Professional Documents

Culture Documents

Us1797509 PDF

Us1797509 PDF

Uploaded by

checolonoskiCopyright:

Available Formats

You might also like

- TM 9-1300-203, Artillery AmmunitionDocument486 pagesTM 9-1300-203, Artillery AmmunitionVlad VladNo ratings yet

- Explosives Akhavan PDFDocument196 pagesExplosives Akhavan PDFbbnchem86% (7)

- Electrowinning From Cupric Chloride SolutionDocument6 pagesElectrowinning From Cupric Chloride SolutionAwaken69100% (2)

- Preparing Perch Lo RatesDocument9 pagesPreparing Perch Lo Rateshussein_150666No ratings yet

- Separating The Six Platinum MetalsDocument9 pagesSeparating The Six Platinum MetalsAFLAC ............100% (1)

- Handbook of Ammunition Used in Irak and Surrounding AreasDocument319 pagesHandbook of Ammunition Used in Irak and Surrounding Areasmalone6993% (15)

- Tsar BombaDocument3 pagesTsar BombaDenish RamnarainNo ratings yet

- Us1928205 PDFDocument4 pagesUs1928205 PDFchecolonoskiNo ratings yet

- Us2473405 PDFDocument5 pagesUs2473405 PDFchecolonoskiNo ratings yet

- United States Patent Office.: Patented Feb. 22, 1916Document3 pagesUnited States Patent Office.: Patented Feb. 22, 1916JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Us1404687 PDFDocument2 pagesUs1404687 PDFchecolonoskiNo ratings yet

- Room Temperature Na-S Batteries With Sulfur Composite Cathode MaterialsDocument4 pagesRoom Temperature Na-S Batteries With Sulfur Composite Cathode MaterialsJahangir MalikNo ratings yet

- Us1399104 PDFDocument2 pagesUs1399104 PDFchecolonoskiNo ratings yet

- Georgia Tech Sponsored ResearchDocument51 pagesGeorgia Tech Sponsored ResearchChristian SmallenNo ratings yet

- Rcccivctl: Manning March RSTH, 1@3Document7 pagesRcccivctl: Manning March RSTH, 1@3Javier Andres Esteban MuñozNo ratings yet

- United States Patent (191Document11 pagesUnited States Patent (191Sushil Kumar RaoNo ratings yet

- Jan. 22, 1963 L.. Domash Etal 3,074,380: Improvement 1N Hydrodesulfurization With Filed Dec. 30, 1958Document5 pagesJan. 22, 1963 L.. Domash Etal 3,074,380: Improvement 1N Hydrodesulfurization With Filed Dec. 30, 1958deni.sttnNo ratings yet

- Appendix A Analysis by The BlowpipeDocument38 pagesAppendix A Analysis by The BlowpipeArsalan BalochNo ratings yet

- Chemical Studies of Polythionic Acid Stress - Corrosion CrackingDocument10 pagesChemical Studies of Polythionic Acid Stress - Corrosion Crackingqueno1No ratings yet

- Us 4570540Document3 pagesUs 4570540erwerNo ratings yet

- Aids Powder Metallurgy: Sintering inDocument12 pagesAids Powder Metallurgy: Sintering inSebastian Edison Muñoz GuerreroNo ratings yet

- Oct. 16, 1934. P. R. Judy Et A 1,977.277: 76e 7727 6&éezze AveDocument3 pagesOct. 16, 1934. P. R. Judy Et A 1,977.277: 76e 7727 6&éezze AveJEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Wilder GetterDocument13 pagesWilder GetterFerhat Bozduman100% (1)

- (1994) - Shen - Development of An Aluminiumhea Water Battery For Subsea ApplicationsDocument9 pages(1994) - Shen - Development of An Aluminiumhea Water Battery For Subsea ApplicationsK A ThomasNo ratings yet

- United States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsenDocument5 pagesUnited States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsencicerojoiasNo ratings yet

- Smoke Suppressant For Copolymers of Ethylene and Cholortrifluoro EthyleneDocument2 pagesSmoke Suppressant For Copolymers of Ethylene and Cholortrifluoro EthyleneVansala GanesanNo ratings yet

- EP0070932B1Document5 pagesEP0070932B1bayuNo ratings yet

- United States Patent: Patented June 15, 1971Document3 pagesUnited States Patent: Patented June 15, 1971cantikNo ratings yet

