Professional Documents

Culture Documents

Standard Equipment: Maximum 982 KW (1317 HP) at 1800 RPM (Continuous Duty)

Standard Equipment: Maximum 982 KW (1317 HP) at 1800 RPM (Continuous Duty)

Uploaded by

AdamPurwantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Equipment: Maximum 982 KW (1317 HP) at 1800 RPM (Continuous Duty)

Standard Equipment: Maximum 982 KW (1317 HP) at 1800 RPM (Continuous Duty)

Uploaded by

AdamPurwantoCopyright:

Available Formats

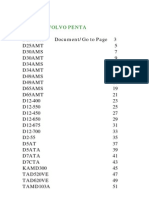

MGX-5321 DC

Twin Disc Marine Transmission

Maximum 982 kW (1317 hp) @ 1800 RPM [CONTINUOUS duty]

Standard Equipment

Vertical offset, nodular iron housing

Electric GP-valve with manual override

EC050 profile module interface for engagement signals

Mounted oil cooler for raw water cooling

Oil strainer and oil filter

Options

Input hub for freestanding installation

SAE J617 input housing no. 0 or no. 00

Flexible coupling for 18" or 21" flywheel (SAE J620 size 460 or 530)

EC050 E-Troll module interface for engagement and trolling signals

Mechanical control valve

Companion flange/bolts set

Special companion flange/bolts set for shaft brake application

Monitoring devices to customer's specification

Output shaft driven trailing pump

Mounted oil cooler for fresh water cooling

Mounting brackets

Live PTO

SAE J744 size 127-2/4, 32-4 (SAE "C", 2/4-bolt) max. 592 Nm

SAE J744 size 127-2/4, 38-4 (SAE "C-C", 2/4-bolt) max. 1187 Nm

Hydraulic clutchable pump mount PTO

SAE J744 size 127-2/4, 32-4 (SAE "C", 2/4-bolt) max. 592 Nm

SAE J744 size 127-2/4, 38-4 (SAE "C-C", 2/4-bolt) max. 1187 Nm

Weight (dry weight with standard equipment): 1754 kg

Contact Twin Disc for Survey Society Approvals and Classifications.

Specifications subject to change without prior notice in the interest of continual product improvement.

MGX-5321 DC

INput Ratings Kilowatts (kW) (Horsepower [hp])*

Intermediate Duty

Reduction Ratios

:1

@ 1800 RPM

@ 2100 RPM

3.35, 4.06

4.42, 4.96

5.46

1044 kW (1400 hp)

1163 kW (1560 hp)

5.96

6.39

893 kW (1198 hp)

1022 kW (1371 hp)

Medium Duty

Continuous Duty

@ 1600 RPM

@ 1800 RPM

@ 1600 RPM

@ 1800 RPM

928 kW (1244 hp)

1044 kW (1400 hp)

882 kW (1183 hp)

982 kW (1317 hp)

865 kW (1160 hp)

969 kW (1300 hp)

861 kW (1155 hp)

969 kW (1300 hp)

776 kW (1041 hp)

863 kW (1157 hp)

737 kW (988 hp)

812 kW (1089 hp)

* Input speed limits: min. 450 rpm/max. 2400 rpm. Ratings shown are for use with standard right hand rotation engines.

Service Classification Definitions

MGX-5321 DC

Pleasure Craft [PC]: Up to 500 hours/year, low load factor usage planing hull

vessels where typical full engine throttle operation is less than 10% of total

time. The balance of operation at 80% of full engine throttle or less. Marine

transmissions for use in long range pleasure cruisers, sportfish charter boats/

patrol boats do not qualify for Pleasure Craft Service.

C

S

Note: Some revenue producing applications such as Planing Hull Bristol Bay

Gillnetter do qualify under Pleasure Craft rating definition.

Light Duty [LD]: Relatively low hour usage (less than 1500 hours per year)

where full throttle operation is 2 hours out of 12.

Typical applications include planing hull vessels such as fire boats, sportfish

charter boats, and patrol/custom boats. This rating is also applicable to some

bow and stern thruster applications.

F

C

S

F

L

R

440.0 mm (17.32 in)

426.4 mm (16.79 in)

757.5 mm (29.82 in)

440.0 mm (17.32 in)

440.0 mm (17.32 in)

Intermediate Duty [ID]: Hour usage of up to 2000 hours/year (for models

MG-5114 Series and smaller) and up to 3000 hours/year (for models larger than

MG-5114 Series) with 50% of the operating time at full engine rating.

Typical applications include planing hull vessels such as ferries, fishing boats,

some crew boats, and some displacement hull yachts as well as some bow and

stern thruster applications.

