Professional Documents

Culture Documents

(1947, June 21) US2547086 Heating Drum

(1947, June 21) US2547086 Heating Drum

Uploaded by

aegosmithOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(1947, June 21) US2547086 Heating Drum

(1947, June 21) US2547086 Heating Drum

Uploaded by

aegosmithCopyright:

Available Formats

April 3, 1951

H. J. MCDERMOTT

2,547,086

HEATING DRUM

Filed June 21, 194'?

INVENTOR.

HENRY d. MCDERMOTT

BY

1%

Patented Apr. 3, 1-951

2,547,086

ram orrics

UNITED - STATES

2,547,086

HEATING DRUM

Henry J. McDermott, Collingdale, Pa., assignor

to American Viscose Corporation, Wilmington,

Del., a corporation of Delaware

Application June 21, 1947, Serial No. 756,153

2 Claims.

1

This invention relates to improvements in heat

ing means. More particularly this invention re

lates to improvements in heating drums having

means for efficiently and uniformly heating the

drum.

In drying materials such as paper, fabric, yarns,

?laments and the like sheet and ?brous materials,

it is a common practice to pass the material over

or between heated drums. These drums are gen~

erally heated by steam or other fluid and it has

been found di?icult to uniformly heat all parts

of the drums. Also difficulty has been encoun

tered in sealing the drums and preventing leakage

of the heating iiuid at the usual connection be

tween the drum and the fluid supply.

This invention has for its principal object to

provide heating drums having means for uni

formly and efliciently heating the drum.

(01. 25'7-=-95)

2

which is of greater diameter than the central

opening in the end portion of the drum like mem

ber and positions the coil substantially through

out its length spaced a short distance from the

inner cylindrical wall of the drum like member.

The stationary connecting block is provided

with suitable ?ttings whereby the inlet and out

let portions of the coil may be connected to supply

and discharge conduits.

The coil may be heated by steam or other

heated ?uid or the coil may be an electrical heat

ing

formed in the same shape and pro

vided with appropriate electrical leads.

The drum

partly ?lled with a high heat

capacity flowable heat conducting media it) such

as chemically inert high boiling oil, paraf?ne,

mercury, or other liquid, or a dry flowable heat

conducting media such as sand, metal powder,

Other objects and advantages of the invention

shot, or salt.

'

will be apparent from the following description 20 In the operation of this form of the invention

and accompanying drawing.

the drum is rotated relative to the heating coil

In the drawing:

and the liquid or dry heat conducting media is

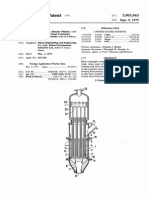

Figure 1 is a longitudinal sectional view of an

carried around by the drum and by the action of

embodiment of the invention.

centrifugal force forms a layer on the inner wall

Figure 2 is another sectional view of theem

of the drum that is su?iciently deep to cover at

bodiment of the invention shown in Figure 1 the

least a portion of the heating coil and conducts

section being taken on the line AA in Figure 1;

the heat from the coil to the inner cylindrical

Referring to the drawing reference character

wall of the drum.

.

_

I indicates generally a revolvable drum like mem~

The heating coil and the central opening in

ber comprising a cylindrical member 2 of high ..

heat conducting material, a closed head portion

3 and an annular end portion 13 having a central

opening l5. The end portion is provided with the

member 5 having the ?ared inner and outer por

tions that surround the central opening and

extend into the drum.

The drum like member is centrally mounted on

and ?xed to the shaft 5 that extends through

the central opening in the end portion, through

the drum, to the head portion by the screw mem

bers i that extend through the head portion into

the flangelike member 8 ?xed to the end of the

shaft.

The shaft is journalled in the bearing member

9 that also serves to support the shaft and the

shaft is driven by suitable means that are not

shown.

The drum like member is provided with heat

ing means that comprise in part the stationary

the end portion of the drum are of such diameter

that an amount of heat conducting media may

be placed in the drum suflicient to cover at least

a portion of the heating coil when the drum is

rotating which will not be discharged from the

open end of the drum when the drum is not

rotating.

The stationary coil causes some turbulence in

the heat conducting media as the drum revolves

so as to maintain the temperature of the heat

conducting media substantially uniform through

out and to uniformly heat all parts of the cylin

drical portion of the drum.

