Professional Documents

Culture Documents

Us 5176330

Us 5176330

Uploaded by

ManivannanMudhaliarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 5176330

Us 5176330

Uploaded by

ManivannanMudhaliarCopyright:

Available Formats

llllllllllllllllllllllIllllllllllllllllllllllllllllllilllIlllllllllllllllll

USOO5176330A

United States Patent [191

[111

[45]

Tone

[54] TRAVERSE DEVICE

Patent Number:

5,176,330

Date of Patent:

Jan. 5, 1993

FOREIGN PATENT DOCUMENTS

[75] Inventor:

Shoichi Tone, Kyoto, Japan

37025 10/1971

Japan .............................. .. 242/43 A

[73] Assignee:

Murata Kikai Kabushiki Kaisha,

29054 of 1911

United Kingdom ........... .. 242/43 A

Kyoto, Japan

[2]] Appl. No.: 813,853

[22] Filed:

[30]

Primary Exam1'nerStanley N. Gilreath

Attorney, Agent, or FirmSpensley Horn Jubas &

Lubitz

Dec. 26, 1991

[57]

Foreign Application Priority Data

Dec. 28, 1990 [JP]

Japan ................................ .. 2-416169

[51]

[52]

Int. Cl.5 .................... ..

3651-1 54/28

US. Cl. ............................................. .. 242/43 A

[58]

Field of Search ................ .. 242/43 A, 43 R, 18.1,

ABSTRACT

A traverse device in which rotary members each having

yarn guide blades are arranged to be overlaid and ro

tated in the direction opposite to each other, and a tra

References Cited

verse guide member is provided along the motion locus

of the yarn guide blades, wherein the number of the

yarn guide blades of the rotary members is differenti

ated, and the rotary speed is differentiated by a recipro

U.S. PATENT DOCUMENTS

cal number of the ratio of the number. The traverse of

242/ 158 B

[56]

834,420

1,475.525

3.374.961

4,505.43?

10/1906

11/1923

3/1968

3/1985

4.867,386

9/1989

242/43

242/43

242/43

242/43

A

A

A

A

Schroff et a1. .................. .. 242/43 A

18a

yarn and speeds of forward path and backward path are

differentiated, and the number of windings between the

forward path and the backward path is changed.

5 Claims, 3 Drawing Sheets

US. Patent

Jan. s, 1993

Sheet 1 0f 3

5,176,330

US. Patent

Jan. 5, 1993

Sheet 2 of 3

Fm. 3 b

P R mR A R T

6 PRIOR ART

5,176,330

U.S. Patent

Jan. 5, 1993

Sheet 3 0f 3

4 PRIOR ART

5PRIOR ART

5,176,330

TRAVERSE DEVICE

delivery of yarn, projecting guides are provided on the

upper and lower surfaces in the proximity of a position

at which the yarn guide blades are overlaid at the turn

BACKGROUND OF THE INVENTION

1. Field of the Invention

points a and b. Further, in order to positively carry out

the delivery of yarn, the rotating center of the rotary

members 1 and 2 is sometimes slightly deviated.

In the traverse device shown in FIGS. 4 and 6, the

speed of forward path of the traverse is the same as that

The present invention relates to a traverse device in

which a yarn is reciprocated (hereinafter referred to as

traverse) in a case where a yarn is formed into a winding

of backward path (the number of winding is constant).

package, and particularly to a traverse device in which

two rotary members having two or more yarn guide 10 Accordingly, as shown in FIG. 3b, an intersection g

between a forward path e and a backward path f forms

blades are arranged to be overlaid and rotated in the

direction opposite to each other, and a traverse guide

surface is provided along the motion locus of said yarn

guide blades.

2. Prior Art

'A conventional traverse device uses a groove cam

mechanism, and the traverse of yarn is effected by the

a straight line in an axial direction of the winding pack

age. Therefore, there arises a problem in that when the

wound package is unwound, it tends to be caught at the

intersection g. resulting in a poor releasability, and there

likely occurs a buldge phenomenon in which opposite

ends of the wound package becomes buldged.

reciprocating motion of the traverse guide in engage

ment with the groove cam mechanism. Therefore, there

occurs extremely great shocks generated at a turn point

of the traverse guide and noises generated therefrom to

limit smooth high-speed rotation. As means for solving

SUMMARY OF THE INVENTION

The present invention has been achieved in view of

the aforesaid problem encountered in prior art. An

object of the present invention is to provide a traverse

drawbacks encountered in such a groove cam mecha

nism as noted above, there is known a traverse device

device using yarn guide blades which rotated in the

direction opposite to each other, which is excellent in

which uses yarn guide blades which rotated in the di 25 releasability and in which the buldge is unlikely to oc

rection opposite to each other to traverse the yarn.

