Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2K viewsLocomotion of A Tensegrity Robot Via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Locomotion of A Tensegrity Robot Via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Uploaded by

Tensegrity WikiTensegrity structures - dynamically stable systems consisting of disjoint rigid elements (rods) connected by tensile elements (strings) - are an intriguing robotic platform due to their relatively high strength-to-weight ratio, resilience to deformation, and collapsability. Furthermore, the homogeneity of the rigid elements lends itself to a modular design . However, for any such design which requires centralized control, as the scale of these robots increases, inter-modular communication becomes a challenge (not just in terms of logistics, but also in the risk of tangled wires during locomotion). An alternative proposed here is to treat each module as a completely autonomous agent, with no explicit inter-modular communication between them. Rather, the only information transmitted and received between modules is through the tension on their respective strings. As such, locomotion arises through the complex interplay of dynamical forces throughout the structure. In this extended abstract we describe a design for such a system, present an assembled model, and describe a means by which controllers can be evolved in order to produce locomotion.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- MODULE 1 - Assumptions and Nature of Arts - Creativity and ImaginationDocument26 pagesMODULE 1 - Assumptions and Nature of Arts - Creativity and ImaginationJomari Falible67% (3)

- Farsi Dictionary PDFDocument2 pagesFarsi Dictionary PDFStephanie0% (2)

- Myp Unit Plan 2Document6 pagesMyp Unit Plan 2api-52484518567% (3)

- English TestDocument4 pagesEnglish TestJose Fernando Orozco Juvinao100% (1)

- Self in TherapyDocument24 pagesSelf in Therapyaastha ahujaNo ratings yet

- Preposition (Phrasal Verbs & Prepositional Verbs)Document18 pagesPreposition (Phrasal Verbs & Prepositional Verbs)Ali JavedNo ratings yet

- ClosechainDocument15 pagesClosechainQuyết Nguyễn CôngNo ratings yet

- Passivity-Based Motion and Force Tracking Control For Constrained Elastic Joint RobotsDocument6 pagesPassivity-Based Motion and Force Tracking Control For Constrained Elastic Joint RobotsThanh Hai NguyenNo ratings yet

- Journal Publication 3Document22 pagesJournal Publication 3bilal MokraniNo ratings yet

- Modelling and Control of A Spherical Inverted Pendulum On A Five-Bar MechanismDocument16 pagesModelling and Control of A Spherical Inverted Pendulum On A Five-Bar MechanismuyhtyuNo ratings yet

- Inverted PendulumDocument18 pagesInverted PendulumLingxi HuangNo ratings yet

- Research On Co-Simulation of Rigid-Flexible Coupling System of Parallel RobotDocument6 pagesResearch On Co-Simulation of Rigid-Flexible Coupling System of Parallel RobotKamel FedaouiNo ratings yet

- Robust Stabilization of Elastic Joint Robots by ESP and PID Control Theory and ExperimentsDocument8 pagesRobust Stabilization of Elastic Joint Robots by ESP and PID Control Theory and ExperimentsThanh Hai NguyenNo ratings yet

- Modeling and Identification of A Single Link Flexible Arm With A Passive Gravity CompensationDocument7 pagesModeling and Identification of A Single Link Flexible Arm With A Passive Gravity CompensationHermogensNo ratings yet

- Kinematic and Static Analysis of A Three-Degree-Of-Freedom Spatial Modular Tensegrity MechanismDocument16 pagesKinematic and Static Analysis of A Three-Degree-Of-Freedom Spatial Modular Tensegrity MechanismAdrian NairdaNo ratings yet

- Sliding Mode Control of Two-Parameter Fourth-Order Chaos Model of Power SystemDocument5 pagesSliding Mode Control of Two-Parameter Fourth-Order Chaos Model of Power SystemPoorani MahesNo ratings yet

- Mechanism and Machine Theory: Ying Wu, Kaiping Yu, Jian Jiao, Rui ZhaoDocument29 pagesMechanism and Machine Theory: Ying Wu, Kaiping Yu, Jian Jiao, Rui ZhaoYazdan RastegarNo ratings yet

- An Acceleration-Based State Observer For Robot Manipulators With Elastic JointsDocument7 pagesAn Acceleration-Based State Observer For Robot Manipulators With Elastic JointsJyotirekha PatiNo ratings yet

- Younis and Abdelati With HeaderDocument6 pagesYounis and Abdelati With HeaderScott MelgarejoNo ratings yet

- Design and Implementation of An Experimental Segway Model: March 2009Document6 pagesDesign and Implementation of An Experimental Segway Model: March 2009SKLNo ratings yet

- Hybrid SPDocument7 pagesHybrid SPlealem girmaNo ratings yet

- Compliant Folded Beam Suspension MechanismDocument18 pagesCompliant Folded Beam Suspension Mechanismomer elaminNo ratings yet

- 01 CHAPTER 1 IntroductionDocument17 pages01 CHAPTER 1 IntroductionJerome XaviorNo ratings yet

- Optimal Control of An Holonomic System: Feedforward Design and LQR Control For A "Pick and Place" SystemDocument6 pagesOptimal Control of An Holonomic System: Feedforward Design and LQR Control For A "Pick and Place" SystemZURY MAUDELIT MESA RIZONo ratings yet

- Commande San Modele Robot A 2dllDocument18 pagesCommande San Modele Robot A 2dllElleuch DorsafNo ratings yet

- 4539 0 Cover Yun ICIADocument1 page4539 0 Cover Yun ICIAkadamsnNo ratings yet

- Dynamic Model of A Onelink Robot Manipulator With Both StructuraDocument6 pagesDynamic Model of A Onelink Robot Manipulator With Both StructurashivaNo ratings yet

- High Precision Formation Control of Mobile Robots Using Virtual StructuresDocument29 pagesHigh Precision Formation Control of Mobile Robots Using Virtual StructuresMuhammad Anaz'sNo ratings yet

