Professional Documents

Culture Documents

Experimental Study of LiTraCon

Experimental Study of LiTraCon

Uploaded by

IOSRjournalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Study of LiTraCon

Experimental Study of LiTraCon

Uploaded by

IOSRjournalCopyright:

Available Formats

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 12, Issue 6 Ver. I (Nov. - Dec. 2015), PP 07-13

www.iosrjournals.org

Experimental study of LiTraCon

1

S.Ravivarman, 2M.Mageswari, 3A.S.Kanagalakshmi.

Student of B.E. in Civil Engineering; Panimalar engineering college ,Chennai-600 123

Professor and Head ;department of Civil Engineering; Panimalar engineering college ,Chennai-600 123

3

Professor;department of Civil Engineering; Panimalar engineering college ,Chennai-600 123

Abstract: Now days, a Small buildings are replaced by high rise buildings and sky scrapers. This arises one of

the problem in deriving natural light in building, due to obstruction of nearby structures. Due to this problem

use of artificial sources for illumination of building is increased by great amount. LiTraCon (light transmitting

concrete) successfully produced the first transparent concrete block in 2003, It is very essential to reduce the

artificial light consumption in structure, Since concrete is strong in compression and weak in tension and

flexure

Keywords: Translucent concrete, optical fibre, energy saving, smart construction

I.

Objective

To cast a special type of concrete with light transmitting properties, to study their characteristics and to

develop a functioning material which is not only energy saving but gives out artistic finish.

II.

Introduction

Concrete has learned to adapt to almost all new challenges that appeared. In 2001, the concept of

transparent concrete was first put forward by Hungarian architect AronLosonzi, and the first transparent

concrete block was successfully produced by mixing large amount of glass fiber into concrete in 2003, named

as LiTraCon. Joel S. and Sergio O.G. developed a transparent concrete material, which can allow 80% light

through and only 30% of weight of common concrete. It is worth mentioning that Italian Pavilion in Shanghai

Expo 2010 shows a kind of transparent concrete developed by mixing glass into concrete in 2010."LitraCon"

has the strength of traditional concrete and an embedded array of glass fibres that can display a view of the

outside world, such as the silhouette of a tree, for example. Thousands of optical glass fibres form a matrix and

run parallel to each other between the two main surfaces of every block. Shadows on the lighter side will appear

with sharp outlines on the darker one. Even the colours remain the same. This special effect creates the general

impression that the thickness and weight of a concrete wall will disappear. The hope is that the new material

will transform the interior appearance of concrete buildings by making them feel light and airy rather than dark

and heavy.

III.

Principle

Based on Nano-Optics. Optical fibres passes as much light when tiny slits are placed directly on top

of each other as when they are staggered. Principal can carry because optical fibers in the concrete act like the

slits and carry the light across throughout the concrete.

IV.

Types Of Optical Fibres

There are three basic types of optical fibers: [1] Multimode gradedindex fiber [2] Multimode stepindex fiber [3] Single-mode stepindex fibers.A multimode fiber can propagate hundreds of light modes at one

time while single-mode fibers only propagate one mode. Where the single-mode fibers propagate light in one

clearly defined path, intermodal dispersion effects is not present, allowing the fiber to operate at larger

bandwidths than a multimode fiber. On the other hand, multimode fibers have large intermodal dispersion

effects due to the many light modes of propagations it handles at one time.

DOI: 10.9790/1684-12610713

www.iosrjournals.org

7 | Page

Experimental study of LiTra Con

Types Of Optical Fibres

V.

Materials

Non sticky clay, Cement, OPTICAL FIBRES, Mortar, concrete, etc

VI.

Mix Proportions

Mix proportions are arrived as follows: Cement 360kg, Sand 560kg, Fibre 4.5kg, Water 190lit

VII.

Placing Of Fibres And Casting Of Concrete

Initially the fibres are arranged in the required pattern in the formwork before casting of concrete.

