Professional Documents

Culture Documents

Aisi 1008 PDF

Aisi 1008 PDF

Uploaded by

IbsonhCopyright:

Available Formats

You might also like

- Astm A123 PDFDocument2 pagesAstm A123 PDFবিপ্লব পাল71% (7)

- Marco o Ring Size Chart Japanese PDFDocument12 pagesMarco o Ring Size Chart Japanese PDFraymond ngoNo ratings yet

- Aisi 1008 Carbon Steel (Uns g10080)Document3 pagesAisi 1008 Carbon Steel (Uns g10080)parasite01100% (1)

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429No ratings yet

- En 10051 PDFDocument2 pagesEn 10051 PDFSrikanth Reddy0% (1)

- D1014Document5 pagesD1014manox007No ratings yet

- Mind Museum PhilippinesDocument4 pagesMind Museum PhilippinesAnna OdroboNo ratings yet

- ULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurDocument2 pagesULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurKiranNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- AstmDocument7 pagesAstmIlyas AhmedNo ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- Hardox 500 Sheet: General Product DescriptionDocument2 pagesHardox 500 Sheet: General Product DescriptionDylkanWingsNo ratings yet

- Jis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresDocument11 pagesJis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresAnonymous gQyrTUHX38No ratings yet

- Sae 1008Document3 pagesSae 1008lokesh38No ratings yet

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDocument1 pageEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4No ratings yet

- MildSteel AISI 1018Document2 pagesMildSteel AISI 1018ramanamurtytv7176No ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- Ansi b18.2.1 Hex Machine BoltDocument1 pageAnsi b18.2.1 Hex Machine BoltBharatNo ratings yet

- Equivalent TableDocument12 pagesEquivalent TableArie HendriyanaNo ratings yet

- S355 EN 10025 - Standard Structural Steel ProductsDocument2 pagesS355 EN 10025 - Standard Structural Steel ProductsAlmir Pendek100% (1)

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- ABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerDocument3 pagesABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerElizabeth HarrisNo ratings yet

- A780 PDFDocument3 pagesA780 PDFMauricio Adame100% (1)

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Astm b221mDocument14 pagesAstm b221mrandi777770% (1)

- Q235BDocument2 pagesQ235BGoh Boon TiongNo ratings yet

- Tolerances To en 10051 For Continuously Rolled HotDocument4 pagesTolerances To en 10051 For Continuously Rolled HotSorin LescaiNo ratings yet

- SPHC, SPHDDocument2 pagesSPHC, SPHD1q2w3e4fNo ratings yet

- ASTM A 499 - 89 Standard Specs For Steel BArs and Shapes, CArbon Rolled From T Rails PDFDocument4 pagesASTM A 499 - 89 Standard Specs For Steel BArs and Shapes, CArbon Rolled From T Rails PDFpolarisNo ratings yet

- ASTM A572 Steel - Grade 50Document1 pageASTM A572 Steel - Grade 50FWICIP100% (1)

- Astm A 153 PDFDocument4 pagesAstm A 153 PDFmahmoud hegazy100% (5)

- BS en 10088-4-2009Document48 pagesBS en 10088-4-2009khanhNo ratings yet

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Astm A500Document2 pagesAstm A500Liquor Liam0% (1)

- Astm F 593-02 E04Document8 pagesAstm F 593-02 E04JORGE ARTURO TORIBIO HUERTANo ratings yet

- Iso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFDocument5 pagesIso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFMitesh MakvanaNo ratings yet

- N38A SR2.2 - NormDocument14 pagesN38A SR2.2 - Normgokul100% (1)

- ASTM F3125 F3125M-19 Minimum Tensile StrengthDocument13 pagesASTM F3125 F3125M-19 Minimum Tensile StrengthJiangleiNo ratings yet

- S275JRDocument1 pageS275JRShahzad QamarNo ratings yet

- Essar Steel Galvanised BrochureDocument9 pagesEssar Steel Galvanised BrochureSukanya Sen DuttaNo ratings yet

