Professional Documents

Culture Documents

Report On Organizational Study at Popular Industries1 - Intro

Report On Organizational Study at Popular Industries1 - Intro

Uploaded by

anjuCopyright:

Available Formats

You might also like

- Training and Development of HDFC BankDocument102 pagesTraining and Development of HDFC BankMaster Printers100% (1)

- HR Company ProfileDocument8 pagesHR Company ProfileSapri SuhailiNo ratings yet

- AJISH ProjectDocument70 pagesAJISH ProjectveeerajNo ratings yet

- Training and Development Final Project / Reserch ReportDocument87 pagesTraining and Development Final Project / Reserch ReportGayan Laknatha AriyarathnaNo ratings yet

- 14 Chapter Vi (Findings, Suggestions and Recommendations)Document2 pages14 Chapter Vi (Findings, Suggestions and Recommendations)hari teja100% (1)

- Merriiboy Organizational StudyDocument60 pagesMerriiboy Organizational Studynoel ben aliasNo ratings yet

- School Library Development PlanDocument165 pagesSchool Library Development PlanLuxe Griffin100% (3)

- Case Study 6 Merton Healthcare TrustDocument2 pagesCase Study 6 Merton Healthcare TrustWylmer Ann Dionisio100% (1)

- Appriasal Letter Format-OriginalDocument1 pageAppriasal Letter Format-Originalvenustaffing100% (1)

- Popular Industries: EdappallyDocument79 pagesPopular Industries: EdappallyAlex John MadavanaNo ratings yet

- Dissertation ReportDocument57 pagesDissertation ReportLikhiteapurvaNo ratings yet

- Training and Development Mba ProjectDocument81 pagesTraining and Development Mba ProjecteswarNo ratings yet

- Job Satisfaction ProjectDocument116 pagesJob Satisfaction Projectmona2ankur100% (3)

- An Organisation Study of Gasha Steels Industry PVTDocument73 pagesAn Organisation Study of Gasha Steels Industry PVTdeepakparlil75% (4)

- ROHITDocument66 pagesROHITRohit John MambalilNo ratings yet

- A Study On Quality of Worklife of Employees With Special Reference To Ksfe, ThrissurDocument88 pagesA Study On Quality of Worklife of Employees With Special Reference To Ksfe, ThrissurUma N100% (1)

- A Study On Employee Welfare Measure at Vimpro Tech PuducherryDocument3 pagesA Study On Employee Welfare Measure at Vimpro Tech PuducherryEditor IJTSRDNo ratings yet

- Project Report On Employee SatisfactionDocument80 pagesProject Report On Employee Satisfactionshreya vatsNo ratings yet

- Training and Development On BSNL SurveyDocument59 pagesTraining and Development On BSNL SurveySHarda BHuyanNo ratings yet

- 19 Recruitment and Selection, KpmpduDocument69 pages19 Recruitment and Selection, KpmpduRAKESHNo ratings yet

- Executive SummaryDocument2 pagesExecutive SummaryMeenakshi Sharma100% (1)

- Analyzing Levels of Employee Satisfaction - LG Electronics-2019Document12 pagesAnalyzing Levels of Employee Satisfaction - LG Electronics-2019MohmmedKhayyum100% (1)

- ConclusionDocument2 pagesConclusionAhmad Ali50% (2)

- Training and DevelopmentDocument62 pagesTraining and Developmentsanjayduttpandey3067% (3)

- Labour Welfare Measures in Neyveli Lignite Corporation Limited NeyveliDocument4 pagesLabour Welfare Measures in Neyveli Lignite Corporation Limited NeyveliDR K DHAMODHARANNo ratings yet

- "EMPLOYEES ATTITUDE TOWARDS MONITORY AND NON-MONITORY BENIFITS" AT HAL (ARDC) LTD., Bangalore.Document65 pages"EMPLOYEES ATTITUDE TOWARDS MONITORY AND NON-MONITORY BENIFITS" AT HAL (ARDC) LTD., Bangalore.atul420fuckNo ratings yet

- HR Project On Employee Motivation in Anglo French Textiles Limited - 151284769Document69 pagesHR Project On Employee Motivation in Anglo French Textiles Limited - 151284769Hemprasad BadgujarNo ratings yet

- A Study On Work Life Balance of Women Working in IT Sectors of Mumbai City.Document5 pagesA Study On Work Life Balance of Women Working in IT Sectors of Mumbai City.theijes100% (2)

- A STUDY ON Employee Career PlanningDocument14 pagesA STUDY ON Employee Career PlanningSwetha ReddyNo ratings yet

- A Study On Employee Relationship Management With Special Reference To DDCMPU KrishnagiriDocument25 pagesA Study On Employee Relationship Management With Special Reference To DDCMPU KrishnagiriCHEIF EDITORNo ratings yet

- Employee SatisfactionDocument50 pagesEmployee SatisfactionConnect Net cafeNo ratings yet

- Employee Perception On Organizational HR Practices and Culture Among Garment Industry in BangloreDocument30 pagesEmployee Perception On Organizational HR Practices and Culture Among Garment Industry in BangloreSanthu SaravananNo ratings yet

- Study of Training and Development at HCL TechnologiesDocument4 pagesStudy of Training and Development at HCL TechnologiesSwetha ENo ratings yet

- A Project Report On Training and Development in Sahara IndiaDocument81 pagesA Project Report On Training and Development in Sahara IndiaVishu RajNo ratings yet

- Emoplyee Engagment in SbiDocument83 pagesEmoplyee Engagment in SbiSukhi Brar0% (1)

- Training & DevelopmentDocument99 pagesTraining & DevelopmentUmesh Rao0% (1)

- Employee Engagement ReportDocument48 pagesEmployee Engagement ReportJantuNo ratings yet

- A Detail Study of Promotion & Rewards Policy An Organization ReportDocument51 pagesA Detail Study of Promotion & Rewards Policy An Organization ReportStudent ProjectsNo ratings yet

- Mba ProjectDocument55 pagesMba ProjectHEBIN RAJ HNo ratings yet

- Attrition Project Report FinalDocument73 pagesAttrition Project Report FinalLatha Reddy67% (3)

- Cholamandalam Investment and Finance Company LimitedDocument11 pagesCholamandalam Investment and Finance Company LimitedFcok100% (1)

- Training and Development in HDFC Standard Life Insurance'Document76 pagesTraining and Development in HDFC Standard Life Insurance'Prem RajNo ratings yet

- Os Nirapara Final PDFDocument83 pagesOs Nirapara Final PDFYadhu Krishna100% (1)

- Research MethodologyDocument3 pagesResearch MethodologyPatel_tarang43100% (2)

- A Study On Consumer Attitude Towards John Deere Tractor: A Case Study of BALAJI TRACTORS HAVERIDocument61 pagesA Study On Consumer Attitude Towards John Deere Tractor: A Case Study of BALAJI TRACTORS HAVERISarva ShivaNo ratings yet

- Job Satisfaction of Employees at RFL-SynopsisDocument13 pagesJob Satisfaction of Employees at RFL-SynopsisNageshwar SinghNo ratings yet

- Emp Satisfaction 18s11e0033 Final m17Document74 pagesEmp Satisfaction 18s11e0033 Final m17Naveen Kumar RudrangiNo ratings yet

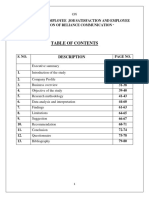

- "To Study The Employee Job Satisfaction and Employee Retention of Reliance CommunicationDocument78 pages"To Study The Employee Job Satisfaction and Employee Retention of Reliance CommunicationAshwani kumarNo ratings yet

- T & D ProjectDocument66 pagesT & D ProjectmbaNo ratings yet

- Review of Literature: Misra, K.K (1974) - Labour Welfare in Indian Industries, Meerut, Meenakshi PrakashanDocument36 pagesReview of Literature: Misra, K.K (1974) - Labour Welfare in Indian Industries, Meerut, Meenakshi PrakashanalwinNo ratings yet

