Professional Documents

Culture Documents

S90 48

S90 48

Uploaded by

Agus Qupink Luph AriaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Evaporation: By: Allie E. Fuentebella-Pomperada, Che, Mengr, PHDTMDocument49 pagesEvaporation: By: Allie E. Fuentebella-Pomperada, Che, Mengr, PHDTMjantskie100% (2)

- Quality Analysis of Connecting Rod For Axial Misalignment: Bend Generated While MachiningDocument5 pagesQuality Analysis of Connecting Rod For Axial Misalignment: Bend Generated While MachiningAgus Qupink Luph AriaNo ratings yet

- Tightening - General - 396 - M020046 - 20EDocument16 pagesTightening - General - 396 - M020046 - 20EAgus Qupink Luph AriaNo ratings yet

- Bilge Pump - MS25024 - 01E-3Document2 pagesBilge Pump - MS25024 - 01E-3Agus Qupink Luph AriaNo ratings yet

- Wear Particle AnalysisDocument20 pagesWear Particle AnalysisAgus Qupink Luph AriaNo ratings yet

- Diesel Engine V 956 Description Manual: FriedrichshafenDocument12 pagesDiesel Engine V 956 Description Manual: FriedrichshafenAgus Qupink Luph AriaNo ratings yet

- E 90 48Document4 pagesE 90 48Agus Qupink Luph AriaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- WellHead PDFDocument6 pagesWellHead PDFsolomonicbdmNo ratings yet

- Piping CalculationsDocument19 pagesPiping CalculationskakoullisgNo ratings yet

- SV Notes Density PressureDocument9 pagesSV Notes Density PressuresmithaNo ratings yet

- Claysius Clapeyron Lab ExperimentDocument11 pagesClaysius Clapeyron Lab Experimentmohamad munzir100% (1)

- Introduction To Oil and Gas AllocationDocument33 pagesIntroduction To Oil and Gas AllocationDiego J. PonceNo ratings yet

- MODULE 4 Fluid Mechanics BSEDDocument17 pagesMODULE 4 Fluid Mechanics BSEDMaden beto100% (1)

- LPG Security DepositDocument1 pageLPG Security DepositRongki PeguNo ratings yet

- 2022 6280 ACG Oxygen Generators Status 30 Junio 2022 FinalesDocument2 pages2022 6280 ACG Oxygen Generators Status 30 Junio 2022 FinalesDeisy BonillaNo ratings yet

- Gas - in - Place - A - Volumetrics - I. KocabasDocument31 pagesGas - in - Place - A - Volumetrics - I. KocabasTadeo ChoqueNo ratings yet

- Full Report 2.odtDocument5 pagesFull Report 2.odtRuth UmerezNo ratings yet

- Operation of Centrifugal PumpDocument16 pagesOperation of Centrifugal PumpvenisamegaNo ratings yet

- Ch15 Differential Momentum BalanceDocument20 pagesCh15 Differential Momentum Balance89kkNo ratings yet

- DR Engp M II p1 1.1 R.5grifadoDocument176 pagesDR Engp M II p1 1.1 R.5grifadoleo100% (1)

- 2021-ME-54 Lab ReportDocument31 pages2021-ME-54 Lab ReportAbdullah ArshadNo ratings yet

- Sheet #7Document4 pagesSheet #7Iam A gnoomNo ratings yet

- Test Bank Ch07Document10 pagesTest Bank Ch07Kagiso MokalakeNo ratings yet

- Overview of Applications of Biomass Fast Pyrolysis Oil: S. Czernik and A. V. BridgwaterDocument9 pagesOverview of Applications of Biomass Fast Pyrolysis Oil: S. Czernik and A. V. BridgwateryemresimsekNo ratings yet

- Afcat Ekt ThermodynamicsDocument7 pagesAfcat Ekt Thermodynamicsankit soniNo ratings yet

- PFD Asam Benzoat - Noor Wahyu & NurulDocument1 pagePFD Asam Benzoat - Noor Wahyu & NurulFahmi ZakariaNo ratings yet