- Astm 795Document7 pagesAstm 795djfreditoNo ratings yet

- Jis G0404 1999Document22 pagesJis G0404 1999puwarin naja100% (1)

- C43Document1 pageC43rudramansingh123No ratings yet

- Product Catalogue For Steel Re-BarsDocument35 pagesProduct Catalogue For Steel Re-BarsCrazyBookWormNo ratings yet

- Astm A325 and A490 Torque ValueDocument1 pageAstm A325 and A490 Torque ValueVictor Manuel Palafox ContrerasNo ratings yet

- Hyundai Formwork - Presentation - 2020Document48 pagesHyundai Formwork - Presentation - 2020smijuNo ratings yet

- As 1874-2000 Aluminium and Aluminium Alloys - Ingots and CastingsDocument7 pagesAs 1874-2000 Aluminium and Aluminium Alloys - Ingots and CastingsSAI Global - APACNo ratings yet

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNo ratings yet

- ASTM Std. F668.atfz8781Document6 pagesASTM Std. F668.atfz8781Eidrish ShaikhNo ratings yet

- ASTM A194 A194M 2022 InglesDocument3 pagesASTM A194 A194M 2022 InglesErickNo ratings yet

- Astm A240-16Document14 pagesAstm A240-16VIPAN RAINo ratings yet

- CZ106 Sheet Strip Foil To BS 2870Document2 pagesCZ106 Sheet Strip Foil To BS 2870zaafrNo ratings yet

- Astm A449Document9 pagesAstm A449Sameercmore0% (1)

- Astm A 1011M PDFDocument8 pagesAstm A 1011M PDFJuan CarlosNo ratings yet

- As 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiDocument7 pagesAs 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiThaiminh VoNo ratings yet

- Aisi 1018Document1 pageAisi 10188085roNo ratings yet

- 17.4 PH Material SpecificationDocument2 pages17.4 PH Material SpecificationDevendra BangarNo ratings yet

- GB 700-88Document5 pagesGB 700-88nazarasimNo ratings yet

- AISI1040Document2 pagesAISI1040Anonymous qRbPsLpuNNo ratings yet

- MaterialData 6877Document2 pagesMaterialData 6877Maxi PianelliNo ratings yet

- AISI 4130 Steel 870C NormalisedDocument3 pagesAISI 4130 Steel 870C NormalisedjimNo ratings yet

- Metal Ferrous Metal Duplex Stainless SteelDocument2 pagesMetal Ferrous Metal Duplex Stainless SteelTomy GeorgeNo ratings yet

- DocumentoDocument8 pagesDocumentoIbsonhNo ratings yet

- Introduction To Finite Element Method: 1D Steady State Conservation LawsDocument49 pagesIntroduction To Finite Element Method: 1D Steady State Conservation LawsIbsonhNo ratings yet

- This Extract From The CATIA V5 Introduction User GuideDocument40 pagesThis Extract From The CATIA V5 Introduction User GuideIbsonhNo ratings yet

- Numerical Methods For Hyperbolic Conservation Laws: Dr. Aamer HaqueDocument27 pagesNumerical Methods For Hyperbolic Conservation Laws: Dr. Aamer HaqueIbsonhNo ratings yet

- Bronze SAE 64 PDFDocument1 pageBronze SAE 64 PDFIbsonhNo ratings yet

- Aco AISI 1020 PDFDocument1 pageAco AISI 1020 PDFIbsonhNo ratings yet

- Aluminio 2024-T3Document2 pagesAluminio 2024-T3IbsonhNo ratings yet

- MMP Awards Specialist Profile..Document2 pagesMMP Awards Specialist Profile..Joy TolentinoNo ratings yet

- Pneumatic Punching Machine DesignDocument3 pagesPneumatic Punching Machine DesignAmrinder SinghNo ratings yet

