Professional Documents

Culture Documents

Oxidative Chlorination of Ethylbenzene

Oxidative Chlorination of Ethylbenzene

Uploaded by

Bagus OktiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oxidative Chlorination of Ethylbenzene

Oxidative Chlorination of Ethylbenzene

Uploaded by

Bagus OktiCopyright:

Available Formats

1~4

M.S. SAZ,U~HOVet al.

10. G. M. GAL'PERN, V. A. IL'INA, P. M. SHUMSKAYA and V. N. ALEgSANDROV,

Khlmlya i tekhnol, monomerov. Tr. Vses, n.-i. i proektn, in-t. monomerov 2, 129,

1970

11. A. M. IVANOV, L. N. KHAKALO and K. A. ~CHEItVINSKII, Neftel~hlmiya 8, 589,

1968

12. Ye. M. TOCHINA, L. M. POSTNIKOV and V. Ya. SHLYAPINTOKH, Izv. AN SSSR,

Ser. khlm. 71, 1968

OXIDATIVE CHLORINATION OF ETHYLBENZENE

AND ISOPROPYLBENZENE*

M. S. SAT,A~I~[OV,~V~.~~.GUSS]~I~OV,CH. A. CH~,A~IEV and D. K. ABD~LAYEV

Stungait Branch of the Institute of Petrochemical Processes Azerb. S.S.R. Academy of

Sciences

(Received 16 July, 1974)

C ~ o ~ x ~ . derivatives of ethyl and isopropylbenzene are obtained b y alkyiatiou

of chlorobenzene in the presence of Friedel-Crafts [1, 2] catalysts b y direct

chlorination of ethylbenzene [3-5] and isopropylbenzene [6, 7]. A1Cls, FeCIa,

ZnCI~, SnC14 and TiC14 are used as catalysts in chlorination of alkylbenzenes.

However, secondary reactions [5, 7] are undesirable in the catalytic process

of chlorination.

Investigations are being carried out in our laboratory in the field of oxidizing chlorination of alkyl-aromatic hydrocarbons [8]. There is no information

in the literature about this problem.

This article is concerned with explaining some relations which govern

the preparation of chlorine derivatives of ethyl- and isopropy!benzene b y oxidative chlorination (with a mixture o f hydrochloric acid and hydrogen perox i d e ) . .....

Experiments were carried out in a glass flask provided with a mechanical

atirrer, d r o p funnel and a thermometer. Reaction temperature was maintained

with an accuracy of 0 . 5 . Commercial hydrochloric acid, ethyl- and isopr0pylbenzene (pure) and a 30% aqueous solution of hydrogen peroxide were

used: for the investigation. The flask was filled with these in given proportions.

Hydrogen peroxide was added to the reaction mass from a drop funnel.

~ The react:ion mixture was analysed a t equal time intervals b y GLC using

an LKhM-7A device with a heat conductivity detector (detector current 90 mA).

* Neftekhlrnlya 15, No. 4, 601-605, 1975.

chlorination of e~hylbenzene

Oxidative

, 1~

Before chromatographic analysis the samples were washed o neutral reaction

a n d dried over calcium chloride. Chromatographic curves were obtained using

II~Z-600 brick modified with PEG-4000 at a carrier gas (nitrogen) velocity

of 60 ml/min. The length of the column was 3 m, analytical temperature 150.

Under these conditions the separation of products of the reaction mixture

is ensured. The peaks were assigned by comparing the retention times of individual compounds and those obtained. Results of chromatographic analysis

and IR spectra of products synthesized show that o-, 10-ehloroethyl- and o-,

ID-chloro-isopropylbenzenes are formed during the reaction.

%

/6

-I,

2oP ll

)

I

X /

100 ZOO

300

r'pm

tJ

10"c,he

400

500

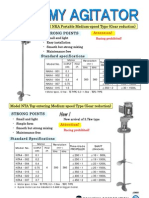

Fze. 1. Effect of the intensity of agitation of the reaction mass on the yield (1-6) and

rate (7) of oxych]orination of ethy]benzene. Temperature 200, intensity of agitation,

rpm: 1--0; 2--100, 3--200; 4--300; 6--400; 6--600.