- Dynamic Modelling of The Compliant KUKA-DLR Lightweight RobotDocument10 pagesDynamic Modelling of The Compliant KUKA-DLR Lightweight RobotAntonis KatsikarelisNo ratings yet

- Delta Robot Literature Riview PDFDocument11 pagesDelta Robot Literature Riview PDFArif AbbasiNo ratings yet

- An Underactuated Modular Robot For Testing Control AlgorithmsDocument7 pagesAn Underactuated Modular Robot For Testing Control AlgorithmsAlina MirelaNo ratings yet

- Anticipating Synchronization With Machine LearningDocument10 pagesAnticipating Synchronization With Machine Learningchenyeyuge94No ratings yet

- Distributed Motion Planning For 3D Modular Robots With Unit-Compressible ModulesDocument17 pagesDistributed Motion Planning For 3D Modular Robots With Unit-Compressible Modules何燕No ratings yet

- Simulation of Industrial Robots' Six Axes Manipulator Arms - A Case StudyDocument9 pagesSimulation of Industrial Robots' Six Axes Manipulator Arms - A Case Studymohmmade .zkNo ratings yet

- How Can Human Motion Prediction Increase Transparency?Document6 pagesHow Can Human Motion Prediction Increase Transparency?jasposiris33No ratings yet

- Kaluza2012 Phase Oscilatory Network As CPGDocument10 pagesKaluza2012 Phase Oscilatory Network As CPGdeepak saiNo ratings yet

- Analisa Kepecahan Stress LifeDocument19 pagesAnalisa Kepecahan Stress LiferahmatNo ratings yet

- Papers Ball and PlateDocument8 pagesPapers Ball and PlateRodriNo ratings yet

- Atm1 2 2005 Sabanovic 17 27Document11 pagesAtm1 2 2005 Sabanovic 17 27Sang NhNo ratings yet

- Med16 2Document7 pagesMed16 2Haile SimachewNo ratings yet

- Robotics Research The International Journal ofDocument12 pagesRobotics Research The International Journal ofMed MaxNo ratings yet

- Stabilization of A Class of Underactuated Mechanical Systems Via Interconnection and Damping AssignmentDocument16 pagesStabilization of A Class of Underactuated Mechanical Systems Via Interconnection and Damping AssignmentVictor PassosNo ratings yet

- 05 - IEEE TRANSACTIONS ON CYBERNETICS 2017 - Adaptive Neural Network ControlDocument10 pages05 - IEEE TRANSACTIONS ON CYBERNETICS 2017 - Adaptive Neural Network ControlLâm BảoNo ratings yet

- 1 s2.0 S1474667015341707 MainDocument6 pages1 s2.0 S1474667015341707 MainLeila JoudiNo ratings yet

- Modeling and Control of Elastic Joint Robots: M.W. SpongDocument10 pagesModeling and Control of Elastic Joint Robots: M.W. SpongCarlos Alberto Cribillero VegaNo ratings yet

- Research Interact With Human Statement 3Document12 pagesResearch Interact With Human Statement 3Alexander Waiganjo MachariaNo ratings yet

- Mechanical Systems and Signal Processing: Zhi-Cheng QiuDocument19 pagesMechanical Systems and Signal Processing: Zhi-Cheng QiuLakshmi Ganesh SudikondaNo ratings yet

- Gandarias 2020Document8 pagesGandarias 2020duonglacbkNo ratings yet

- International Journal of Engineering Science: Farooq M, Dao Bo WangDocument13 pagesInternational Journal of Engineering Science: Farooq M, Dao Bo Wangphyco1954No ratings yet

- Bounded-Impedance Absolute Stability of Bilateral Teleoperation Control Systems-PnqDocument13 pagesBounded-Impedance Absolute Stability of Bilateral Teleoperation Control Systems-PnqArchNo ratings yet

- Icinco2020 For springerLNEE v2Document25 pagesIcinco2020 For springerLNEE v21032220018No ratings yet

- Contact Control Concepts in Manipulation Robotics-An: Miomir andDocument13 pagesContact Control Concepts in Manipulation Robotics-An: Miomir andHaider NeamaNo ratings yet

- Projection-Based Force Reflection Algorithm For Stable Bilateral Teleoperation Over NetworksDocument6 pagesProjection-Based Force Reflection Algorithm For Stable Bilateral Teleoperation Over Networkssamim_khNo ratings yet

- SFB637 A5 10 014 IcDocument8 pagesSFB637 A5 10 014 IcSummrina KanwalNo ratings yet

- Is RR 01 ContactDocument8 pagesIs RR 01 Contactأحمد دعبسNo ratings yet

- Stability of Haptic Systems With Fractional Order ControllersDocument6 pagesStability of Haptic Systems With Fractional Order Controllerssuman sahaNo ratings yet

- Broadcast Control Mechanism For Positional Consensus in Multiagent SystemsDocument20 pagesBroadcast Control Mechanism For Positional Consensus in Multiagent SystemsSarathNo ratings yet

- A Brachiating Robot ControllerDocument15 pagesA Brachiating Robot Controller舒雯No ratings yet

- Michielsen - 2012 - Steady-State Dynamics of A 3D Tensegrity Structure Simulations and ExperimentsDocument16 pagesMichielsen - 2012 - Steady-State Dynamics of A 3D Tensegrity Structure Simulations and Experimentsdiogorossot_85125119No ratings yet

- The Particle Swarm - Explosion, Stability, and Convergence in A Multidimensional Complex Space PDFDocument16 pagesThe Particle Swarm - Explosion, Stability, and Convergence in A Multidimensional Complex Space PDFAzad HannanNo ratings yet

- Stable Flocking Algorithm For Multi-Robot Systems Formation ControlDocument6 pagesStable Flocking Algorithm For Multi-Robot Systems Formation ControlPiyush SinghNo ratings yet

- A Force-Controllable Compact Actuator Module For A Wearable Hand ExoskeletonDocument6 pagesA Force-Controllable Compact Actuator Module For A Wearable Hand ExoskeletonKAREN DAYANA TRUJILLO BARRIOSNo ratings yet

