Professional Documents

Culture Documents

Artigo Anais

Artigo Anais

Uploaded by

André Luís KirstenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artigo Anais

Artigo Anais

Uploaded by

André Luís KirstenCopyright:

Available Formats

Home

9 Congresso Brasileiro de Eletrnica de Potncia - 9th Brazilian Power Electronics Conference

ELECTRONIC BALLAST TO SUPPLY HPS LAMPS WITH LOW FREQUENCY

SQUARE WAVEFORM IN PUBLIC LIGHTING SYSTEMS

Andr L. Kirsten, Jackson Piazza, Tiago B. Marchesan,

Murilo Cervi, Alexandre Campos, Ricardo N. do Prado

Universidade Federal de Santa Maria - UFSM

Santa Maria, Brasil

cervi@mail.ufsm.br, tiagobm@ieee.org, rnprado@ieee.org

Abstract This paper presents a topology that

integrates the inverter stage and the power control stage

for supplying high-pressure sodium lamps applied to

public lighting system. The topology consists of a

bidirectional

flyback

converter

operating

in

discontinuous conduction mode (DCM), in order to

supply the lamp with a low frequency square waveform

and avoid the acoustic resonance phenomenon. The aim

of this work is to integrate the inverter stage and the

lamp power control, thus reducing the components and

the ballast final cost. A DC voltage is used to supply the

proposed topology, once electronic ballast requires a

power factor correction stage to be applied to the public

lighting system, due to the lamp power demand. Some

experimental results are presented to validate the

proposed topology.

Keywords acoustic resonance phenomenon,

bidirectional flyback, electronic ballasts, high-pressure

sodium (HPS) lamps, public lighting.

I. INTRODUCTION

The public lighting corresponds about 7% of the national

demand and 3.3% of all electric energy consumption in

Brazil [1]. For this reason the implementation of more

efficient lamps and ballasts represents fundamental

importance for energy saving.

The high-pressure mercury lamps are usually used in

Brazilian public lighting systems. Although these lamps

bring long useful life, the presented energy efficacy is low,

when compared to the high-pressure sodium lamps (HPS).

The useful life of HPS lamps is about 24000h, which

guarantee low maintenance costs, and its high luminous

efficacy brings a significant energy saving. These lamps

radiate light of yellowish color, due to sodium, what results a

low color rendering index. However, this characteristic is not

the most relevant one, when considering open-air

environments, where the color rendering index is not a

problem. These characteristics become the HPS lamp an

excellent option for using in public lighting system.

The negative incremental resistance characteristic

becomes unfeasible the direct connection of HPS lamp to the

main. The using of a device (ballast) capable of controlling

the lamp current is needed, in order to guarantee a stable

operation [2].

The HPS lamps are usually fed by electromagnetic

ballasts. However, these devices present some unpleased

characteristics, as low efficiency, sparkling, audible noise

204

and decreasing of the lamp useful life [3]. Besides, they are

large and weighty.

With the purpose of overcome these problems, researches

have been developed electronic ballasts for supplying highpressure discharge lamps.

The using of electronic ballasts to feed low-pressure

discharge lamps, as fluorescents lamps, is already a reality.

However, the development of electronic ballasts to supply

high-pressure discharge lamps, for instance the HPS lamps,

presents some particularities. The most relevant

characteristic of these lamps is the acoustic resonance

phenomenon, which makes impossible the using of

conventional electronic ballasts for supplying them.

II. ACOUSTIC RESONANCE PHENOMENON

The acoustic resonance phenomenon occurs in a discharge

lamp when its operation frequency is close to the lamp

natural frequencies, making the pressure waves diffuse and

causing the disturb in discharge course [4]. However, that

disturb becomes visible when the energy related to the

resonance frequency is big enough, although the effects of

the acoustic resonance are detected even when there are not

visible modifications in the discharge course. For this reason,

the identification of the phenomenon through the visual

inspection is not suitable [5], [6].

The light color changing, instability of the discharge

course, inconstancy of the shine intensity and, in extreme

situation, the break of the discharge tube, are some results

caused by the acoustic resonance phenomenon.

The acoustic resonance phenomenon occurs in high

frequency range, as shown in figure 1. In extra-high

frequency range, at megahertz lamp operation, the acoustic

resonance phenomenon does not occur [7]. However,

parasitic inductances and capacitances should be taken into

account in the design, what becomes it more complicated.

