Professional Documents

Culture Documents

Valvula de Purga para Caldera SerieVP-2013

Valvula de Purga para Caldera SerieVP-2013

Uploaded by

Renzo TartariniCopyright:

Available Formats

You might also like

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pilot Operated Pressure Regulator 6" 25P: Typical ApplicationsDocument2 pagesPilot Operated Pressure Regulator 6" 25P: Typical ApplicationsMatias MancillaNo ratings yet

- 25P 6inchDocument2 pages25P 6inchNguyen Xuan QuangNo ratings yet

- ADocument64 pagesAjuanca_eduNo ratings yet

- Valve Spirax Sarco 25P Ti-3-015-UsDocument2 pagesValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- Válvula de SeguridadDocument8 pagesVálvula de Seguridadmark_59No ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- E 90 21 - FireDocument2 pagesE 90 21 - Firepequenita34No ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocument5 pagesComeval Cast Steel Gate Valve ANSI 150 PDFblizanacNo ratings yet

- Kitz Stainless Steel Catalog NewDocument58 pagesKitz Stainless Steel Catalog NewFerri HermawanNo ratings yet

- CLAVAL Pressure Reducing ValveDocument4 pagesCLAVAL Pressure Reducing ValvermgatocNo ratings yet

- 31261Document7 pages31261Athirah Amer HamzahNo ratings yet

- PRV SizingDocument4 pagesPRV SizingTiffany CombsNo ratings yet

- Ansi-Valve Body Material SelectionDocument3 pagesAnsi-Valve Body Material SelectionsatthukotienNo ratings yet

- 90-01 Reductora de Presion Cla-ValDocument4 pages90-01 Reductora de Presion Cla-ValPablo SolisNo ratings yet

- Valve Manson PDFDocument37 pagesValve Manson PDFRogerNo ratings yet

- 05 Ok Shell Test Pressures Refer To API 598Document0 pages05 Ok Shell Test Pressures Refer To API 598ZoebairNo ratings yet

- 07 - Valves - 1Document8 pages07 - Valves - 1yusuf.yuzuakNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- Piping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015Document37 pagesPiping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015shameer_febiNo ratings yet

- Valvula ContraincendioDocument6 pagesValvula ContraincendiowidNo ratings yet

- L&T GateGlobe&CheckValves-API 600Document31 pagesL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- Ansi Classes Body Material SelectionDocument3 pagesAnsi Classes Body Material SelectionManh Tien HoangNo ratings yet

- SECTION 15100 ValvesDocument10 pagesSECTION 15100 ValvesintequabNo ratings yet

- 150 26-EG1-Engineering Guide-Model YCWL Water-Cooled Scroll Liquid Chiller Style A 60 HZDocument74 pages150 26-EG1-Engineering Guide-Model YCWL Water-Cooled Scroll Liquid Chiller Style A 60 HZJose MeraNo ratings yet

- CS Series Float & Thermostatic Steam TrapsDocument2 pagesCS Series Float & Thermostatic Steam TrapsGustavo Garces GuerreroNo ratings yet

- E 50 49 - FireDocument2 pagesE 50 49 - FireJulio C. Sivira CallejaNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- AAP S19 Check Valves & Strainers SDocument13 pagesAAP S19 Check Valves & Strainers SAppleuk SudarNo ratings yet

- Valve Standards ANSI BS APIDocument6 pagesValve Standards ANSI BS APInaveenbaskaran1989No ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- E X52eDocument4 pagesE X52eTommy DavisNo ratings yet

- L&T GateGlobe&CheckValves-API 600Document24 pagesL&T GateGlobe&CheckValves-API 600Yang Gul LeeNo ratings yet

- Valves: Ail Cast Steel Gate, Globe & CheckDocument32 pagesValves: Ail Cast Steel Gate, Globe & CheckParveen KohliNo ratings yet

- Astm A529 1972Document5 pagesAstm A529 1972dharlanuctcom0% (1)