To find optimum conditions for oxychlorination, the.effects of the intensity

of stirring the reaction mass, the concentration of hydrochloric acid, hydrogen

peroxide feed rate, t h e molar ratio of reacting substances and temperature

on the yield of chlorine derivatives of ethyl- and isopropylbenzene were

examined.

RESULTS

In the initial stage of the experiment we determined the reaction range.

Since initial a~omatic hydrocarbons (and chloroalkylaromatic compounds)

do, not dissolve in hydrochloric acid it was assumed that reaction rate might

b e a~ected by difl~usion factors. In fact, results of experiments (Fig/ I ) s h o w

that the intensity of sirring the reaction mixture has a marked effect on the

field of monochloroethylbenzene and the rate of oxyehlorination.::: ThUs,

without agitation (curve 1, Fig. 1) t h e m a x i m u m yield Of ehloroethylbenzene

'!156

M.S.

SAT.A~OV ~ a/.

does not exceed 18%, while an increase in the intensity of agitation to 400

rev/min (curve 5) increases yield to 91/o. A further increase of agitation

intensity to 600 rev/min has no effect on the yield of chlo~oethylbenzene.

To obtain comparable results by a di~erential method, initial reaction rates

were calculated at dii~erent intensities of agitation.

A marked increase in reaction rate in the interval of 200-400 rev/min

(Fig. 1, curve 7), apparently, points to a transition of the reaction from the

diffusion (<200 rev/mi'n) into the kinetic range (>400 rev/min).

Oxychlorination of aromatic hydrocarbons consists of two step-by-step

reactions: interaction of hydrogen peroxide with hydl'ogen chloride takes

place in the first stage to form chlorine

2HCI~-H20= -+ CI~-2tt20,

(1)

in the second stage of the process the chlorine separated reacts with hydroca2o

bon by the system

(2)

CI,+ ~ - R - - ~ - R + H C I

C1

Consequently, the yield and rate of chlorine formation depend on the

concentration of hydrochloric acid.

%

100~

54

////

3

5

T, h r

Ill/~

7

~o. 2

"c~ hr

Fzo. 3

F I o . 2. Effect of t h e concentration of hydroohloric acid on the yield of ehloroethyl.

benzene. Temperature 20C, intensity of agitation 400 rev/rnln~ (~0]~jCt]~l : H t O a ~ 1 : 1.

Concentration o f hydrochloric acid, % wt.: 1--12; 2--10; 3--20; 4--20; 5--30.

FIG. 3. Effect of t h e feed rate of hydrogen peroxide on the yield of ohloroethylbenzene.

C+H,C~H, : HCI : H = O , ~ 1 : 6 : 1; feed r~te: 1 - - simultaueotm Rllln~; 2--30; 3--15; 4 - - 1 0

g/hr.

157,

Oxidative chlorination of ethylbenzene

Results of Fig. 2 indicate t h a t the yield of ehloroethylbenzene and t h e

rate of its formation depend on the concentration of hydrochloric acid and the

reaction does not take place in practice if acid concentration is lower t h a n

12~o. An increase in He1 concentration to 36% increases the yield of chloroethylbenzene to 91% in 2 hr.

Oxidative chlorination of aromatic hydrocarbons depends both on reaction

(1) and reaction (2). I f the rate of reaction (2) is equal to, or considerably higher

than, the rate of reaction (1) the separation of free chlorine m a y be excluded.

I t was established t h a t without aromatic compounds reaction (1) takes place

at a high rate and it m a y be adjusted b y the rate of hydrogen peroxide supply.

Consequently, it was essential to select conditions under which the chlorine

separated in the first stage fully reacted with aromatic hydrocarbons. Results

in Fig. 3 indicate t h a t a feed rate of hydrogen peroxide of 10 g/hr is optimum;

at this rate a 98-99~/o yield of chloroethylbenzene is ensured in terms of t h e

hydrogen peroxide taken. The Figure shows that with the simultaneous supply

of all reacting substances the rate of oxidative chlorination is higher t h a n

with the gradual feed of Hz0~, b u t the yield of chlorine derivatives is only

790/0, i.e. part of chlorine is not used up in the reaction.