The traverse device using the yarn guide blades

which rotate in the direction opposite to each other will

be described hereinbelow with reference to FIGS. 4 to

6. In FIGS. 4 and 5. a spun yarn Y is alternately tra

versed by yarn guide blades 3. 3, 4, 4' provided on

cur.

In order to achieve the aforesaid object, the present

in invention provides a traverse device in which two

rotary members each having yarn guide blades are ar

ranged to be overlaid and rotated in the direction oppo

site to each other, and a traverse guide member is pro

rotary members 1 and 2 and wound on a winding pack

vided along the motion locus of the yarn guide blades,

age 7 rotated by a touch roller 6 while being guided on

characterized in that the number of the yarn guide

a traverse guide surface d ofa traverse guide member 5.

The rotary members 1 and 2 have one and the same 35 blades of the two rotary members is differentiated, and

the rotary speed is differentiated by a reciprocal number

rotating center and are provided on rotary shafts 8 and

of the ratio of the number of the yarn guide blades.

9, respectively so that they are rotated in the direction

When the number of the yarn guide blades of two

opposite to each other. A bevel gear 10 is provided on

rotary members is differentiated and the rotary speeds

the other end of the rotary shaft 8, and a bevel gear 1]

is provided on the other end ofthe other rotary shaft 9. 40 thereof are differentiated by a reciprocal number of the

ratio of number of the yarn guide blades, the speed of

forward path of the yarn traverse is different from that

of backward path. Since the number of revolutions of

the touch roller is constant, the number of windings of

which have one and the same rotating center and rotate 45 the forward path is different from that of the backward.

As a result, intersections of yarns are scattered.

in the direction opposite to each other, yarn guide

blades 3, 3 and yarn guide blades 4, 4 are secured to the

BRIEF DESCRIPTION OF THE DRAWINGS

rotary member 1 and the rotary member 2, respectively,

These bevel gears 10 and 11 are meshed with a bevel

gear 12 driven by an electric motor 13 so that rotating

motion opposite to each other are applied to the rotary

members 1 and 2. Around the rotary members 1 and 2

at intervals of 180" by means of screws or the like.

The device will be described in more detail with

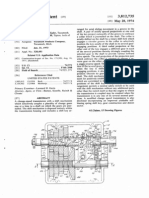

FIG. 1 is a side view of a traverse device according to

the present invention.

FIG. 2 is a sectional view taken on line 2--2 of FIG.

reference to FIG. 6. The distance from the rotating

1.

center of the respective extreme ends of the yarn guide

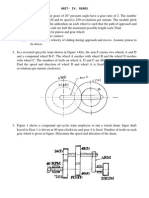

FIG. 3a illustrates the operation of a traverse device

blades 3, 3' and 4, 4' is the same radius, and a circular

in accordance with one embodiment of the present

locus indicated at chain line C is depicted by the rota

tion thereof. The yarn Y is carried by the sides of the 55 invention.

FIG. 3b illustrates the operation of a conventional

yarn guide blades and performs left and right traverse

motions while being exchanged with yarn guide blades

which rotate in the direction opposite to each other at

turn points a and b along the curve of a traverse guide

surface d of the traverse guide member 5. In order to

secure positive and smooth turning of a yarn at the turn

points a and b, the following structure is employed.

More speci?cally, mounting positions of the yarn guide

blades 3 and 3' and 4 and 4' with respect to the rotary

members 1 and 2 are spaced through 180, and an angle 65

of aOb is 90 in order that the upper and lower guide

blades are overlaid at the turn points a and b of the

traverse motion. In order to positively carry out the

traverse device.

FIG. 4 is a side view of a conventional traverse de

vice.

FIG. 5 is a top view of a conventional traverse de

vice.