The soft switching technique must be required to reduce the

switching power losses and the EMI emission [8].

The DC lamp current operation is another option to avoid

acoustic resonance occurrence, but it causes the deterioration

in one of the lamp electrodes, which causes a drastic

reduction of its useful life.

The using of low frequencies to supply the lamp enables a

stable operation without the drawback presented by DC lamp

current. It explains the great demand for electromagnetic

ballasts, which feed the lamp with the low frequency of the

main (50/60 hertz).

Home

9 Congresso Brasileiro de Eletrnica de Potncia - 9th Brazilian Power Electronics Conference

The amplitude of the output voltage ripple must be kept

below 20% of the square wave amplitude in order to

guarantee that the acoustic resonance phenomenon is below a

secure threshold value [4].

IV. IGNITION PROCESS

Fig. 1. HPS lamps instability behavior related to the frequency [9].

Considering the methods employed to prevent the harmful

consequences of the acoustic resonance phenomenon, the

option of supplying the HPS lamp with low frequency square

waveform through the use of electronic ballasts seems to be

the most reliable option [10]. This method presents some

advantages as preventing the re-ignition process, improving

the lamp useful life and the visual comfort of the lighting.

III. PROPOSED CIRCUIT

Figure 2 shows the proposed inverter, which consists of

two Flyback converters sharing the same output and an

igniter circuit.

The arrangement of the switches M3 and M4 brings a

bidirectional characteristic to the topology. According to the

correct operation of switches M1, M2, M3 and M4, it is

possible to obtain a low frequency symmetrical square

waveform applied to the lamp.

A similar topology was presented by the same authors in

[11]. It was applied two flyback transformer cores and four

high frequency switches to obtain a low frequency lamp

voltage, instead of one transformer core, two low frequency

and two high frequency switches applied in the proposed

inverter.

The switches commuting signals are controlled through

the use of a microcontroller, which enables the lamp power

control and makes possible to obtain a network

communication through the public lighting systems.

The capacitor in parallel to the lamp acts as a high

frequency filter. It is designed to obtain a small output

voltage ripple, avoiding the acoustic resonance occurrence

due to the converter operational frequency (50kHz). Even so,

its project requires some caution, in order to allow a fast

inversion at the lamp voltage each low frequency period.

The beginning of the ignition process denotes the

alteration of the gas from a non-conducting state to a

conducting state. This modification is obtained through the

application of a voltage pulse with enough amplitude, width

and rising time [4].

An igniter circuit of the lamp has been developed in order

to supply a voltage pulse of 2.5 to 4kV (according to NBR

IEC662/1997 standard) for lamp ignition.

One of the main problems of the igniter project for HPS

lamp electronic ballasts is the isolation of the high voltage

pulse needed to start the ignition process. It has been

obtained using an output of the flyback converter.

The igniter circuit is shown in the hatched area of figure 2.

Inductor L discharges its energy over capacitor C1 through

diode D. When the voltage across capacitor C1 reaches the

Sidac breakdown voltage, the energy is transferred from

capacitor C1 to the primary side of the transformer T. The

high turns ratio of this transformer brings the needed high

voltage pulse to the lamp igniting process at secondary side.

V. OPERATION STAGES

The proposed ballast operation stages are shown in figure

3 and figure 4, and described as follows:

A. First Stage

The M4 switch is turned on during this stage, which

corresponds to the positive half cycle of the lamp voltage

waveform. A high frequency modulation is provided by the

M1 switch at the same time, as shown in figure 3.

Figure 3 (a) shows the interval when the energy is

transferred into the transformer by M1. During this interval

there is no current in the secondary side of the transformer

due to the reverse bias of D3, even though the gate signal on

M4 is maintained.

Figure 3 (b) shows the transfer of this energy to the load,

which happens when M1 is turned off and M4 assumes the

load current.

B. Second Stage

The second stage corresponds to the negative half cycle of

the lamp voltage, as shown in figure 4.

In this stage, the switches M1 and M4 are kept off, the

switch M3 is turned on and the high frequency modulation is

provided by M2 switch.

Figure 4 (a) shows the interval when the switch M2 is

turned on and the energy is transferred into the transformer.

The gate signal of the switch M3 is maintained during this

interval, even though it does not have any drain current due

to the blocking provided by D3.

Figure 4 (b) shows the transfer of this energy to the load,

which happens when M2 is turned off and M3 assumes the

load current.

Fig. 2. Proposed topology.