- CSR by SBIDocument33 pagesCSR by SBIPooja MoreNo ratings yet

- A Study On Employee Satisfaction (With Special Reference To A.P.S.R.T.C Sangareddy Bus Depot)Document9 pagesA Study On Employee Satisfaction (With Special Reference To A.P.S.R.T.C Sangareddy Bus Depot)Mukesh ManwaniNo ratings yet

- Synopsis On Employee MotivationDocument6 pagesSynopsis On Employee MotivationBhagvan Patel100% (2)

- Summer Training ReportDocument65 pagesSummer Training ReportAmanpreet KaurNo ratings yet

- Career PlanningDocument9 pagesCareer PlanningNova BansalNo ratings yet

- Sample SIP Report 19Document25 pagesSample SIP Report 19shruti modiNo ratings yet

- A Employee Welfare Measures in TSNPDCLDocument7 pagesA Employee Welfare Measures in TSNPDCLMaskamanNo ratings yet

- A Study On The Various Employee Welfare SchemesDocument14 pagesA Study On The Various Employee Welfare SchemesSimran pokhriyalNo ratings yet

- Absenteeism Final Project 2Document74 pagesAbsenteeism Final Project 2masook2k10100% (1)

- Project Report On Employee MoraleDocument21 pagesProject Report On Employee MoraleSuresh Babu Reddy67% (3)

- Employee EngagementDocument65 pagesEmployee Engagementakash sharmaNo ratings yet

- Training &developement in HDFC BankDocument56 pagesTraining &developement in HDFC BankDipali ParkarNo ratings yet

- Hrd Practices in Apsrtc: A Case Study with Special Reference to Vizianagaram ZoneFrom EverandHrd Practices in Apsrtc: A Case Study with Special Reference to Vizianagaram ZoneNo ratings yet

- Organizational Study Travangore SugarsDocument53 pagesOrganizational Study Travangore SugarsRemya Sathish Sathish Sarma60% (5)

- Presented By, Ansu Anna Kurian S3 MbaDocument27 pagesPresented By, Ansu Anna Kurian S3 MbaanjuNo ratings yet

- 7th ClassDocument13 pages7th ClassanjuNo ratings yet

- TransactionsDocument16 pagesTransactionsanjuNo ratings yet

- Orgnl 2Document118 pagesOrgnl 2anjuNo ratings yet

- Org. As A System 5Document13 pagesOrg. As A System 5anjuNo ratings yet

- System Concept 4Document10 pagesSystem Concept 4anjuNo ratings yet

- Module 5Document46 pagesModule 5anjuNo ratings yet

- 000964Document30 pages000964anjuNo ratings yet

- Factor and Location Ratings: Module - 2Document11 pagesFactor and Location Ratings: Module - 2anjuNo ratings yet

- Factor and Location RatingsDocument172 pagesFactor and Location RatingsanjuNo ratings yet

- Final ProjectDocument61 pagesFinal ProjectanjuNo ratings yet

- Module 1Document35 pagesModule 1anjuNo ratings yet

- 7d15bd25f148-Lekhika Gautam Resume 2Document2 pages7d15bd25f148-Lekhika Gautam Resume 2Sourav NandaNo ratings yet

- IATA Aviation HR Report 2018Document16 pagesIATA Aviation HR Report 2018Shotin PatanasornNo ratings yet

- Final Report BBADocument75 pagesFinal Report BBArohanfyaz00100% (1)

- An Ontology For Modelling Human Resources Management Based On StandardsDocument8 pagesAn Ontology For Modelling Human Resources Management Based On Standardsdaniel_roca2No ratings yet

- Saidur Rahman: Personal InformationDocument2 pagesSaidur Rahman: Personal Informationsaidur RahmanNo ratings yet

- Human Resources During A Major Product Recall Ts Tech Alabama CaseDocument7 pagesHuman Resources During A Major Product Recall Ts Tech Alabama Caseasadasghar1009No ratings yet

- 4539243Document4 pages4539243venkat naiduNo ratings yet

- AG ZurichDocument48 pagesAG ZurichMuhammad Umer0% (1)

- What Is Meant by Industrial RelationsDocument7 pagesWhat Is Meant by Industrial Relationsfarad6aNo ratings yet

- THE CONCEPT OF KAIZEN-How Hybe Corporation Implements The Principle of Continuous Improvement - KERENOBARADocument16 pagesTHE CONCEPT OF KAIZEN-How Hybe Corporation Implements The Principle of Continuous Improvement - KERENOBARAKeren ObaraNo ratings yet

- B. Esther Rani - LinkedInDocument4 pagesB. Esther Rani - LinkedInkarim_budeNo ratings yet

- OmgtDocument4 pagesOmgtXTNNo ratings yet

- New Trends in International HRMDocument2 pagesNew Trends in International HRMSmriti Bhushan100% (1)

- MEd Annual SystemDocument30 pagesMEd Annual SystemAtif RehmanNo ratings yet

- Chapter 5: Activity Based Costing (ABC) and G Management: Student Learning OutcomesDocument8 pagesChapter 5: Activity Based Costing (ABC) and G Management: Student Learning OutcomesKen Mosende TakizawaNo ratings yet

- New Hire Orientation Process and AgendaDocument2 pagesNew Hire Orientation Process and AgendaTaimoorNo ratings yet

- New CV of Olawale, T. ADocument3 pagesNew CV of Olawale, T. AtaolawaleNo ratings yet

- PWC S - MetricsDocument13 pagesPWC S - MetricsNurettin TPNo ratings yet

- Truss 2001Document30 pagesTruss 2001NoureenHusnaniNo ratings yet

- Presentation OnOrganisation Study at Shahi Exports PVTDocument2 pagesPresentation OnOrganisation Study at Shahi Exports PVTSri JayakumarNo ratings yet

- Job Analysis: Job Description, Job Specification, Kra/KpiDocument11 pagesJob Analysis: Job Description, Job Specification, Kra/Kpiarchana.ramachandra88No ratings yet

- Varsha ResumeDocument2 pagesVarsha ResumeMonika ShuklaNo ratings yet

- Pallavi Srivastava Pune 2.00 YrsDocument2 pagesPallavi Srivastava Pune 2.00 YrsadityasutarNo ratings yet

- Management FinalDocument13 pagesManagement FinalAdil Javed KhanNo ratings yet

- A Study On Virtual Recruitment Process in The Pandemic Situation With Reference To Bangalore CityDocument94 pagesA Study On Virtual Recruitment Process in The Pandemic Situation With Reference To Bangalore CityjayminkumrNo ratings yet

Report On Organizational Study at Popular Industries1 - Intro

Report On Organizational Study at Popular Industries1 - Intro

Uploaded by

anjuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report On Organizational Study at Popular Industries1 - Intro

Report On Organizational Study at Popular Industries1 - Intro

Uploaded by

anjuCopyright:

Available Formats

Organization study at Popular Industry, Edappally

Chapter-1

INTRODUCTION

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

INTRODUCTION

Organization is a social unit which is deliberately constructed and

reconstructed to seek specific goals. An organization comes in to existence when there are a

number of persons in communication and relationship to each other and are willing to contribute

towards a common Endeavour. The evolution or organization dates back to the early stages of

human civilization when two or more persons began to cooperate and combine together for

fulfilling their basic needs of food, clothing, shelter and protection of life. Thus, an organization

is born when people combine their efforts for some common purpose. It is a universal truth that

an individual is unable to fulfill his needs and desires alone because he lacks strength, ability and

resources. So he seeks the cooperation of other people who share goals with him.

This study is done at POPULAR INDUSTRIES, Edappally. It has been carried

out to get an understanding of the structure and functioning of the organization. This study

undertaken to get an exposure to the functioning of different departments of the company. It also

helps to interact with managers of different departments and to observe the workers at their

work place I and to act together with them. Main purpose of the study is to get a clear-cut idea

about the functioning of different departments of the company.