- Robust Collaborative Object Transportation Using Multiple MavsDocument25 pagesRobust Collaborative Object Transportation Using Multiple MavsMegan RileyNo ratings yet

- Two-Way Coupling of Rigid and Deformable BodiesDocument9 pagesTwo-Way Coupling of Rigid and Deformable Bodies3bdo HelalNo ratings yet

- Attractor Networks: Fundamentals and Applications in Computational NeuroscienceFrom EverandAttractor Networks: Fundamentals and Applications in Computational NeuroscienceNo ratings yet

- Pinuad Dynamics CRCDocument62 pagesPinuad Dynamics CRCTensegrity WikiNo ratings yet

- Tensegrity Beam Wave Dynamics 2019Document20 pagesTensegrity Beam Wave Dynamics 2019Tensegrity WikiNo ratings yet

- Marching Procedure For Tensegrity 2007Document26 pagesMarching Procedure For Tensegrity 2007Tensegrity WikiNo ratings yet

- Weiwei FSN CDC42Document6 pagesWeiwei FSN CDC42Tensegrity WikiNo ratings yet

- Han LMI Struct Linear Cdc03Document6 pagesHan LMI Struct Linear Cdc03Tensegrity WikiNo ratings yet

- Optimal Topology and Geometry For Controllable Tensegrity Systems by Jager, Masic, SkeltonDocument6 pagesOptimal Topology and Geometry For Controllable Tensegrity Systems by Jager, Masic, SkeltonTensegrity WikiNo ratings yet

- Intro To Mechanics of Tensegrity StructuresDocument6 pagesIntro To Mechanics of Tensegrity StructuresTensegrity WikiNo ratings yet

- Equilibrium Conditions of A Tensegrity Structure by Williamson, Skelton, Han 2002Document18 pagesEquilibrium Conditions of A Tensegrity Structure by Williamson, Skelton, Han 2002Tensegrity WikiNo ratings yet

- Stiffness of Planar Tensegrity Truss Topologies by Jager, Skelton 2006Document23 pagesStiffness of Planar Tensegrity Truss Topologies by Jager, Skelton 2006Tensegrity WikiNo ratings yet

- Structure Optimization Approach For Minimum-Time Reconfiguration of Tensegrity Systems by Aldrich, SkeltonDocument12 pagesStructure Optimization Approach For Minimum-Time Reconfiguration of Tensegrity Systems by Aldrich, SkeltonTensegrity WikiNo ratings yet

- Tensegrity Airfoils Henrickson, Skelton, Valasek 2016Document25 pagesTensegrity Airfoils Henrickson, Skelton, Valasek 2016Tensegrity WikiNo ratings yet

- Deployment of A Class 2 Tensegrity Boom by Pinauda, Solaria, SkeltonDocument8 pagesDeployment of A Class 2 Tensegrity Boom by Pinauda, Solaria, SkeltonTensegrity WikiNo ratings yet

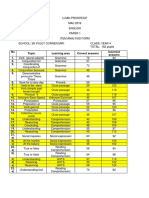

- Analisis Item Bahasa Inggeris Tahun 4 Mac 2019Document2 pagesAnalisis Item Bahasa Inggeris Tahun 4 Mac 2019Izzatie Nadia SubriNo ratings yet

- (Michel de Certeau) The Writing of History PDFDocument198 pages(Michel de Certeau) The Writing of History PDFGuri SchwarzNo ratings yet

- Stability Analysis of Dynamic SystemsDocument26 pagesStability Analysis of Dynamic SystemsClarissa AlfaroNo ratings yet

- 2 Design Thinking - EN - pptx-ALVDocument18 pages2 Design Thinking - EN - pptx-ALVSalma Dhiya FauziyahNo ratings yet

- FeelingSecret - Disec - AsifaHaniffDocument14 pagesFeelingSecret - Disec - AsifaHaniffKetan TiwariNo ratings yet

- Limited Media Effect TheoryDocument13 pagesLimited Media Effect TheoryGargiRanaNo ratings yet

- 001 Luhmann On Learning How To ReadDocument2 pages001 Luhmann On Learning How To ReadFrancivaldo LourençoNo ratings yet

- (Anna Niżegorodcew (Auth.), Mirosław Pawlak (Eds (B-Ok - CC) PDFDocument388 pages(Anna Niżegorodcew (Auth.), Mirosław Pawlak (Eds (B-Ok - CC) PDFLe Thi Tuyet Hanh100% (1)

- Study On Clinical Presentations, Level of Stress & Role of Family Environment Among Dissociative Disorder PatientsDocument10 pagesStudy On Clinical Presentations, Level of Stress & Role of Family Environment Among Dissociative Disorder PatientsIJAR JOURNALNo ratings yet

- Test AI Cannot BeatDocument4 pagesTest AI Cannot BeatаяиNo ratings yet

- Stress Among CaregiversDocument3 pagesStress Among CaregiversAlbert TettehNo ratings yet

- Aggression Essay PlansDocument16 pagesAggression Essay PlansashnaNo ratings yet

- Oral Communication, Written Communication: Message SenderDocument8 pagesOral Communication, Written Communication: Message SenderATHIRA MOHANNo ratings yet

- Module - Principles of Teaching 2Document11 pagesModule - Principles of Teaching 2noreen agripa78% (9)

- Using The Learning Criteria To Support 21st Century LearnersDocument15 pagesUsing The Learning Criteria To Support 21st Century LearnersCameron RiceNo ratings yet

- 15 232F13 Dummy DeckDocument13 pages15 232F13 Dummy DeckKaren RicafrenteNo ratings yet

- Lesson Plan Class XI (Chapter - 4 - PHYSICAL EDUCATION & SPORTS FOR CWSN (CHILDREN WITH SPECIAL NEEDS DIVYANG) )Document2 pagesLesson Plan Class XI (Chapter - 4 - PHYSICAL EDUCATION & SPORTS FOR CWSN (CHILDREN WITH SPECIAL NEEDS DIVYANG) )bharat.harit7No ratings yet