205

Home

9 Congresso Brasileiro de Eletrnica de Potncia - 9th Brazilian Power Electronics Conference

(a)

(b)

Fig.3. Positive lamp voltage semi-cycle.

(a)

(b)

Fig.4. Negative lamp voltage semi-cycle.

In this stage, the lamp is supplied with the same energy of

the first stage, but its voltage polarity is inverted, what results

in a symmetrical square lamp voltage supply.

Figure 5 shows the command signal of four switches,

where G1 represents the gate drive of switch M1, G2

represents the gate drive of switch M2 and so on.

In the first stage, M1 is commuted with a high frequency

signal (50 kHz) and M4 is kept on, while M2 and M3 are both

kept off.

In the second stage, M2 is commuted with a high

frequency (50 kHz) and M3 is kept on, while M1 and M4 are

both kept off.

It is important to notice that M3 and M4 switches do not

commutate in a high frequency. Therefore, it is possible to

apply low frequency switches, such as bipolar transistors, to

the secondary side of the flyback converter.

VI. INVERTER DESIGN

The inverter design has been done to supply a 70W highpressure sodium lamp with a low frequency (400Hz) square

voltage. The converter parameters are shown in table I.

The primary inductances of the flyback transformer are

solved as shown in (1).

L p1 = L p 2 =

Where:

Lp1 and Lp2

V DC 2 .D 2

. = 170 H

2.Pout .Fs

(1)

- primary inductances,

VDC

- input DC voltage,

- duty cycle,

Pout

- lamp power,

Fs

- switching frequency,

- efficiency.

The secondary inductance LS of the coupling that supplies

the lamp is calculated as shown in (2).

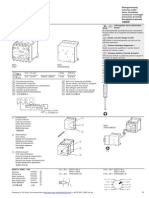

TABLE I

Summarized Parameters

Fig. 5. Gate drives.

206

Parameters

Values

Input Voltage

Output Voltage

Lamp Current

Lamp Frequency

Switching Frequency

Maximum Duty Cycle

VDC = 100 Vdc

Vout = 72 V

Iout = 0,98 A

FLAMP = 400 Hz

Fs = 50 kHz

Dmax = 0,4

Home

9 Congresso Brasileiro de Eletrnica de Potncia - 9th Brazilian Power Electronics Conference

Ls =

Lp

Vin .D

V (1 D )

out

= 204 H

(2)

The output capacitor C is obtained through (3), considering

a 15% lamp voltage ripple in order to avoid the acoustic

resonance phenomenon occurrence.

Iout D

(3)

C=

= 726nF

Fs Vout

Where Iout is the lamp output current and Vout is the lamp

voltage.

It has been built a prototype using the components

described in table II, in order to obtain experimental results

to validate the proposed inverter.

Fig. 7. M1 and M4 gate signals (10V/div).

VII. EXPERIMENTAL RESULTS

In order to prove the viability of the proposed inverter,

some experimental results are shown.

Figure 6 shows the gate signal of the switches M1 and M2,

commutated with a high frequency. The gate signals of M1

and M4 are shown in figure 7 and detailed in figure 8, which

allow the visualization of M1 high frequency operation and

the M4 low frequency commuting.

Figure 9 shows the voltage and current in the LP1 primary

winding of the flyback transformer during a positive half

cycle of the lamp voltage, and figure 10 shows the voltage in

the switch M4 and the current in the secondary side of the

flyback, during the same lamp voltage half cycle.

Finally, figure 11 shows the lamp voltage and current

obtained through the use of the implemented inverter.

TABLE II

Components List

Component

Specification

Lp1 and Lp2 inductances

Ls inductance

Transformer core

M1, M2, M3 e M4 switches

C output capacitor

170H

204H

EE 42/15 (IP12) Thornton

IRFBE30 MOSFET

680nF/250V

Fig. 8. Detail of the M1 and M4 gate signals (10V/div).

Fig. 9. Voltage and current in the primary side of the flyback

transformer (100V/div and 2 A/div ).

Fig. 6. M1 and M2 gate signals (10V/div).

207

Home

9 Congresso Brasileiro de Eletrnica de Potncia - 9th Brazilian Power Electronics Conference

REFERENCES

Fig. 10. Voltage in M4 (100V/div) and current in the secondary side

of the flyback (2 A/div).

Fig. 11. Lamp voltage and current (100V/div. and 1 A/div.).