Organization study is confinedto 30 days based on the primary data obtained

from the head of various departments, the middle level managers and supervisory staff. This

covers in brief in the present position of the candles industry and the company. Organization

study is conducted by personally visiting the company at Edappally. Primary data have been

collected by structured interview with the managers and other personnel of the company. All the

information about manufacturing process has been gathered by interacting with different

personnel of the organization at various levels.

1.1. Need and significance of the study

Combining the theoretical background, we have gained so far and the practical study of the

organization makes it possible to have a clear cut understanding and a broader perspective of an

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

organization and its functional and the operational aspects. Organization study at POPULAR

INDUSTRIES helped me to acquire practical knowledge through personal study and

observation. Apart from analyzing and understanding the recent trends and strategies in different

Industries of POPOLAR INDUSTRIES, the investigation had multi-dimensional focus on the

following areas:

Type of business performed by the company and its nature.

Various functions and operations of the company.

To know the market position of the organization

Production process performed by the company

Financial and accounting patterns of the company

Human resource management of the company

1.2. Objective of the study

To analyze the functioning of each department and organization as whole.

To study the various functions of the organization

To identify the relative position of the company

To get in touch with the industrial and organizational environment.

To know about the organizational structure.

1.3. Scope of the study

This organization study is useful in getting the quality and performance of the company.

It will help to conduct a detailed study on the structure of the functional areas of the

organization. It also helps to identify the strength and weakness of organization and also helps to

find out the area where the organization should improve. This study also helps researcher to

familiarize with the candle industry and also ascertain the present position of the company.

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

1.4. Research methodology

Primary data:

It is collected through the discussion with managers, various department heads, officers, and

employees, observation

Secondary data:

It is collected from:

Internet

Annual report

Office records

This study is done by personally visiting the company at Edappally, Ernakulum. All the

primary datas have been collected by structured interview with general manager, managers of

various departments and other personnel including supervisors, workers etc... of the company.

Information about manufacturing process has been collected by observing the functioning of

machines and equipments in the plant. The quality manual, publications of government of India,

ministry of candles, magazines, periodicals relating to the candles industry, internet etc, were the

useful source of the secondary data.

1.5. Limitations of the study

As in- depth analysis on the functional activities of various departments was not possible

Constraints regarding entry to various departments.

As the department heads seemed to be busy, collection of detailed information was not

possible.

Lack of confidential data.

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

CHAPTER-2

REVIEW OF RELATED LITERATURE

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

2.1. REVIEW ON GENERAL MANAGEMENT

Management

Management is universal in nature as every organization requires making of decisions,

procurement of resources, coordination of activities, leading of people and evaluation of

performance directed towards its objectives. Modern organizations are open systems which have

continuous interface with the external environment .They get various inputs such as men, money,

machines, materials and information from the environment and supply their outputs to the

environment. Thus to achieve success in managing, a manager must have a thorough knowledge

of management functions, principles and techniques.

Definition of management

In the words of Harold Koontz, management is the art of getting things done through and with

people in formally organized groups. It is the art of creating an environment in which people can

perform as individuals and yet corporate towards attainment of group goals. Thus management

is the process of effective utilization human and material resources to achieve enterprise

objectives.

Subject matter of management

Management is a continuous process and is made up of basic management functions like

planning, organizing, staffing, directing and controlling. These components form the subject

matter of management.

Functional Areas of Management

The various functional areas of management include;

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

Production management

It is concerned with managerial functions related to the design of the production system and

operation and control of the production system.ie production planning and control.

Financial management

It is concerned with managerial activities related to procurement and utilization of funds for

business purposes.

Marketing management

It deals with planning, organizing, directing and controlling the activated related to the marketing

of goods and services to satisfy the customers needs.

Human resource management

It covers various aspects relating to the employees of the organization such as training and

development compensation, motivation etc.

Purchasing and materials management

It is considered as the part of the production function. The objective mainly includes the

procurement of right types of materials at the right time of right quality in right quantity.

Legal function

The legal department may be organized to ensure that the business house abiding by the rules

and regulation framed by the government.

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

Public relations functions

This department organizes publicity campaigns to increase the image and goodwill of the

business in the society.

Organization

It is backbone of management. Without efficient organization, no management can perform its

functions smoothly. It is the process of establishing relationships among the various persons

working in an organization i.e. between workers and workers, workers and managers and

managers and managers.

2. 2. IMPORTANCE OF ORGANIZATION

Optimum utilization of resources

It ensures optimum utilization of resources both human and physical resources.

Ensures coordination

It facilitates coordination. The activities of the various individual and department are combined

together to accomplish company goals.

Facilitates effective management

A properly designed and balanced organization facilitates effective management of the

organization. It avoids confusion, delays and duplication of work.

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

Facilitates delegation of authority

It enables people in the organization to work effectively and efficiently. Without proper

delegation it will not be possible to conduct the activities of the organization smoothly and

quickly.

Facilitates growth

Good organizations achieve good progress; this enables the organization to growth and

diversifies.

Mangalam college of engineering, Ettumanoor

Organization study at Popular Industry, Edappally

Chapter-3

INDUSTRY PROFILE

Mangalam college of engineering, Ettumanoor

10

Organization study at Popular Industry, Edappally

3.1. INDUSTRY AND EVOLUTION

A candle is a solid block or cylinder of wax with an embedded wick, which is lit to provide light

and sometimes heat.

Today, most candles are made from paraffin. Candles can also be made from beeswax, soy,

other plant waxes, and tallow (a by-product of beef-fat rendering). Gel candles are made from a

mixture of mineral oil and a polymer.

A candle manufacturer is traditionally known as a chandler. Various devices have been

invented to hold candles, from simple table top candle holders, to elaborate chandeliers.

The heat of match used to light the candles melts and vaporizes a small amount of fuel. Once

vaporized, the fuel combines with oxygen in the atmosphere to form a flame. This flame

provides sufficient heat to keep the candle burning via a self-sustaining chain of events: the heat

of the flame melts the top of the mass of solid fuel, the liquefied fuel then moves upward through

the wick via capillary action, and the liquefied fuel is then vaporized to burn within the candles

flame.

The burning of the fuel takes place in several distinct regions (as evidenced by the various

colors that can be seen within the candles flame). Within the blue regions, hydrogen is being

separated from the fuel and burned to form water vapor. The brighter, yellow part of the flame is

the remaining carbon being oxidized to form carbon dioxide.

As the mass of solid fuel is melted and consumed, the candle grows shorter. Portions of the

wicks that are not emitting vaporized fuel are consumed in the flame. The incineration of the

wick limits the exposed length of the wick, thus maintaining a constant burning temperature and

rate of fuel consumption. Some wick require regular trimming with scissors (or a specialized

wick trimmer), usually to about one-quarter inch (~0.7 cm), to promote slower, steady burning,

and also to prevent smoking. In early times, the wick needed to be trimmed quite frequently and

special candle-scissors, referred to as snuffers until the 20th century, were produced for his

Mangalam college of engineering, Ettumanoor

11

Organization study at Popular Industry, Edappally

purpose, and often combined with an extinguisher. In modem candles, the wick is constructed so

that it curves over as it burns, so that the end of the wick gets oxygen and is then consumed by

fire a self-trimming wick.

3.2. HISTORY OF CANDLES

Candles have been used for light and to illuminate mans celebrations for more than5000

years, yet little is known about their origin.

It is often written that the first candles were developed by the ancient Egyptians, who used

rush lights or torches made by soaking the pithy core of reeds in melted animal fat. However, the

rush light had no wick like a true candle.

Early wicked candles

The Egyptians were using wicked candle in 3000 B.C., but the ancient Romans are generally

credited with developing the wicked candle before that time by dipping rolled papyrus repeatedly

in, melted tallow or beeswax. The resulting candles were used to light their homes, to aid

travelers at night, and in religious ceremonies.