- Grade 9 - Unit 5 - ELADocument3 pagesGrade 9 - Unit 5 - ELAnemwel capolNo ratings yet

- Presentation 1Document11 pagesPresentation 1Roxan SilorioNo ratings yet

- AAST HR FinalDocument9 pagesAAST HR Finala7med3abdeenNo ratings yet

- AnalogyDocument24 pagesAnalogyTrung TranNo ratings yet

- Cowan ResumenDocument18 pagesCowan ResumenvictoriaNo ratings yet

- Akmajian, Demers, Farmer & Harnish - Linguistics, An Introduction To Language and CommunicationDocument309 pagesAkmajian, Demers, Farmer & Harnish - Linguistics, An Introduction To Language and CommunicationPhillippa88% (16)

- LESSON 7 GreadDocument2 pagesLESSON 7 Greadmuhaaamedzhanovaaa100% (1)

Locomotion of A Tensegrity Robot Via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Locomotion of A Tensegrity Robot Via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Uploaded by

Tensegrity Wiki0 ratings0% found this document useful (0 votes)

2K views3 pagesTensegrity structures - dynamically stable systems consisting of disjoint rigid elements (rods) connected by tensile elements (strings) - are an intriguing robotic platform due to their relatively high strength-to-weight ratio, resilience to deformation, and collapsability. Furthermore, the homogeneity of the rigid elements lends itself to a modular design . However, for any such design which requires centralized control, as the scale of these robots increases, inter-modular communication becomes a challenge (not just in terms of logistics, but also in the risk of tangled wires during locomotion). An alternative proposed here is to treat each module as a completely autonomous agent, with no explicit inter-modular communication between them. Rather, the only information transmitted and received between modules is through the tension on their respective strings. As such, locomotion arises through the complex interplay of dynamical forces throughout the structure. In this extended abstract we describe a design for such a system, present an assembled model, and describe a means by which controllers can be evolved in order to produce locomotion.

Original Title

Locomotion of a Tensegrity Robot via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTensegrity structures - dynamically stable systems consisting of disjoint rigid elements (rods) connected by tensile elements (strings) - are an intriguing robotic platform due to their relatively high strength-to-weight ratio, resilience to deformation, and collapsability. Furthermore, the homogeneity of the rigid elements lends itself to a modular design . However, for any such design which requires centralized control, as the scale of these robots increases, inter-modular communication becomes a challenge (not just in terms of logistics, but also in the risk of tangled wires during locomotion). An alternative proposed here is to treat each module as a completely autonomous agent, with no explicit inter-modular communication between them. Rather, the only information transmitted and received between modules is through the tension on their respective strings. As such, locomotion arises through the complex interplay of dynamical forces throughout the structure. In this extended abstract we describe a design for such a system, present an assembled model, and describe a means by which controllers can be evolved in order to produce locomotion.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2K views3 pagesLocomotion of A Tensegrity Robot Via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Locomotion of A Tensegrity Robot Via Dynamically Coupled Modules by Rieffel, Stuk, Cuevas Lipson

Uploaded by

Tensegrity WikiTensegrity structures - dynamically stable systems consisting of disjoint rigid elements (rods) connected by tensile elements (strings) - are an intriguing robotic platform due to their relatively high strength-to-weight ratio, resilience to deformation, and collapsability. Furthermore, the homogeneity of the rigid elements lends itself to a modular design . However, for any such design which requires centralized control, as the scale of these robots increases, inter-modular communication becomes a challenge (not just in terms of logistics, but also in the risk of tangled wires during locomotion). An alternative proposed here is to treat each module as a completely autonomous agent, with no explicit inter-modular communication between them. Rather, the only information transmitted and received between modules is through the tension on their respective strings. As such, locomotion arises through the complex interplay of dynamical forces throughout the structure. In this extended abstract we describe a design for such a system, present an assembled model, and describe a means by which controllers can be evolved in order to produce locomotion.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Locomotion of a Tensegrity Robot

via Dynamically Coupled Modules

John Rieffel1 , Ryan James Stuk1 , Francisco J. Valero-Cuevas1 and Hod Lipson1

1 Computational Synthesis Laboratory, Cornell University, Ithaca NY

rieffel@cornell.edu

Abstract

Tensegrity structures - dynamically stable systems consist-

ing of disjoint rigid elements (rods) connected by tensile el-

ements (strings) - are an intriguing robotic platform due to

their relatively high strength-to-weight ratio, resilience to de-

formation, and collapsability. Furthermore, the homogeneity

of the rigid elements lends itself to a modular design . How-

ever, for any such design which requires centralized control,

as the scale of these robots increases, inter-modular com-

munication becomes a challenge (not just in terms of logis-

tics, but also in the risk of tangled wires during locomotion).

An alternative proposed here is to treat each module as a

completely autonomous agent, with no explicit inter-modular Figure 1: A simple three-bar tensegrity structure

communication between them. Rather, the only information

transmitted and received between modules is through the ten-

sion on their respective strings. As such, locomotion arises

through the complex interplay of dynamical forces through- Challenges in Tensegrity Robotics

out the structure. In this extended abstract we describe a de- Recent attention has been paid to the control and manipula-

sign for such a system, present an assembled model, and de-

scribe a means by which controllers can be evolved in order

tion of tensegrity structures. Skelton et al. have been able

to produce locomotion. to demonstrate both active vibration damping (Chan et al.,

2004) and open-loop control of simple structures. More re-

cently, Paul et al. demonstrated an ability to produce static

and dynamic gaits for 3- and 4-bar tensegrity robots via evo-

Introduction

lutionary optimization, and implemented these gaits on a

The word tensegrity, a concatenation of tensile integrity was physical robot (Paul et al., 2006). Related work demon-

coined by Buckminster Fuller to describe structures first de- strated how the overall stability of these structures results

veloped by the sculptor Kenneth Snelson in 1948 (Fuller, in beneficial resilience and redundancy of control mecha-