- Catalytic Isomerization of Light Alkanes - T.loftenDocument133 pagesCatalytic Isomerization of Light Alkanes - T.loftenIrina Ammosova100% (2)

- Apl XGDocument3 pagesApl XGPravin ShindeNo ratings yet

- 135 137 PMR Jul09Document3 pages135 137 PMR Jul09syaNo ratings yet

- RebeccaDocument133 pagesRebeccabennetNo ratings yet

- Us2487906 PDFDocument2 pagesUs2487906 PDFchecolonoskiNo ratings yet

- Electrodeposition Palladium-Silver Alloys Arnrnoniacal ElectrolytesDocument8 pagesElectrodeposition Palladium-Silver Alloys Arnrnoniacal ElectrolytescicerojoiasNo ratings yet

- Final Paper Laporte BalfourDocument52 pagesFinal Paper Laporte Balfourapi-249533478No ratings yet

- Electrode Position of PT PMR v32 I4 188 197Document10 pagesElectrode Position of PT PMR v32 I4 188 197bissonaNo ratings yet

- Cat Forklift Tc30 Spare Parts ManualDocument22 pagesCat Forklift Tc30 Spare Parts Manualandrewbell190802bfe100% (26)

- Effect of Alumina - Titania Supports On The Activity of PD, PT and Bimetallic PD - PT Catalysts For Hydrorefining ApplicationsDocument5 pagesEffect of Alumina - Titania Supports On The Activity of PD, PT and Bimetallic PD - PT Catalysts For Hydrorefining ApplicationssaraseeNo ratings yet

- Arc Plasma Processing of PT and PD Catalysts SupportedDocument4 pagesArc Plasma Processing of PT and PD Catalysts SupportedFei ZhouNo ratings yet

- Jan. 3, 1933. H. Walter Et Al: Filed Feb. 19, 1931 2 Sheets-Sheet 1Document5 pagesJan. 3, 1933. H. Walter Et Al: Filed Feb. 19, 1931 2 Sheets-Sheet 1Rzn LaviNo ratings yet

- Us3437534 PDFDocument3 pagesUs3437534 PDFchecolonoskiNo ratings yet

- United States Patento: Ratented Nov. 4, 1$I58Document7 pagesUnited States Patento: Ratented Nov. 4, 1$I58Stella AguirreNo ratings yet

- Pure Titanium: Metallurgy of T Itanium and Its AlloysDocument8 pagesPure Titanium: Metallurgy of T Itanium and Its AlloysLowry GuettaNo ratings yet

- Japan Sea WaterDocument8 pagesJapan Sea WaterVikk SuriyaNo ratings yet

- Referencia 74Document5 pagesReferencia 74XDEWSZAQNo ratings yet

- Isomer CatalystDocument133 pagesIsomer CatalystSoran SabirNo ratings yet

- The Direct Electrochemical Synthesis of ( (C6H5) 3Ph) 2 (CoCl4)Document2 pagesThe Direct Electrochemical Synthesis of ( (C6H5) 3Ph) 2 (CoCl4)Pavle RadojkovićNo ratings yet

- United States Patent (19) (11) Patent Number: 4,717,459: Nakazawa Et Al. (45) Date of Patent: Jan. 5, 1988Document6 pagesUnited States Patent (19) (11) Patent Number: 4,717,459: Nakazawa Et Al. (45) Date of Patent: Jan. 5, 1988cicerojoiasNo ratings yet

- Practice Problem Set 4 Atomic Absorption SpectrosDocument14 pagesPractice Problem Set 4 Atomic Absorption SpectrosKassimNo ratings yet

- Us2589532 PDFDocument7 pagesUs2589532 PDFchecolonoskiNo ratings yet

- Of Of: by John A. Scherrer. Rosemond K. Bell. and William D. MogermanDocument4 pagesOf Of: by John A. Scherrer. Rosemond K. Bell. and William D. MogermanMahmood UllahNo ratings yet

- Electrolytic Concentration of Aqueous Solutions of Nitric Acid. I. Henry Jermain Maude CreightonDocument7 pagesElectrolytic Concentration of Aqueous Solutions of Nitric Acid. I. Henry Jermain Maude Creightoneduard morarNo ratings yet