Historians have found evidence that many other early civilization developed wicked candles

using waxes made from available plants and insects. Early Chinese candles are said to have been

molded in paper tubes, using rolled rice paper for the wick, and wax from an indigenous insect

that was combined with seeds. In JAPAN, candles were made of wax extracted from tree nuts,

while in India; candle wax was made by boiling the fruit of the cinnamon tree.

It is also known that candles played an important role in early religious ceremonies.

Hanukkah, the Jewish Festival which centers on the lighting of candles, dates back to 165 B.C.

Mangalam college of engineering, Ettumanoor

12

Organization study at Popular Industry, Edappally

there are several Biblical reference to candles, and the Emperor Constantine is reported to have

th

called for the use of candles during an Easter service in the 4 century.

Middle ages

Most early Western culture relied preliminary on candles rendered from animal fat(tallow). A

major improvement came in the middle Ages, when beeswax candles were introduced in Europe.

Unlike animal-based tallow, beeswax burned pure and cleanly, without producing a smoky

flame. It also emitted a pleasant sweet smell rather than the foul, acid order of tallow. Beeswax

candles were widely used for church ceremonies, but because they were expensive, few

individuals other than the wealthy could afford to burn them in the home.

th

Tallow candles were the common household candles for Europeans, and by the 13 century,

candle making had become a guide craft in England and France. The candle makers (chandlers)

went from house to house making candles from the kitchen fats saved for that purpose, or made

and sold their own candles from small shops.

Colonial times

Colonial women offered Americans first contribution to candle making, when they

discovered that boiling the grayish-green berries of bayberry bushes produced a sweet-smelling

wax that burned cleanly. However, extracting the wax from the bayberries was extremely

tedious. As a result, the popularity of bayberry candles soon diminished.

The growth of whaling industry in the late 18th century brought the first major change in

candle making since the middle Ages, when spermacetia wax obtained by crystallizing sperm

whale oil- -became available in quantity. Like beeswax, the spermaceti wax did not licit a

repugnant odor when burned, and produced a significantly brighter light. It also was harder than

their tallow or beeswax, so it wouldnt soften or bend in the summer heat.

Mangalam college of engineering, Ettumanoor

13

Organization study at Popular Industry, Edappally

Historians note that the first standard candles were made from spermaceti wax. Also, a

pure spermaceti candle is measure for candlepower. Candlepower is a common term for

describing light output. It is based on sixth of a pound, burning at a rate of 120grams per hour.

19th century Advances

Most of the major developments impacting contemporary candle making occurred during the

19th century. In the 1820s, French chemist Michele Eugene Chevreul discovered how to extract

stearic acid from animal fatty acids. This leads to development of stearin wax, which was hard,

durable and burned cleanly. Stearin candles remain popular in Europe today.

In 1834, inventor Joseph Morgan helped to further the modern-day candle industry by

developing a machine that allowed for continuous production of molded candles by using a

cylinder with a movable piston to eject candles as they solidified. With the introduction of

mechanized production, candles became an easy affordable commodity for the masses.

Paraffin wax was introduced in the 1850s, after chemists learned how to efficiently separate the

naturally-occurring waxy substance from petroleum and refine it. Odorless and bluish-white in

color, paraffin was a boon to candle making because it burned cleanly, consistently and was a

low melting point.

This was soon overcome by adding the harder static acid, which had become widely available.

With the introduction of the light bulb in 1879, candle making began to decline.

The 20th century

th

Candles enjoyed renewed popularity during the first half of the 20 century, when the growth

of U.S oil and meatpacking industries brought an increase in the byproducts that had become the

basic ingredients of candles - paraffin stearic acid.

Mangalam college of engineering, Ettumanoor

14

Organization study at Popular Industry, Edappally

The popularity of candles remained steady until the mid-1980s, when interest in candles as

decorative items, mood-setters and gift began to increase notably. Candles were suddenly

available in a board array of sizes, shapes and colors, and consumer interest in scented candles

began to escalate.

The 1990s witnessed an unprecedented suege in the popularity of candles, and for the first

time in more than a century, new types of candles waxes were being developed. In the U.S.

agricultural chemists began to develop soybean wax, a softer and slower burning wax than

paraffin. On the other side of the globe, efforts were underway to develop palm wax for use in

candles.

Todays candles

Todays candle is vastly different from the candles of old, the industry has grown and matured

into a well oiled machine. You can purchase almost any type, size, style, or fragrance of your

choice. And the internet was made it easier to come by candles than ever before. Candles have

come a long way since their initial use. Although no longer man's major source of light, they

continue to grow in popularity and use. Today, candles symbolize celebration, mark romance,

soothe the senses, define ceremony, and accent home decors casting a warm and lovely glow for

all to enjoy.

3.3. History of candle making

Candle making was developed independently in many countries throughout history. The

earliest known candles were made from whale fat by Chinese, during the Qin Dynasty (221-206BC). In early china and Japan, tapers were made with wax from insects and seeds, wrapped in

paper. In India, wax from boiling cinnamon was used for temple candles. During the 1st century

AD, indigenous people of the pacific northwest fused oil from the eulachon, or candlefish, for

illumination.

Mangalam college of engineering, Ettumanoor

15

Organization study at Popular Industry, Edappally

In parts of Europe, the middle=east and Africa, where lamp oil made from olives was readily

available, candle making remained unknown until the early middle-ages.

300-1 BC

Qin Shi Huang (259-210-BC) was the first emperor of the Chinese Qin Dynasty (221 -206

BC). His mausoleum, which was rediscovered in the 1990s, twenty-two miles east of Xian,

contained candles made from whale fat. The word zhu in Chinese originally meant torch and

could have the warning states period (403-221 BC); some excavated bronze wares from that era

feature a pricket thought to hold a candle. The Han dynasty (202 BC-220 AD) Jizhupian

dictionary of about 40 BC hints at candles being made of beeswax, while the book of jin

(compiled in 648) covering the Jin Dynasty (265-420) makes a solid reference to the beeswax

candle in regards to its use by the statesman ZHOU Yi (d. 322). An excavated earthenware bowl

from the 4th century AD, located at the Luoyang Museum, has a hollowed socket where traces of

wax were found.

1 AD - 1500 AD

There is a fish called the eulachon or candlefish, a type of smelt which is found from Oregon

to Alaska. During the 1st century AD, indigenous people from this region used oil from this fish

for illumination. A simple candle could be made by putting the dried fish on a forked stick and

then lighting it, The first candles to appear in Europe were made by nomadic tribes in the late

Roman era, but are thought to have been in use much earlier in the colder climates of Northern

Europe, where olive oil was scarce. These early candles were made from tallow or animal fat.

The tallow was put into the melting pot, the poured into molds made of bronze. A trough

underneath would catch the excess wax and return it to the melting pot- For the wick a cord,

usually made from the pith of rushes, was suspended from a horizontal rod over the mold when

the tallow was poured in. after the fall of the Roman Empire, when olive oil become increasingly

scarce, and therefore expensive, the use of tallow candles spread across western Europe. Later

wax candles made from various plant extracts replaced tallow as the preferred source of

illumination.

Mangalam college of engineering, Ettumanoor

16

Organization study at Popular Industry, Edappally

Making candles for timekeeping

Although candles could not be used to fined a specific time they were instrumental in able to

indicate passage of predetermined periods of time. For example the Anglo-Saxon king Alfred the

Great (c. 849-899) used graduated candles, later known as candle-clocks. He used this candle to

divide up his day into equal periods of study and prayer, royal duties, and rest. There were lines

around the sides to show the passing of each hour. Later, 24-hour candles were invented based

on the same concepts. During the sung dynasty in China (960-1279) calibrated candles and sticks

of incense measured time. The concept of this clock utilized six different threads with weights on

the end. These were draped over incense stick at regular intervals and as the incense burned, the

threads simultaneously burned one by one and the weights dropped onto a sounding plate below.