Fixing of fibres done in a plastic sheet and behind this thermo coal is placed to hold it. After installation of

fibre, one end is connected to the lighting source and other end is left free on the surface of the concrete

which is to be casted. Then the wet mix is applied on the slab mould prepared. Allow the concrete to cure

for 7-15 days. After curing, these slabs will transmit light on its surface. Fibres are glowing at end by

giving light source on another end of the fibres

VIII.

Procedure Of Making Light Transmitting Concrete

1)Making Of Mould

You need to roll some polymer craft clay into a flat circle. Make it as level as possible ,Cut out a

ring from a spray paint can lid...anything that is waterproof will work. After you cut it, press it into the

clay. The whole point of this is to make a mold to cast the concrete into.

2)Fibre Optics

Get one of those plastic fibre optic toys. They have that sort of 'frill' of glowing wires... see the photo.

Cut a bunch small 1 inch segments short en masse.

DOI: 10.9790/1684-12610713

www.iosrjournals.org

8 | Page

Experimental study of LiTra Con

3)Placing Of Fibres

Fiber are placed individually in mold with some spacings are given due to avoiding interconnections

4)Pouring Of Concrete

Pour the concrete carefully and slowly in fiber placed mould ,the concrete is fully layed over the

mould and spreading each other,there is no any air gaps

5)Breaking Of Mould

Once the concrete is cured for 24 hours, pull off the polymer clay and cut off the plastic ring. The

concrete will not stick to the clay...in fact, it's practically repelled by it! That the repultion will be easy

during breaking

DOI: 10.9790/1684-12610713

www.iosrjournals.org

9 | Page

Experimental study of LiTra Con

6)Trim The Fibres

After you let the de-moulded concrete dry out over night, cut off the extra long fibers

7)Polishing

Use sandpaper to polish and Light, even colored light, is able to pass right through and create a

pixelized likeness on the opposite side...!

IX.

Construction

Transparent concrete is produced out of fine-grain concrete and translucent fabric which is layer

cast in prefabricated mould. Because of relatively small amount of fabric, solidity and consistency of

transparent concrete are the same as the high-strength concrete. Almost free energy loss light penetration

through optic fibres makes it possible to see light, shadows and even colours through concrete even by

very thick walls. It can be produced as prefabricated building blocks and panels. Due to the small size of

the fibres, they blend into concrete becoming a component of the material like small pieces of aggregate. In

this manner, the result is not mixed material like glass in concrete but a new material, which is

homogeneous in its inner structure as well as on its main surfaces. The optical fibres lead light by points

between the two sides of the blocks. Because of their parallel position, the light-information on the brighter

side of such a wall appears unchanged on the darker side. The most interesting form of this phenomenon is

DOI: 10.9790/1684-12610713

www.iosrjournals.org

10 | Page

Experimental study of LiTra Con

probably the sharp display of shadows on the opposing side of the wall. Moreover, the colour of the light

also remains the same

X.

Manufacturing Process

The manufacturing process of transparent concrete is almost same as regular concrete. Only optical

fibres are spread throughout the aggregate and cement mix. Small layers of the concrete are poured on top of

each other and infused with the fibers and are then connected. Thousands of strands of optical fibers are cast

into concrete to transmit light, either natural or artificial.Lighttransmitting concrete is produced by adding 4%

to 5% optical fibers by volume into the concrete mixture. The concrete mixture is made from fine materials

only it does not contain coarse aggregate. Thickness of the optical fibers can be varied between 2 m and 2 mm

to suit the particular requirements of light transmission.Automatic production processes use woven fibres fabric

instead of single filaments.Fabric and concrete are alternately inserted into molds at intervals of approximately

2 mm to 5 mm.Smaller or thinner layers allow an increased amount of light to pass through the concrete.