T A B L E 1. E F F E C T OF ~:J~JS A M O U N T OF H Y D R O G E N C H L O R I D E ON T~lJ~ ~2"J[ELD OF CHLORO"~.~t"Y'L- A N D CHLOROISOPROP~irLBENZ]ENE8

Temperature 20C; molar ratio of alkylbenzene : H,O~----1 : 1

HC1,

mole

1

2

4

6

8

10

C,HsC,H,C1

overall I o-I p28

57

85

91

91

91

17

35

52

55

i 55

56

11

22

33

36

36

35

Yield, %

CsH~C6H,C1

C~IIC,HsC1,

veraU I " I P"

0

2

4

7

7.5

8

23

51

7O

80

81

82

11 112

25

26

34.5 35.5

39.5 40.5

40 i 41

40"5 I 41.5

CsH,CeH,CI~

2.5

5

8

11

11

The effect of the amount of hydrochloric acid in the initial mixture on

the yield of chloroalkylbenzenes is shown in Table 1. Investigations were

carried out at an intensity of agitation of the reaction mixture of 400-450

rev/min and a rate of hydrogen peroxide feed of 10 g/hr. An increase in t h e

molar concentration of hydrochloric acid from 1 to 6 moles pet mole hydrogen

peroxide increases the yields of monochloroethylbenzene and monochlorois0propylbenzene from 28 to 91% and from 23 to 80%, respectively.

The relatively low yield of monochloro-isopropylbenzene, particularly

o-isomers is probably due to the sterie effect of the isopropyl radical (Tables

1 and 2). A further increase in the content of hydrochloric acid increases tho

1~. S. SAT.Alg'Frovet a~=

158

formation of dicMoroderivatives of aromatic compounds, the yields of which

v a r y between 8 and 11 ~ .

A study of the effect of temperature on the yields of chloroaromatic hydrocarbons in the temperature range of 0-40 at a rate of hydrogen peroxide feed

of 10 g/hr (Fig. 4a, b) indicates that an increase in temperature accelerates

oxychlorination of ethyl- and isopropylbenzenes. The time to achieve a maxim u m yield of the intermediate product at 40 decreases from 9 to 3 hr, this

yield, however, is lower than at 0 . This dependence of the yield of ehloroethylbenzene on temperature is due to the. acceleration of subsequent chlorination

of t h e chloroethylbenzene formed to dichloroethylbenzenes. In fact, it follows

from curves 2'-5' (Fig. 4a) that with an increase of temperature from 10 to

40 , diehloroethylbenzene yield varies between 4 and 18~o and at 0 the latter

is not formed at all. Consequently, to achieve selective oxychlorination,

the process should be carried out at low temperature (20 and lower) or at

high temperatures with a duration of up to 3 hr.

a/a /

100

r,hr

FIG. 4. Dependence of the yields of chloroaromatic hydrocarbons on reaction t i m e :

a - - chloroethyl (1-5) and dichloroethylbenzene (2'-5"); b -- chloroisopropyl (1-4) and

dichloroisopropyl benzene (1'-4'). Molar ratio of C6HsAI HC1 : H=O----1 : 6 : 1; tempera

ture, C: 1--0; 2, 2'--10; 3, 3'--20; 4, 4'--30; 5, 5'--40.

Similar results were obtained for oxychlorination of isopropylbenzene (Fig.

4b). In this case with an increase of temperature the yield of monochloroisopropylbenzene decreases and the content of dichloroisopropylbenzene increases.

Results in Fig. 4 indicate that the formation of dichloroderivatives of

ethyl- and isopropylbenzenes begins after a 4 5 ~ conversion of initial alkylaromatic compounds. Therefore, in order to increase process selectivity,

a s t u d y was made of the effect of molar quantitites of ethyl- and isopropylbenzenes in the reaction mixture (Table 2).

Oxidative chlorination of ethylbenzene

159

I t was f o u n d t h a t w i t h a n e q u i m o l e c u l a r r a t i o of a r o m a t i c h y d r o c a r b o n s

a n d h y d r o g e n p e r o x i d e u p to 7-8~/o d i c h l o r o d e r i v a t i v e s are f o r m e d .