. FIG. 6 is a sectional view taken on line 6-6 of FIG.

4.

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENTS

Am embodiment of the present invention will be de

scribed below with reference to the drawings. FIG. 1 is

5,176,330

a side view ofa traverse device according to the present

While in the aforementioned embodiment, a combina

invention; and FIG. 2 is a sectional view taken on line

tion of two blades and three blades has been illustrated,

2-2 of FIG. 1. Parts which operate in the same manner

it is to be noted that the present invention is not limited

as those explained in connection with FIGS. 4 to 6 of

thereto but even in cases ofa combination oftwo blades

prior art are indicated by the same reference numerals 5 and four blades or a combination of three blades and

four blades, a shape of a traverse guide member and a

and a description thereof is omitted.

phase difference between blades are determined so that

In FIG. 1, betweena bevel gear 12 and bevel gears 10

the rotational speed is set to a reciprocal number of the

and 11 are provided intermediate bevel gears 14, 15

different in number ofteeth, and rotary members 16 and

17 have different rotational speeds. In the illustrated

embodiment, the ratio of number of teeth between the

intermediate bevel gear 14 and the intermediate bevel

gear 15 is 3:2, and the ratio of rotational speed between

the rotary member 16 and the rotary member 17 is 2:3.

For example, if the number of revolutions of the rotary

member 16 is 600 rpm. the number of revolutions of the

rotary member 17 is 900 rpm.

In FIG. 2, the rotary member 16 has three yarn guide

blades 18a, 18b and 18c at positions divided by 120 in

the circumference thereof, and the rotary member 17

has two yarn guide blades 19a and 19b at positions di

vided by ISO" in the circumference thereof. That is, the

ratio of the number of blades between the rotary mem

ber 16 and the rotary member 17 is 3:2 which is a recip

rocal ratio of2z3 ofthe ratio of rotational speed between

the rotary members 16 and 17. A phase difference be

tween the yarn guide blades 18a , 18b and 180 and the

yarn guide blades 19a and 19b is deviated at the ratio of

the number of revolutions therebetween with the

shown position as a reference.

In FIG. 2, an angle aOb formed by turn points a and

b of a traverse guide surface d of a traverse guide mem

ber 20 is 72". That is, when the slow yarn guide blade

18a rotates through 36 clockwise from the shown posi

tion and arrives at the turn point b, the fast yarn guide

blade 19a rotates through 54 counterclockwise from

the shown position and arrives at the turn point b. and

the traverse guide surface d of the traverse guide mem

ber 20 is determined so that positions at which 36z54 is

2:3 of the ratio of rotary speeds assume turn points.

The operation of the traverse device constructed as

ratio of number of blades and turn points are coincided,

whereby the operation and effect similar to those of the

aforementioned embodiment can be obtained.

The present invention provides a traverse device in

which two rotary members each having yarn guide

blades are arranged to be overlaid and rotated in the

direction opposite to each other, and a traverse guide

member is provided along the motion locus of said yarn

guide blade, wherein the number of the yarn guide

blades of the two rotary members is differentiated, and

the rotary speed is differentiated by a reciprocal number

of the ratio of the number of the yarn guide blades.

Therefore, the traverse of yarn and the speeds of for

ward path and backward path are different (the number

of windings between the forward path and the back

ward path is different). Since the intersections of yarns

are scattered, the releasability is improved and the

buldge phenomenon is hard to occur.

What is claimed is:

1. A traverse device, comprising:

a ?rst rotary member de?ning a ?rst predetermined

number of yarn guide blades;

a second rotary member, in spaced relation to the ?rst

rotary member, de?ning a second predetermined

number of yarn guide blades, the second predeter

mined number being different than the ?rst prede

termined number; and

rotatingmeans for rotating the ?rst rotary member at

a ?rst speed and the second rotary member at a

second speed such that a ratio of the ?rst and sec

ond speeds is substantially equal to the inverse of a

ratio of the ?rst and second numbers of yarn guide

blades.