- Miscible EorDocument45 pagesMiscible Eormexx4u2nvNo ratings yet

- Material Balance MethodDocument25 pagesMaterial Balance MethodUzumaki28No ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022Document31 pagesIM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022acurvz2005No ratings yet

- Over Speed TestDocument8 pagesOver Speed TestsaitamaopmofficialNo ratings yet

- Oxygen Cones: Worldwide Manufacturer of PSA GeneratorsDocument2 pagesOxygen Cones: Worldwide Manufacturer of PSA GeneratorsddadaraNo ratings yet

- Koya University: (Viscosity & Yield Point)Document11 pagesKoya University: (Viscosity & Yield Point)zazoNo ratings yet

- Basics of Distillation: V. K. KapoorDocument62 pagesBasics of Distillation: V. K. Kapoorstardeepakrati100% (1)

- Hy14-3300 VCL PDFDocument4 pagesHy14-3300 VCL PDFPartsGopher.comNo ratings yet

S90 48

S90 48

Uploaded by

Agus Qupink Luph AriaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S90 48

S90 48

Uploaded by

Agus Qupink Luph AriaCopyright:

Available Formats

Purchase Specification

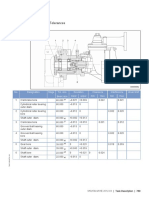

Model No. 90-48/690-48

PRESSURE REDUCING VALVE WITH LOW FLOW BY-PASS

Sizes 1 1/4 - 24

Function

The Pressure Reducing Valve with Low Flow By-Pass automatically reduces a higher inlet pressure to a

steady lower downstream pressure regardless of changing flow rate. The low flow by-pass capability is

achieved by using the Cla-Val Model No. CRD40 balanced Direct Acting Pressure Reducing Valve as an

integral part of the main valve.

Tying of equipment into packages for the purpose of thwarting competition shall be considered to be in

non-compliance with these specifications. Manufacturers shall price items under different subsections or

sections separately.

Main Valve

The valve shall be hydraulically operated, single diaphragm-actuated, globe or angle pattern. The valve

shall consist of three major components: the body with seat installed, the cover with bearings installed,

and the diaphragm assembly. The diaphragm assembly shall be the only moving part and shall form a

sealed chamber in the upper portion of the valve, separating operating pressure from line pressure.

Packing glands and/or stuffing boxes are not permitted and there shall be no pistons operating the main

valve or pilot controls.

Main Valve Body

No separate chambers shall be allowed between the main valve cover and body. Valve body and cover

shall be of cast material. Ductile Iron is standard and other materials shall be available. No fabrication or

welding shall be used in the manufacturing process. Total shipping weight shall be equal or greater in all

respects to the Hytrol 100-01/100-20 body.

The valve shall contain a resilient, synthetic rubber disc, with a rectangular cross-section contained on

three and one-half sides by a disc retainer and forming a tight seal against a single removable seat insert.

No O-ring type discs (circular, square, or quad type) shall be permitted as the seating surface. The disc

guide shall be of the contoured type to permit smooth transition of flow and shall hold the disc firmly in

place. The disc retainer shall be of a sturdy one-piece design capable of withstanding opening and

closing shocks. It must have straight edge sides and a radius at the top edge to prevent excessive

diaphragm wear as the diaphragm flexes across this surface. No hourglass-shaped disc retainers shall be

permitted and no V-type or slotted type disc guides shall be used.

The diaphragm assembly containing a non-magnetic 303 stainless steel stem of sufficient diameter to

withstand high hydraulic pressures, shall be fully guided at both ends by a bearing in the valve cover and

an integral bearing in the valve seat. The seat shall be a solid, one-piece design and shall have a

minimum of a five-degree taper on the seating surface for a positive, drip-tight shut off. No center guides

shall be permitted. The stem shall be drilled and tapped in the cover end to receive and affix such

accessories as may be deemed necessary. The diaphragm assembly shall be the only moving part and

shall form a sealed chamber in the upper portion of the valve, separating operating pressure from line

pressure.