VIII. CONCLUSION

This paper presents an inverter topology based on a

bidirectional flyback converter combined to an igniter circuit,

which makes possible the HPS lamp ignition through a high

voltage pulse.

The flyback converter supplies the lamp during the

igniting process and in steady state, and makes possible the

integration of the lamp power control and the inverter stage.

The implemented prototype is supplied from a DC voltage

source due to the need for a power factor correction stage in

electronic ballast applied to public lighting systems, because

of the 70W lamp power, according to IEC61000-3-2

standard.

The lamp is supplied with a low frequency symmetrical

square wave, in order to avoid the acoustic resonance

phenomenon occurrence.

208

[1] ELETROBRS Ministrio de Minas e Energia.

Programa

RELUZ.

Available

in:

http://www.eletrobras.com.br/EM_Programas_Reluz/def

ault.asp>. Access: 15 jun, 2006.

[2] E. Deng and S. Cuk, Negative Incremental Impedance

and Stability of Fluorescent Lamps, Applied Power

Electronics Conference and Exposition, vol.2, pp. 10501056, 1997.

[3] Y. S. Youn and G. H. Cho, Regenerative Signal

Amplifying Gate Driver of Self-Excited Electronic

Ballast for High Pressure Sodium (HPS) Lamp, Power

Electronics Specialists Conference, vol.2, pp. 993-998,

1996.

[4] J. de Groot and J. V.Vliet, The High-Pressure Sodium

Lamp, Mac Millan Educational, 1st Edition, London,

1986.

[5] M. J. Jongerius, J. A. Ras and Q. H. Vrehen,

Optogalvanic Detection of Acoustic Resonances in a

High- pressure Sodium Discharge, Journal of Applied

Physics, vol.55, pp. 2685-2692, April 1984.

[6] J. Olsen and W. P. Moskowitz, Detrimental Effect of a

Small Amount of Ripple in a Metal Halide System,

Conference Records of the IEEE IAS Annual Meeting,

vol.3, pp. 1581-1587, 2005.

[7] M. Gulko and S. Ben-Yaakov, A Mhz electronic

ballasts for automotive HID lamps, Power Electronics

Specialists Conference, vol.1, pp.39-45, 1997.

[8] J. O. Duk, J. K. Hee and C. M. Kyu, A digital

controlled electronic ballast using high frequency

modulation method for the metal halide lamp, Power

Electronics Specialists Conference, vol.1, pp. 181-186,

2002.

[9] M. W. Fellows, A Study of the High Intensity

Discharge Lamp Electronic Ballast Interference,

Conference Records of the IEEE IAS Annual Meeting,

vol.2, pp. 1043-1048, 2003.

[10] M. A. C, C. Z. Rezende, D. S. L. Simonetti, J. L. F.

Vieira and P. C. A. Almeida, Microcontrolled electronic

gear for low wattage metal halide (MH) and highpressure sodium (HPS) lamps, Conference Records of

the IEEE IAS Annual Meeting, vol.3, pp. 1863-1868,

2002.

[11] M. Cervi, T. B. Marchesan, A. Campos and R. N. do

Prado, Electronic Ballast to Supply HID Lamps Based

on Differential Connection of Two DC/DC Converters,

Conference Records of the IEEE IAS Annual Meeting,

vol.3, pp. 1081-1085, 2006.

You might also like

- Practical Design of LCCDocument4 pagesPractical Design of LCCkarthiksmartNo ratings yet

- 99 Ipec2 No ImgDocument7 pages99 Ipec2 No ImgNima MahmoudpourNo ratings yet

- 113 Resumo Estendido GEDRE 06Document4 pages113 Resumo Estendido GEDRE 06Muhamad Harya SaputraNo ratings yet

- Circuit Design Criteria Xenon FlasherDocument5 pagesCircuit Design Criteria Xenon FlasherJaime BarraganNo ratings yet

- Electric Arc Furnace Transformer Secondary Circuit CalculationsDocument13 pagesElectric Arc Furnace Transformer Secondary Circuit CalculationsikamelyaastutiNo ratings yet

- Reduction of Electromagnetic Interference in DC-DC Converter Using ChaosDocument4 pagesReduction of Electromagnetic Interference in DC-DC Converter Using ChaosPrasenjit WakodeNo ratings yet

- How Compact Fluorescent Lamps Work - and How To Dim ThemDocument8 pagesHow Compact Fluorescent Lamps Work - and How To Dim ThemMatthew DickersonNo ratings yet