T~BLE 2. EFFECT OF ~ ' ~ M O ~

' ~

YIELD

OF

PROPORTION OF ETJ~t~Jb-ANDISOPROPYI,BEN~ENES ON

MONO-

AND

DICH~LOROA_I.~YI,BENZENES

Temperature 20C hydroperoxide feed rate 10 g/hr; molar ratio of H C I : H I O s

=6:1

CIHsC,H~C1

Alkylbenzene,

overall

opmole

1

2

4

6

8

10

91

55

36

93

95

96

96

97

57

58

58

58

59

37

37

38

38

38

CaHTCeH,C1

I C,H6C,HaC1.

overall

o-

p-

80

94

95

96

97

97

39.5

46-5

47

47.5

48

48

40"5

47"5

48

48"5

49

49

CsHTC,HaCII

On increasing t h e m o l a r r a t i o o f a l k y l b e n e z e n e : h y d r o g e n p e r o x i d e t o

10 : 1, t h e c o n t e n t s o f d i c h l o r o - d e r i v a t i v e s decreases to 1.0~/o a n d t h e yield

o f m o n o c h l o r o - a l k y l b e n z e n e s increases to 97.0%.

SUMMARY

l. A s t u d y was m a d e of o x y c h l o r i n a t i o n of e t h y l - a n d i s o p r o p y l b e n z e n e

w i t h a m i x t u r e of h y d r o g e n p e r o x i d e a n d h y d r o c h l o r i c acid. I t was s h o w n

t h a t w i t h v i g o r o u s s t i r r i n g (over 400 r e v / m i n ) t h e r e a c t i o n t a k e s p l a c e in t h o

k i n e t i c range.

2. On using 36~/o h y d r o c h l o r i c acid a n d a m o l a r r a t i o o f A r : HCI : H 2 0 a

of 1:1:1,

yields o f c h l o r e t h y l - a n d c h l o r i s o p r o p y l b e n z e n e s are 28 a n d 23

a n d w i t h a r a t i o o f 1 : 6 : 1 t h e y increase to 91 a n d 80~/o, r e s p e c t i v e l y . A n

increase in t h e c o n c e n t r a t i o n of t h e a r o m a t i c c o m p o u n d to 10 m o l e results

in t h e f o r m a t i o n of ortho- a n d para-isomers.

REFERENCES

1.

2.

3.

4.

5.

6.

7.

8.

Yu. G. MAMEDALIYEV and Sh. V. VEIAYEV, Dokl. AN SSSR 92, 325, 1953 ~

M. B. TUROVA-POLYAK and M. A. MASLOVA, Zh. obshch, khimii 27, 897, 1957

S. N. USHAKOV and P. A. MATUZOV, Zh. obshch, khimii 14, 120, 1944

Yu. G. MAMEDALIYEV, M. M. GUSEINOV, D. Ye. MISHIYEV, R. S. AT.E~IARDANOV

and P. A. PETROSYAN, Azerb. khim. zh. No. 4, 9, 1962

Yu. S. KROPANEV, V. G. PLYUSNIN, N. I. PLOTKINA and L. P. UL'YANOVA,

Neftckl~imlya 9, 591, 1969

Yu. G. MAMEDALIYEV, Izbrannyye proizvcdcniya (Selected Works), Izd. AN Azerb.

SSR 1, 1964

Yu. S. KROPANEV, V. G. PLYUSNIN and P. I. PLOTKINA, Ncftebhimiya 7, 398,

1967

Auth. Cert. U.S.S.R. 386891, 18. 10. 1972. Otkr. isobr., prom. obr. i toy. znaki, No. 27,

59, 1973

You might also like

- Synthesis of 2-Acetylcyclohexanone Using Pyrrolidine-EnamineDocument3 pagesSynthesis of 2-Acetylcyclohexanone Using Pyrrolidine-Enaminerobet12No ratings yet

- AOAC Official Method 999.15 Vitamin K in MilkDocument2 pagesAOAC Official Method 999.15 Vitamin K in MilkAnju Doraisamy100% (1)

- Kinetics of Catalytic Dehydrogenation of Ethylbenzene To StyreneDocument5 pagesKinetics of Catalytic Dehydrogenation of Ethylbenzene To Styreneibrahim3318No ratings yet