Following casting, the material is cut into panels or blocks of the specified thickness and the surface is then

typically polished, resulting in finishes ranging from semi-gloss to high-gloss

Transparent Concrete When Optical Fibres Are In

Organic Distribution

XI.

Other Properties Of Transperent Concrete

There arent many manufacturers of translucent concrete. There are very few of them, namely

LitraCon, Lucon and Lucem Lichbeton. The costing of this, according to Litracon is $1000/m 2 for 25mm

thickness. The LitraCube lamp which is hollow cube of four interlocking panels, costs 595 euros. It is quite

expensive, as it is pretty rare. But it is totally worth the cost. On the performance side, its simply a concrete

embedded with optical fibers running in a matrix while still retaining the strength of concrete. Therefore it

still retains the high density top layer. It is also frost and de-icing salt resistant, making it highly

recommendable in cold countries. Similarly, it is under fire protection classification A2 and provides very

high UV resistance

Transparent Concrete When Optical Fibres Are In

Layered Distribution

DOI: 10.9790/1684-12610713

www.iosrjournals.org

11 | Page

Experimental study of LiTra Con

XII.

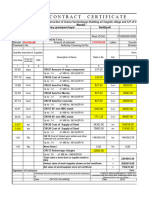

Experimental Investigation:

Workability:

The workability of the concrete is determined by conducting the slump cone test and the observed

slump is 92mm

Compressive Strength:

The compressive strength is usually obtained experimentally by means of a compressive test. The

compressive strength of the concrete is determined by cast the cubes of size 150mm x150mm x150mm, The

compressive strength of the conventionalconcrete and light transmitting concrete in 7, 14 and 28 days.

Flexural Strength

The flexural strength (single beam with centre point load method) of the conventional concrete

and light transmitting concrete in 7, 14 and 28 days and Hence the application of optical fibre will make

the concrete decorative as well as can make the concrete structural efficient and The strength results of

decorative concrete are correlated with results of ordinary plain cement concrete.The results evidently

show that the decorative concrete also performance based on the strength aspect is also considerably high.

Hence the application of optical fibre will make the concrete decorative as well as can make the concrete

structural efficient .

XIII.

Conclusions And Remarks

Translucent concrete blocks can be used in many ways and implemented into many forms and be

highly advantageous. Yet, the only drawback would be its high cost. That doesnt stop high class architects from

using it. Its a great sign of attraction and artistic evolution. Any structure with a small hint of translucent

concrete is bound to make heads turn and make them stand in awe. Apart from the beauty aspects, theres also

this security and supervision. Large houses, with big security walls are often low on security. Thats why they

are mostly fitted with electrocuted fencing Green buildings would get an easy accreditation under daylight

savings with this. Large and tall office buildings can share the lighting when the ceilings are translucent. Energy

savings as well as heat insulation simple adds to the list of its amazing properties. Transparent concrete is the

future. It is the smart way of optimising and utilising light, a smart way of living. This decorative concrete can

be used in interior design of buildings as panels in slabs, walls etc. The decorative concrete can be used in place

DOI: 10.9790/1684-12610713

www.iosrjournals.org

12 | Page

Experimental study of LiTra Con

of windows because it can transmit the sunlight. Hence the application of optical fibre will make the concrete

decorative as well as can make the concrete structural efficient.

Acknowledgement

The research work would not have been possible without my guide and my soul motivation

Dr.M.Mageswari, M.E,PhD, A.S.Kanagalakshmi, ME,PhD Also the facts and works provided in this paper is

dedicated to all the civil engineers to look world in a smart way. And lastly I want to thank my parents for their

unconditional support.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

[10].

Basma F. Bashbash. (2013). Basics of light Transmitting Concrete, pp 079-083, (2013)

Jianping He. (2011). Study on Smart Transparent Concrete Product and its performances, 6 thinternational workshop on advanced

smart materials and smart structures technology, (2011)

IS: 10262-1982 Recommended Guidelines for Concrete Mix Design.