- Valve Rating Per ASME B16.34Document16 pagesValve Rating Per ASME B16.34uniqueel4136No ratings yet

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- Yidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfDocument2 pagesYidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfTravelergr KallogiroyNo ratings yet

- Milliken AWWA Swing Check ValveDocument8 pagesMilliken AWWA Swing Check ValveDiego Fernando PerdomoNo ratings yet

- CVF-SVF - BaumannDocument16 pagesCVF-SVF - BaumannMwila Chamba100% (1)

- 08 - SpeckDocument5 pages08 - SpeckSezer CetinNo ratings yet

- VALVULAS - Series2200, NORRISEALDocument8 pagesVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNo ratings yet

- Valves For Steam ServiceDocument17 pagesValves For Steam ServiceqaiserNo ratings yet

- Triple Duty 1Document6 pagesTriple Duty 1Diana Andreina Linarez ContrerasNo ratings yet

- Main Relief ValveDocument2 pagesMain Relief ValveJesseNo ratings yet

- Regulatory Standards For Gate ValvesDocument1 pageRegulatory Standards For Gate ValvesRohin Venu100% (1)

- Compuerta Fierro Fundido (WWW - Vaporisa.cl)Document2 pagesCompuerta Fierro Fundido (WWW - Vaporisa.cl)Luis Gutiérrez AlvarezNo ratings yet

- Dartmouth College Design January 3, 2012 & Construction GuidelinesDocument6 pagesDartmouth College Design January 3, 2012 & Construction GuidelinesSalman AkramNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Design and Simulation of UART Serial Communication Module Based On VHDLDocument4 pagesDesign and Simulation of UART Serial Communication Module Based On VHDLJohn RamaraoNo ratings yet

- Burg Eltz PPDocument10 pagesBurg Eltz PPmegacahsNo ratings yet

- Aashto CM 4 PDFDocument234 pagesAashto CM 4 PDFsidiq7No ratings yet

- Pro VK Lea enDocument28 pagesPro VK Lea enmacariegratielaNo ratings yet

- MSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001Document6 pagesMSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001vladmir18No ratings yet

- Keyboard Shortcuts For Visio VisioDocument20 pagesKeyboard Shortcuts For Visio Visiock_peyNo ratings yet

- Brentwood PDFDocument52 pagesBrentwood PDFlince1936No ratings yet

- Configuring ODI External User AuthenticationDocument18 pagesConfiguring ODI External User AuthenticationMurugan RajaNo ratings yet

- X Domain Setup For BirthrightDocument3 pagesX Domain Setup For BirthrightBarbie TuricNo ratings yet

- Unit 7Document25 pagesUnit 7rameshbabu_1979No ratings yet

- Module - 4 Vmware Vcenter ServerDocument33 pagesModule - 4 Vmware Vcenter ServerIjazKhanNo ratings yet

- Upgrading Autonomous Cisco Aironet Access Points To Lightweight Mode - Cisco SysDocument2 pagesUpgrading Autonomous Cisco Aironet Access Points To Lightweight Mode - Cisco SysLan WanNo ratings yet

- Mtech 2 Sem Advanced Reinforced Concrete Design Cepc202 2019Document2 pagesMtech 2 Sem Advanced Reinforced Concrete Design Cepc202 2019AMITNo ratings yet

- CFD Analysis of Ventilation System For An Engine Room: December 2016Document13 pagesCFD Analysis of Ventilation System For An Engine Room: December 2016Vincent RogNo ratings yet

- Vanity FareDocument14 pagesVanity Farepickles4ukNo ratings yet

- BuildingDocument28 pagesBuildingGnetum GnemonNo ratings yet

- IIR CustomersDocument85 pagesIIR Customersnuthakki123100% (1)

- Technical Civil QuestionsDocument4 pagesTechnical Civil QuestionsVivek SharmaNo ratings yet

- 1.5.1.1 Lab - Researching Network Attacks and Security Audit Tools (Norshafira Binti Samsudin - Sx129616CSRF04)Document4 pages1.5.1.1 Lab - Researching Network Attacks and Security Audit Tools (Norshafira Binti Samsudin - Sx129616CSRF04)Zuraifah RahamanNo ratings yet