- Level Anti-Crossings of An NV Center in Diamond: Decoherence-Free Subspaces and 3D Sensors of Microwave Magnetic FieldsDocument7 pagesLevel Anti-Crossings of An NV Center in Diamond: Decoherence-Free Subspaces and 3D Sensors of Microwave Magnetic FieldsKoti KamineniNo ratings yet

- 3 ReviewDocument5 pages3 ReviewJNo ratings yet

- Surface Vehicle Information: Rev. AUG2002Document29 pagesSurface Vehicle Information: Rev. AUG2002Julio Herrera VenegasNo ratings yet

- Tarot For BeginnersDocument46 pagesTarot For BeginnersmatarrayoNo ratings yet

- CE Board Problems in PhysicsDocument4 pagesCE Board Problems in PhysicsChristopher PantojaNo ratings yet

- 5 Aerosol Pioneer Edited Aug CNDaviesDocument3 pages5 Aerosol Pioneer Edited Aug CNDaviesNarinder SinghNo ratings yet

- Air Compressor TermsDocument9 pagesAir Compressor TermsUniversal CollabNo ratings yet

- Selection of Induction MotorsDocument5 pagesSelection of Induction MotorsadauNo ratings yet

- Processo Lavagem - 7. Pulp Washing 12 Session 7Document66 pagesProcesso Lavagem - 7. Pulp Washing 12 Session 7Ricardo MendesNo ratings yet

- Company ProfileDocument5 pagesCompany ProfileiezohreNo ratings yet

- L15 - Deflection-Conjugate Beam MethodDocument18 pagesL15 - Deflection-Conjugate Beam MethodRaghul TNo ratings yet

- Cambridge International Examinations Cambridge Ordinary LevelDocument3 pagesCambridge International Examinations Cambridge Ordinary LevelAmanNo ratings yet

- Multidimensional ScalingDocument43 pagesMultidimensional ScalingAndrea TeohNo ratings yet

- PSM Shaft Linear MotorDocument2 pagesPSM Shaft Linear MotorjuliangoalNo ratings yet

- Light Energy Grade 6 PWSDocument5 pagesLight Energy Grade 6 PWSG ANo ratings yet

- Lecture 17 - Signalized Intersection DelayDocument34 pagesLecture 17 - Signalized Intersection DelayBasoz Arif AhmadNo ratings yet

- 6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenDocument4 pages6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenAmeya SavnalNo ratings yet

- User Manual For Darktable ToolDocument124 pagesUser Manual For Darktable ToolmishraanadiNo ratings yet

- LOS Rate Estimation Techniques For Proportional Navigation Guided MissilesDocument6 pagesLOS Rate Estimation Techniques For Proportional Navigation Guided MissilesDpt HtegnNo ratings yet

- The Liberation of GeometryDocument8 pagesThe Liberation of GeometryGeorge Mpantes mathematics teacherNo ratings yet

- A Decant CentrifugeDocument2 pagesA Decant Centrifugevijay kumar honnaliNo ratings yet

- Sieve Analysis-03.11Document2 pagesSieve Analysis-03.11ASHOKKUMARNo ratings yet

- ADC Book CompleteDocument125 pagesADC Book CompleteBenjamín BuskeNo ratings yet

- Waves and SoundDocument98 pagesWaves and SoundLegdor EdralaNo ratings yet

- Characteristics of The Weibull Distribution, This Issue - S Reliability BasicDocument8 pagesCharacteristics of The Weibull Distribution, This Issue - S Reliability BasicmarsulexNo ratings yet

- Maneuvre of VesselDocument70 pagesManeuvre of VesselLuisPazPerdomo100% (1)

Aisi 1008 PDF

Aisi 1008 PDF

Uploaded by

IbsonhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisi 1008 PDF

Aisi 1008 PDF

Uploaded by

IbsonhCopyright:

Available Formats

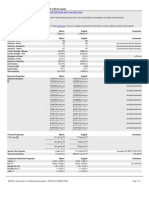

AISI 1008 Steel, CQ, DQ, and DQSK sheet, 1.6-5.