Sometimes the sticks of incense had varying scents so that hours were marked by a change in

fragrance.

The first use of calibrated candle for time keeping in England was 870.

The candle clock was also used as a timer. A heavy nail inserted onto the candle at the indicated

mark would fall onto a hard surface after the wax surrounding the nail melted.

Profession of candle making

Candles were also common place in many households scattered throughout Europe. In England

and France candle making had become a guild graft by the 13th century. These candle makers

(chandlers) went from house to house to making candles from fats saved from the kitchen or sold

their own candles from within their shops.

During the middle ages in Europe, the popularity of candles is known by their use in Candlemas

and on Saint Lucy festivities. Tallow Chandlers Company of London was formed about 1300 in

London, and in 1456 was granted a coat of arms. Dating from about 1330, the wax chandlers

company acquired its charter in 1484. By 1415, tallow candles were used in street lighting. The

trade of chandlers is also recorded by the more picturesque names of "smeremongere, since they

oversaw the manufacture of sauces, vinegar, soap and cheese. The unpleasant smell of tallow

candles is due to the glycerin they contain. For churches and royal events, candles from beeswax

Mangalam college of engineering, Ettumanoor

17

Organization study at Popular Industry, Edappally

were used, as the smell was usually less unpleasant. The smell of the manufacturing process was

so unpleasant that it was banned by ordinance in several cities. The first candle mould comes

from 15 century Paris.

The first American colonists discovered that bayberries could be used to make candles, but the

yield was very poor. Fifteen pounds of boiled bayberries would provide only one pound of wax.

By the 18th century, the Chinese designed weights into the sides of candles; as such a candle

melted, the weights fell off and made a noise as they landed an a bowl.

The growth of whaling industry in the late 18 century spermaceti, oils that comes from sperm

whale, this was the first major change in candle making since the middle ages. Spermaceti was a

wax obtained by crystallizing the oil of a sperm whale. It became available in mass quantities.

Like wax, the spermaceti wax did not elicit a repugnant odor when burned, and produced a

significantly brighter light. It also was harder than either tallow or beeswax, so it wouldnt soften

or bend in summer heat. Historians note that the first standard candles were made from

spermaceti wax. By 1800 a much cheaper alternative was discovered. Colza oil, derived trom

Brassica campestris and similar oil derived from rapeseed, yielded candles that produce clear,

smokeless flames. The French chemists Michel Eugene Chevreul (1786-1889) and Joseph-Louis

gay- Lussac (1778-1850) patented stearin, in 1811. Like tallow, this was derived from animals,

but had no glycerin content.

Manufacturing of candles

Joseph Sampson was granted a United State patent for a new method of candle making in 1790

(this was the second patent ever granted by the US).

In 1834, Joseph Morgan began to industrialize the production of candles by using a cylinder with

a movable piston to reject candles as they solidified. This more efficient mechanized production

produced about 1500 candles per hour which allowed candles to become an easily affordable

commodity for the masses.

Mangalam college of engineering, Ettumanoor

18

Organization study at Popular Industry, Edappally

A chemist called Laurent distilled paraffin from achiest in 1830. Another chemist, Dumas,

obtained paraffin from coal-tar in 1835. Not until 1850 did paraffin become commercially viable,

when James Young filed a patent to produce it from coal. Paraffin could be used to make

inexpensive candle of high quality. Paraffin was also processed by distilling reside left after

crude petroleum was refined. It was a bluish- white wax, which was able to bum cleanly, and

leave no unpleasant odor, something the predecessor could not achieve like the tallow candles.

Although paraffin had a low melting point the discovery of stearic solved this problem. Stearic

acid was hard and very durable which helped elevate the melting point of paraffin. It was being

produced in mass quantity at the end of the 29th century. By this period, most candles being

manufactured consisted of paraffin and stearic acid.

3.4. Decline of Candles

Despite advances in candle making, the candle industry was devastated soon after by the

distillation of kerosene (a fuel used in lamps) and the 1879 invention of the light bulb. From this

point, candles became more of a decorative item.

In 1829, William Wilson of prices candles invested in 1000 acres (4km) of coconut plantation in

Sri Lanka. His aim was to make candles from coconut oil. Later he tried palm oil from palm

trees. An accidental discovery swept all his ambitions aside when his brother George Wilson

distilled the first petroleum oil in 1854. In 1919, Lever Brothers purchased prices Candles and

in 1922, a joint-owned company called Candles ltd was created. By 1991, the last remaining

owner of Candles ltd was Shell Oil Company, who sold off the candle making part of business.

Mangalam college of engineering, Ettumanoor

19

Organization study at Popular Industry, Edappally

CHAPTER-4

COMPANY PROFILE

Mangalam college of engineering, Ettumanoor

20

Organization study at Popular Industry, Edappally

4.1. ABOUT COMPANY

Type

: proprietorship

Nature of business

: manufacturer

Founded

: 1968

Major markets

: Indian sub continent, East Asia, Middle East & South East Asia

Products

: candles

Level to expand

: National

Popular Industries, the candle manufacturing factory was started 47 years ago, on a fine X'mas

morning of 1968. This factory is functioning in Kerala State (south tip of India), the State blessed

with most comfortable climate and known as "The God's Own Country", in Kochi (formerly

Cochin), and the city known as "Queen of Arabian Sea". Kochi has another specialty; it is the

Industrial Capital and business center of Kerala.

Mangalam college of engineering, Ettumanoor

21

Organization study at Popular Industry, Edappally

The factory is easily accessible by Air and Sea,

From Nedumbassery International Air Port of Kochi - 25 KM.

From Kochi Sea Port 20 KM.

The candles manufactured in Popular Industries, is marketed all over India and abroad in

the Brand name "POPULAR CANDLES, In this well equipped factory, more than 100 varieties

of candles are manufactured and packed in strong attractive packets. Visit our products page for

more details. Purely refined Paraffin wax manufactured in the best Oil Refineries in India as well

as imported from different parts of the world is the major raw material.

As Popular Industries keeps best quality control and reasonable prices, a good percentage of

internal requirements of candles in INDIA are catered from Popular Industries. Also, Popular

Candles have demand and approval in lots of foreign countries. Popular Industries believe that,

day by day increase of users of Popular Candles is another acceptance and approval on the

candles.

More than 100 varieties of candles are there in the popular candles range. Popular industries

launched the concept of torch candle for the first time in India. During New Year 2000 eve, a

mammoth candle weighing 2000kg was lighted at the famous st.George, sizes, used in festivals

and functions, perfumed candles in different attractive fragrances, color candles used in hotel and

clubs. Utility candles for domestic purpose, birthday digital candles, cup candles, VIP candles

etc...

The important raw material paraffin wax is sourced from abroad, mainly from the refineries

in China, Iran, and Egypt as well as refineries in India like Chennai petroleum corporation and

Assam oil division loc etc. one of the main advantage of the industry is its elaborate factory

building, spacious god owns and facility for parking containers, lories and trucks, loading and

unloading and good employees.

Mangalam college of engineering, Ettumanoor

22

Organization study at Popular Industry, Edappally

The firm has got its own vehicles by which they distribute the product to the customers all over

Kerala speedily and promptly. Now, popular industries are governed by its four partners, Mrs.

Sherly Jose, Mrs. Sheeba Babu, Mrs. Jee Joy and Mrs. Lini Baiju, all are of pallipadan house,

Edappally, Kochi-682024. All have equal responsibility in the day to day activities of the firm

and they are attending their duties in the business.

4.2. Vision

To reach the excellent quality standards in the coming year To keep in place with modem

technologies and concepts

To organize supply of materials with minimum cost to maximum extent possible without

any compromise in quality

A world class manufacturing company focusing on all round business excellence through

Total Quality Management System with committed leadership effective team work

delighted customers and satisfied employees in an environment friendly organization.