- Centre Georges PompidouDocument4 pagesCentre Georges PompidouAsurathyNo ratings yet

- Grey Iron CastingsDocument3 pagesGrey Iron CastingsAnonymous NbBSlJaODNo ratings yet

- The Central AsiaDocument52 pagesThe Central AsiaSrashti singhNo ratings yet

- Grid GuideDocument13 pagesGrid Guidedatadisk10No ratings yet

- (Elearnica - Ir) - Experimental Measurements and CFD Simulation of A Ground Source Heat ExchanDocument9 pages(Elearnica - Ir) - Experimental Measurements and CFD Simulation of A Ground Source Heat ExchanSeyedNo ratings yet

- BPA CPS OverviewDocument14 pagesBPA CPS OverviewChandan Mukherjee100% (1)

- Assignment Islamic ArchitectureDocument6 pagesAssignment Islamic Architecturebakhtawar soniaNo ratings yet

- Beko DW603 - IB - TC PDFDocument32 pagesBeko DW603 - IB - TC PDFABW35No ratings yet

- TMT Company Profile AgroDocument34 pagesTMT Company Profile AgroahmedNo ratings yet

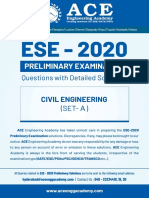

- ACE-ACADEMY-CE-SET-A-2020 (Gate2016.info)Document32 pagesACE-ACADEMY-CE-SET-A-2020 (Gate2016.info)Ajay GoelNo ratings yet

Valvula de Purga para Caldera SerieVP-2013

Valvula de Purga para Caldera SerieVP-2013

Uploaded by

Renzo TartariniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula de Purga para Caldera SerieVP-2013

Valvula de Purga para Caldera SerieVP-2013

Uploaded by

Renzo TartariniCopyright:

Available Formats

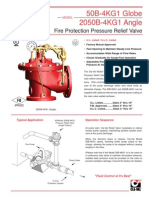

Series VP

Boiler Blowdown Valve

Series VP Blowdown Valves

Series VP

Construction Materials

10

1

4

5

Table 1

12

9

6

Description

1

1

1

1

1

1

1

1

1

1

Var.

Var.

1

1

Inlet body

Outlet body

Disc

Seat

Disc spring

Disc holder

Stem

Stem spring

Stem pivot

Handle

Body bolt

Body nut

Body gasket

Stem packing

1

2

3

3A

4

5

6

7

8

9

10

11

12

13

3

13

Item Qy

11

Class 300

Seat Detail

3A

Class 250

Material

ASTM A126 WCB

ASTM A126 WCB

AISI 420 Hard.

Outlet Body Material

AISI 302

ASTM A126 WCB

Brass

AISI 302

Carbon Steel

ASTM A536

Steel Grade 2

Steel Grade 2

108AF Aramid Fiber

Silicone

Class 300

ASTM A216 WCB

ASTM A216 WCB

AISI 420 Hard.

AISI 420 Hard. (Insert)

AISI 302

ASTM A126 WCB

AISI 304

AISI 302

Carbon Steel

ASTM A536

Steel Grade 8

Steel Grade 2H

108AF Aramid Fiber

Silicone

Operation

Straight-through flow .

Line pressure and heavy conical spring hold the disc firmly against the body seat, sealing off the flow .

When operated, the disc slides across the outlet body seat, pushing harmful boiler scale away , wiping clean

the precision lapped surface.

Pressure Ratings

Table 2 shows operating pressure ratings for each valve configuration.

See Table 4 to verify that selected valve meets criteria for your boiler application, according to current

ASME Boiler Piping codes.

Table 2

Quick

Opening

Max.