8 mm thick

Categories:

Metal; Ferrous Metal; Carbon Steel; AISI 1000 Series Steel; Low Carbon Steel

Material

Notes:

Usually produced as rimmed, capped, semikilled, and fully killed, Rimmed have exceptional cold fomability. Weldability (spot, projection, butt, and fusion) and

brazeability are excellent. Applications include extruded, cold headed, cold upset, and cold pressed parts and forms.

Key Words:

UNS G10080, JIS G3141(96) SPCC, ASTM A29, ASTM A108, ASTM A510, ASTM A519, ASTM A545, ASTM A577, ASTM A576, ASTM A787, ASTM A830,

FED QQ-S-637 (C1008), FED QQ-S-698 (C1008), MIL SPEC MIL-S-11310 (CS1008), SAE J405, SAE J412, SAE J414, DIN 1.0204, UNI CB10 FU

Vendors:

Click here to view all available suppliers for this material.

Please click here if you are a supplier and would like information on how to add your listing to this material.

Physical Properties

Density

Mechanical Properties

Tensile Strength, Ultimate

Tensile Strength, Yield

Elongation at Break

Modulus of Elasticity

Bulk Modulus

Poissons Ratio

Machinability

Shear Modulus

Electrical Properties

Electrical Resistivity

Thermal Properties

CTE, linear 20C

CTE, linear 250C

CTE, linear 500C

CTE, linear 1000C

Specific Heat Capacity

Metric

7.872 g/cc

English

0.2844 lb/in

Metric

303 - 358 MPa

180 - 240 MPa

42.0 - 48.0 %

200 GPa

140 GPa

0.290

55.0 %

English

43900 - 51900 psi

26100 - 34800 psi

42.0 - 48.0 %

29000 ksi

20300 ksi

0.290

55.0 %

80.0 GPa

11600 ksi

in 50 mm.

Typical for steel

Typical for steel

Typical For Steel

Based on AISI 1212 steel. as 100% machinability. The machinability

of Group I bar, rod, and wire products can be improved by cold

drawing.

Typical for steel

Metric

0.0000142 ohm-cm

0.0000190 ohm-cm

English

0.0000142 ohm-cm

0.0000190 ohm-cm

Comments

annealed specimen, Composition 0.08% C, 0.31% Mn.; 20C (68F)

annealed specimen, Composition 0.08% C, 0.31% Mn.