The flexible, non-wicking, FDA approved diaphragm shall consist of nylon fabric bonded with synthetic

rubber compatible with the operating fluid. The center hole for the main valve stem must be sealed by the

vulcanized process or a rubber grommet sealing the center stem hole from the operating pressure. The

diaphragm must withstand a Mullins Burst Test of a minimum of 600 psi per layer of nylon fabric and shall

be cycle tested 100,000 times to insure longevity. The diaphragm shall not be used as the seating

surface. The diaphragm shall be fully supported in the valve body and cover by machined surfaces which

support no less than one-half of the total surface area of the diaphragm in either the fully opened or fully

closed position.

The main valve seat and the stem bearing in the valve cover shall be removable. The cover bearing and

seat in 6 and smaller size valves shall be threaded into the cover and body. Valve seat in 8 and larger

Purchase Specification

size valves shall be retained by flat head machine screws for ease of maintenance. The lower bearing of

the valve stem shall be contained concentrically within the seat and shall be exposed to the flow on all

sides to avoid deposits. To insure proper alignment of the valve stem, the valve body and cover shall be

machined with a locating lip. No pinned covers to the valve body shall be permitted. Cover bearing, disc

retainer, and seat shall be made of the same material. All necessary repairs and/or modifications other

than replacement of the main valve body shall be possible without removing the valve from the pipeline.

Packing glands and/or stuffing boxes shall not be permitted and components including cast material shall

be of North American manufacture.

The valve manufacturer shall warrant the valve to be free of defects in material and workmanship for a

period of three years from date of shipment, provided the valve is installed and used in accordance with

all applicable instructions. Electrical components shall have a one-year warranty.

The valve manufacturer shall be able to supply a complete line of equipment from 1 1/4 through 24

sizes and a complete selection of complementary equipment. The valve manufacturer shall also provide a

computerized cavitation chart which show flow rate, differential pressure, percentage of valve opening, Cv

factor, system velocity, and if there will be cavitation damage.

Material Specification

Valve Size:

Main Valve Body and Cover:

Main Valve Trim:

End Detail:

Pressure Rating:

Temperature Range:

Rubber Material:

Coating:

Desired Options:

Pilot Control System

The pressure reducing pilot control shall be a direct-acting, adjustable, spring-loaded, normally open,

diaphragm valve designed to permit flow when controlled pressure is less than the spring setting. The

pilot control is held open by the force of the compression on the spring above the diaphragm and it closes

when the delivery pressure acting on the underside of the diaphragm exceeds the spring setting. The pilot

control system shall include a fixed orifice. No variable orifices shall be permitted. The pilot system shall

include an opening speed control on all valves 3 and smaller on the Model 90-48 and 4 and smaller on

the Model 690-48 as standard equipment.

The pilot control shall have a second downstream sensing port which can be utilized to install a pressure

gauge.

The pilot system shall include a direct-acting pressure reducing valve installed in the unused body ports

of the main valve to act as a low flow by-pass of the main valve assembly.

A direct factory representative shall be made available for start-up service, inspection and necessary

adjustments.

Material Specification for Pilot Control:

Pressure Rating:

Trim:

Rubber Material:

Tubing and Fittings:

Adjustment Range:

Operating Fluids:

Desired Options:

This valve shall be a Cla-Val Co. Model No. 90-48/690-48 Combination Pressure Reducing with Low Flow

By-Pass Valve. As manufactured by Cla-Val Co., Newport Beach, CA 92659-0325.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Evaporation: By: Allie E. Fuentebella-Pomperada, Che, Mengr, PHDTMDocument49 pagesEvaporation: By: Allie E. Fuentebella-Pomperada, Che, Mengr, PHDTMjantskie100% (2)

- Quality Analysis of Connecting Rod For Axial Misalignment: Bend Generated While MachiningDocument5 pagesQuality Analysis of Connecting Rod For Axial Misalignment: Bend Generated While MachiningAgus Qupink Luph AriaNo ratings yet

- Tightening - General - 396 - M020046 - 20EDocument16 pagesTightening - General - 396 - M020046 - 20EAgus Qupink Luph AriaNo ratings yet

- Bilge Pump - MS25024 - 01E-3Document2 pagesBilge Pump - MS25024 - 01E-3Agus Qupink Luph AriaNo ratings yet

