LeaksJames "Chip" NorthrupNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Foundry Practice - A Treatise On Moulding And Casting In Their Various DetailsFrom EverandFoundry Practice - A Treatise On Moulding And Casting In Their Various DetailsNo ratings yet

- Practical Blacksmithing Vol. III: A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright" and Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex ForgingsFrom EverandPractical Blacksmithing Vol. III: A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright" and Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex ForgingsRating: 5 out of 5 stars5/5 (1)

- The Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationFrom EverandThe Rudiments Of Practical Bricklaying - In Six Sections: General Principles Of Bricklaying, Arch Drawing, Cutting, And Setting, Different Kinds Of Pointing, Paving, Tiling, Materials, Slating, And Plastering, Practical Geometry MensurationNo ratings yet

- Perkins 4.41Document2 pagesPerkins 4.41spez88100% (1)

- How Design of PV Trackers Accommodates Large-Format Modules: Presented byDocument36 pagesHow Design of PV Trackers Accommodates Large-Format Modules: Presented byMiguel GarzaNo ratings yet

- A Novel Offset Based PWMDocument13 pagesA Novel Offset Based PWMLindsay ClarkNo ratings yet

- ReadDocument3 pagesReadbram jukiNo ratings yet

- ECDL Module 6 PresentationDocument48 pagesECDL Module 6 PresentationvidriziNo ratings yet

- Synchronous Servo Motors: AutomationDocument32 pagesSynchronous Servo Motors: AutomationAllison GallowayNo ratings yet

- 0.1 Simple Pump Model Theory: n+1 N N n+1 NDocument4 pages0.1 Simple Pump Model Theory: n+1 N N n+1 NJack CavaluzziNo ratings yet

- D7G 92VDocument184 pagesD7G 92Valexander100% (3)

- Ford Customer FullfilmentDocument9 pagesFord Customer FullfilmentHamizah HairuddinNo ratings yet

- Miroslav Philharmonik Sound Set User ManualDocument63 pagesMiroslav Philharmonik Sound Set User ManualYanier HechavarriaNo ratings yet

- SAP Change Log TablesDocument2 pagesSAP Change Log TablesBoban VasiljevicNo ratings yet

- Daftar Kelompok Kepemimpinan G402Document2 pagesDaftar Kelompok Kepemimpinan G402Merry DiandaNo ratings yet

- What Is The Complexity Cube?Document1 pageWhat Is The Complexity Cube?Wilson Perumal & Company100% (1)

- Genima 485 Parts CatalogueDocument30 pagesGenima 485 Parts Cataloguecupid75No ratings yet

- The Art of Data ScienceDocument12 pagesThe Art of Data Sciencekrk4568No ratings yet

- 3.0 Cooling Load CalculationDocument29 pages3.0 Cooling Load CalculationRenneil De PabloNo ratings yet

- Comco Product Information Package 2004Document65 pagesComco Product Information Package 2004JinshanWangNo ratings yet

- 61992e PDFDocument177 pages61992e PDFGilson BaldoNo ratings yet

- Mimarlıkta Nanoteknolojinin YeriDocument11 pagesMimarlıkta Nanoteknolojinin YeriTuğçe ÖzdemirNo ratings yet

- 7.urudu Anatomic Therapy Healer BaskarDocument163 pages7.urudu Anatomic Therapy Healer BaskarcrispajNo ratings yet

- Product Name Seeded Paper Packet: DescriptionDocument16 pagesProduct Name Seeded Paper Packet: DescriptionshowmelocalNo ratings yet

- Universal CentrifugesDocument8 pagesUniversal CentrifugesLrojas SisacperuNo ratings yet

- 7 OrderReshop 18.1 Implementation GuideDocument295 pages7 OrderReshop 18.1 Implementation Guidesubhayan.nittNo ratings yet

- 1 Openstack Neutron Distributed Virtual RouterDocument11 pages1 Openstack Neutron Distributed Virtual RouterShabeer UppotungalNo ratings yet

- Tcpdump Usage ExamplesDocument2 pagesTcpdump Usage ExamplesdownloadpostaNo ratings yet

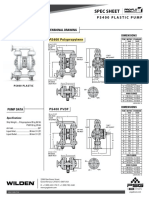

- Spec Sheet: Ps400 Plastic Pump 38 MM (1-1/2") Pump Maximum Flow Rate: 458 LPM (121 GPM)Document2 pagesSpec Sheet: Ps400 Plastic Pump 38 MM (1-1/2") Pump Maximum Flow Rate: 458 LPM (121 GPM)Flavio MedranoNo ratings yet

- MaxabsDocument7 pagesMaxabskaushal patelNo ratings yet