- 2003 MofsetDocument6 pages2003 MofsetGomez CarlierNo ratings yet

- Design and Research of Fiber Optically Powered Rogowski Coil Current TransformerDocument5 pagesDesign and Research of Fiber Optically Powered Rogowski Coil Current TransformerirwintilsonNo ratings yet

- PaperID227 SingerDocument6 pagesPaperID227 Singerrushimunde1212No ratings yet

- Comparative Study of Electromagnetic and Electronic Ballasts - An Assessment On Harmonic EmissionDocument7 pagesComparative Study of Electromagnetic and Electronic Ballasts - An Assessment On Harmonic EmissionAbhishek ThakurNo ratings yet

- Class e Resonant InverterDocument6 pagesClass e Resonant InverterHitesh MehtaNo ratings yet

- Analysis of High Frequency Multi-Phase Multi-Stage Boost ConverterDocument7 pagesAnalysis of High Frequency Multi-Phase Multi-Stage Boost ConverterKaruna MudliyarNo ratings yet

- Dhika Arya NugrahaDocument7 pagesDhika Arya NugrahaGilang Surya AtmajaNo ratings yet

- Convert Id or Z Usado en Lamparas LedDocument7 pagesConvert Id or Z Usado en Lamparas LedLiliany Valderrama MuñozNo ratings yet

- 4 Areen Shankar PDFDocument5 pages4 Areen Shankar PDFAl MtdrsNo ratings yet

- Basic Experimental Study On Helical Antennas of Wireless Power Transfer For Electric Vehicles by Using Magnetic Resonant CouplingsDocument5 pagesBasic Experimental Study On Helical Antennas of Wireless Power Transfer For Electric Vehicles by Using Magnetic Resonant CouplingsjNo ratings yet

- Lighting: Lighting Power Semiconductor Applications Philips SemiconductorsDocument34 pagesLighting: Lighting Power Semiconductor Applications Philips SemiconductorsbarbosiNo ratings yet

- Vs Capacitors RangeDocument24 pagesVs Capacitors RangeThomas Irwin DsouzaNo ratings yet

- 87Document5 pages87vinay kumarNo ratings yet

- Physics-Investigatory-Project-Transformer-4-638 (1) IbrahimDocument21 pagesPhysics-Investigatory-Project-Transformer-4-638 (1) IbrahimBarnaba PadmanabanmNo ratings yet

- A New PWM DimmerDocument5 pagesA New PWM DimmerNeeraj MuralidharanNo ratings yet

- An Electronic Ballast With Power Factor Correction For Fluorescent LampsDocument5 pagesAn Electronic Ballast With Power Factor Correction For Fluorescent Lampsjeeva_ebookNo ratings yet

- Ijireeice3d A Gibi ModelingDocument4 pagesIjireeice3d A Gibi ModelingRaka RidaNo ratings yet

- Ac Contro Llers For High Frequency Induction HeatingDocument5 pagesAc Contro Llers For High Frequency Induction HeatingAmarsingh ChoudharyNo ratings yet

- Emi-Free DC-DC Buck Converter For AerospaceDocument4 pagesEmi-Free DC-DC Buck Converter For AerospaceInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Synthesized High-Frequency Thyristor For Dielectric Barrier Discharge Excimer LampsDocument9 pagesSynthesized High-Frequency Thyristor For Dielectric Barrier Discharge Excimer Lampsdigital2000No ratings yet

- Industrial Training Project ReportDocument15 pagesIndustrial Training Project ReportArshdeep Singh MalhanNo ratings yet

- Effects of Dynamic Reactive Compensation Arc Furnace Operation Characteristics and Its Economic BenefitsDocument6 pagesEffects of Dynamic Reactive Compensation Arc Furnace Operation Characteristics and Its Economic BenefitsAhmed Mohamed HassanNo ratings yet

- Photo Voltaic OperationDocument8 pagesPhoto Voltaic OperationNiharika KashyapNo ratings yet

- Low Power Very High Frequency Switch-Mode Power Supply With 50 V Input and 5 V OutputDocument12 pagesLow Power Very High Frequency Switch-Mode Power Supply With 50 V Input and 5 V OutputaliflailasurumiNo ratings yet

- Wireless Power Transmission 2Document6 pagesWireless Power Transmission 2St. Anne's CET (EEE Department)No ratings yet

- 0 - Physics Investigatory ProjectDocument20 pages0 - Physics Investigatory ProjectBhoomi UpadhyayNo ratings yet