- Wear Particle AnalysisDocument20 pagesWear Particle AnalysisAgus Qupink Luph AriaNo ratings yet

- Diesel Engine V 956 Description Manual: FriedrichshafenDocument12 pagesDiesel Engine V 956 Description Manual: FriedrichshafenAgus Qupink Luph AriaNo ratings yet

- E 90 48Document4 pagesE 90 48Agus Qupink Luph AriaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:09:04 TEMA SheetWael BadriNo ratings yet

- WellHead PDFDocument6 pagesWellHead PDFsolomonicbdmNo ratings yet

- Piping CalculationsDocument19 pagesPiping CalculationskakoullisgNo ratings yet

- SV Notes Density PressureDocument9 pagesSV Notes Density PressuresmithaNo ratings yet

- Claysius Clapeyron Lab ExperimentDocument11 pagesClaysius Clapeyron Lab Experimentmohamad munzir100% (1)

- Introduction To Oil and Gas AllocationDocument33 pagesIntroduction To Oil and Gas AllocationDiego J. PonceNo ratings yet

- MODULE 4 Fluid Mechanics BSEDDocument17 pagesMODULE 4 Fluid Mechanics BSEDMaden beto100% (1)

- LPG Security DepositDocument1 pageLPG Security DepositRongki PeguNo ratings yet

- 2022 6280 ACG Oxygen Generators Status 30 Junio 2022 FinalesDocument2 pages2022 6280 ACG Oxygen Generators Status 30 Junio 2022 FinalesDeisy BonillaNo ratings yet

- Gas - in - Place - A - Volumetrics - I. KocabasDocument31 pagesGas - in - Place - A - Volumetrics - I. KocabasTadeo ChoqueNo ratings yet

- Full Report 2.odtDocument5 pagesFull Report 2.odtRuth UmerezNo ratings yet

- Operation of Centrifugal PumpDocument16 pagesOperation of Centrifugal PumpvenisamegaNo ratings yet

- Ch15 Differential Momentum BalanceDocument20 pagesCh15 Differential Momentum Balance89kkNo ratings yet

- DR Engp M II p1 1.1 R.5grifadoDocument176 pagesDR Engp M II p1 1.1 R.5grifadoleo100% (1)

- 2021-ME-54 Lab ReportDocument31 pages2021-ME-54 Lab ReportAbdullah ArshadNo ratings yet

- Sheet #7Document4 pagesSheet #7Iam A gnoomNo ratings yet

- Test Bank Ch07Document10 pagesTest Bank Ch07Kagiso MokalakeNo ratings yet

- Overview of Applications of Biomass Fast Pyrolysis Oil: S. Czernik and A. V. BridgwaterDocument9 pagesOverview of Applications of Biomass Fast Pyrolysis Oil: S. Czernik and A. V. BridgwateryemresimsekNo ratings yet

- Afcat Ekt ThermodynamicsDocument7 pagesAfcat Ekt Thermodynamicsankit soniNo ratings yet

- PFD Asam Benzoat - Noor Wahyu & NurulDocument1 pagePFD Asam Benzoat - Noor Wahyu & NurulFahmi ZakariaNo ratings yet

- Miscible EorDocument45 pagesMiscible Eormexx4u2nvNo ratings yet

- Material Balance MethodDocument25 pagesMaterial Balance MethodUzumaki28No ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022Document31 pagesIM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022acurvz2005No ratings yet

- Over Speed TestDocument8 pagesOver Speed TestsaitamaopmofficialNo ratings yet

- Oxygen Cones: Worldwide Manufacturer of PSA GeneratorsDocument2 pagesOxygen Cones: Worldwide Manufacturer of PSA GeneratorsddadaraNo ratings yet

- Koya University: (Viscosity & Yield Point)Document11 pagesKoya University: (Viscosity & Yield Point)zazoNo ratings yet

- Basics of Distillation: V. K. KapoorDocument62 pagesBasics of Distillation: V. K. Kapoorstardeepakrati100% (1)

- Hy14-3300 VCL PDFDocument4 pagesHy14-3300 VCL PDFPartsGopher.comNo ratings yet