1975). Broadly speaking, a tensegrity structure is a set of nisms (Paul et al., 2005).

disjoint rigid elements (rods) whose endpoints are connected The physical implementation of tensegrity-based robots is

by tensile elements (strings), and which maintains its shape a double-edged sword. On one hand the homogeneity of the

due to the synergy between the compressive forces on its rigid elements allows for a high degree of modularity: each

rods and the complementary forces in its cables, as shown in rod can contain identical sets of sensors and actuators – the

Figure 1. Such structures are pre-stress stable, in the sense parts of a 10-bar tensegrity could be identical to those of a

that, in equilibrium, each rigid element is under compression 3-bar one.

and each tensile element is under tension, and that the struc- On the other hand, any solution which relies upon cen-

ture has a tendency to return to its stable configuration after tralized control of the robot faces a crucial problem: that of

subjected to any moderate temporary perturbation (Connelly communication between modules. As the number of mod-

and Back, 1998). ules increases, the lines of communication (quite literally)

These principles of tensegrity can be found in a variety of increase, bringing with them the risk of tangles.

man made and natural objects, ranging from free-standing Rather than resort to potentially expensive and time con-

camping tents and geodesic domes to the cellular cytoskele- suming solutions to inter-modular communication such as

ton and even the structure of proteins (Ingber, 1998). wireless technology, we propose a simpler alternative: to

do away with the notion of explicit inter-modular commu-

nication completely - replacing locomotion via centralized

control with locomotion which emerges purely as a conse-

quence of the distributed dynamics of the system.

Decentralized Control of Dynamically

Coupled Modules

The resilience of tensegrity structures is due in large part to

their pre-stress stability: any perturbation in one section of

the structure results in a corresponding redistribution and re- Figure 2: Schematic for one end of a tensegrity element

balancing of compressive and tensile forces throughout the

structure (Ingber, 1998).

Controller Discovery

We can harness this intrinsic dynamic coupling of ele-

ments as a means of inter-modular communication. Pro- While relying on the coupled dynamics of the tensegrity

vided a module were capable of measuring changes in its lo- modules described above solves the issue of inter-modular

cal force vectors, such as the tension of its cables, it would communication, it complicates the task of control. In or-

be capable of sensing distal stimuli. Correspondingly, if a der to achieve locomotion, for instance, each module’s con-

module were capable of manipulating its local force vectors, troller may need to be out of phase or, in the extreme, each

it would able to affect the behavior of distant modules. module may require an entirely unique controller.

Given the complexity of the task, we have chosen to use

In principle, therefore, it is possible to program individual

evolutionary optimization over analytical approaches. In

modular controllers which exploit this dynamical coupling

this method, each module’s controller consists of a simple 2-

in order to produce complex behaviors such as locomotion.

layer neural network whose inputs are the forces measured

Such a system could certainly be said to be performing mor-

on each servo, and whose outputs are a consequential de-

phological computation. In the remainder of this extended

sired rest length for each string. Given the destructive na-

abstract we will describe our design of such a system.

ture of in-situ evolution, controllers are evaluated in simula-

tion (using the Open Dynamics Engine, in a manner similar

Module Design to (Paul et al., 2006) before being transferred to the physical

robot.

In order to realize such a dynamically coupled modular A movie showing an initial result of loco-

tensegrity robot we must first design modules capable of motion can be found at the author’s web site

sensing and affecting their local tension. In our case, cen- (http://www.mae.cornell.edu/rieffel/).

tral to this function is the Robotis AX-12 servo motor

(www.tribotix.com), which is capable of continuous rotation Conclusion

and, more importantly, contains an integrated load sensor. In our ongoing research we are exploring a means of loco-

As a consequence, it is capable of serving as both sensor and motion in tensegrity robots which arises from the complex

actuator. Each servo is then coupled with a simple touch sen- coupled dynamics of multiple independent modules, whose

sor and battery pack to form an element end-piece. Figure 2 only means of communication is the propagation of force

contains a schematic of this package, and Figure 3 shows its throughout the structure. In the particular design described

physical implementation. above, each modular structural element is capable of sens-

Each full modular element consists of two of these servo ing the tension at each endpoint, and of reactively affect-

payloads connected by a hollow nylon rod, as shown in Fig- ing forces through the structure by activating the connect-

ure 4. Concentrating the payload at the endpoints in this ing strings. As such, centralized control is replaced by the

manner improves clearances between modules, and allows de-centralized, emergent collective behavior of the modules.

for the creation of larger structures by simply using a longer Armed with this hardware, and with a corresponding sim-

connecting rod. ulated robot, we are presently evolving the modular con-

Modules are then connected together using nylon string trollers in order to produce locomotion.

as the tensile elements. The schematic of a complete 3-bar

robot is shown in Figure 5, and the corresponding physical References

robot is shown in Figure 6. Chan, W. L., Arbelaez, D., Bossens, F., and Skelton, R. E.:

The simplicity and flexibility of this modular system al- 2004, Active vibration control of a three-stage tensegrity

lows us to scale to larger structures with more elements rel- structure, in Proceedings of SPIE 11th Annual Interna-

atively easily. tional Symposium on Smart Structures and Materials.