@Temperature 100 C

@Temperature 212 F

0.0000263 ohm-cm

0.0000263 ohm-cm

@Temperature 200 C

@Temperature 392 F

0.0000458 ohm-cm

0.0000458 ohm-cm

@Temperature 400 C

@Temperature 752 F

0.0000734 ohm-cm

0.0000734 ohm-cm

@Temperature 600 C

@Temperature 1110 F

0.0000905 ohm-cm

0.0000905 ohm-cm

@Temperature 700 C

@Temperature 1290 F

0.0001081 ohm-cm

0.0001081 ohm-cm

@Temperature 800 C

@Temperature 1470 F

0.000113 ohm-cm

0.000113 ohm-cm

@Temperature 900 C

@Temperature 1650 F

0.0001165 ohm-cm

0.0001165 ohm-cm

@Temperature 1000 C

@Temperature 1830 F

0.0001193 ohm-cm

0.0001193 ohm-cm

@Temperature 1100 C

@Temperature 2010 F

0.0001216 ohm-cm

0.0001216 ohm-cm

@Temperature 1200 C

@Temperature 2190 F

Metric

12.6 m/m-C

13.1 m/m-C

13.5 m/m-C

13.7 m/m-C

14.2 m/m-C

14.6 m/m-C

14.9 m/m-C

16.6 m/m-C

13.7 m/m-C

0.481 J/g-C

0.519 J/g-C

English

7.00 in/in-F

7.28 in/in-F

7.50 in/in-F

7.61 in/in-F

7.89 in/in-F

8.11 in/in-F

8.28 in/in-F

9.22 in/in-F

7.61 in/in-F

0.115 BTU/lb-F

0.124 BTU/lb-F

@Temperature 150 - 200 C

@Temperature 302 - 392 F

0.536 J/g-C

0.128 BTU/lb-F

@Temperature 200 - 250 C

@Temperature 392 - 482 F

0.553 J/g-C

0.132 BTU/lb-F

@Temperature 250 - 300 C

@Temperature 482 - 572 F

0.595 J/g-C

0.142 BTU/lb-F

@Temperature 350 - 400 C

@Temperature 662 - 752 F

0.662 J/g-C

0.158 BTU/lb-F

@Temperature 450 - 500 C

@Temperature 842 - 932 F

0.754 J/g-C

0.180 BTU/lb-F

@Temperature 550 - 600 C

@Temperature 1020 - 1110 F

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM

/

0.846 J/g-C

@Temperature 850 - 900 C

0.202 BTU/lb-F

@Temperature 1560 - 1650 F

0.867 J/g-C

0.207 BTU/lb-F

@Temperature 650 - 700 C

@Temperature 1200 - 1290 F

1.105 J/g-C

0.2641 BTU/lb-F

Comments

Composition 0.06% C, 0.38% Mn, 0.01% Si, annealed at 925C

Comments

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

annealed specimen, Composition 0.08% C, 0.31% Mn.

Comments

0-100C

0-200C

0-300C (68-570F)

0-400C (68-750F)

0-500C (68-930F)

0-600C (68-1110F)

0-700C (68-1290F)

0-800C (68-1470F)

0-1000C (68-1830F)

50-100C (122-212F)

Page 1 / 2

@Temperature 350 - 400 C

Thermal Conductivity

Material Components Properties

Carbon, C

Iron, Fe

Manganese, Mn

Phosphorous, P

Sulfur, S

@Temperature 662 - 752 F

0.662 J/g-C

0.158 BTU/lb-F

@Temperature 450 - 500 C

@Temperature 842 - 932 F

0.754 J/g-C

0.180 BTU/lb-F

@Temperature 550 - 600 C

@Temperature 1020 - 1110 F

0.846 J/g-C

0.202 BTU/lb-F

@Temperature 850 - 900 C

@Temperature 1560 - 1650 F

0.867 J/g-C

0.207 BTU/lb-F

@Temperature 650 - 700 C

@Temperature 1200 - 1290 F

1.105 J/g-C

0.2641 BTU/lb-F

@Temperature 700 - 750 C

@Temperature 1290 - 1380 F

27.3 W/m-K

189 BTU-in/hr-ft-F

@Temperature 1000 C

@Temperature 1830 F

28.4 W/m-K

197 BTU-in/hr-ft-F

@Temperature 800 C

@Temperature 1470 F

36.3 W/m-K

252 BTU-in/hr-ft-F

@Temperature 600 C

@Temperature 1110 F

45.2 W/m-K

314 BTU-in/hr-ft-F

@Temperature 400 C

@Temperature 752 F

54.7 W/m-K

380 BTU-in/hr-ft-F

@Temperature 200 C

@Temperature 392 F

60.2 W/m-K

418 BTU-in/hr-ft-F

@Temperature 100 C

@Temperature 212 F

65.2 W/m-K

452 BTU-in/hr-ft-F

Metric

<= 0.100 %

99.31 - 99.7 %

0.300 - 0.500 %

<= 0.0400 %

<= 0.0500 %

English

<= 0.100 %

99.31 - 99.7 %

0.300 - 0.500 %

<= 0.0400 %

<= 0.0500 %

0C

Comments

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistant format. Users requiring more precise data for scientific or

engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise that you only use the original value or one of its raw conversions in your

calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and terms of use regarding this information. Click here to view all the property values for this datasheet as they were originally

entered into MatWeb.