Blow-Off

Service

(psig)

250

200

300

485

Slow

Opening

Primary

Service

Rating

250

200

300

485

Model

VP250-QO

VP250F -QO

VP300-QO

VP300F -QO

VP250-SO

VP250F -SO

VP300-SO

VP300F -SO

End

Type

SCR

FLG

SCR

FLG

SCR

FLG

SCR

FLG

Body

Material

Cast Iron

Cast Iron

Steel

Steel

Cast Iron

Cast Iron

Steel

Steel

Applications acording to CRN, the Maximum allowed working pressure is 100 PSI.

Maximum Operating Pressures - Chart shows

suggested Operating Pressure Limits (psig) for

easy operation with standard lever. Longer levers

are available for higher pressure upon request.

1"

1-1/4"

1-1/2"

2"

2-1/2"

250

250

400

400

250

250

400

400

250

250

300

300

250

250

300

300

200

200

200

200

200

200

200

200

200

200

200

200

200

200

200

200

100

100

100

100

100

100

100

100

Series VP Blowdown Valves

Series VP

ASME / ANSI Requirements for Boiler Blowdown

Boiler blowdown valve use is regulated by ASME Code for Power Piping B31.1 - 2004 (most current version). The following excerpts

are provided for guidance only. The current codes in force, at the time of selection, should always be checked for complete details.

ASME Code for Pressure Piping

B31.1 2004 (Revision of ASME B31.1 2001)

Paragraph 122.1.7

The minimum pressure rating for all valves and fittings in steam, feedwater, blowoff and miscellaneous piping shall be equal to the

pressure and temperature specified for the connected piping on the side that has the higher pressure, except that in no case shall the

pressure be less than 100 psig, and for pressures not exceeding 100 psig in feedwater and blowoff service, the valves and fittings

shall be equal at least to the requirements of the ASME standards for Class 125 cast iron or Class 150 steel.

Section C

(C.4) For all boilers [except electric steam boilers having a normal water content not exceeding 100 gal, traction purpose, and

portable steam boilers; see (C.11) and (C.12) below] with allowable working pressure in excess of 100 psig, each bottom

blowoff pipe shall have two slow-opening valves, or one quick-opening valve or cock, at the boiler nozzle followed by a

slow-opening valve. All valves shall comply with the requirements of (C.5) and (C.6) below.

(C.5) When the value of P required by para. 122.1.4(A.1) does not exceed 250 psig, the valves or cocks shall be of bronze, cast

iron, ductile iron or steel. The valves or cocks, if of cast iron, shall not exceed NPS 2-1/2 and shall meet the requirements of

the applicable ASME standard for Class 250, as given in Table 126.1, and if of bronze, steel, or ductile iron construction,

shall meet the requirements of the applicable standards.

(C.6) When the value of P required by para. 122.1.4(A.1) is higher than 250 psig, the valves or cocks shall be of steel

construction equal at least to the requirements of Class 300 of the applicable ASME standard. The minimum pressure

rating shall be equal to the value of P required by para. 122.1.4(A.1).

Table 4

Boiler Type

Fig. 1

For traction or

portable boilers

Fig. 2

Fig. 3

Required

Installation

Piping Components Design

Pressure P (psig)

Required

Installation

< 250

Class 250

Blowdown

Valve Rating

Fig. 1 or 3

> 250

Class 300

Boilers with:

> 100 PSI MAWP

> 100 Gal.

Capacity

< 250

Class 250

> 250

Class 300

Electric boilers,

portable or

traction boilers.

< 250

Class 250

> 250

Class 300

Fig. 2

Fig. 3

Series VP Blowdown Valves

Series VP

Dimensions

Quick Opening - QO

Slow Opening - SO

HF

HF

H

Dimensions (in) and Approximate Weights (lbs)

Quick Opening - QO

Sizes

1"

1

1

2"

2

H (FLG)

HF

(SCR) 250# 300#

7,5

7,5

8,9

9

10,5

12

12

11,6

12

23

3,6

3,6

4,5

4,6

5,2

7,9

7,9

8,9

9

12

Slow Opening - SO

Dimensions (in)

Weights (lbs)

Dimensions (in)