2. The traverse device of claim 1, wherein the guide

described above will be explained hereinafter. In FIG.

blades de?ne an arcuate path, the device further com

2, the yarn Y is guided to be moved rightward along the

prising:

traverse guide surface d by the yarn guide blade 180 45

a traverse guide member provided along the path of

which is slow in rotational speed. When the yarn guide

the yarn guide blades.

blade 18:: arrives at the turn point b, the yarn guide

3. The traverse device of claim 2, wherein the tra

blade 19a arrives at the turn point b, and the yarn is

verse guide member de?nes turning points, and wherein

delivered. Subsequently, the yarn guide blade 19a is

locations of the turning points and the speeds of the

guided to be moved leftward and arrives at the turn

rotary members are de?ned such that the blades of the

point a, then the yarn guide blade 18c arrives at the turn

respective rotary members cross at the turning points.

point a and the yarn is delivered. The above-described

4. A traverse device, comprising:

steps are-repeated to effect the traverse of the yarn Y.

a ?rst rotary member de?ning a ?rst number of yarn

Since the ratio of rotational speeds between the rotary

guide blades and an axis of rotation;

members 16 and 17 is 2:3 , the number of windings of the

a second rotary member, in spaced relation to, and

forward path is different from that of the backward

de?ning the same axis of rotation as, the ?rst rotary

path.

member, the second rotary member de?ning a sec

Next, a package different in the number of windings

ond number of yarn guide blades, the second num

will be described with reference to FIG. 3a. In FIG. 3a,

ber of blades being different than the ?rst number

the number of windings of the forward path h is 4 and

I of blades;

that of the backward path i is 6, as illustrated. Intersec

a ?rst rotary shaft de?ning ?rst and second ends, the

tions of the forward path h and the backward path i are

?rst end supporting the ?rst rotary member and the

scattered into two points j and k. As compared with the

second end supporting a ?rst gear de?ning a ?rst

case of FIG. 3b in prior art, yarn caught is decreased

number of teeth;

when the yarn is unwound, and the buldge phenomenon 65 a second rotary shaft de?ning ?rst and second ends,

in which opposite ends of the package buldge is re

the ?rst end supporting the second rotary member

lieved. Reference symbol S is a traverse width, and D is

and the second end supporting a second gear de?n

a diameter of a package.

ing a second number of teeth, the second number of

5,176,330

teeth being different then the ?rst number ofteeth;

shaft, respectively, a plurality of ?rst yarn guide blades

provided in a circumference of the ?rst rotary member,

a plurality of second yarn guide blades provided in a

and

a third gear driven by a motor, the third gear posi

tioned between, and meshed with, the ?rst and

second gears;

wherein a ratio of respective speeds of the ?rst and

circumference of the second rotary member, a ?rst

bevel gear provided on the other end of the ?rst rotary

shaft, a second bevel gear provided on the other end of

the second rotary shaft, a third bevel gear driven by an

electronic motor, and a ?rst and second intermediate

bevel gears which are provided between and meshed

with the third bevel gear and the ?rst and second bevel

gears and are different in number of teeth, the number

second rotary members is substantially equal to the

inverse of a ratio of the ?rst and second numbers of

blades.

5. A traverse device in which two rotary members

each having yarn guide blades are arranged to be over

laid and rotated in the direction opposite to each other,

of said ?rst yarn guide blades and said second yarn

guide blades being differentiated and the rotary speed of

and a traverse guide member is provided along the

motion locus of said yarn guide blade, wherein said

said ?rst rotary member and said second rotary member

being differentiated by a reciprocal number of the ratio

of the number of the ?rst and second yarn guide blades.

traverse device includes ?rst and second rotary mem

bers having one and same rotating center and being

provided on a ?rst rotary shaft and a second rotary

25

35

45

55

65

it

You might also like

- Module 3.2 LD 4-Stage Compressor TMS CARDIFF-En 2014 - Rev02 PDFDocument40 pagesModule 3.2 LD 4-Stage Compressor TMS CARDIFF-En 2014 - Rev02 PDFiuliiulianNo ratings yet

- Primera Entrega Cultura y Economia Regional de EuropaDocument20 pagesPrimera Entrega Cultura y Economia Regional de EuropaAndrea Lara0% (1)