Victoria Bailey, Translucent Concrete, published on MEEN 3344-001, 11:00-11:50 MWF

http://www.materialproject.org/wiki/Translucent_concrete

http://www.luccon.de/en

http://www.lucem.de/index.php?id=156&L=1

http://www.litracon.hu/

https://www.google.com/patents/EP1947069A1?cl=en&dq=translucent+concrete&hl=en&sa=X&ei=NnsCUo

aNdDyrQfj0oDQBw&sqi=2&pjf=1&ved=0CDQQ6AEwAA

https://www.gaoogle.com/patents/EP2410103A2?cl=en&dq=translucent+concrete&hl=en&sa=X&ei=NnsCUoaNdDyrQfj0oDQBw

&sqi=2&pjf=1&ved0CDsQ6AEwAQ

DOI: 10.9790/1684-12610713

www.iosrjournals.org

13 | Page

You might also like

- Airchoc5 (16.6.16)Document89 pagesAirchoc5 (16.6.16)TinTunNaing100% (4)

- Woodwool Slabs - Manufacture, Properties and UseDocument24 pagesWoodwool Slabs - Manufacture, Properties and UseDanielJob07No ratings yet

- Open Ended LabDocument13 pagesOpen Ended LabMuhammad Zulhusni Che RazaliNo ratings yet

- Final PPT LITRACONDocument15 pagesFinal PPT LITRACONRAmyaNo ratings yet

- Light Transmitting ConcreteDocument19 pagesLight Transmitting ConcreteSurabhi AnandNo ratings yet

- IJEIT1412201302 - 18 - Study On Transparent Concrete 2013Document5 pagesIJEIT1412201302 - 18 - Study On Transparent Concrete 2013Diana ChisiuNo ratings yet

- Light Transmitting Concrete-A New InnovationDocument6 pagesLight Transmitting Concrete-A New InnovationDeara Putri SupriadiNo ratings yet

- Light Transmitting ConcreteDocument14 pagesLight Transmitting ConcreteAchmad Zultan MansurNo ratings yet

- Eng-To Evaluate-Neha R.nagdiveDocument8 pagesEng-To Evaluate-Neha R.nagdiveImpact JournalsNo ratings yet

- Covaleov 2019 IOP Conf. Ser. Earth EDocument6 pagesCovaleov 2019 IOP Conf. Ser. Earth Ejuan carlos manriqueNo ratings yet

- Translucent Concrete: Omkar KadamDocument14 pagesTranslucent Concrete: Omkar KadamJakka hitheshiniNo ratings yet

- Transparent Concrete 7442 LoKcVAMDocument21 pagesTransparent Concrete 7442 LoKcVAMChetan HalladNo ratings yet

- Light Transmitting ConcreteDocument29 pagesLight Transmitting ConcreteAnvesh Jakke67% (3)

- Transparent ConcreteDocument20 pagesTransparent ConcreteAbhipsha SwainNo ratings yet

- Myseminarppt 150826145204 Lva1 App6891 PDFDocument27 pagesMyseminarppt 150826145204 Lva1 App6891 PDFKamran ImtiyazNo ratings yet

- Seminar Report On Fiber Reinforced Concrete-1Document13 pagesSeminar Report On Fiber Reinforced Concrete-1Mo.kaifNo ratings yet

- Study of Transparent Concrete: Presented ByDocument17 pagesStudy of Transparent Concrete: Presented ByGaurav JainNo ratings yet

- LitraconDocument17 pagesLitraconVamshi KandikatlaNo ratings yet

- Lighttransmitting ConcreteDocument31 pagesLighttransmitting Concretesuhanihk100% (1)

- Translucent ConcreteDocument17 pagesTranslucent Concretekush patelNo ratings yet

- Transparent ConcreteDocument14 pagesTransparent ConcreteMaharNadirAliNo ratings yet