Medium Duty [MD]: Hour usage of up to 4000 hours/year with up to 80% of

operating time at full engine power. This duty classification is for usage where

some variations in engine speed/power occur as part of normal vessel operation.

Typical vessels include mid-water trawlers, crew/supply boats, ferries, and some

inland water tow boats.

Continuous Duty [CD]: For use in continuous operation with little or no variation

in engine speed/power setting.

Typical vessels include fishing trawlers, tow/tug boats and ocean going vessels.

Important Notice: Torsional Vibration: Disregarding propulsion system

torsional compatibility could cause damage to components in the drive train

resulting in loss of mobility. At minimum, system incompatibility could result in

gear clatter at low speeds.

The responsibility for ensuring that the torsional compatibility of the propulsion

system is satisfactory rests with the assembler of the drive and driven equipment.

Torsional vibration analysis can be made by the engine builder, marine survey

societies, independent consultants and others. Twin Disc is prepared to assist

in finding solutions to potential torsional problems that relate to the marine

transmission.

Twin Disc, Incorporated reminds users of these products that their safe operation

depends on use in compliance with engineering information provided in

this bulletin. Users are also reminded that safe operation depends on proper

installation, operation and routine maintenance and inspection under prevailing

conditions. It is the responsibility of the user (and not Twin Disc, Incorporated)

to provide and install guards or safety devices which may be required by

recognized safety standards or by the Occupational Safety and Health Act of

1970 and its subsequent provision.

Bulletin-MGX-5321DC 2/2013

2013, Twin Disc, Incorporated

Printed in the United States of America

Twin Disc, Incorporated

Racine, Wisconsin 53403 U.S.A

Phone +1-262-638-4000

Fax +1-262-638-4482

www.twindisc.com

You might also like

- EEDIDocument5 pagesEEDIvamsiarangi100% (2)

- Cat C32 ACERT Marine EngineDocument4 pagesCat C32 ACERT Marine EngineRktBatam80% (5)

- IntelliVue Information Center HL7 Programmer S Guide PDFDocument210 pagesIntelliVue Information Center HL7 Programmer S Guide PDFhugutuxNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Relations and Functions Performance TaskDocument8 pagesRelations and Functions Performance Taskapi-242221534100% (1)

- Cat C32 ACERT Spec Sheet - CommercialDocument12 pagesCat C32 ACERT Spec Sheet - Commercialzzsq3550% (2)

- c32-1000 BHP Spec SheetDocument6 pagesc32-1000 BHP Spec SheetPeter John Packiaraj100% (1)

- Perkins M215C and M185C 1006 SeriesDocument2 pagesPerkins M215C and M185C 1006 SeriesDamian Cid Morales100% (1)

- HJ Designers Manual LQ 2009Document12 pagesHJ Designers Manual LQ 2009shafranskij100% (2)

- Caterpillar Service TrainingDocument694 pagesCaterpillar Service TrainingQuangvu Hoang95% (44)

- Marine - Medium - D2866 - E-17-11 (D2866 LXE 40)Document4 pagesMarine - Medium - D2866 - E-17-11 (D2866 LXE 40)arnat6967% (3)

- Ipu Admit Card PDFDocument4 pagesIpu Admit Card PDFAbhinav DixitNo ratings yet

- Advance Baking CompilationDocument44 pagesAdvance Baking CompilationCherry Brutas100% (1)

- Global Reporting System User Manual GRS-Rig V4.0: TitleDocument161 pagesGlobal Reporting System User Manual GRS-Rig V4.0: Titlevikrant911No ratings yet

- MGX6848SCDocument2 pagesMGX6848SCzorgh23No ratings yet

- MGX-5135 Bulletin PDFDocument2 pagesMGX-5135 Bulletin PDFvanhelsing03No ratings yet

- Standard Equipment: Maximum 1489 KW (1997 HP) at 1800 RPM (Intermediate Duty)Document2 pagesStandard Equipment: Maximum 1489 KW (1997 HP) at 1800 RPM (Intermediate Duty)Jhonnatan Quispe Franco100% (1)

- MG5114Document2 pagesMG5114Alejandro MujicaNo ratings yet

- Maximum 1950 KW (2615 HP) at 1950 RPM (Intermediate Duty) : Standard EquipmentDocument2 pagesMaximum 1950 KW (2615 HP) at 1950 RPM (Intermediate Duty) : Standard EquipmentQuant ExalmarNo ratings yet

- Cat C32 ACERT Spec Sheet - CommercialDocument13 pagesCat C32 ACERT Spec Sheet - CommercialMario Godoy100% (2)

- 1100 Series - M250C & M300CDocument2 pages1100 Series - M250C & M300Cprasadcshetty0% (1)