'

The drum is rotated in such direction that the

helical coil tends to direct the heat conducting

media toward the closed head portion away from

the open end of the drum. The ?ared member

surrounding the central opening in the end of

the drum deflects heat conducting media away

from, the central opening and serves to prevent

helical or spiral coil of tubing H3 made up of a 50 its discharge through the opening.

plurality of spaced turns extending into the drum

In order to increase the turbulence of the heat

with the inlet portion II and outlet portion !2

conducting media in the drum and to increase

of the coil ?tted into the stationary connecting

the mixing of the heat conducting media to main

block is through an opening in which the shaft

tain the temperature of all parts of the heat con

extends, The connecting block supports the coil 55 ducting media uniform, ba?ie means I! may be

2,547,086

3

provided. The baf?e means may comprise a

longitudinally extending riblike member ?xed

to the heating coil near the top and extending

radially outwardly beyond the coil to a position

just short of contact with the inner cylindrical

wall of the drum like member, this distance being

of the order of several hundredths of an inch.

The baffle means removes all but a thin layer of

2. A heating means comprising a rotatable

drum-like member having a cylindrical wall of

heat conducting material, a closed end portion,

and an end portion having a central opening,

means for supporting the drum-like member ex

tending through the central opening and ?xed

to the closed end portion, a stationary heating

means positioned in the drum-like member ex

tending around and spaced from the cylindrical

the heat conducting media from the inner wall of 10 Wall thereof, a flowable heat conducting media in

the drum and causes the heat conducting media

the drum-like member covering at least a portion

to cascade through the heating coil and uni

of the heating means, means for deflecting heat

formly conduct the heat from the coil to the heat

conducting media away from the central opening

conducting media and to the cylindrical portion

of the drum.

While a preferred embodiment of the invention

has been shown and described it is to be under

stood that changes and variations may be made

without departing from the spirit and scope of

the invention as de?ned in the appended claims.

I claim:

1. A heating means comprising a rotatable

drum-like member having a cylindrical wall of

heat conducting material and an end portion

having a central opening, a stationary heating

means positioned in the drum-like member ex

tending around and spaced from the cylindrical

wall thereof, a ?owable heat conducting media

in the drum-like member covering at least a

in the end portion of the drum-like member com

prising anoutwardly ?ared member ?xed to that

end portion of the drum-like member, surround

ing the central opening and extending into the

drum-like member and longitudinally extending

ba?le means carried by the heating means and

spaced from the cylindrical wall for directing

heat conducting media into contact with the

heating means.

HENRY J. MCDERMOTT.

REFERENCES CITED

rvIhe following references are of record in the

?le of this patent:

portion of the heating means, means for de?ect 30

UNITED STATES PATENTS

ing heat conducting media away from the eerie

Number

Name

Date

tral opening in the end portion of the drum-like

695,041

Fues ____________ __ Mar. 11, 1902

member comprising an outwardly ?ared member

1,521,223

Wyld ____________ __ Dec. 30, 1924

?xed to that end portion of the drum-like mem

ber surrounding the central opening and extend

ing into the drum-like member and longitu

dinally extending ba?ie means carried. by the

heating means for directing heat conducting

media into contact with the heating means.

1,640,662

1,672,036

1,754,826

2,365,271

2,365,678

Lutschen ________ __ Aug. 30,

Oltman __________ __ June 5,

Hitchcock ________ __ Apr. 15,

Hornlbostel _______ __ Dec. 19,

Butler ___________ __ Dec. 26,

1927

1928

1930

19%

1944

You might also like

- Test of A Tubular CondenserDocument9 pagesTest of A Tubular CondenserDevin Bea0% (1)

- Human Face of Big Data - Teachers Guide PDFDocument7 pagesHuman Face of Big Data - Teachers Guide PDFim247blackNo ratings yet

- Video ArtDocument5 pagesVideo ArtEsminusNo ratings yet

- Biruk Endale Design On Heat Exchanger-1Document32 pagesBiruk Endale Design On Heat Exchanger-1nigus gereziherNo ratings yet

- DSG 18 21 Parts Manual 33 PgsDocument33 pagesDSG 18 21 Parts Manual 33 PgskacemNo ratings yet

- (1975, Sept. 9) US3903963 Heat ExchangerDocument4 pages(1975, Sept. 9) US3903963 Heat ExchangeraegosmithNo ratings yet

- Umted States Patent (191 (111 4,138,969: Tho-Plan Et A1. (45) Feb. 13, 1979Document12 pagesUmted States Patent (191 (111 4,138,969: Tho-Plan Et A1. (45) Feb. 13, 1979_Asylum_No ratings yet