- Hypoid Gear CuttingDocument9 pagesHypoid Gear CuttingHano LourensNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- United States Patent (19) : Primary Examiner-Samuel ScottDocument7 pagesUnited States Patent (19) : Primary Examiner-Samuel ScottRockerss RockerssNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Us 3688484Document4 pagesUs 3688484James LindonNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Description: (OCR Text May Contain Errors)Document6 pagesDescription: (OCR Text May Contain Errors)geeNo ratings yet

- 1.15 The Slider-Crank Chain: Mechanisms and MachinesDocument8 pages1.15 The Slider-Crank Chain: Mechanisms and MachinesNAGU2009No ratings yet

- Module-5 Toothed GearingDocument4 pagesModule-5 Toothed Gearingonkarlamkane4No ratings yet

- rr310304 Kinematics of MachineryDocument12 pagesrr310304 Kinematics of MachinerySrinivasa Rao GNo ratings yet

- Sept. 11, 1951 B. B. Scott 2,567,735: His AttorneyDocument3 pagesSept. 11, 1951 B. B. Scott 2,567,735: His AttorneyTri PujiyantoNo ratings yet

- Improved Yarn Traversing Mechanism For A Filter Winder: Dr. Milind KoranneDocument6 pagesImproved Yarn Traversing Mechanism For A Filter Winder: Dr. Milind KoranneShobhit JaiswalNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- March 22, 1949.: ' Méd May 2o, Y1947Document4 pagesMarch 22, 1949.: ' Méd May 2o, Y1947Fred JohnsonNo ratings yet

- Mod-3. Spur GearDocument18 pagesMod-3. Spur GearSharthak GhoshNo ratings yet

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoagleNo ratings yet

- 9A14402 Theory of MachinesDocument8 pages9A14402 Theory of MachinessivabharathamurthyNo ratings yet

- US5186686Document11 pagesUS5186686雷黎明No ratings yet

- Gear TrainsDocument16 pagesGear Trainsraju100% (1)

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Nov. 24, 1953 I. Properz 2,659,948: Machine For The Continuous Casting of Metal RodsDocument3 pagesNov. 24, 1953 I. Properz 2,659,948: Machine For The Continuous Casting of Metal RodsmazaherramazaniNo ratings yet

- United States Patent (191: Von Kale! Et AlDocument18 pagesUnited States Patent (191: Von Kale! Et AlJoão Paulo Canto RibeiroNo ratings yet

- TEPZZZ89Z4 - 4B - T: European Patent SpecificationDocument25 pagesTEPZZZ89Z4 - 4B - T: European Patent Specificationzweisteine777No ratings yet

- 9A03401 Kinematics of MachineryDocument8 pages9A03401 Kinematics of MachinerysivabharathamurthyNo ratings yet

- Feb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3Document7 pagesFeb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3ValBMSNo ratings yet

- Target Kite (1944)Document7 pagesTarget Kite (1944)CAP History LibraryNo ratings yet

- Howe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Document8 pagesHowe MacHine Co. v. National Needle Co., 134 U.S. 388 (1890)Scribd Government DocsNo ratings yet

- Section-A: Q. 1.1. (A) Explain Machine With Suitable ExamplesDocument59 pagesSection-A: Q. 1.1. (A) Explain Machine With Suitable ExamplesravindrababugNo ratings yet

- Chapter 1Document20 pagesChapter 1ankursolanki13No ratings yet

- 3 TYPES OF GEARS & Gear TrainsDocument17 pages3 TYPES OF GEARS & Gear TrainsabinmwangiNo ratings yet

- Analysis OF Mechanisms GTU IMPDocument5 pagesAnalysis OF Mechanisms GTU IMPSwastik PanchalNo ratings yet

- 1895 - Us570025Document5 pages1895 - Us570025Enrico Bruce GioloNo ratings yet

- Experiment 2Document11 pagesExperiment 2rajeevNo ratings yet

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineDocument4 pages%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoNo ratings yet

- Screw Thread CuttingDocument41 pagesScrew Thread CuttingRocio Mtz100% (2)

- AISSMSCOEDocument3 pagesAISSMSCOEAtharva ChoudhariNo ratings yet

- United States Patent (191: Broadway Et Al. (45) Jul. 6, 1982Document9 pagesUnited States Patent (191: Broadway Et Al. (45) Jul. 6, 1982debasishmee5808No ratings yet