- Maximum 716 KW (960 HP) at 2500 RPM (Pleasure Craft) : Standard EquipmentDocument2 pagesMaximum 716 KW (960 HP) at 2500 RPM (Pleasure Craft) : Standard EquipmentFranklin RojasNo ratings yet

- TwinDisc Hitachi Nico Marine Transmissions CapacityTableDocument42 pagesTwinDisc Hitachi Nico Marine Transmissions CapacityTableNguyễn Tấn Trưởng71% (7)

- Spec C32 746kW@1800rpmDocument15 pagesSpec C32 746kW@1800rpmPhuc Dc100% (1)

- Application Note: Solving A Critical Propulsion Problem at Volvo Penta Using Two Torsional Vibration Meters Type 2523Document8 pagesApplication Note: Solving A Critical Propulsion Problem at Volvo Penta Using Two Torsional Vibration Meters Type 2523jhon vargasNo ratings yet

- Presentation o Ea 2015 Low Loss ConceptDocument26 pagesPresentation o Ea 2015 Low Loss ConceptWAPP100% (1)

- Compressor L7044GSI-7045 - 1210Document2 pagesCompressor L7044GSI-7045 - 1210Dedy Chasan Aflah MutoharNo ratings yet

- 1) Aux. Genset K-Series Cummins, O&mmDocument57 pages1) Aux. Genset K-Series Cummins, O&mmhapiwi7838No ratings yet

- Marine Diesel Engines CatalogDocument16 pagesMarine Diesel Engines CatalogDamian Cid Morales100% (1)

- Marine Medium D2842 E-17-11Document4 pagesMarine Medium D2842 E-17-11g66501350% (2)

- Differences in Marine and Land Based Power Generation ApplicationDocument7 pagesDifferences in Marine and Land Based Power Generation ApplicationChaitra Pm0% (1)

- CAT Engine Specifications: 3508B Offshore Emergency Generator SetDocument6 pagesCAT Engine Specifications: 3508B Offshore Emergency Generator SetGazNo ratings yet

- Marine Propulsion Systems: DescriptionDocument4 pagesMarine Propulsion Systems: DescriptionlatrancaNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualMailson Apaza KatataNo ratings yet

- Marine Engine Application and Installation GuideDocument7 pagesMarine Engine Application and Installation GuideMontell JordanNo ratings yet

- Gpu400 120Document2 pagesGpu400 120dedonezaNo ratings yet

- L7044gsi 7045 0710Document2 pagesL7044gsi 7045 0710Martin Alejandro NievaNo ratings yet

- D2848 Medium DutyDocument4 pagesD2848 Medium Dutyyuniardimz100% (1)

- Diesel Engine Product GuideDocument28 pagesDiesel Engine Product GuideYansen Alex Sander100% (1)

- Iso CronousDocument4 pagesIso Cronousyudhistira agungNo ratings yet

- Marine Engine Genset Product GuideDocument104 pagesMarine Engine Genset Product GuideAngga Ardiansyah86% (7)

- MG5222DCDocument2 pagesMG5222DCTarjaya tarjayaNo ratings yet

- POWER DISTRIBUTION and THRUSTER SYSTEMSDocument23 pagesPOWER DISTRIBUTION and THRUSTER SYSTEMSRoyNo ratings yet

- Engines For Industrial, Genset and Marine Applications: Scania Engines Range. Edition 1:2007Document4 pagesEngines For Industrial, Genset and Marine Applications: Scania Engines Range. Edition 1:2007IRR_2012No ratings yet

- MTU - S60 Marine ContinuousDocument2 pagesMTU - S60 Marine ContinuousRomie HarieNo ratings yet

- ZF 2000Document7 pagesZF 2000talabiz0% (1)

- Woodward GovernorDocument4 pagesWoodward GovernorAbhijit Manna100% (2)

- D3 Solas: VOLVO PENTA Life-And Rescue Boat Propulsion EnginesDocument2 pagesD3 Solas: VOLVO PENTA Life-And Rescue Boat Propulsion EnginesEdgar MaldonadoNo ratings yet

- My14 SOLAS D4 D6Document2 pagesMy14 SOLAS D4 D6pngchanhNo ratings yet

- Volvo Penta - Catalogo Motores MarinosDocument76 pagesVolvo Penta - Catalogo Motores MarinosTam Argento83% (6)

- 3512B 1500RPM 1300KW BrochureDocument4 pages3512B 1500RPM 1300KW BrochuresalembatopNo ratings yet