Figure 3: The physical assembly of the module end in Fig-

ure 2

Figure 6: The fully assembled modular tensegrity robot

Paul, C., Valero-Cuevas, F. J., and Lipson, H.: 2005, Re-

dundancy in the control of robots with highly coupled

mechanical structures, in Int. Conf. on Intelligent Robots

and Systems, pp 802–808

Paul, C., Valero-Cuevas, F. J., and Lipson, H.: 2006, Design

Figure 4: A complete module and control of tensegrity robots for locomotion, IEEE

Transactions on Robotics 22(5)

Figure 5: CAD model of a complete modular tensegrity

robot

Connelly, R. and Back, A.: 1998, Mathematics and tenseg-

rity, American Scientist 86

Fuller, R. B.: 1975, Synergetics—Explorations in the Ge-

ometry of Thinking, Macmillan Publishing Co

Ingber, D. E.: 1998, The architecture of life, Scientific

American

You might also like

- MODULE 1 - Assumptions and Nature of Arts - Creativity and ImaginationDocument26 pagesMODULE 1 - Assumptions and Nature of Arts - Creativity and ImaginationJomari Falible67% (3)

- Farsi Dictionary PDFDocument2 pagesFarsi Dictionary PDFStephanie0% (2)

- Myp Unit Plan 2Document6 pagesMyp Unit Plan 2api-52484518567% (3)

- English TestDocument4 pagesEnglish TestJose Fernando Orozco Juvinao100% (1)

- Self in TherapyDocument24 pagesSelf in Therapyaastha ahujaNo ratings yet

- Preposition (Phrasal Verbs & Prepositional Verbs)Document18 pagesPreposition (Phrasal Verbs & Prepositional Verbs)Ali JavedNo ratings yet

- ClosechainDocument15 pagesClosechainQuyết Nguyễn CôngNo ratings yet

- Passivity-Based Motion and Force Tracking Control For Constrained Elastic Joint RobotsDocument6 pagesPassivity-Based Motion and Force Tracking Control For Constrained Elastic Joint RobotsThanh Hai NguyenNo ratings yet

- Journal Publication 3Document22 pagesJournal Publication 3bilal MokraniNo ratings yet

- Modelling and Control of A Spherical Inverted Pendulum On A Five-Bar MechanismDocument16 pagesModelling and Control of A Spherical Inverted Pendulum On A Five-Bar MechanismuyhtyuNo ratings yet

- Inverted PendulumDocument18 pagesInverted PendulumLingxi HuangNo ratings yet

- Research On Co-Simulation of Rigid-Flexible Coupling System of Parallel RobotDocument6 pagesResearch On Co-Simulation of Rigid-Flexible Coupling System of Parallel RobotKamel FedaouiNo ratings yet

- Robust Stabilization of Elastic Joint Robots by ESP and PID Control Theory and ExperimentsDocument8 pagesRobust Stabilization of Elastic Joint Robots by ESP and PID Control Theory and ExperimentsThanh Hai NguyenNo ratings yet

- Modeling and Identification of A Single Link Flexible Arm With A Passive Gravity CompensationDocument7 pagesModeling and Identification of A Single Link Flexible Arm With A Passive Gravity CompensationHermogensNo ratings yet

- Kinematic and Static Analysis of A Three-Degree-Of-Freedom Spatial Modular Tensegrity MechanismDocument16 pagesKinematic and Static Analysis of A Three-Degree-Of-Freedom Spatial Modular Tensegrity MechanismAdrian NairdaNo ratings yet

- Sliding Mode Control of Two-Parameter Fourth-Order Chaos Model of Power SystemDocument5 pagesSliding Mode Control of Two-Parameter Fourth-Order Chaos Model of Power SystemPoorani MahesNo ratings yet

- Mechanism and Machine Theory: Ying Wu, Kaiping Yu, Jian Jiao, Rui ZhaoDocument29 pagesMechanism and Machine Theory: Ying Wu, Kaiping Yu, Jian Jiao, Rui ZhaoYazdan RastegarNo ratings yet

- An Acceleration-Based State Observer For Robot Manipulators With Elastic JointsDocument7 pagesAn Acceleration-Based State Observer For Robot Manipulators With Elastic JointsJyotirekha PatiNo ratings yet

- Younis and Abdelati With HeaderDocument6 pagesYounis and Abdelati With HeaderScott MelgarejoNo ratings yet

- Design and Implementation of An Experimental Segway Model: March 2009Document6 pagesDesign and Implementation of An Experimental Segway Model: March 2009SKLNo ratings yet

- Hybrid SPDocument7 pagesHybrid SPlealem girmaNo ratings yet

- Compliant Folded Beam Suspension MechanismDocument18 pagesCompliant Folded Beam Suspension Mechanismomer elaminNo ratings yet

- 01 CHAPTER 1 IntroductionDocument17 pages01 CHAPTER 1 IntroductionJerome XaviorNo ratings yet

- Optimal Control of An Holonomic System: Feedforward Design and LQR Control For A "Pick and Place" SystemDocument6 pagesOptimal Control of An Holonomic System: Feedforward Design and LQR Control For A "Pick and Place" SystemZURY MAUDELIT MESA RIZONo ratings yet

- Commande San Modele Robot A 2dllDocument18 pagesCommande San Modele Robot A 2dllElleuch DorsafNo ratings yet

- 4539 0 Cover Yun ICIADocument1 page4539 0 Cover Yun ICIAkadamsnNo ratings yet

- Dynamic Model of A Onelink Robot Manipulator With Both StructuraDocument6 pagesDynamic Model of A Onelink Robot Manipulator With Both StructurashivaNo ratings yet

- High Precision Formation Control of Mobile Robots Using Virtual StructuresDocument29 pagesHigh Precision Formation Control of Mobile Robots Using Virtual StructuresMuhammad Anaz'sNo ratings yet

- Dynamic Modelling of The Compliant KUKA-DLR Lightweight RobotDocument10 pagesDynamic Modelling of The Compliant KUKA-DLR Lightweight RobotAntonis KatsikarelisNo ratings yet

- Delta Robot Literature Riview PDFDocument11 pagesDelta Robot Literature Riview PDFArif AbbasiNo ratings yet

- An Underactuated Modular Robot For Testing Control AlgorithmsDocument7 pagesAn Underactuated Modular Robot For Testing Control AlgorithmsAlina MirelaNo ratings yet

- Anticipating Synchronization With Machine LearningDocument10 pagesAnticipating Synchronization With Machine Learningchenyeyuge94No ratings yet

- Distributed Motion Planning For 3D Modular Robots With Unit-Compressible ModulesDocument17 pagesDistributed Motion Planning For 3D Modular Robots With Unit-Compressible Modules何燕No ratings yet