M1008D

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM /

Page 2 / 2

You might also like

- Astm A123 PDFDocument2 pagesAstm A123 PDFবিপ্লব পাল71% (7)

- Marco o Ring Size Chart Japanese PDFDocument12 pagesMarco o Ring Size Chart Japanese PDFraymond ngoNo ratings yet

- Aisi 1008 Carbon Steel (Uns g10080)Document3 pagesAisi 1008 Carbon Steel (Uns g10080)parasite01100% (1)

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429No ratings yet

- En 10051 PDFDocument2 pagesEn 10051 PDFSrikanth Reddy0% (1)

- D1014Document5 pagesD1014manox007No ratings yet

- Mind Museum PhilippinesDocument4 pagesMind Museum PhilippinesAnna OdroboNo ratings yet

- ULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurDocument2 pagesULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurKiranNo ratings yet

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- AstmDocument7 pagesAstmIlyas AhmedNo ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- Hardox 500 Sheet: General Product DescriptionDocument2 pagesHardox 500 Sheet: General Product DescriptionDylkanWingsNo ratings yet

- Jis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresDocument11 pagesJis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresAnonymous gQyrTUHX38No ratings yet

- Sae 1008Document3 pagesSae 1008lokesh38No ratings yet

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDocument1 pageEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4No ratings yet

- MildSteel AISI 1018Document2 pagesMildSteel AISI 1018ramanamurtytv7176No ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- Ansi b18.2.1 Hex Machine BoltDocument1 pageAnsi b18.2.1 Hex Machine BoltBharatNo ratings yet

- Equivalent TableDocument12 pagesEquivalent TableArie HendriyanaNo ratings yet

- S355 EN 10025 - Standard Structural Steel ProductsDocument2 pagesS355 EN 10025 - Standard Structural Steel ProductsAlmir Pendek100% (1)

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- ABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerDocument3 pagesABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerElizabeth HarrisNo ratings yet

- A780 PDFDocument3 pagesA780 PDFMauricio Adame100% (1)

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Astm b221mDocument14 pagesAstm b221mrandi777770% (1)

- Q235BDocument2 pagesQ235BGoh Boon TiongNo ratings yet

- Tolerances To en 10051 For Continuously Rolled HotDocument4 pagesTolerances To en 10051 For Continuously Rolled HotSorin LescaiNo ratings yet

- SPHC, SPHDDocument2 pagesSPHC, SPHD1q2w3e4fNo ratings yet

- ASTM A 499 - 89 Standard Specs For Steel BArs and Shapes, CArbon Rolled From T Rails PDFDocument4 pagesASTM A 499 - 89 Standard Specs For Steel BArs and Shapes, CArbon Rolled From T Rails PDFpolarisNo ratings yet

- ASTM A572 Steel - Grade 50Document1 pageASTM A572 Steel - Grade 50FWICIP100% (1)

- Astm A 153 PDFDocument4 pagesAstm A 153 PDFmahmoud hegazy100% (5)

- BS en 10088-4-2009Document48 pagesBS en 10088-4-2009khanhNo ratings yet

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Astm A500Document2 pagesAstm A500Liquor Liam0% (1)

- Astm F 593-02 E04Document8 pagesAstm F 593-02 E04JORGE ARTURO TORIBIO HUERTANo ratings yet

- Iso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFDocument5 pagesIso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFMitesh MakvanaNo ratings yet

- N38A SR2.2 - NormDocument14 pagesN38A SR2.2 - Normgokul100% (1)

- ASTM F3125 F3125M-19 Minimum Tensile StrengthDocument13 pagesASTM F3125 F3125M-19 Minimum Tensile StrengthJiangleiNo ratings yet