- Food Hydrocolloids Volume Issue 2019 (Doi 10.1016 - J.foodhyd.2019.02.023) Huang, Hao Belwal, Tarun Liu, Songbai Duan, Zhenhua Luo, Zis - Novel Multi-Phase Nano-Emulsion Preparation For Co-Loadin PDFDocument37 pagesFood Hydrocolloids Volume Issue 2019 (Doi 10.1016 - J.foodhyd.2019.02.023) Huang, Hao Belwal, Tarun Liu, Songbai Duan, Zhenhua Luo, Zis - Novel Multi-Phase Nano-Emulsion Preparation For Co-Loadin PDFdikativiNo ratings yet

- Preparation of Chlorotoluene by Oxidizing Chlorination of TolueneDocument5 pagesPreparation of Chlorotoluene by Oxidizing Chlorination of ToluenejavasoloNo ratings yet

- Applied Catalysis Volume 69 Issue 1 1991 [Doi 10.1016%2Fs0166-9834%2800%2983297-2] Jean Bandiera; Claude Naccache -- Kinetics of Methanol Dehydration on Dealuminated H-mordenite- Model With Acid and Basic Active CeDocument10 pagesApplied Catalysis Volume 69 Issue 1 1991 [Doi 10.1016%2Fs0166-9834%2800%2983297-2] Jean Bandiera; Claude Naccache -- Kinetics of Methanol Dehydration on Dealuminated H-mordenite- Model With Acid and Basic Active CePuji LestariNo ratings yet

- Macdougall 1996Document12 pagesMacdougall 1996jfjd6889No ratings yet

- Schonberg and Mostafa Photo-Reactions. Part VI.: The Kinetics of Aromatic Halogenation. Part I - BrominationDocument4 pagesSchonberg and Mostafa Photo-Reactions. Part VI.: The Kinetics of Aromatic Halogenation. Part I - BrominationAnonymous FigYuONxuuNo ratings yet

- FORMIC ACID AND FORMALDEHYDE AS SPIN-OFF PRODUCTS IN WGSLP-1989-KHANDocument10 pagesFORMIC ACID AND FORMALDEHYDE AS SPIN-OFF PRODUCTS IN WGSLP-1989-KHANleonardoNo ratings yet

- I Io. Chemical Physics Letters: Votr N CDocument5 pagesI Io. Chemical Physics Letters: Votr N CthucinorNo ratings yet

- Transesterification Kinetics of Phenyl Salicylate 2Document20 pagesTransesterification Kinetics of Phenyl Salicylate 2Lucas de Lima e SousaNo ratings yet

- Reaction Testing of Phenol Hydroxylation and Cyclohexane Oxidation by Gas Chromatography: Influence of Residual Hydrogen PeroxideDocument10 pagesReaction Testing of Phenol Hydroxylation and Cyclohexane Oxidation by Gas Chromatography: Influence of Residual Hydrogen PeroxideAmino BowwowNo ratings yet

- Some Aspects of The Toluene Pyrolysis'Document4 pagesSome Aspects of The Toluene Pyrolysis'Kuganathan Slowfingers PadmanathanNo ratings yet

- Kinetics of Petroleum Resin Epoxidation by Peracetic Acid: SciencedirectDocument5 pagesKinetics of Petroleum Resin Epoxidation by Peracetic Acid: SciencedirectArii WAhyudiiNo ratings yet

- Scipharm 70 00015Document5 pagesScipharm 70 00015Davi Abreu Carvalho MotheNo ratings yet

- J. Appl. Chem. Biotechnol. 1974, 24, 759-768Document10 pagesJ. Appl. Chem. Biotechnol. 1974, 24, 759-768Robert L JonesNo ratings yet

- Non-Catalytic Pyrolysis of Ethane To Ethylene in The Presence of CO2 With or Without Limited O2Document7 pagesNon-Catalytic Pyrolysis of Ethane To Ethylene in The Presence of CO2 With or Without Limited O2Sharry ApudNo ratings yet

- ########Hepatic Oxidation of Choline and Arsenocholine - NCBI 9pDocument9 pages########Hepatic Oxidation of Choline and Arsenocholine - NCBI 9pwealth10No ratings yet

- HYD de Propylbenzene 1984Document3 pagesHYD de Propylbenzene 1984Minh Tuấn NguyễnNo ratings yet

- Isothermal Batch ReactorDocument10 pagesIsothermal Batch ReactorSaswiny Ritchie0% (2)