- Simulation of Industrial Robots' Six Axes Manipulator Arms - A Case StudyDocument9 pagesSimulation of Industrial Robots' Six Axes Manipulator Arms - A Case Studymohmmade .zkNo ratings yet

- How Can Human Motion Prediction Increase Transparency?Document6 pagesHow Can Human Motion Prediction Increase Transparency?jasposiris33No ratings yet

- Kaluza2012 Phase Oscilatory Network As CPGDocument10 pagesKaluza2012 Phase Oscilatory Network As CPGdeepak saiNo ratings yet

- Analisa Kepecahan Stress LifeDocument19 pagesAnalisa Kepecahan Stress LiferahmatNo ratings yet

- Papers Ball and PlateDocument8 pagesPapers Ball and PlateRodriNo ratings yet

- Atm1 2 2005 Sabanovic 17 27Document11 pagesAtm1 2 2005 Sabanovic 17 27Sang NhNo ratings yet

- Med16 2Document7 pagesMed16 2Haile SimachewNo ratings yet

- Robotics Research The International Journal ofDocument12 pagesRobotics Research The International Journal ofMed MaxNo ratings yet

- Stabilization of A Class of Underactuated Mechanical Systems Via Interconnection and Damping AssignmentDocument16 pagesStabilization of A Class of Underactuated Mechanical Systems Via Interconnection and Damping AssignmentVictor PassosNo ratings yet

- 05 - IEEE TRANSACTIONS ON CYBERNETICS 2017 - Adaptive Neural Network ControlDocument10 pages05 - IEEE TRANSACTIONS ON CYBERNETICS 2017 - Adaptive Neural Network ControlLâm BảoNo ratings yet

- 1 s2.0 S1474667015341707 MainDocument6 pages1 s2.0 S1474667015341707 MainLeila JoudiNo ratings yet

- Modeling and Control of Elastic Joint Robots: M.W. SpongDocument10 pagesModeling and Control of Elastic Joint Robots: M.W. SpongCarlos Alberto Cribillero VegaNo ratings yet

- Research Interact With Human Statement 3Document12 pagesResearch Interact With Human Statement 3Alexander Waiganjo MachariaNo ratings yet

- Mechanical Systems and Signal Processing: Zhi-Cheng QiuDocument19 pagesMechanical Systems and Signal Processing: Zhi-Cheng QiuLakshmi Ganesh SudikondaNo ratings yet

- Gandarias 2020Document8 pagesGandarias 2020duonglacbkNo ratings yet

- International Journal of Engineering Science: Farooq M, Dao Bo WangDocument13 pagesInternational Journal of Engineering Science: Farooq M, Dao Bo Wangphyco1954No ratings yet

- Bounded-Impedance Absolute Stability of Bilateral Teleoperation Control Systems-PnqDocument13 pagesBounded-Impedance Absolute Stability of Bilateral Teleoperation Control Systems-PnqArchNo ratings yet

- Icinco2020 For springerLNEE v2Document25 pagesIcinco2020 For springerLNEE v21032220018No ratings yet

- Contact Control Concepts in Manipulation Robotics-An: Miomir andDocument13 pagesContact Control Concepts in Manipulation Robotics-An: Miomir andHaider NeamaNo ratings yet

- Projection-Based Force Reflection Algorithm For Stable Bilateral Teleoperation Over NetworksDocument6 pagesProjection-Based Force Reflection Algorithm For Stable Bilateral Teleoperation Over Networkssamim_khNo ratings yet

- SFB637 A5 10 014 IcDocument8 pagesSFB637 A5 10 014 IcSummrina KanwalNo ratings yet

- Is RR 01 ContactDocument8 pagesIs RR 01 Contactأحمد دعبسNo ratings yet

- Stability of Haptic Systems With Fractional Order ControllersDocument6 pagesStability of Haptic Systems With Fractional Order Controllerssuman sahaNo ratings yet

- Broadcast Control Mechanism For Positional Consensus in Multiagent SystemsDocument20 pagesBroadcast Control Mechanism For Positional Consensus in Multiagent SystemsSarathNo ratings yet

- A Brachiating Robot ControllerDocument15 pagesA Brachiating Robot Controller舒雯No ratings yet

- Michielsen - 2012 - Steady-State Dynamics of A 3D Tensegrity Structure Simulations and ExperimentsDocument16 pagesMichielsen - 2012 - Steady-State Dynamics of A 3D Tensegrity Structure Simulations and Experimentsdiogorossot_85125119No ratings yet

- The Particle Swarm - Explosion, Stability, and Convergence in A Multidimensional Complex Space PDFDocument16 pagesThe Particle Swarm - Explosion, Stability, and Convergence in A Multidimensional Complex Space PDFAzad HannanNo ratings yet

- Stable Flocking Algorithm For Multi-Robot Systems Formation ControlDocument6 pagesStable Flocking Algorithm For Multi-Robot Systems Formation ControlPiyush SinghNo ratings yet

- A Force-Controllable Compact Actuator Module For A Wearable Hand ExoskeletonDocument6 pagesA Force-Controllable Compact Actuator Module For A Wearable Hand ExoskeletonKAREN DAYANA TRUJILLO BARRIOSNo ratings yet

- Robust Collaborative Object Transportation Using Multiple MavsDocument25 pagesRobust Collaborative Object Transportation Using Multiple MavsMegan RileyNo ratings yet

- Two-Way Coupling of Rigid and Deformable BodiesDocument9 pagesTwo-Way Coupling of Rigid and Deformable Bodies3bdo HelalNo ratings yet

- Attractor Networks: Fundamentals and Applications in Computational NeuroscienceFrom EverandAttractor Networks: Fundamentals and Applications in Computational NeuroscienceNo ratings yet

- Pinuad Dynamics CRCDocument62 pagesPinuad Dynamics CRCTensegrity WikiNo ratings yet

- Tensegrity Beam Wave Dynamics 2019Document20 pagesTensegrity Beam Wave Dynamics 2019Tensegrity WikiNo ratings yet