- Heat Exchanger 4Document9 pagesHeat Exchanger 4Karter KhelaNo ratings yet

- Heat Transfer & ExchangersDocument19 pagesHeat Transfer & ExchangersSanadNo ratings yet

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDocument6 pages(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNo ratings yet

- Chapter - 1 1.1 BackgroundDocument83 pagesChapter - 1 1.1 BackgroundRojithNo ratings yet

- Heat Exchangers DesignDocument28 pagesHeat Exchangers Designagarwalashwin320% (1)

- United States Patent (19) : Assistant Examiner-Arthur O. HendersonDocument7 pagesUnited States Patent (19) : Assistant Examiner-Arthur O. HendersonDylan WielfredNo ratings yet

- US4143639 Friction Heat Space Heater, Eugene FrenetteDocument6 pagesUS4143639 Friction Heat Space Heater, Eugene FrenetteBastien Gall de SilléNo ratings yet

- Heat ExchangersDocument32 pagesHeat ExchangersAnto KattikkaranNo ratings yet

- Turbine Blade CoolingDocument34 pagesTurbine Blade CoolingmidgardsothothNo ratings yet

- Conceptual Diagram of A Plate and Frame Heat Exchanger02Document9 pagesConceptual Diagram of A Plate and Frame Heat Exchanger02sai thesisNo ratings yet

- ContentsDocument5 pagesContentsgintosaju_792849166No ratings yet

- United States Patent (19) : Patent Number: (45) Date of PatentDocument10 pagesUnited States Patent (19) : Patent Number: (45) Date of PatentMichael JordanNo ratings yet

- Module-06-Heat Exchanger PDFDocument46 pagesModule-06-Heat Exchanger PDFHaitham Saleem Al-ani100% (1)

- United States Patent (191: Willbanks (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: Willbanks (11) Patent Number: (45) Date of PatentОливер АндовскиNo ratings yet

- 1.1 Research Background: Heat Exchanger FCB40302Document68 pages1.1 Research Background: Heat Exchanger FCB40302ImranMustaffaNo ratings yet

- United States Patent (191: Briickner Et A1Document6 pagesUnited States Patent (191: Briickner Et A1PeterWangNo ratings yet

- United States PatentDocument10 pagesUnited States Patentvictor bellidoNo ratings yet

- Power Engineering MicroprojectDocument14 pagesPower Engineering MicroprojectROHANNo ratings yet

- Heat PipeDocument3 pagesHeat PipeVenkitaraj K PNo ratings yet

- 109CH0458 PDFDocument41 pages109CH0458 PDFoverdose500No ratings yet

- Heat Transfer Analysis On A Straight Triangular Fin BB - Draft - 1Document15 pagesHeat Transfer Analysis On A Straight Triangular Fin BB - Draft - 1Ratandeep PandeyNo ratings yet

- FrenetteDocument4 pagesFrenetteJohn WestfieldNo ratings yet

- Three-Plate MoldDocument24 pagesThree-Plate MoldRizky AntikawatiNo ratings yet

- General Marine EngineeringDocument67 pagesGeneral Marine EngineeringSailorprof100% (3)

- Air Preheaters Superheaters EconomizersDocument26 pagesAir Preheaters Superheaters Economizerskowsar0221No ratings yet

- Chenglong WangDocument10 pagesChenglong Wangpreetham108100% (1)

- Engineering Drawing Project Report: Heat ExchangerDocument10 pagesEngineering Drawing Project Report: Heat ExchangerDhanis ParamaguruNo ratings yet

- Heat Transfer in Finned Tubes Lab ReportDocument6 pagesHeat Transfer in Finned Tubes Lab ReportHarikrishnan Cb0% (1)

- Heat Exchanger TypesDocument15 pagesHeat Exchanger TypesDanish BaigNo ratings yet

- Heat ExchangerDocument4 pagesHeat ExchangerRahul KumarNo ratings yet

- Illlllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLDocument18 pagesIlllllllllllllillllllllllllllllllllllillllllllllllllllllll - L - L - L - L - LLSteric ZeytraNo ratings yet

- US5231917 - Wobble PistonDocument5 pagesUS5231917 - Wobble PistondevheadbotNo ratings yet