- Bromate-Bromide Rateconstant PDFDocument4 pagesBromate-Bromide Rateconstant PDFPawan BabelNo ratings yet

- Preparation of Propylene Chlorohydrin : GuseinovDocument1 pagePreparation of Propylene Chlorohydrin : GuseinovShiro IshiiNo ratings yet

- Hydration of Acetylene To Acetaldehyde Using K (Run' (EDTA-II) C11211a0Document7 pagesHydration of Acetylene To Acetaldehyde Using K (Run' (EDTA-II) C11211a0Syuhadah NoordinNo ratings yet

- Hydrolysis Lab 2006Document7 pagesHydrolysis Lab 2006Phạm Thành LýNo ratings yet

- Kinetic Investigations On The Esterification of Phthalic Anhydride With N-Heptyl, N-Nonyl or N-Undecyl Alcohol Over Sulfuric Acid CatalystDocument7 pagesKinetic Investigations On The Esterification of Phthalic Anhydride With N-Heptyl, N-Nonyl or N-Undecyl Alcohol Over Sulfuric Acid CatalystVimal PatelNo ratings yet

- 2009 Water-Gas Shift Kinetics Over FeCr-Based Catalyst - Sel...Document18 pages2009 Water-Gas Shift Kinetics Over FeCr-Based Catalyst - Sel...Taniadi SuriaNo ratings yet

- Influence of Reaction Conditions On The Effect of Co-Feeding Ethene in The FTS On A Fused-Iron Catalyst in The Liquid PhaseDocument13 pagesInfluence of Reaction Conditions On The Effect of Co-Feeding Ethene in The FTS On A Fused-Iron Catalyst in The Liquid PhaseLong Nhật PhanNo ratings yet

- Short Communications: Coal Gasification by Microwave Plasma in Water VapourDocument3 pagesShort Communications: Coal Gasification by Microwave Plasma in Water VapourDinda Naiya AzhariNo ratings yet

- Practice QuestionsDocument2 pagesPractice QuestionsAhmad MuzammilNo ratings yet

- Kinetics and Mechanism of Urea FormaldehydeDocument5 pagesKinetics and Mechanism of Urea FormaldehydeDessy A. SariNo ratings yet

- Butyl ChlorideDocument7 pagesButyl ChloridepizzlemNo ratings yet

- Bro Min Anti OnDocument4 pagesBro Min Anti OnSoumya NairNo ratings yet

- The Fischer Esterification of BenzocaineDocument5 pagesThe Fischer Esterification of BenzocaineMikeNo ratings yet

- Equilibrio de Benceno, CiclohexanoDocument5 pagesEquilibrio de Benceno, CiclohexanoLuiz AzpilcuetaNo ratings yet

- Acetylcysteine BP2Document12 pagesAcetylcysteine BP2RPh Krishna Chandra Jagrit100% (1)

- Ipa Acetone KineticsDocument6 pagesIpa Acetone Kineticsbobcruise2k2No ratings yet

- Chapter 1-3Document22 pagesChapter 1-3Aiman LatifNo ratings yet

- A Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystDocument17 pagesA Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystFrank LordNo ratings yet

- Phase Transfer Catalysts As Co-Catalysts in The Ethoxylation of Nonyl PhenolDocument6 pagesPhase Transfer Catalysts As Co-Catalysts in The Ethoxylation of Nonyl PhenolveronikaNo ratings yet

- Journal of The Chemical Society. ADocument3 pagesJournal of The Chemical Society. ADeimonhighNo ratings yet

- Removal of Nonylphenol by Pulsed Corona Discharge in WaterDocument4 pagesRemoval of Nonylphenol by Pulsed Corona Discharge in Waternima_h10No ratings yet

- Infrared Spectroscopic Study of Thermally Treated LigninDocument4 pagesInfrared Spectroscopic Study of Thermally Treated LigninLata DeshmukhNo ratings yet

- Paper - Vía Sal de BencendiazonioDocument11 pagesPaper - Vía Sal de BencendiazonioValeria Villanueva CervantesNo ratings yet