- Marching Procedure For Tensegrity 2007Document26 pagesMarching Procedure For Tensegrity 2007Tensegrity WikiNo ratings yet

- Weiwei FSN CDC42Document6 pagesWeiwei FSN CDC42Tensegrity WikiNo ratings yet

- Han LMI Struct Linear Cdc03Document6 pagesHan LMI Struct Linear Cdc03Tensegrity WikiNo ratings yet

- Optimal Topology and Geometry For Controllable Tensegrity Systems by Jager, Masic, SkeltonDocument6 pagesOptimal Topology and Geometry For Controllable Tensegrity Systems by Jager, Masic, SkeltonTensegrity WikiNo ratings yet

- Intro To Mechanics of Tensegrity StructuresDocument6 pagesIntro To Mechanics of Tensegrity StructuresTensegrity WikiNo ratings yet

- Equilibrium Conditions of A Tensegrity Structure by Williamson, Skelton, Han 2002Document18 pagesEquilibrium Conditions of A Tensegrity Structure by Williamson, Skelton, Han 2002Tensegrity WikiNo ratings yet

- Stiffness of Planar Tensegrity Truss Topologies by Jager, Skelton 2006Document23 pagesStiffness of Planar Tensegrity Truss Topologies by Jager, Skelton 2006Tensegrity WikiNo ratings yet

- Structure Optimization Approach For Minimum-Time Reconfiguration of Tensegrity Systems by Aldrich, SkeltonDocument12 pagesStructure Optimization Approach For Minimum-Time Reconfiguration of Tensegrity Systems by Aldrich, SkeltonTensegrity WikiNo ratings yet

- Tensegrity Airfoils Henrickson, Skelton, Valasek 2016Document25 pagesTensegrity Airfoils Henrickson, Skelton, Valasek 2016Tensegrity WikiNo ratings yet

- Deployment of A Class 2 Tensegrity Boom by Pinauda, Solaria, SkeltonDocument8 pagesDeployment of A Class 2 Tensegrity Boom by Pinauda, Solaria, SkeltonTensegrity WikiNo ratings yet

- Analisis Item Bahasa Inggeris Tahun 4 Mac 2019Document2 pagesAnalisis Item Bahasa Inggeris Tahun 4 Mac 2019Izzatie Nadia SubriNo ratings yet

- (Michel de Certeau) The Writing of History PDFDocument198 pages(Michel de Certeau) The Writing of History PDFGuri SchwarzNo ratings yet

- Stability Analysis of Dynamic SystemsDocument26 pagesStability Analysis of Dynamic SystemsClarissa AlfaroNo ratings yet

- 2 Design Thinking - EN - pptx-ALVDocument18 pages2 Design Thinking - EN - pptx-ALVSalma Dhiya FauziyahNo ratings yet

- FeelingSecret - Disec - AsifaHaniffDocument14 pagesFeelingSecret - Disec - AsifaHaniffKetan TiwariNo ratings yet

- Limited Media Effect TheoryDocument13 pagesLimited Media Effect TheoryGargiRanaNo ratings yet

- 001 Luhmann On Learning How To ReadDocument2 pages001 Luhmann On Learning How To ReadFrancivaldo LourençoNo ratings yet

- (Anna Niżegorodcew (Auth.), Mirosław Pawlak (Eds (B-Ok - CC) PDFDocument388 pages(Anna Niżegorodcew (Auth.), Mirosław Pawlak (Eds (B-Ok - CC) PDFLe Thi Tuyet Hanh100% (1)

- Study On Clinical Presentations, Level of Stress & Role of Family Environment Among Dissociative Disorder PatientsDocument10 pagesStudy On Clinical Presentations, Level of Stress & Role of Family Environment Among Dissociative Disorder PatientsIJAR JOURNALNo ratings yet

- Test AI Cannot BeatDocument4 pagesTest AI Cannot BeatаяиNo ratings yet

- Stress Among CaregiversDocument3 pagesStress Among CaregiversAlbert TettehNo ratings yet

- Aggression Essay PlansDocument16 pagesAggression Essay PlansashnaNo ratings yet

- Oral Communication, Written Communication: Message SenderDocument8 pagesOral Communication, Written Communication: Message SenderATHIRA MOHANNo ratings yet

- Module - Principles of Teaching 2Document11 pagesModule - Principles of Teaching 2noreen agripa78% (9)

- Using The Learning Criteria To Support 21st Century LearnersDocument15 pagesUsing The Learning Criteria To Support 21st Century LearnersCameron RiceNo ratings yet

- 15 232F13 Dummy DeckDocument13 pages15 232F13 Dummy DeckKaren RicafrenteNo ratings yet

- Lesson Plan Class XI (Chapter - 4 - PHYSICAL EDUCATION & SPORTS FOR CWSN (CHILDREN WITH SPECIAL NEEDS DIVYANG) )Document2 pagesLesson Plan Class XI (Chapter - 4 - PHYSICAL EDUCATION & SPORTS FOR CWSN (CHILDREN WITH SPECIAL NEEDS DIVYANG) )bharat.harit7No ratings yet

- Grade 9 - Unit 5 - ELADocument3 pagesGrade 9 - Unit 5 - ELAnemwel capolNo ratings yet

- Presentation 1Document11 pagesPresentation 1Roxan SilorioNo ratings yet

- AAST HR FinalDocument9 pagesAAST HR Finala7med3abdeenNo ratings yet

- AnalogyDocument24 pagesAnalogyTrung TranNo ratings yet

- Cowan ResumenDocument18 pagesCowan ResumenvictoriaNo ratings yet

- Akmajian, Demers, Farmer & Harnish - Linguistics, An Introduction To Language and CommunicationDocument309 pagesAkmajian, Demers, Farmer & Harnish - Linguistics, An Introduction To Language and CommunicationPhillippa88% (16)

- LESSON 7 GreadDocument2 pagesLESSON 7 Greadmuhaaamedzhanovaaa100% (1)