SCR

FLG

250# 300# 250# 300#

13

14

23

28

45

Table 3

18

19

31

34

49

24

24

34

44

69

20

26

42

46

72

Weights (lbs)

L

H (FLG)

HF

SCR

FLG

(SCR) 250# 300# SHUT OPEN 250# 300# 250#

- 300#

7,5

33

39

3,6

7,9 14,9 12,6 27

3,6

4,5

4,6

5,2

7,5

8,9

9

10,5

7,9

8,9

9

12

14,9

15,5

15,4

17,4

12,6

12,8

12,9

14,5

28

38

42

61

34

45

48

65

48

57

86

41

57

60

90

Typical Installation

Boiler Floor

Guidelines

Install valve making sure the inlet side is as marked.

Provide enough lever clearance with boiler body to

ensure easy access and full open-close operation;

check dimension

L above.

Install valve with either thread sealant or appropriate

flange gaskets.

Series VP Blowdown Valves

Series VP

Ordering Code

VP

Size

Class Rating

Class

Connections

Type

Code

Threaded

T

Flanged

F

Code

250 #

250

300 #

300

Operation

Type

Code

Quick Opening

QO

Slow Opening

SO

NPT / Flanged

Code

1"

100

1-1/4"

125

1-1/2"

150

2"

200

2-1/2"

250

Spare Parts Ordering Codes

2

Table 5

S p a r e P a r ts S e ts

Size

1" & 1-1/4"

1-1/2" & 2"

2-1/2"

Class

250

300

250

300

250

300

Stem Packing &

Body Gasket Set

Disc Spring

Set

Stem Spring

Set

Disc

Stem

VP-SP-01-1

VP-SP-02-1

VP-SP-03-1

VP-SP-04-1

VP-SP-01-2

VP-SP-02-2

VP-SP-03-2

VP-SP-04-2

VP-SP-01-3

VP-SP-02-3

VP-SP-03-3

VP-SP-04-3

VP-SP-05-1

VP-SP-05-2

VP-SP-05-3

VP-SP-05-4

VP-SP-05-5

VP-SP-05-6

Series VP Blowdown Valves

Series VP

Other Tecval Products

Series 800 Regulators

Series 810

Direct Acting

Series 820

Direct Acting

Series 850

Pillot Acting

Series 700 Safety Relief Valves

Series 750

Bronze-Safety

Series 760

Stainless-Safety Relief

Series 770

Flanged - Safety

Safety

ventas@tecvalsas.com

Regulation

Control

www.tecvalonline.com

You might also like

- Forged Steel Valves PDFDocument12 pagesForged Steel Valves PDFDiwakar NigamNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pilot Operated Pressure Regulator 6" 25P: Typical ApplicationsDocument2 pagesPilot Operated Pressure Regulator 6" 25P: Typical ApplicationsMatias MancillaNo ratings yet

- 25P 6inchDocument2 pages25P 6inchNguyen Xuan QuangNo ratings yet

- ADocument64 pagesAjuanca_eduNo ratings yet

- Valve Spirax Sarco 25P Ti-3-015-UsDocument2 pagesValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- Válvula de SeguridadDocument8 pagesVálvula de Seguridadmark_59No ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- E 90 21 - FireDocument2 pagesE 90 21 - Firepequenita34No ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Comeval Cast Steel Gate Valve ANSI 150 PDFDocument5 pagesComeval Cast Steel Gate Valve ANSI 150 PDFblizanacNo ratings yet

- Kitz Stainless Steel Catalog NewDocument58 pagesKitz Stainless Steel Catalog NewFerri HermawanNo ratings yet

- CLAVAL Pressure Reducing ValveDocument4 pagesCLAVAL Pressure Reducing ValvermgatocNo ratings yet

- 31261Document7 pages31261Athirah Amer HamzahNo ratings yet

- PRV SizingDocument4 pagesPRV SizingTiffany CombsNo ratings yet

- Ansi-Valve Body Material SelectionDocument3 pagesAnsi-Valve Body Material SelectionsatthukotienNo ratings yet