- S275JRDocument1 pageS275JRShahzad QamarNo ratings yet

- Essar Steel Galvanised BrochureDocument9 pagesEssar Steel Galvanised BrochureSukanya Sen DuttaNo ratings yet

- Astm 795Document7 pagesAstm 795djfreditoNo ratings yet

- Jis G0404 1999Document22 pagesJis G0404 1999puwarin naja100% (1)

- C43Document1 pageC43rudramansingh123No ratings yet

- Product Catalogue For Steel Re-BarsDocument35 pagesProduct Catalogue For Steel Re-BarsCrazyBookWormNo ratings yet

- Astm A325 and A490 Torque ValueDocument1 pageAstm A325 and A490 Torque ValueVictor Manuel Palafox ContrerasNo ratings yet

- Hyundai Formwork - Presentation - 2020Document48 pagesHyundai Formwork - Presentation - 2020smijuNo ratings yet

- As 1874-2000 Aluminium and Aluminium Alloys - Ingots and CastingsDocument7 pagesAs 1874-2000 Aluminium and Aluminium Alloys - Ingots and CastingsSAI Global - APACNo ratings yet

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNo ratings yet

- ASTM Std. F668.atfz8781Document6 pagesASTM Std. F668.atfz8781Eidrish ShaikhNo ratings yet

- ASTM A194 A194M 2022 InglesDocument3 pagesASTM A194 A194M 2022 InglesErickNo ratings yet

- Astm A240-16Document14 pagesAstm A240-16VIPAN RAINo ratings yet

- CZ106 Sheet Strip Foil To BS 2870Document2 pagesCZ106 Sheet Strip Foil To BS 2870zaafrNo ratings yet

- Astm A449Document9 pagesAstm A449Sameercmore0% (1)

- Astm A 1011M PDFDocument8 pagesAstm A 1011M PDFJuan CarlosNo ratings yet

- As 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiDocument7 pagesAs 1554.5-1995 Amdt 1-1998 Structural Steel Welding - WeldiThaiminh VoNo ratings yet

- Aisi 1018Document1 pageAisi 10188085roNo ratings yet

- 17.4 PH Material SpecificationDocument2 pages17.4 PH Material SpecificationDevendra BangarNo ratings yet

- GB 700-88Document5 pagesGB 700-88nazarasimNo ratings yet

- AISI1040Document2 pagesAISI1040Anonymous qRbPsLpuNNo ratings yet

- MaterialData 6877Document2 pagesMaterialData 6877Maxi PianelliNo ratings yet

- AISI 4130 Steel 870C NormalisedDocument3 pagesAISI 4130 Steel 870C NormalisedjimNo ratings yet

- Metal Ferrous Metal Duplex Stainless SteelDocument2 pagesMetal Ferrous Metal Duplex Stainless SteelTomy GeorgeNo ratings yet

- DocumentoDocument8 pagesDocumentoIbsonhNo ratings yet

- Introduction To Finite Element Method: 1D Steady State Conservation LawsDocument49 pagesIntroduction To Finite Element Method: 1D Steady State Conservation LawsIbsonhNo ratings yet

- This Extract From The CATIA V5 Introduction User GuideDocument40 pagesThis Extract From The CATIA V5 Introduction User GuideIbsonhNo ratings yet

- Numerical Methods For Hyperbolic Conservation Laws: Dr. Aamer HaqueDocument27 pagesNumerical Methods For Hyperbolic Conservation Laws: Dr. Aamer HaqueIbsonhNo ratings yet

- Bronze SAE 64 PDFDocument1 pageBronze SAE 64 PDFIbsonhNo ratings yet

- Aco AISI 1020 PDFDocument1 pageAco AISI 1020 PDFIbsonhNo ratings yet

- Aluminio 2024-T3Document2 pagesAluminio 2024-T3IbsonhNo ratings yet

- MMP Awards Specialist Profile..Document2 pagesMMP Awards Specialist Profile..Joy TolentinoNo ratings yet