- Us 3642838 PatentDocument3 pagesUs 3642838 PatentElsie XiaoNo ratings yet

- Ruta 7Document9 pagesRuta 7DORIS HELENA GUTIÉRREZ LONDOÑONo ratings yet

- Artículo 2Document8 pagesArtículo 2Exlonk Gil PeláezNo ratings yet

- The Chemistry of The Aminochromes: Part Vi. The Reaction O F Adrenochrome With Glutathione' "3Document7 pagesThe Chemistry of The Aminochromes: Part Vi. The Reaction O F Adrenochrome With Glutathione' "3Nstm3No ratings yet

- Hydrolysis of Pentosans in Bagasse Pith: Charles IDocument5 pagesHydrolysis of Pentosans in Bagasse Pith: Charles IRika SusdimanNo ratings yet

- A Spectrophotometric Method For Determination of UreaDocument5 pagesA Spectrophotometric Method For Determination of Urealox agencyNo ratings yet

- Kinetics of HF in AlkylationDocument8 pagesKinetics of HF in AlkylationAnthonyNo ratings yet

- Superoxide Dismutase Assay by Marklund and Marklund 1974Document6 pagesSuperoxide Dismutase Assay by Marklund and Marklund 1974Andal YakinudinNo ratings yet

- Differential Pulse Polarographic Determination of Ofloxacin in Pharmaceuticals and Biological FluidsDocument7 pagesDifferential Pulse Polarographic Determination of Ofloxacin in Pharmaceuticals and Biological FluidslorenzoseijoNo ratings yet

- Toluene Vanadium Electrolytic OxidationDocument5 pagesToluene Vanadium Electrolytic Oxidationles_gaidzionis9376No ratings yet

- Un Bonito BonitoDocument4 pagesUn Bonito BonitojuanitoNo ratings yet

- Vol 43 - 3 0004Document112 pagesVol 43 - 3 0004karamniaNo ratings yet

- Chem213 Formal Final Report 2Document14 pagesChem213 Formal Final Report 2Amanda Long100% (2)

- 48 - 2 - New York - 10-03 - 0600Document2 pages48 - 2 - New York - 10-03 - 0600Apichat JunsodNo ratings yet

- Equilibrium Constants Methyl Tert-Butyl Ether Liquid-Phase SynthesisDocument5 pagesEquilibrium Constants Methyl Tert-Butyl Ether Liquid-Phase Synthesisjulior87No ratings yet

- The Willgerodt Reaction.11. A Study of Reaction Conditions With None and Other KetonesDocument5 pagesThe Willgerodt Reaction.11. A Study of Reaction Conditions With None and Other KetonesKybernetikum0% (1)

- FTPDocument5 pagesFTPSurendar Vejayan100% (1)

- Material: Natural Rubber (NR) : Max Spare Code: NR 70Document1 pageMaterial: Natural Rubber (NR) : Max Spare Code: NR 70Bagus OktiNo ratings yet

- Horizontal Belt Filters: For Efficient and Reliable DewateringDocument6 pagesHorizontal Belt Filters: For Efficient and Reliable DewateringBagus OktiNo ratings yet

- Data Sheet Jetflex Disc Diffuser - HD 270: Jaeger Group of CompaniesDocument4 pagesData Sheet Jetflex Disc Diffuser - HD 270: Jaeger Group of CompaniesBagus OktiNo ratings yet

- Microorganisms 08 00286Document22 pagesMicroorganisms 08 00286Bagus OktiNo ratings yet

- P&ID SymbolDocument18 pagesP&ID SymbolBagus Okti100% (2)

- MixerDocument4 pagesMixerArun GuptaNo ratings yet

- 7 CoagulationDocument103 pages7 CoagulationAkulSenapatiNo ratings yet

- SolubilityDocument7 pagesSolubilityahmedwamai100% (4)

- 6 Biorefineries BakkerDocument23 pages6 Biorefineries BakkerBagus OktiNo ratings yet

- 10 - Thermodynamics of The Solubility of Borax 2009Document5 pages10 - Thermodynamics of The Solubility of Borax 2009Bagus OktiNo ratings yet

- Text Book of COD TestDocument51 pagesText Book of COD TestBagus OktiNo ratings yet