- USRE10124Document3 pagesUSRE10124nmfzkwy2rNo ratings yet

- Industrial Process FurnacesDocument11 pagesIndustrial Process FurnacesMohammed AlkhafajiNo ratings yet

- Heat ExchangersDocument93 pagesHeat ExchangersBrahim LetaiefNo ratings yet

- Experimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFDocument6 pagesExperimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFRengga Ahmad PrasetiaNo ratings yet

- Heating With Coils and Jackets - Spirax SarcoDocument14 pagesHeating With Coils and Jackets - Spirax SarcoWEN GIE KONGNo ratings yet

- Unit 3 Fractionation & Distillation EquipmentDocument15 pagesUnit 3 Fractionation & Distillation EquipmentKha Mn100% (1)

- Superheater EnggresDocument2 pagesSuperheater EnggresMArifHidayahNo ratings yet

- Case Study Power Plant 2Document11 pagesCase Study Power Plant 2qasdinabatrisyia28No ratings yet

- Experiment On A Continuous Heat Regenerative Adsorption Refrigerator Using Spiral Plate Heat Exchanger As AdsorbersDocument11 pagesExperiment On A Continuous Heat Regenerative Adsorption Refrigerator Using Spiral Plate Heat Exchanger As AdsorbersHamza MoussaNo ratings yet

- Introduction To Heat ExchangerDocument15 pagesIntroduction To Heat ExchangernsfvhsfNo ratings yet

- Shell and Tube Heat Exchanger: Wall ThicknessDocument10 pagesShell and Tube Heat Exchanger: Wall ThicknessZeke KazamiNo ratings yet

- Silo Combustion Chamber For A Gas Turbine: United StatesDocument25 pagesSilo Combustion Chamber For A Gas Turbine: United StatesDannyelNo ratings yet

- 1588155056unit IV Heat Exchange EquipmentsDocument8 pages1588155056unit IV Heat Exchange EquipmentsPNo ratings yet

- Heat ExchangerDocument5 pagesHeat ExchangerMurtaza NaeemNo ratings yet

- General Introduction To Heat ExchangersDocument11 pagesGeneral Introduction To Heat ExchangersHashem HomadyNo ratings yet

- The Geothermal Concept: A Homeowner'S Guide To Geothermal Heating and Cooling Comfort SystemsDocument16 pagesThe Geothermal Concept: A Homeowner'S Guide To Geothermal Heating and Cooling Comfort SystemsNouman YasarNo ratings yet

- July 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Document5 pagesJuly 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Yanpiero BalladoresNo ratings yet

- 'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679Document5 pages'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679ShameekaNo ratings yet

- 1.1 Purpose: Chapter 1: Introduction To Heat PipesDocument26 pages1.1 Purpose: Chapter 1: Introduction To Heat PipesVilas RautNo ratings yet

- Ornos, Janlyn Z. MEL 2 Assessment 1Document4 pagesOrnos, Janlyn Z. MEL 2 Assessment 1Janlyn OrnosNo ratings yet

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useFrom EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useNo ratings yet

- Seperation Sequances PDFDocument38 pagesSeperation Sequances PDFaegosmithNo ratings yet

- Size Effect of Layered Double Hydroxide Platelets On The Crystallization Behavior of Isotactic PolypropyleneDocument8 pagesSize Effect of Layered Double Hydroxide Platelets On The Crystallization Behavior of Isotactic PolypropyleneaegosmithNo ratings yet

- Static Liquid Holdup in Packed Beds of Spherical ParticlesDocument4 pagesStatic Liquid Holdup in Packed Beds of Spherical ParticlesaegosmithNo ratings yet

- Chapter 23 Thermophilic Biohydrogen Production PDFDocument12 pagesChapter 23 Thermophilic Biohydrogen Production PDFaegosmithNo ratings yet

- Appendix 5 A Selection of Other Useful Contact Points Including Networks and WebsitesDocument4 pagesAppendix 5 A Selection of Other Useful Contact Points Including Networks and WebsitesaegosmithNo ratings yet

- Adsorption of Phenanthrene On Activated Carbons - Breakthrough Curve ModelingDocument9 pagesAdsorption of Phenanthrene On Activated Carbons - Breakthrough Curve ModelingaegosmithNo ratings yet

- Appendix 3 Equipment SuppliersDocument16 pagesAppendix 3 Equipment SuppliersaegosmithNo ratings yet

- Appendix 2 NomenclatureDocument2 pagesAppendix 2 NomenclatureaegosmithNo ratings yet