- 90-01 Reductora de Presion Cla-ValDocument4 pages90-01 Reductora de Presion Cla-ValPablo SolisNo ratings yet

- Valve Manson PDFDocument37 pagesValve Manson PDFRogerNo ratings yet

- 05 Ok Shell Test Pressures Refer To API 598Document0 pages05 Ok Shell Test Pressures Refer To API 598ZoebairNo ratings yet

- 07 - Valves - 1Document8 pages07 - Valves - 1yusuf.yuzuakNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- Piping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015Document37 pagesPiping Codes, Valve Standards and Ball Valve Selection: Ron Manson, March 2015shameer_febiNo ratings yet

- Valvula ContraincendioDocument6 pagesValvula ContraincendiowidNo ratings yet

- L&T GateGlobe&CheckValves-API 600Document31 pagesL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- Ansi Classes Body Material SelectionDocument3 pagesAnsi Classes Body Material SelectionManh Tien HoangNo ratings yet

- SECTION 15100 ValvesDocument10 pagesSECTION 15100 ValvesintequabNo ratings yet

- 150 26-EG1-Engineering Guide-Model YCWL Water-Cooled Scroll Liquid Chiller Style A 60 HZDocument74 pages150 26-EG1-Engineering Guide-Model YCWL Water-Cooled Scroll Liquid Chiller Style A 60 HZJose MeraNo ratings yet

- CS Series Float & Thermostatic Steam TrapsDocument2 pagesCS Series Float & Thermostatic Steam TrapsGustavo Garces GuerreroNo ratings yet

- E 50 49 - FireDocument2 pagesE 50 49 - FireJulio C. Sivira CallejaNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- AAP S19 Check Valves & Strainers SDocument13 pagesAAP S19 Check Valves & Strainers SAppleuk SudarNo ratings yet

- Valve Standards ANSI BS APIDocument6 pagesValve Standards ANSI BS APInaveenbaskaran1989No ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- E X52eDocument4 pagesE X52eTommy DavisNo ratings yet

- L&T GateGlobe&CheckValves-API 600Document24 pagesL&T GateGlobe&CheckValves-API 600Yang Gul LeeNo ratings yet

- Valves: Ail Cast Steel Gate, Globe & CheckDocument32 pagesValves: Ail Cast Steel Gate, Globe & CheckParveen KohliNo ratings yet

- Astm A529 1972Document5 pagesAstm A529 1972dharlanuctcom0% (1)

- Valve Rating Per ASME B16.34Document16 pagesValve Rating Per ASME B16.34uniqueel4136No ratings yet

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- Yidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfDocument2 pagesYidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfTravelergr KallogiroyNo ratings yet

- Milliken AWWA Swing Check ValveDocument8 pagesMilliken AWWA Swing Check ValveDiego Fernando PerdomoNo ratings yet

- CVF-SVF - BaumannDocument16 pagesCVF-SVF - BaumannMwila Chamba100% (1)

- 08 - SpeckDocument5 pages08 - SpeckSezer CetinNo ratings yet

- VALVULAS - Series2200, NORRISEALDocument8 pagesVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNo ratings yet

- Valves For Steam ServiceDocument17 pagesValves For Steam ServiceqaiserNo ratings yet

- Triple Duty 1Document6 pagesTriple Duty 1Diana Andreina Linarez ContrerasNo ratings yet

- Main Relief ValveDocument2 pagesMain Relief ValveJesseNo ratings yet

- Regulatory Standards For Gate ValvesDocument1 pageRegulatory Standards For Gate ValvesRohin Venu100% (1)

- Compuerta Fierro Fundido (WWW - Vaporisa.cl)Document2 pagesCompuerta Fierro Fundido (WWW - Vaporisa.cl)Luis Gutiérrez AlvarezNo ratings yet

- Dartmouth College Design January 3, 2012 & Construction GuidelinesDocument6 pagesDartmouth College Design January 3, 2012 & Construction GuidelinesSalman AkramNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Design and Simulation of UART Serial Communication Module Based On VHDLDocument4 pagesDesign and Simulation of UART Serial Communication Module Based On VHDLJohn RamaraoNo ratings yet