- Transparent Concrete As An Eco-Friendly Material For BuildingDocument8 pagesTransparent Concrete As An Eco-Friendly Material For BuildinginventionjournalsNo ratings yet

- Transparent Concrete ReferenceDocument7 pagesTransparent Concrete ReferenceRicha ShahNo ratings yet

- Translucent ConcreteDocument22 pagesTranslucent ConcreteRicha ShahNo ratings yet

- Transparent Concrete DocumntnDocument45 pagesTransparent Concrete DocumntnJyothsnaNo ratings yet

- Study of Transparent Concrete: BY: Praful N K 2GI12CSE12 Mtech 2 SEMDocument17 pagesStudy of Transparent Concrete: BY: Praful N K 2GI12CSE12 Mtech 2 SEMRachitha PrachithaNo ratings yet

- A GLOWING FUTURE - TRANSPARENT CONCRETE Ijariie6254Document6 pagesA GLOWING FUTURE - TRANSPARENT CONCRETE Ijariie6254smukhtarNo ratings yet

- Palgarised Energy Efficiency and Experimental Analysis of Translucent Concrete (Research Paper)Document5 pagesPalgarised Energy Efficiency and Experimental Analysis of Translucent Concrete (Research Paper)Udaykumar PhatakNo ratings yet

- Study of Transparent Concrete: BY: Praful N K 2GI12CSE12 Mtech 2 SEMDocument17 pagesStudy of Transparent Concrete: BY: Praful N K 2GI12CSE12 Mtech 2 SEMRachitha PrachithaNo ratings yet

- A Study On Transparent Concrete: A Novel Architectural Material To Explore Construction SectorDocument6 pagesA Study On Transparent Concrete: A Novel Architectural Material To Explore Construction SectorsehunNo ratings yet

- Transparent ConcreteDocument17 pagesTransparent ConcreteIrfan KhanNo ratings yet

- Translucent ConcreteDocument7 pagesTranslucent ConcreteNyla VaidyaNo ratings yet

- Ijierm Dec 2019Document11 pagesIjierm Dec 2019Elegant PrinceNo ratings yet

- Experimental Study On Light Transmitting ConcreteDocument9 pagesExperimental Study On Light Transmitting ConcretesaikirankasivojjulaNo ratings yet

- Pilipenko 2018 IOP Conf. Ser. Mater.Document8 pagesPilipenko 2018 IOP Conf. Ser. Mater.juan carlos manriqueNo ratings yet

- REPORTDocument13 pagesREPORTMerwyn mathiasNo ratings yet

- Translucent Concrete: by - Shubham JaiswalDocument15 pagesTranslucent Concrete: by - Shubham JaiswalshubhamNo ratings yet

- Exprimental Study On Transparent Concreteby Using Plastic Optical FiberDocument4 pagesExprimental Study On Transparent Concreteby Using Plastic Optical FiberBEYENA GEDEFANo ratings yet

- Transparent ConcreteDocument15 pagesTransparent ConcreteJaka SurantoNo ratings yet

- Transparent ConcreteDocument15 pagesTransparent ConcreteUnknown PersonNo ratings yet

- Total Quantity Management TOPIC: Light Emitting ConcreteDocument23 pagesTotal Quantity Management TOPIC: Light Emitting ConcreteTEMSUSUNEPNo ratings yet

- SeminarDocument21 pagesSeminarsoukhya100% (1)

- A Study On Translucent Concrete and It's PropertiesDocument7 pagesA Study On Translucent Concrete and It's PropertiessehunNo ratings yet

- Beton Translucid 2Document6 pagesBeton Translucid 2Nicoleta Diana DuiculeteNo ratings yet

- Amartya SynopsisDocument12 pagesAmartya SynopsisSaurabh PandeyNo ratings yet

- Transperent ConcreteDocument13 pagesTransperent Concreteprahalad 17R-154No ratings yet