- CopyrightDocument1 pageCopyrightaegosmithNo ratings yet

- Chemical Process Safety: Learning From Case HistoriesDocument1 pageChemical Process Safety: Learning From Case HistoriesaegosmithNo ratings yet

- Experimental Methods and Instrumentation For Chemical EngineersDocument1 pageExperimental Methods and Instrumentation For Chemical EngineersaegosmithNo ratings yet

- Olefin Metathesis in Organic SynthesisDocument19 pagesOlefin Metathesis in Organic SynthesisaegosmithNo ratings yet

- M2M HEC - YaleDocument5 pagesM2M HEC - YaleBBA BIT NOIDANo ratings yet

- OOAD (U1) InceptionDocument8 pagesOOAD (U1) InceptionchinnaaNo ratings yet

- STVEP - (Entrepreneurship9) Sheet Quarter 2 - MELC 8: ActivityDocument9 pagesSTVEP - (Entrepreneurship9) Sheet Quarter 2 - MELC 8: ActivitySun Shine OalnacarasNo ratings yet

- GSM ALARMDocument17 pagesGSM ALARMDragan StanicNo ratings yet

- Ôn DLKTDocument21 pagesÔn DLKTLinh DoanNo ratings yet

- Whitepaper Data Communication With Victron Energy Products - ENDocument13 pagesWhitepaper Data Communication With Victron Energy Products - ENDefiant OverlandNo ratings yet

- Passion Project-Lesson 3Document2 pagesPassion Project-Lesson 3api-479524591No ratings yet

- Alpha RT PDFDocument8 pagesAlpha RT PDFHugo GranadosNo ratings yet

- 17-619 Introduction To Real-Time Software and Systems: Carnegie MellonDocument7 pages17-619 Introduction To Real-Time Software and Systems: Carnegie Mellonbkit_n_haiNo ratings yet

- Macdermid Inc - Metex Strip Aid - 6810-00-113-0036Document2 pagesMacdermid Inc - Metex Strip Aid - 6810-00-113-0036Luiz FernandoNo ratings yet

- Chapter 5 Electrical Installation 2021 JANDocument242 pagesChapter 5 Electrical Installation 2021 JANNaing Win TunNo ratings yet

- Bus121 Course CompactDocument10 pagesBus121 Course CompactFadele1981No ratings yet

- Cek Virus CMDDocument3 pagesCek Virus CMDMohamad Razif Abd RazakNo ratings yet

- Andrew VHLP1 23Document4 pagesAndrew VHLP1 23Marcela Rojas TorresNo ratings yet

- Elevator Class SlidesDocument16 pagesElevator Class Slidesapi-312462673No ratings yet

- Literary Analysis Final DraftDocument4 pagesLiterary Analysis Final Draftapi-645801422No ratings yet

- Bala MuruganDocument6 pagesBala MuruganBala Murugan100% (1)

- Fabm1 q3 Mod1 Introductiontoaccounting FinalDocument20 pagesFabm1 q3 Mod1 Introductiontoaccounting FinalJomark RebolledoNo ratings yet

- Presentation Group Decision MakingDocument14 pagesPresentation Group Decision MakingRakesh Shrestha0% (1)

- Unit 2 Definition of Knowledge and Its Basic AssumptionsDocument9 pagesUnit 2 Definition of Knowledge and Its Basic AssumptionssubhayudanNo ratings yet

- PriyankaDocument2 pagesPriyankaPriyanka AmazonNo ratings yet

- Digital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Document236 pagesDigital Astrophotography A Guide To Capturing The Cosmos (PDFDrive)Paolo Fasselli100% (1)

- Childhood SchizophreniaDocument14 pagesChildhood SchizophreniaAnalia WriterNo ratings yet

- Vessel InformationDocument241 pagesVessel InformationNayem PoshariNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 6,054,488: Oliver Et Al. (45) Date of Patent: Apr. 25, 2000Document8 pagesUlllted States Patent (19) (11) Patent Number: 6,054,488: Oliver Et Al. (45) Date of Patent: Apr. 25, 2000Nia MachyNo ratings yet

- Experiment No 16Document3 pagesExperiment No 16Usama MughalNo ratings yet

- Quantum Field Theory - R. Clarkson, D. McKeonDocument266 pagesQuantum Field Theory - R. Clarkson, D. McKeonKepler4246No ratings yet