- Srno. ContentDocument10 pagesSrno. ContentAnurag SinghNo ratings yet

- Induction Heating PaperDocument8 pagesInduction Heating PaperSyed Salman AliNo ratings yet

- Wireless Power Transmission Batch7Document7 pagesWireless Power Transmission Batch7St. Anne's CET (EEE Department)No ratings yet

- DocumentsDAB EfficiencyDocument6 pagesDocumentsDAB EfficiencyPiyush MenghaniNo ratings yet

- A Proper Impedance Model of CCFL Applied To The Display UnitDocument4 pagesA Proper Impedance Model of CCFL Applied To The Display UnitinfoseakNo ratings yet

- Energy Contactless Transfer SystemDocument24 pagesEnergy Contactless Transfer SystemParmita NaikNo ratings yet

- Induction CookersDocument5 pagesInduction CookersVăn LinNo ratings yet

- Magnetron AmplifierDocument5 pagesMagnetron AmplifierroccosanNo ratings yet

- Voltage Sag Mitigation in Electric Arc Furnace With D-STATCOMDocument7 pagesVoltage Sag Mitigation in Electric Arc Furnace With D-STATCOMPudhur Kannan ManiNo ratings yet

- Bidirectional LLC Resonant Converter For Energy Storage ApplicationsDocument7 pagesBidirectional LLC Resonant Converter For Energy Storage ApplicationsRodrigo MesquitaNo ratings yet

- Implementation of Analysis and Design of Forward Converter With Energy Regenerative Snubber PDFDocument8 pagesImplementation of Analysis and Design of Forward Converter With Energy Regenerative Snubber PDFKamal KamalgNo ratings yet

- Harmonics From Compact Fluorescent Lamps: R. AllingDocument5 pagesHarmonics From Compact Fluorescent Lamps: R. AllingKoushik SasmalNo ratings yet

- Design of A LLC Resonant Converter For Powering A Pem Electrolyzerrenewable Energy and Power Quality JournalDocument7 pagesDesign of A LLC Resonant Converter For Powering A Pem Electrolyzerrenewable Energy and Power Quality JournalNicolás MelladoNo ratings yet

- Impulse Electromagnetic Interference GeneratorDocument4 pagesImpulse Electromagnetic Interference GeneratorManish BairagiNo ratings yet

- Impact of Variable Switching Frequency Over Power Loss On Converter TopologiesDocument6 pagesImpact of Variable Switching Frequency Over Power Loss On Converter TopologiesskrtamilNo ratings yet

- Design of Zeta Converter Based Electronic Ballast For Fluorescent LampsDocument7 pagesDesign of Zeta Converter Based Electronic Ballast For Fluorescent LampscamiloNo ratings yet

- Analysis of Power Loss and Improved Simulation Method of A High Frequency Dual-Buck Full-Bridge InverterDocument18 pagesAnalysis of Power Loss and Improved Simulation Method of A High Frequency Dual-Buck Full-Bridge InverteranujNo ratings yet

- Compact Florescent Lamp-2Document5 pagesCompact Florescent Lamp-2AdhiNo ratings yet

- By Sumit Final Print Out 3Document47 pagesBy Sumit Final Print Out 3Jitendra DubeyNo ratings yet

- A New Model of Bipolar Power Supplies For Lnls Steering Magnets Using Full-Bridge TopologyDocument5 pagesA New Model of Bipolar Power Supplies For Lnls Steering Magnets Using Full-Bridge TopologyGustavo LimaNo ratings yet

- Application Notes Discharge CircuitsDocument14 pagesApplication Notes Discharge CircuitsejmelchiorsNo ratings yet

- Rectangular To Circular Waveguide Converter For Microwave Devices CharacterizationDocument10 pagesRectangular To Circular Waveguide Converter For Microwave Devices Characterizationjalmeida88No ratings yet

- Modelling PDFDocument8 pagesModelling PDFhewitt isaacNo ratings yet

- Generation of Energy Usig MagnetsDocument26 pagesGeneration of Energy Usig MagnetsSridhar PatilNo ratings yet

- Thong So ESPDocument6 pagesThong So ESPduongthetinhqbNo ratings yet

- Globalcap EuropgapDocument26 pagesGlobalcap Europgapgustavo5No ratings yet

- Minicargador 246D A 299D2 Plano Electrico 2017 SISDocument6 pagesMinicargador 246D A 299D2 Plano Electrico 2017 SISFabrizio Jesus Morales SalirrosasNo ratings yet