- Light Emitting Translucent Concrete SynopsisDocument10 pagesLight Emitting Translucent Concrete Synopsissaurabh singhNo ratings yet

- 6 - State-Of-The-Art Developments in Light Transmitting ConcreteDocument7 pages6 - State-Of-The-Art Developments in Light Transmitting ConcreteEng ChristianNo ratings yet

- History and Case Study On Light Transmittingconcrete: H.B.Valambhiya, T.J.Tuvar, P.V.RayjadaDocument9 pagesHistory and Case Study On Light Transmittingconcrete: H.B.Valambhiya, T.J.Tuvar, P.V.Rayjadarohan khanvilkarNo ratings yet

- Transparent Concrete: Seminar ONDocument13 pagesTransparent Concrete: Seminar ONGopi naguNo ratings yet

- History and Case Study On Light Transmittingconcrete: H.B.Valambhiya, T.J.Tuvar, P.V.RayjadaDocument9 pagesHistory and Case Study On Light Transmittingconcrete: H.B.Valambhiya, T.J.Tuvar, P.V.Rayjadarohan khanvilkarNo ratings yet

- B005 - Translucent ConcreteDocument18 pagesB005 - Translucent ConcreteNyla VaidyaNo ratings yet

- A Review On Transparent Concrete: J. Sree Naga Chaitanya, Dr. K. Chandramouli, K. Divya, P. Surendra KumarDocument4 pagesA Review On Transparent Concrete: J. Sree Naga Chaitanya, Dr. K. Chandramouli, K. Divya, P. Surendra KumarShaik yahiya rizwanNo ratings yet

- Transparent ConcreteDocument10 pagesTransparent ConcreteJaimin PatelNo ratings yet

- Transparent Concr TeDocument10 pagesTransparent Concr TeAbhijeeth NagarajNo ratings yet

- Translucent ConcreteDocument10 pagesTranslucent ConcreteSamuel Julca HuingoNo ratings yet

- An Experimental Study On Lightemitting Concrete: Kavya S, Karthik D, Sivaraja MDocument5 pagesAn Experimental Study On Lightemitting Concrete: Kavya S, Karthik D, Sivaraja MBanNo ratings yet

- Transparent ConcreteDocument7 pagesTransparent Concretekrishna reddyNo ratings yet

- 13 Innovative Construction MaterialsDocument11 pages13 Innovative Construction MaterialsOmpatileOagileRiccoIsauNo ratings yet

- Translucent ConcreteDocument22 pagesTranslucent ConcreteClassic PrintersNo ratings yet

- DE Sem 5Document30 pagesDE Sem 5Pratik MistryNo ratings yet

- Transparent Concrete: An Evolution Towards Better India: e-ISSN: 2456-3463Document6 pagesTransparent Concrete: An Evolution Towards Better India: e-ISSN: 2456-3463BEYENA GEDEFANo ratings yet

- Plasma Etching Processes for Interconnect Realization in VLSIFrom EverandPlasma Etching Processes for Interconnect Realization in VLSINicolas PossemeNo ratings yet

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocument7 pagesSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)No ratings yet

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocument5 pages"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocument6 pagesThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)No ratings yet

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocument4 pagesInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)No ratings yet

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Document15 pagesA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)No ratings yet

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocument5 pagesAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)No ratings yet

- The Impact of Technologies On Society: A ReviewDocument5 pagesThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Assessment of The Implementation of Federal Character in Nigeria.Document5 pagesAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)No ratings yet

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocument7 pagesA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)No ratings yet

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocument5 pagesEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)No ratings yet

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocument14 pagesAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)No ratings yet

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocument7 pagesComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)No ratings yet

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocument5 pagesRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)No ratings yet

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocument5 pagesDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalNo ratings yet

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocument7 pagesTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)No ratings yet

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocument6 pagesImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)No ratings yet

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocument6 pagesRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)No ratings yet