- Pneumatic Punching Machine DesignDocument3 pagesPneumatic Punching Machine DesignAmrinder SinghNo ratings yet

- Level Anti-Crossings of An NV Center in Diamond: Decoherence-Free Subspaces and 3D Sensors of Microwave Magnetic FieldsDocument7 pagesLevel Anti-Crossings of An NV Center in Diamond: Decoherence-Free Subspaces and 3D Sensors of Microwave Magnetic FieldsKoti KamineniNo ratings yet

- 3 ReviewDocument5 pages3 ReviewJNo ratings yet

- Surface Vehicle Information: Rev. AUG2002Document29 pagesSurface Vehicle Information: Rev. AUG2002Julio Herrera VenegasNo ratings yet

- Tarot For BeginnersDocument46 pagesTarot For BeginnersmatarrayoNo ratings yet

- CE Board Problems in PhysicsDocument4 pagesCE Board Problems in PhysicsChristopher PantojaNo ratings yet

- 5 Aerosol Pioneer Edited Aug CNDaviesDocument3 pages5 Aerosol Pioneer Edited Aug CNDaviesNarinder SinghNo ratings yet

- Air Compressor TermsDocument9 pagesAir Compressor TermsUniversal CollabNo ratings yet

- Selection of Induction MotorsDocument5 pagesSelection of Induction MotorsadauNo ratings yet

- Processo Lavagem - 7. Pulp Washing 12 Session 7Document66 pagesProcesso Lavagem - 7. Pulp Washing 12 Session 7Ricardo MendesNo ratings yet

- Company ProfileDocument5 pagesCompany ProfileiezohreNo ratings yet

- L15 - Deflection-Conjugate Beam MethodDocument18 pagesL15 - Deflection-Conjugate Beam MethodRaghul TNo ratings yet

- Cambridge International Examinations Cambridge Ordinary LevelDocument3 pagesCambridge International Examinations Cambridge Ordinary LevelAmanNo ratings yet

- Multidimensional ScalingDocument43 pagesMultidimensional ScalingAndrea TeohNo ratings yet

- PSM Shaft Linear MotorDocument2 pagesPSM Shaft Linear MotorjuliangoalNo ratings yet

- Light Energy Grade 6 PWSDocument5 pagesLight Energy Grade 6 PWSG ANo ratings yet

- Lecture 17 - Signalized Intersection DelayDocument34 pagesLecture 17 - Signalized Intersection DelayBasoz Arif AhmadNo ratings yet

- 6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenDocument4 pages6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenAmeya SavnalNo ratings yet

- User Manual For Darktable ToolDocument124 pagesUser Manual For Darktable ToolmishraanadiNo ratings yet

- LOS Rate Estimation Techniques For Proportional Navigation Guided MissilesDocument6 pagesLOS Rate Estimation Techniques For Proportional Navigation Guided MissilesDpt HtegnNo ratings yet

- The Liberation of GeometryDocument8 pagesThe Liberation of GeometryGeorge Mpantes mathematics teacherNo ratings yet

- A Decant CentrifugeDocument2 pagesA Decant Centrifugevijay kumar honnaliNo ratings yet

- Sieve Analysis-03.11Document2 pagesSieve Analysis-03.11ASHOKKUMARNo ratings yet

- ADC Book CompleteDocument125 pagesADC Book CompleteBenjamín BuskeNo ratings yet

- Waves and SoundDocument98 pagesWaves and SoundLegdor EdralaNo ratings yet

- Characteristics of The Weibull Distribution, This Issue - S Reliability BasicDocument8 pagesCharacteristics of The Weibull Distribution, This Issue - S Reliability BasicmarsulexNo ratings yet

- Maneuvre of VesselDocument70 pagesManeuvre of VesselLuisPazPerdomo100% (1)