4.3. Mission

Candles and processed candles as per the customer specification efficiently

in a professional and environment friendly manner, on time, and at the right cost with at most

customer specification to become a world class organization through improvement.

Mangalam college of engineering, Ettumanoor

23

Organization study at Popular Industry, Edappally

4.4. Objectives

Increase sales of value added item by 20% from the existing level

Reduce rejection by 10% from the present level.

Reduce customer complaint by 10%.

Increase product range by introducing new types of candles

4.5. PRESENT STATUS

Since the firm started in 1968 they are supplying the products to various customers all over the

India gradually or super market departmental stores and civil supply stores and thus the business

expanded to present stage. They appointed district wise distributors all over India. They are

placing orders for bulk quantities and taking the product from factory god owns. But the

government departmental markets are directly placing orders and the company transports the

goods to their god owns. The financial statement show attached show the statement of the

industry. But in some years the unit has to control its production and sales subjects to the unit

and the unit they tried to prevent some harms from loss. In such periods small full in turnover

and net profit can be seen. But at the present the unit has overcome all the problems and runs

smoothly.

4.6. FUTURE SCOPE

The companys previous track records and fifty years business tradition is self explaining and

testimony to their true commitment, sincere and dedicated work culture. Also the have good

scope in marketing for their entire product by efficiently making use of their business contact

Mangalam college of engineering, Ettumanoor

24

Organization study at Popular Industry, Edappally

and already existing distributing network and also by their financial standing and available

infrastructure. They pledge their sincere and dedicated efforts from their heart to active target

unlimited.

4.7. PRODUCT PROFILE

Utility candle

These candles are produced for day to day use. There are various

varieties of these candles, available in packets containing 6

candles and 32 candles. These candle are produced from pure white

Paraffin wax giving bright light for hours.

The size of candles and duration of burning:

ITEM.

250 gm.

215 gm.

170 gm.

150 gm.

80 gm.

HEIGHT. DIAMETER.

20.5 cm

18 cm.

21 cm.

19 cm.

18 cm.

Mangalam college of engineering, Ettumanoor

1.75 cm.

1.7 cm.

1.5 cm.

1.3 cm.

1.0 cm.

BURNING TIME

4 hours

3 hours

2 hours

1.5 hours

1 hours

25

Organization study at Popular Industry, Edappally

Torch candle

This candle is in cylindrical shape and is available in seven attractive colors.

The small| metal top fixed on the candle gets warm by the flame and helps to

burn in an equal level and also prevent flow of melted wax. The metal part can

be pressed by hand according to the melting and burning of candle.

If the candle is kept lighting in a place ,where we cannot attend it, it is better

to enlighten the torch candle, removing the metal top to avoid improper burning

in the absence of the pressing down the metal top.

Burning time 15 hours, Height 21.5 cm, Diameter 5.5 cm, Weight 460 gms.

Cup candle

These are made in Aluminum cups with a steady wick in

centre. These candles are used for the festivals like X 'mas,

Deepavali, Karthika, etc; . As the melted wax does not flow

out and as it is kept in the Aluminum cups, this candle gives

light for many hours. These candles can be placed on the

boundary walls, Varanthas, or in any place where we wish to

decorate with special arrangement or designs. Light of these

arranged candles are very attractive. These candles can also be

used in water as floating candle.

Burning time: 1 hour and Weight: 14 gms.

Mangalam college of engineering, Ettumanoor

26

Organization study at Popular Industry, Edappally

Party candle

This variety of candle is mainly used on Dinner party tables, arranged in

different and desired methods. This model is only made to order.

Digital Candle

This candle is made in the form of 0 to 9 separate digits, in big

size and in different colours . This is mainly used in memorial sweet days like Birthday,

Wedding anniversary etc; one packet contains 5 candles in single digit.

Mangalam college of engineering, Ettumanoor

27

Organization study at Popular Industry, Edappally

Festival Candle

This candle is used during festival celebrations. This model is made to order.

Twisted Millennium

This candle is very attractive, available in

different colors. White candle is used, mainly in

First Holy Communion ceremonies and procession

in Church. Color candles can be used in festival

functions. These candles are available in different

lengths and sizes in the names ROYAL &

MILLENIUM Brands.

Length: 26.5cm, Fully Twisted diameter: 2 cm.

Burning time: 3 hours, Weight 100 gms.

Mangalam college of engineering, Ettumanoor

28

Organization study at Popular Industry, Edappally

Twisted Tower

These models are available in different colors. And are not available readily, only made as per

your order.

Coconut shell

This candle is made pouring wax mixed with natural

coconut perfume into coconut shells. Burning time

7-8 hours.

Mangalam college of engineering, Ettumanoor

29

Organization study at Popular Industry, Edappally

Super Light Coloured Candle

.

This candle is available in different attractive colours. Burning time

6 hours, height 23cm, diameter 2.5cm, weight 100 gms. Contains 6 Nos. in a packet.

OTHER PRODUCTS

Perfumed Candle

Mangalam college of engineering, Ettumanoor

30

Organization study at Popular Industry, Edappally

Rose Flower Candle

Last Supper Candle

Mangalam college of engineering, Ettumanoor

31

Organization study at Popular Industry, Edappally

Gel Glass Candle

Grotto Candle

Mangalam college of engineering, Ettumanoor

32

Organization study at Popular Industry, Edappally

Decorative Candle

Thulabharam Candle

Mangalam college of engineering, Ettumanoor

33

Organization study at Popular Industry, Edappally

Wedding Candle

Mangalam college of engineering, Ettumanoor

34

Organization study at Popular Industry, Edappally

ORGANISATIONAL STUCTURE

Mangalam college of engineering, Ettumanoor

35

Organization study at Popular Industry, Edappally

Mangalam college of engineering, Ettumanoor

36

Organization study at Popular Industry, Edappally

Chapter-5

DEPARTMENT PROFILE

Mangalam college of engineering, Ettumanoor

37

Organization study at Popular Industry, Edappally

HR department

Finance department

Production department

Marketing department

Purchase department

Store department

Mangalam college of engineering, Ettumanoor

38

Organization study at Popular Industry, Edappally

5.1. WORKERS DETAILS

Total numbers of customers

120

HR department

25 workers

Finance department

20 workers

Production department

30 workers

Marketing department

18 workers

Purchase department

15 workers

Store department

12 workers

Mangalam college of engineering, Ettumanoor

39

Organization study at Popular Industry, Edappally

5.2. HUMAN RESOURCE DEPARTMENT

Now days, Human Recourse is considered as one of the important asset of an organization.

Behind every success company their need a great people making recruitment and retention.

Companies must find new ways to engage the knowledge, experience talents of the employees to

find the hidden values in organization and leverage that value to achieve strategic goods. The

popular industry has a good HR Department and it maintains good relations with the

employees. This helped the company to achieve tremendous growth. All the employees related

activities are managed by this department. The company employees over 110 workers and does

not have any trade union problems.

Workers and management sit across the table and negotiate their demands and rights. The

company has an efficient administrative department which carried out the several functions.

The main function or role of personnel manager and Administration manager

Advisory Role: Industrial psychology and Sociology.

Operative and Service role.

Conciliators Role.

Specialist advisory Role

Role of Personnel Manager

To create necessary infrastructure for HR development activities.

To lease with HR manager in identifying areas for HR development.

To arrange proper placement to trained employees.

To activate association and employees to take part in HR development activities which

are beneficial to both employee and Management.

To monitor utilization and effectiveness of HR development training.