- Burg Eltz PPDocument10 pagesBurg Eltz PPmegacahsNo ratings yet

- Aashto CM 4 PDFDocument234 pagesAashto CM 4 PDFsidiq7No ratings yet

- Pro VK Lea enDocument28 pagesPro VK Lea enmacariegratielaNo ratings yet

- MSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001Document6 pagesMSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001vladmir18No ratings yet

- Keyboard Shortcuts For Visio VisioDocument20 pagesKeyboard Shortcuts For Visio Visiock_peyNo ratings yet

- Brentwood PDFDocument52 pagesBrentwood PDFlince1936No ratings yet

- Configuring ODI External User AuthenticationDocument18 pagesConfiguring ODI External User AuthenticationMurugan RajaNo ratings yet

- X Domain Setup For BirthrightDocument3 pagesX Domain Setup For BirthrightBarbie TuricNo ratings yet

- Unit 7Document25 pagesUnit 7rameshbabu_1979No ratings yet

- Module - 4 Vmware Vcenter ServerDocument33 pagesModule - 4 Vmware Vcenter ServerIjazKhanNo ratings yet

- Upgrading Autonomous Cisco Aironet Access Points To Lightweight Mode - Cisco SysDocument2 pagesUpgrading Autonomous Cisco Aironet Access Points To Lightweight Mode - Cisco SysLan WanNo ratings yet

- Mtech 2 Sem Advanced Reinforced Concrete Design Cepc202 2019Document2 pagesMtech 2 Sem Advanced Reinforced Concrete Design Cepc202 2019AMITNo ratings yet

- CFD Analysis of Ventilation System For An Engine Room: December 2016Document13 pagesCFD Analysis of Ventilation System For An Engine Room: December 2016Vincent RogNo ratings yet

- Vanity FareDocument14 pagesVanity Farepickles4ukNo ratings yet

- BuildingDocument28 pagesBuildingGnetum GnemonNo ratings yet

- IIR CustomersDocument85 pagesIIR Customersnuthakki123100% (1)

- Technical Civil QuestionsDocument4 pagesTechnical Civil QuestionsVivek SharmaNo ratings yet

- 1.5.1.1 Lab - Researching Network Attacks and Security Audit Tools (Norshafira Binti Samsudin - Sx129616CSRF04)Document4 pages1.5.1.1 Lab - Researching Network Attacks and Security Audit Tools (Norshafira Binti Samsudin - Sx129616CSRF04)Zuraifah RahamanNo ratings yet

- Centre Georges PompidouDocument4 pagesCentre Georges PompidouAsurathyNo ratings yet

- Grey Iron CastingsDocument3 pagesGrey Iron CastingsAnonymous NbBSlJaODNo ratings yet

- The Central AsiaDocument52 pagesThe Central AsiaSrashti singhNo ratings yet

- Grid GuideDocument13 pagesGrid Guidedatadisk10No ratings yet

- (Elearnica - Ir) - Experimental Measurements and CFD Simulation of A Ground Source Heat ExchanDocument9 pages(Elearnica - Ir) - Experimental Measurements and CFD Simulation of A Ground Source Heat ExchanSeyedNo ratings yet

- BPA CPS OverviewDocument14 pagesBPA CPS OverviewChandan Mukherjee100% (1)

- Assignment Islamic ArchitectureDocument6 pagesAssignment Islamic Architecturebakhtawar soniaNo ratings yet

- Beko DW603 - IB - TC PDFDocument32 pagesBeko DW603 - IB - TC PDFABW35No ratings yet

- TMT Company Profile AgroDocument34 pagesTMT Company Profile AgroahmedNo ratings yet

- ACE-ACADEMY-CE-SET-A-2020 (Gate2016.info)Document32 pagesACE-ACADEMY-CE-SET-A-2020 (Gate2016.info)Ajay GoelNo ratings yet