- Operating Experience With Modern High Speed Diesel Engine in Ship Assist Tugs and Related Requirements For Future Engine DevelopmentDocument18 pagesOperating Experience With Modern High Speed Diesel Engine in Ship Assist Tugs and Related Requirements For Future Engine DevelopmentYao WeiNo ratings yet

- Cat C 15 AccertDocument4 pagesCat C 15 AccertRobles JmrNo ratings yet

- MG5321Document2 pagesMG5321Manuel Armando Salazar BravoNo ratings yet

- D5A-A T GensetDocument4 pagesD5A-A T Gensetknp2809No ratings yet

- Big Red 600Document4 pagesBig Red 600sergesxNo ratings yet

- +diesel Electric Propulsion Plants Engineering GuidelineDocument27 pages+diesel Electric Propulsion Plants Engineering GuidelinelesmosNo ratings yet

- CA Motors Product DetailsDocument25 pagesCA Motors Product DetailsP Venkata Suresh100% (2)

- Dual Fuel Engine Development and DesignDocument40 pagesDual Fuel Engine Development and DesignHenrique MorgadoNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Shreya Shukla Case Study-2Document41 pagesShreya Shukla Case Study-2Rishabh UpadhyayNo ratings yet

- Catalog Copeland KCLDocument40 pagesCatalog Copeland KCLIsidro MendozaNo ratings yet

- Telephone EnglishDocument5 pagesTelephone EnglishZaw WinOoNo ratings yet

- CCBoot Manual - Server SettingsDocument89 pagesCCBoot Manual - Server SettingsHasnan IbrahimNo ratings yet

- Petrochemical Standards (PDFDrive)Document68 pagesPetrochemical Standards (PDFDrive)fatimahNo ratings yet

- IELTS All 4 Tests at Méthode Barnes Anglais RecommanderDocument21 pagesIELTS All 4 Tests at Méthode Barnes Anglais Recommanderbarnes method books internationalNo ratings yet

- Duxbury Clipper 2011 - 02 - 02Document44 pagesDuxbury Clipper 2011 - 02 - 02Duxbury ClipperNo ratings yet

- Section Q - Ventilation:: Chapter 511-6-1Document27 pagesSection Q - Ventilation:: Chapter 511-6-1Kingsley OchiengNo ratings yet

- Pre Issue ManagementDocument19 pagesPre Issue Managementbs_sharathNo ratings yet

- Brochure Leaching 4824 01 23 en MNGDocument8 pagesBrochure Leaching 4824 01 23 en MNGOsamaNo ratings yet

- A VFP-SQL Server Application From The BeginingDocument38 pagesA VFP-SQL Server Application From The Beginingmohsin.computers3076No ratings yet

- A. RAPID Research Grant: Total Faculty Costs 0Document3 pagesA. RAPID Research Grant: Total Faculty Costs 0Uzma TahirNo ratings yet

- Maxey Mark Pauline 1965 JapanDocument28 pagesMaxey Mark Pauline 1965 Japanthe missions networkNo ratings yet

- Personnel ManagementDocument9 pagesPersonnel Managementhammed lateefNo ratings yet

- Instruction SMA TripowerDocument10 pagesInstruction SMA TripowerMirea AurelNo ratings yet

- 11 HUMSS JQR - Family Earthquake PreparednessDocument4 pages11 HUMSS JQR - Family Earthquake PreparednessCLARIZZE JAINE MANALONo ratings yet

- DokDocument5 pagesDokNur IdahNo ratings yet

- Text - Cambay BasinDocument58 pagesText - Cambay BasinBidyut MandalNo ratings yet

- Kalimat Simple Present Tense Aktif Kalimat Simple Past Tense AktifDocument2 pagesKalimat Simple Present Tense Aktif Kalimat Simple Past Tense AktifRestu PamujiNo ratings yet

- Grade 8 Integrated Science Week 2 Lesson 2Document5 pagesGrade 8 Integrated Science Week 2 Lesson 2Balram HaroldNo ratings yet

- List of Candidates For Entrance Test of PH D (Tech) in Pharma Through M Pharm & M Tech For Entrance Test 2015 - 2016Document7 pagesList of Candidates For Entrance Test of PH D (Tech) in Pharma Through M Pharm & M Tech For Entrance Test 2015 - 2016mppatilmayur1679No ratings yet

- FBS Pre TestDocument4 pagesFBS Pre TestEvelyn Santos100% (1)

- Murphybed dn1117Document17 pagesMurphybed dn1117mcvelli40100% (2)

- The Seven Types of Yellow Sapphire and Their Stability To Light PDFDocument10 pagesThe Seven Types of Yellow Sapphire and Their Stability To Light PDFdebjeet royNo ratings yet

- Sepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603Document114 pagesSepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603makarandmone100% (9)