Mangalam college of engineering, Ettumanoor

40

Organization study at Popular Industry, Edappally

The Activities normally associated with this Department are:

a) Human Resource Planning

b) Recruitment

c) Selection Procedure

d) Training and Development

e) Performance appraisal

f)

Employee remuneration

g) Bonus

h) Statutory rules for employees

i)

Leave rules

j)

Shifts

k) Employee welfare

Mangalam college of engineering, Ettumanoor

41

Organization study at Popular Industry, Edappally

Structure of HR Department

(Fig. No: 5.1)

Director of HR

Personal

Assistant

Deputy Director of HR

HR executive staff

development

HR Manager

Administration

Contracts

& Payrolls

Mangalam college of engineering, Ettumanoor

HR Manager

Recruitment

HR Manager

Employee

relations

Recruitment

42

Organization study at Popular Industry, Edappally

5.3. FINANCE DEPARTMENT

Finance is the life blood of business. Finance department consists of all the managerial activities

of raising funds and effective utilization. Finance department lies in decision making area of

investment, finance and dividend. Recruitment and promotion in production are the activities of

H.R Department. But it requires the payment of wages, salaries and other benefits; these are done

by finance department. Finance manager is the head of finance in POPULAR. He decides when

and where to acquire funds to meet firms investment needs. He should determine the proposition

of equity debt. The finance department should strive for obtaining the optimum capital structure

for the organization.

Functions of Finance Department

There are 20 workers in finance department. The activities expected from a finance department

cover a wide range from basic bookkeeping to providing information to assisting managers in

making strategic decisions What to expect from your finance department will depend largely on

factors such as how much involvement the owner/manager has in the organization.

At the base level, your finance department will be responsible for all the day to day

transactional accounting for the business. This will include the tracking of all transactions and

the management of any government reporting. In very small owner-managed businesses this role

is often filled by a family member with accounting experience. An outside accounting firm is

usually used for annual financial statements and returns. In larger organizations this role will

extend right through to preparing the financial statements with an external auditor engaged for

assurance purposes.

The finance department is also responsible for management of the organizations cash flow

and ensuring there are enough funds available to meet the day to day payments. This area also

encompasses the credit and collections policies for the companys customers, to ensure the

organization is paid on time, and that there is a payment policy for the companys suppliers. In

Mangalam college of engineering, Ettumanoor

43

Organization study at Popular Industry, Edappally

most organizations there will be some form of forecast prepared on a regular basis to

systematically calculate the ongoing cash needs.

Recording day to day business transaction - accounting

Preparation of various statements regarding stock, receivables etcwhich are to be

submitted to various authorities like bankers, insurers etc...

Planning and controlling of the expenses or funds for production

Approving and making payments to different parties or creditors or suppliers

Receiving payments from customers or dealers in specific time

Raising short term loan or credit from bank and other financial institutions

Preparation of sales budget or revenue budgets and expenditure budgets on a quarterly

basis

Preparation and maintenance of costing records

Preparation of fund flow and cash flow statements every month

Timely preparation and filling of financial reports and records

Preparing and filling of quarterly and financial income tax returns

Preparation and implementation of cost reduction and cost control programs In addition

to the above mentioned works

Mangalam college of engineering, Ettumanoor

44

Organization study at Popular Industry, Edappally

Structure of Finance Department

Chairman & Managing

director

(Fig. No: 5.2)

General Manager

Manager(Finance)

Manager(Accounts)

Assistant Manager

Assistant Manager

Executive

(Bank)

Executive

(Data Entry)

Executive

(Tax)

Executive

(General)

Cashier

Manager (finance) - managing and controlling the financial requirements of the company.

Manager (accounts) - preparing and keeping books of accounts

Assistant manager (finance) - helps finance manager to find the sources of finance and

how to manage it properly.

Assistant manager (accounts) - helps accounts manager to collect relevant data to prepare

book of accounts.

Executive (bank) - deals the transactions with bank Executive (data entry) - maintaining

all data in a data base Cashier - collect cash from creditors

Executive (tax) - calculate the amount to be paid as tax and keeping information about

the payment of deferent taxes

Executive (general) - manage the general affairs

Mangalam college of engineering, Ettumanoor

45

Organization study at Popular Industry, Edappally

5.4. PRODUCTION DEPARTMENT

There are 30 workers in production department. Production is the process by which raw

materials and other inputs are converted in to outputs. Among all functional areas of

management, production is considered to be crucial in any organization like popular industries

mainly the production of candles takes place under the production department.

Functions of Production Department

The following are the main functions of production department

a. Design of product

b. Design of production system

c. Production planning and control

d. Layout of plant

e. Selection of location

f. Selection of plant and equipment

g. Research and development

Mangalam college of engineering, Ettumanoor

46

Organization study at Popular Industry, Edappally

Structure of Production Department

(Fig. No: 5.3)

Chairman & Managing Director

General Manager

Assistant

Manager

Assistant

Manager

Shift in

charge

Jobber

Preparatory

in charge

Maintenance

Electrical

engineer

Helper

Mangalam college of engineering, Ettumanoor

47

Organization study at Popular Industry, Edappally

5.5. MARKETING DEPARTMENT

There are 18 workers under marketing department. Marketing is the activity

through which a company is able to generate the revenue for the functioning of the organization.

POPULAR INDUSTRY Has got a very good marketing department controlled by efficient and

dynamic marketing manager. Marketing manager reports to General Manager and Managing

Director. Marketing department is divided in to two such as Marketing and Advertising and

Sales Promotion.

Under each section, Assistant Managers, Marketing Executives, Sales

Executives and Sales are there to assist him popular markets its processed product. Mainly

through dealers. Almost popular products are available at the dealer shops. The products are

transported to the dealers by deliver vans. Sales Executives take orders of different items from

the dealers once in a month the company is having 1000s dealers spread all over Kerala.

The company is selling their product as such to various exporters to Mumbai,

Bangalore, Delhi, Chennai, Calcutta, Ahmadabad etc... 75 % of the sale is done through

authorized agents on commission basis and balance is through Direct Marketing. The candles

manufactured by the group under the brand name popular candles are accepted all over the

world.

Marketing manager is the one who decides the marketing strategies for every

major decision, which effects marketing. But while making some strategic and important

decisions, approval of the Managing Director is required after collecting the orders, Marketing

Managers forward their order to Production Department. Marketing Manager and Production

Manager sits together and decides the production plan.

Mangalam college of engineering, Ettumanoor

48

Organization study at Popular Industry, Edappally

Marketing Policy

This company has a strategic marketing policy. The company mainly targets its

customers and promotional activities are based on the above aspects. The company doesnt

entertain any middle man. They deal directly with their dealers. The company is following a

hierarchical channel of distribution.

Company

Dealers

Consumers

Marketing Function

A popular industry has a dealers network of more than 2500 dealers spread all over Kerala.

The sales of customer goods are concentrated on Kerala, Tamilnadu, and Karnataka. In addition

the company has direct outlets in Kerala and Tamilnadu.

Dealership is allotted only after assessing the credit worthiness, efficiency, and the products are

delivered through the van of the company either at the dealers goes down or at the dealers show

room.

The company is selling their candles as such to various candles exporters to Mumbai,

Bangalore, Delhi, Chennai, Calcutta etc. 75 % of the sales is done through authorized agents on

commission basis and balance is through direct marketing. The candles manufactured by the

Mangalam college of engineering, Ettumanoor

49

Organization study at Popular Industry, Edappally

group under the brand name POPULAR INDUSTRIES are accepted all over the world

Marketing Strategies

The marketing department is one of the efficient and effective departments in popular. This

department is always vigilant about its environment and very conscious about the market

potential, major competitors strategies, weaknesses etc. Maintaining the efficiency and

effectiveness the top management appointed a General Manager for marketing department. The

present GM (marketing) is an experienced management professional.

In the case of all major companies, the margin is very high when they sell their products to

dealers. However, in the case of popular industry the margin is comparatively low. The major

problems of competitors products are poor quality Compared to other products, most customers

choose popular brand because of its high quality despite of its a bit high pricing.