- Module3 TutorialDocument7 pagesModule3 TutorialAayush KNo ratings yet

- US1892217Document9 pagesUS1892217oreamigNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- Pawelski and TeutschDocument1 pagePawelski and TeutschVanganuru SunilNo ratings yet

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- US2009857 FORMADOR SOBRES PotdevinDocument3 pagesUS2009857 FORMADOR SOBRES PotdevinJhonnatan E Avendaño FlorezNo ratings yet

- Design of Transmission System Unit IIIDocument57 pagesDesign of Transmission System Unit IIIRaj MohanNo ratings yet

- UnitDocument6 pagesUnitPreethi SharmiNo ratings yet

- Mannlicher Us1166913Document6 pagesMannlicher Us1166913cll1968No ratings yet

- US2125697Document3 pagesUS2125697davarniyaalirezasepehrelectricNo ratings yet

- Assignment 3 - Tom Ii (1) - PDFDocument2 pagesAssignment 3 - Tom Ii (1) - PDFAshutosh RajawatNo ratings yet

- Project ASSEMBLYDocument5 pagesProject ASSEMBLYfachrifadlurrohman8No ratings yet

- Kinematics of MachineryDocument8 pagesKinematics of MachinerySri RNo ratings yet

- Assignment Unit - 1: 2) .A Pair of Involute Gears Is in Mesh. The Application Restricts The Space To Accommodate TheseDocument4 pagesAssignment Unit - 1: 2) .A Pair of Involute Gears Is in Mesh. The Application Restricts The Space To Accommodate TheserahulNo ratings yet

- Rotary ActuatorDocument16 pagesRotary ActuatoramishcarNo ratings yet

- US2145490 Miller Magnetic Pick Up For Musical Instruments 1939Document3 pagesUS2145490 Miller Magnetic Pick Up For Musical Instruments 1939Duane BlakeNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0112687 A1Document7 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0112687 A1Robert DeaconuNo ratings yet

- Dynamics of the Rigid Solid with General Constraints by a Multibody ApproachFrom EverandDynamics of the Rigid Solid with General Constraints by a Multibody ApproachNo ratings yet

- Kinematic Differential Geometry and Saddle Synthesis of LinkagesFrom EverandKinematic Differential Geometry and Saddle Synthesis of LinkagesNo ratings yet

- The European Pressure Equipment Directive (Ped)Document6 pagesThe European Pressure Equipment Directive (Ped)ManivannanMudhaliarNo ratings yet

- PT PRO FOR ExamDocument3 pagesPT PRO FOR ExamManivannanMudhaliarNo ratings yet

- HAC CrackDocument8 pagesHAC CrackManivannanMudhaliarNo ratings yet

- Convex and Concave MirrorDocument2 pagesConvex and Concave MirrorManivannanMudhaliarNo ratings yet

- National Step Tablet Vs Step Wedge Comparision FilmDocument4 pagesNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarNo ratings yet

- Welder Qualification Test CertificateDocument1 pageWelder Qualification Test CertificateManivannanMudhaliar100% (1)

- PED02Document7 pagesPED02ManivannanMudhaliarNo ratings yet

- Webinar New Ped 2014 68 EuDocument19 pagesWebinar New Ped 2014 68 EuManivannanMudhaliar100% (1)

- Aluminum Welding ProceduresDocument8 pagesAluminum Welding ProceduresManivannanMudhaliar0% (1)

- To Avoid Nitride Precepitation in 25% CR Steel:: SL N o Ele Spec Actual Aim Preferred Aim Range PreferredDocument2 pagesTo Avoid Nitride Precepitation in 25% CR Steel:: SL N o Ele Spec Actual Aim Preferred Aim Range PreferredManivannanMudhaliarNo ratings yet

- May 2014 - Risk Assessment - Make It Easier Than It AppearsDocument4 pagesMay 2014 - Risk Assessment - Make It Easier Than It AppearsManivannanMudhaliarNo ratings yet

- Note - Book - School of Applied NDTDocument29 pagesNote - Book - School of Applied NDTManivannanMudhaliarNo ratings yet

- Cobalt Base Alloy - 6 in Amine ApplicationDocument2 pagesCobalt Base Alloy - 6 in Amine ApplicationManivannanMudhaliarNo ratings yet