- Lecture 16 - Cracking: RC14-1334: Concrete Structures 1Document16 pagesLecture 16 - Cracking: RC14-1334: Concrete Structures 1'Riky Dwi Prasetyo'No ratings yet

- R.B.K PrintedDocument280 pagesR.B.K PrintedPothaiah TanuNo ratings yet

- Deltaplate CFP: Pt. Deltacretindo Wira MandiriDocument2 pagesDeltaplate CFP: Pt. Deltacretindo Wira MandiriIndra RifaldyNo ratings yet

- Bar ChartDocument1 pageBar ChartM ShahidNo ratings yet

- BMC Ebook by Je Civil Adda PDFDocument9 pagesBMC Ebook by Je Civil Adda PDFKailash ChaudharyNo ratings yet

- Chemrite 303 SPDocument3 pagesChemrite 303 SPICPL-RWPNo ratings yet

- Use of Rubber As Aggregate in Concrete: A Review: April 2015Document6 pagesUse of Rubber As Aggregate in Concrete: A Review: April 2015Suno AliNo ratings yet

- Revised Data (Buildings)Document95 pagesRevised Data (Buildings)sasidharkatari91572No ratings yet

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- InternshipDocument39 pagesInternshipsinghamit39699No ratings yet

- Guide Lines For Erection of Verticallift GatesDocument46 pagesGuide Lines For Erection of Verticallift GatesMahipal Reddy100% (1)

- Kwik Bolt 3 Exp Anchor Hilti PDFDocument21 pagesKwik Bolt 3 Exp Anchor Hilti PDFarturoncNo ratings yet

- BBA Cert 12-R149 For Redi-Rock Modular Block System (March 2012)Document12 pagesBBA Cert 12-R149 For Redi-Rock Modular Block System (March 2012)sandycastleNo ratings yet

- Irc CodesDocument8 pagesIrc CodesPamirNo ratings yet

- Design of Precast BeamDocument4 pagesDesign of Precast BeamMUTHUKKUMARAMNo ratings yet

- Research Paper On MetalsDocument5 pagesResearch Paper On Metalsfvg2005k100% (1)

- Nlanson CedDocument63 pagesNlanson CedKOFI BROWNNo ratings yet

- Energex Commercial and Industrial PMT App ADocument8 pagesEnergex Commercial and Industrial PMT App AdseugenioNo ratings yet

- Manar Steel Waler SystemDocument56 pagesManar Steel Waler Systemtarek.fileNo ratings yet

- 2010 Edward Cording - Assessment of Excavation Induced Building DamageDocument20 pages2010 Edward Cording - Assessment of Excavation Induced Building DamageImran SaikatNo ratings yet

- CBRI Annual Report 2017 2018 1 PDFDocument297 pagesCBRI Annual Report 2017 2018 1 PDFKshitij JainNo ratings yet

- 15th Euroseminar On Microscopy Applied To Building MaterialsDocument426 pages15th Euroseminar On Microscopy Applied To Building MaterialsAlbertoNo ratings yet

- C2!6!455 Grout and Adhesive Rev.BDocument50 pagesC2!6!455 Grout and Adhesive Rev.BAreaya mahetemNo ratings yet

- Initial and Final Setting Time of CementDocument4 pagesInitial and Final Setting Time of CementHasini GamageNo ratings yet

- Fundamentals of Reinforced ConcreteDocument28 pagesFundamentals of Reinforced ConcreteHarold Jackson MtyanaNo ratings yet

- Amankrah Kojo Asare - Finite Element Assessment of Precast Concrete Slab Using Ansys Structural - 2015Document93 pagesAmankrah Kojo Asare - Finite Element Assessment of Precast Concrete Slab Using Ansys Structural - 2015IgorNo ratings yet

- CEPIS Small Dia Submarine Outfall PDFDocument37 pagesCEPIS Small Dia Submarine Outfall PDFrandtanNo ratings yet