Market Segmentation

Co-Ordination of Marketing Activities All Sales Executives is

directed to report to the Assistant Managers (sales) every day. The Assistant Manager and the

Marketing Manager are in constant touch with all Sales Executives who are in the field. All Sales

Executives are expected to submit the Daily Sales Report (DSR) on all Mondays. On all

Mondays there is a meeting of all personnel in Marketing Department preceded over by the

General Manager. In this meeting all the activities and achievements of the departments are

discussed, new plans and strategies to increase sales are formulated and other issues connected

with marketing are discussed. Show Rooms the Company has showroom sales in addition to

sales to its authorized dealers and franchisees. There are about 20 show rooms all over in Kerala.

Mangalam college of engineering, Ettumanoor

50

Organization study at Popular Industry, Edappally

Channels of distribution

Producer

consumer

Producer

retailer

Producer

wholesaler

consumer

retailer

consumer

Structure of Marketing Department

(Fig. No: 5.4)

Managing Director

General Manager

Senior Marketing Manager

Marketing

Manager

Internal

Communication

Employer

Outreach

Mangalam college of engineering, Ettumanoor

General

Outreach

Media

51

Organization study at Popular Industry, Edappally

5.6. PURCHASE DEPARTMENT

Substantial part of the companies finance is committed which effects cash flow position of

the company. The company is having a centralized Purchase department headed by the purchase

manager. He is assisted by 2-purchase officers and an office assistant. Mr.Sadiq is The Purchase

manager of popular industries he is assisted by two purchase officers and an office assistant.

The Purchase manager reports to the General Manager and Managing Director. The Purchase

manager coordinates the entire purchase activities. In case of local purchase or minor items

which are frequently required, it is the responsibility of the purchase officers to ensure the timely

procurement of materials as the purchase requisitions issued by the stores when the items of

materials have reached the re-ordering level.

The basic objective of setting up a separate purchasing department is to ensure continuous

availability of quality materials, so that production is not held up and reduce the cost of finished

product according to their proper plan.

Duties and Responsibilities of Purchase Manager

To make continuous availability so that there may be uninterrupted flow of material for

production

To make purchase competitive and price at the most economical form

To make purchase in reasonable qualities to keep investment in material minimum.

To purchase proper quantity of material to have minimum possible wastage of material

and loss in production

To develop alternative source of supply so that material can be purchased from those

alternative source if particular supplier fails to supply the material

To adopt the most advance method of purchase to ensure smooth delivery of material

from supplier and to avoid the risk of any dispute and financial loss.

Mangalam college of engineering, Ettumanoor

52

Organization study at Popular Industry, Edappally

To serve as an information centre on the material knowledge relating to purchase, source

of supply specification and mode of supply

Purchasing procedure

1. Identifying the materials

2. Exploring the sources of suppliers

3. Issuing purchase order

4. Receiving and inspecting materials

5. Checking and passing of Bills for payment

Factors considering while selecting supplier

Manufacturing capacity.

Reliability of suppliers.

Financial condition of the suppliers.

The management of supply firms.

Price quoted.

Terms of payment Terms of delivery.

Specification to which products are manufactured.

Quantity for which price quoted is applicable.

Mangalam college of engineering, Ettumanoor

53

Organization study at Popular Industry, Edappally

Structure of Purchase Department

(Fig. No: 5.5)

Purchase Manager

Secretary

Purchasing

Agent

Contract

Section Clerk

Data Entry

Clerk

Mangalam college of engineering, Ettumanoor

Bid Section

Lead Clerk

Order Section

Lead Clerk

Bid Section

Clerk

Order Section

Clerk

54

Organization study at Popular Industry, Edappally

5.7. STORES DEPARTMENT

The stores department is headed by store manager. He is assisted by four persons; two in

general shift and one each in other two shift. The stores manager is reporting to the general

manager storage of all items of raw materials including sizing chemicals, spare parts, electrical

items, lubricants, tools, office stationery packing materials, etc... Are the responsibility of the

stores department .functioning of the stores department is controlled or administered by the

stores manager. Materials storage is planned by the stores manager with the help of the

purchase production department, yam and packing materials are stored in the production

department go down and packing section respectively, due to lack of sufficient space in the store

and to facilitate easy handling both the items .but the stores department controls the issue of both

these items.

PROCEDURE OF ISSUE OF RAW MATERIALS

When particular item of raw material spare parts or tools are required for production, the

supervisor of the concerned section of the production department issues a material requisition.

On receipt of the materials requisition note or material indent, the stores manager sees whether

the item demanded in stock in the stores.

If the required item is sorted in the stores, to the concerned department or section and the

acknowledgement for the same is obtained and field in the stores. If the particular item or

material is not available with the stores or the same has re-ordering level, the stores department

informs the purchase department and issuing purchase requisition.

The quantity, quality and other specification of the item issued are recorded in the issue are

recorded in the store ledger control account, prepared and maintained by the stores. Issues of

packing materials are recorded in the stores ledger control account even though they are not

stored in the stores the store department is fully computerized.

Mangalam college of engineering, Ettumanoor

55

Organization study at Popular Industry, Edappally

A special software package 5 designed and installed for inventory management in stores. All the

receipts and issues are recorded in the company. ABC analysis of inventory is done regular basic

physical stock taking is done once in every month by the stock taking by the statutory auditor.

The stock verification is done independent of the store keeper and stores manager.

All stock of raw materials and spare parts are stored in assigned areas only .Access to those areas

is restricted. All stock of raw materials, spare parts, tools, etc are insured against fire and hail

damage. A record is maintained for the insurance policies are duly complied with perpetual stock

records are kept for races materials, stores, spares, work in progress and finished goods these

records are periodically reconciled with accounting records.

MATERIALS CONTROL SYSTEM

The company has a materials control system, which ensures that right quality of materials is

available in the right quality at the right time and right place with the right amount of investment.

It is a, but at the same time minimizing investment of funds. Because materials constitute such a

significant part of product cost and since this cost is controllable. The comprehensive frame

work for the accounting and control of materials court designed with the objective of maintaining

materials suppliers at a level so as to ensure uninterrupted production company has proper

planning, purchasing, handling and accounting for materials. Two levels of material control trust

in the companyquality control and financial control.

Production manager and stores manager are primarily interested in quality control, because it is

their responsibility to see that there should be no stock out problem. Finance manager, on the

other hand is interested that too much money should not be invested in materials and every rupee

spends on materials should be effective and efficiently utilized.

Mangalam college of engineering, Ettumanoor

56

Organization study at Popular Industry, Edappally

TECHNIQUES OF MATERIAL CONTROL

The following are the main techniques of material control used by the stores

department level setting,

1. Economic order quantity

2. ABC analysis

3. Perpetual inventory system

4. Material turnover ratio

5. Material cost report

The company does not have any stock in public warehouse or with consigns.

Some stocks are lying with job workers, which are given to them for processing.

Mangalam college of engineering, Ettumanoor

57

Organization study at Popular Industry, Edappally

Structure of Store Department

(Fig. No: 5.6)

MD

Manager

Store

Manager

Shift in

Charge

Store

Keeper

Mangalam college of engineering, Ettumanoor

58

Organization study at Popular Industry, Edappally

Chapter-6

SWOT ANALYSIS

Mangalam college of engineering, Ettumanoor

59

Organization study at Popular Industry, Edappally

The basic objectives of SWOT Analysis is to provide a frame work to

reflect on the ability to overcome barriers and to avail of opportunities emerging in the changing

environment, the diagnosis of strength and weakness can be fruitfully on if the environment

factors and market conditions are considered always with the internal capabilities.

SWOT analysis is important tool to find strength, weakness, opportunities

and threats. These factors reveal the internal and external factors which affects the company.

Strength, weakness, opportunities and threats are the elements or key factors that influence the

survival and development of any organization.

The followings are the SWOT analysis of POPULAR INDUSTRIES.

Strength

1. Largest manufacturer of candles products in Kerala