- Glossary Terms VTDocument5 pagesGlossary Terms VTManivannanMudhaliarNo ratings yet

- Back To Basics Testing With J1 - Use ReaderDocument4 pagesBack To Basics Testing With J1 - Use ReaderManivannanMudhaliarNo ratings yet

- Metengr: Engg Tips Forum Discussion Reg - Casting PropertiesDocument2 pagesMetengr: Engg Tips Forum Discussion Reg - Casting PropertiesManivannanMudhaliarNo ratings yet

- Warman Slurry Correction Factors HR and ER Pump Power: MPC H S S L Q PDocument2 pagesWarman Slurry Correction Factors HR and ER Pump Power: MPC H S S L Q Pyoel cueva arquinigoNo ratings yet

- William Stallings Computer Organization and Architecture 9 EditionDocument28 pagesWilliam Stallings Computer Organization and Architecture 9 EditionAnggi Riza Amirullah SidhartaNo ratings yet

- LevellingDocument11 pagesLevellingetikaf50% (2)

- Abita Brand GuideDocument7 pagesAbita Brand GuideGabriel Bedini de JesusNo ratings yet

- The 2021 EY Scholarship: The Bahamas, Bermuda, British Virgin Islands and The Cayman IslandsDocument3 pagesThe 2021 EY Scholarship: The Bahamas, Bermuda, British Virgin Islands and The Cayman IslandsKingshuk MukherjeeNo ratings yet

- 3storeyresidence Final ModelDocument1 page3storeyresidence Final ModelRheafel LimNo ratings yet

- Jemstone Global 2014 ProfileDocument7 pagesJemstone Global 2014 Profileapi-156958414No ratings yet

- EU Imports of Organic Agri-Food Products: Key Developments in 2019Document17 pagesEU Imports of Organic Agri-Food Products: Key Developments in 2019Dani FrancoNo ratings yet

- Python MortgagesDocument5 pagesPython MortgagesSonali MethaniyaNo ratings yet

- GrammarDocument23 pagesGrammarYMNo ratings yet

- 014 - 030 Single Reduction Worm IntroductionDocument17 pages014 - 030 Single Reduction Worm IntroductionAlejandro MartinezNo ratings yet

- Applied Physics On Spectros PDFDocument71 pagesApplied Physics On Spectros PDFKaskus FourusNo ratings yet

- Garmin Oregon 750Document6 pagesGarmin Oregon 750Rihit kumarNo ratings yet

- Aerodynamics of Rugby BallDocument5 pagesAerodynamics of Rugby BallChandra Harsha100% (1)

- Arlec Wireless SecurityDocument10 pagesArlec Wireless Securityalfi56kNo ratings yet

- Ielts Reading Test 1Document7 pagesIelts Reading Test 1Bách XuânNo ratings yet

- Ex Lecture1Document2 pagesEx Lecture1AlNo ratings yet

- Computer Vision Module 5Document22 pagesComputer Vision Module 5lukerichman29100% (1)

- Courseplay English User ManualDocument12 pagesCourseplay English User ManualCelticgirlNo ratings yet

- Drivewindow BasicsDocument34 pagesDrivewindow BasicsYaa ShinNo ratings yet

- Background of Money Market in BangladeshDocument5 pagesBackground of Money Market in Bangladeshanamikabhoumik100% (1)

- 20220725Document39 pages20220725Zenon CondoriNo ratings yet

- Microsoft Excel Is A Spreadsheet Developed by Microsoft For WindowsDocument9 pagesMicrosoft Excel Is A Spreadsheet Developed by Microsoft For WindowsSherryl ZamonteNo ratings yet

- Info Sheet IndivDocument2 pagesInfo Sheet IndivFRAULIEN GLINKA FANUGAONo ratings yet

- CH 01 Wooldridge 5e PPTDocument23 pagesCH 01 Wooldridge 5e PPTKrithiga Soundrajan100% (1)

- NCMEC Sextortion Fact SheetDocument3 pagesNCMEC Sextortion Fact SheetJacob Rodriguez100% (1)

- Crane Overhaul ProcedureDocument8 pagesCrane Overhaul ProcedureHưng ĐỗNo ratings yet

- Group 3Document59 pagesGroup 3Grey Sinclair100% (1)