- RP-HPLC Method For Simultaneous Estimation of Alprazolam and Imipramine As Per Ich GuidelinesDocument13 pagesRP-HPLC Method For Simultaneous Estimation of Alprazolam and Imipramine As Per Ich GuidelinesBaru Chandrasekhar RaoNo ratings yet

- 7 FDD1622 D 01Document6 pages7 FDD1622 D 01dizismineNo ratings yet

- 1 s2.0 S0278691503001893 Main PDFDocument35 pages1 s2.0 S0278691503001893 Main PDFMarcelo ClarosNo ratings yet

- Physical Tests and Determinations: Á591Ñ Zinc DeterminationDocument168 pagesPhysical Tests and Determinations: Á591Ñ Zinc DeterminationsbiasotoNo ratings yet

- Rios Romero 2018Document8 pagesRios Romero 2018Meitha RizqiNo ratings yet

- AbyysDocument31 pagesAbyysGoody's workNo ratings yet

- ChromatographyDocument18 pagesChromatographyYerram Raju BeharaNo ratings yet

- Chang 2019Document6 pagesChang 2019Nguyệt Linh LưuNo ratings yet

- Report Data LoggerDocument3 pagesReport Data LoggerIntan NoranizaNo ratings yet

- Plate Number Requirements For Establishing Method SuitabilityDocument6 pagesPlate Number Requirements For Establishing Method SuitabilityAhmed MahmoudNo ratings yet

- Qa Chromato 2324 A5Document70 pagesQa Chromato 2324 A5Diego FigueiraNo ratings yet

- B.sc. Hons. InstrumentationDocument64 pagesB.sc. Hons. InstrumentationSaurabh YadavNo ratings yet

- H9 User Manual A3Document88 pagesH9 User Manual A3Michael Tanglao0% (1)

- A Comparison of Fully Porous C18 Reversed Phase HPLC ColumnsDocument11 pagesA Comparison of Fully Porous C18 Reversed Phase HPLC ColumnsMarcelo RigatuzoNo ratings yet

- Loba Chemie Price List 2017-18Document272 pagesLoba Chemie Price List 2017-18Varsha Kankani50% (2)

- Shree CV - 2019Document4 pagesShree CV - 2019Anonymous QE8HMXSNo ratings yet

- Principal Component Analysis PCA of PhysicochemicaDocument11 pagesPrincipal Component Analysis PCA of PhysicochemicaAliaAmerNo ratings yet

- Ephedrine Ma-Huang PDFDocument7 pagesEphedrine Ma-Huang PDFRichard PortillooNo ratings yet

- These Resume Samples Are Taken From The UCSD Triton Career GuideDocument7 pagesThese Resume Samples Are Taken From The UCSD Triton Career GuideluchoNo ratings yet

- Makalah Kapita Selekta Kimia AnalitikDocument32 pagesMakalah Kapita Selekta Kimia AnalitikFianChristianNo ratings yet

- SBCC 1106-1Document30 pagesSBCC 1106-1opolla nianorNo ratings yet

- Evaluation of Leaching Parameters For A Refractory GoldDocument10 pagesEvaluation of Leaching Parameters For A Refractory Goldboanerges wino pattyNo ratings yet

- 8000c v3 PDFDocument66 pages8000c v3 PDFjljimenez1969No ratings yet

- Amine DerivatizationDocument5 pagesAmine DerivatizationOksana RotkajaNo ratings yet

- Quantitative Analysis of Cardiac GlycosidesDocument12 pagesQuantitative Analysis of Cardiac GlycosidesAmir ShamsNo ratings yet

- EstradiolDocument12 pagesEstradiolJuan PerezNo ratings yet

- Determination of Phenolic Compounds in WastewaterDocument8 pagesDetermination of Phenolic Compounds in WastewaterReda HassanNo ratings yet

- European Journal Nutrition Curcumin PDFDocument10 pagesEuropean Journal Nutrition Curcumin PDFAndres FacuNo ratings yet

![Applied Catalysis Volume 69 Issue 1 1991 [Doi 10.1016%2Fs0166-9834%2800%2983297-2] Jean Bandiera; Claude Naccache -- Kinetics of Methanol Dehydration on Dealuminated H-mordenite- Model With Acid and Basic Active Ce](https://imgv2-1-f.scribdassets.com/img/document/249493359/149x198/d00c274c1f/1418028470?v=1)