- Oxidation and ReductionDocument12 pagesOxidation and Reductionmuhsin94No ratings yet

- Flame PhotometerDocument2 pagesFlame PhotometerDebleena ChakrabortyNo ratings yet

- Brexco - Emulinit 2 - TDS - 2023Document1 pageBrexco - Emulinit 2 - TDS - 2023brexcoNo ratings yet

- SPN 157 CircuitDocument5 pagesSPN 157 Circuitabdelrhmangbr86No ratings yet

- Test Report: Physical Test Conductor: (Class-5)Document1 pageTest Report: Physical Test Conductor: (Class-5)jamilNo ratings yet

- Catalogo Pararrayo - IndelDocument9 pagesCatalogo Pararrayo - IndelYonatan Pallin YalleNo ratings yet

- Fish Finder EagleDocument40 pagesFish Finder EagleLarry MilamNo ratings yet

- Cylinder Liner - Production Recommendation 0742048 3Document17 pagesCylinder Liner - Production Recommendation 0742048 3thiha aungNo ratings yet

- Thermal Mass For Cool Temperate Climates: Australian Solar Energy SocietyDocument4 pagesThermal Mass For Cool Temperate Climates: Australian Solar Energy SocietyEmi MonarNo ratings yet

- 5063-E-EPC-PTR-DE-C-V-002 - Temperature Rise Calculation Cat IDocument5 pages5063-E-EPC-PTR-DE-C-V-002 - Temperature Rise Calculation Cat ISUSOVAN BISWASNo ratings yet

- Fuel Dilution of In-Service Lubricants Using Surface Acoustic Wave SensingDocument6 pagesFuel Dilution of In-Service Lubricants Using Surface Acoustic Wave SensingNabeel H. Al-SaighNo ratings yet

- Parts Catalog: Outdoor UnitDocument8 pagesParts Catalog: Outdoor UnitMirali HeydariNo ratings yet

- Usa ST 036 072 PK Motor OnlyDocument4 pagesUsa ST 036 072 PK Motor Onlyjmpateiro1985No ratings yet

- Freego Manual de OperacionDocument42 pagesFreego Manual de OperacionCarlos LopezNo ratings yet

- Paper Presentation On Green BuildingDocument14 pagesPaper Presentation On Green BuildingSurya VasuNo ratings yet

- Biodata: Phonepe - India'S Payment AppDocument5 pagesBiodata: Phonepe - India'S Payment AppSrinivas RSPNo ratings yet

- Electro ChemDocument11 pagesElectro ChemAshok PradhanNo ratings yet

- Final Report,,,ChevronDocument21 pagesFinal Report,,,ChevronemonenjoyNo ratings yet

- Potential Design Solutions Fired Equipment (11) No. Operational Deviations Failure Scenarios Inherently Safer/Passive Active ProceduralDocument10 pagesPotential Design Solutions Fired Equipment (11) No. Operational Deviations Failure Scenarios Inherently Safer/Passive Active ProceduralCharls JamesNo ratings yet

- Internal Wall and PartitionDocument2 pagesInternal Wall and PartitionteeyuanNo ratings yet

- 31st Ethylene Producers Conference 2019: New Orleans, Louisiana, USA 31 March - 4 April 2019Document5 pages31st Ethylene Producers Conference 2019: New Orleans, Louisiana, USA 31 March - 4 April 2019Moca PhoenixNo ratings yet

- Caso1 - Solar PV Analisis For A Power PlantDocument3 pagesCaso1 - Solar PV Analisis For A Power PlantAlexander Valencia Valencia RendonNo ratings yet

- Pompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsDocument11 pagesPompa Dari Embung Ke Bak Sirkulasi / Penjernih: ContentsewamihawkNo ratings yet

- Rebo Use DP 2018 1801 PDFDocument95 pagesRebo Use DP 2018 1801 PDFMd. Tanvir Ahamed TuhinNo ratings yet

- KEMETDocument64 pagesKEMETBrunoNo ratings yet

- Formal Interpretations 2019Document18 pagesFormal Interpretations 2019sgttomasNo ratings yet

- Eaton Dilet 70Document2 pagesEaton Dilet 70chamberlanesNo ratings yet

- Osha ProjectDocument24 pagesOsha Projectsandhya kondapurNo ratings yet