- 07 - Chapter 1Document46 pages07 - Chapter 1jakinNo ratings yet

- A Mechanism For The Oxidation-Related in Uence On The Thermoelectric Behavior of PalladiumDocument32 pagesA Mechanism For The Oxidation-Related in Uence On The Thermoelectric Behavior of PalladiumGlobal QualityNo ratings yet

- Bu77.2/4/ É. Sucée: Fig. 5. Hig 4Document5 pagesBu77.2/4/ É. Sucée: Fig. 5. Hig 4k-groupNo ratings yet

- Lead Metallurgy (From Heavy Non Ferrous Metals N. SEVRYUKOV)Document24 pagesLead Metallurgy (From Heavy Non Ferrous Metals N. SEVRYUKOV)Tsakalakis G. KonstantinosNo ratings yet

- Photoelectrochemical Water Splitting in Separate Oxygen and Hydrogen CellsDocument7 pagesPhotoelectrochemical Water Splitting in Separate Oxygen and Hydrogen Cellskhan47pkNo ratings yet

- 1 s2.0 002207289280421Y MainDocument11 pages1 s2.0 002207289280421Y MainananthuNo ratings yet

- Awad 2007Document7 pagesAwad 2007Ben Duncan Málaga EspichánNo ratings yet

- Ethylene Oxide Kinetics and MechanismDocument10 pagesEthylene Oxide Kinetics and MechanismjohnNo ratings yet

- Method For Producing Methyl Chloride PattenDocument23 pagesMethod For Producing Methyl Chloride PattenMufita RamadhinaNo ratings yet

- Patent US2960558 - Dry Cell - Google PatentsDocument5 pagesPatent US2960558 - Dry Cell - Google PatentsAyasmitaPadhiaryNo ratings yet

- A System of Instruction in the Practical Use of the Blowpipe Being A Graduated Course Of Analysis For The Use Of Students And All Those Engaged In The Examination Of Metallic CombinationsFrom EverandA System of Instruction in the Practical Use of the Blowpipe Being A Graduated Course Of Analysis For The Use Of Students And All Those Engaged In The Examination Of Metallic CombinationsNo ratings yet

- A System of Instruction in the Practical Use of the BlowpipeFrom EverandA System of Instruction in the Practical Use of the BlowpipeNo ratings yet

- Benzocaine (2 Steps)Document11 pagesBenzocaine (2 Steps)checolonoski0% (1)

- Anti-Corrosion Methods and Materials: Article InformationDocument6 pagesAnti-Corrosion Methods and Materials: Article InformationchecolonoskiNo ratings yet

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsDocument9 pagesPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiNo ratings yet

- Us2589532 PDFDocument7 pagesUs2589532 PDFchecolonoskiNo ratings yet

- Us4278480 PDFDocument3 pagesUs4278480 PDFchecolonoskiNo ratings yet

- جورنال عراقى (جامعة تكريت) PDFDocument10 pagesجورنال عراقى (جامعة تكريت) PDFchecolonoskiNo ratings yet

- Us2344840 PDFDocument3 pagesUs2344840 PDFchecolonoskiNo ratings yet

- Us2942965 PDFDocument2 pagesUs2942965 PDFchecolonoskiNo ratings yet

- Us857580 PDFDocument2 pagesUs857580 PDFchecolonoskiNo ratings yet

- Us2741543 PDFDocument6 pagesUs2741543 PDFchecolonoskiNo ratings yet

- Ravi2011 PDFDocument11 pagesRavi2011 PDFchecolonoskiNo ratings yet

- Urey1931 PDFDocument9 pagesUrey1931 PDFchecolonoskiNo ratings yet

- Nitrate Solid Solution. I: Distributed byDocument37 pagesNitrate Solid Solution. I: Distributed bychecolonoskiNo ratings yet

- Forensic 103Document6 pagesForensic 103Francheska Kate LabiosNo ratings yet

- Firecracker: For Other Uses, SeeDocument4 pagesFirecracker: For Other Uses, SeeJrPelayoNo ratings yet

- Protocol For Explosive Related Incidents Investigation: Seminar: A.B.K.D CECU ButuanDocument18 pagesProtocol For Explosive Related Incidents Investigation: Seminar: A.B.K.D CECU ButuanBowie DanoNo ratings yet

- Nonel ManualDocument56 pagesNonel Manuallaxman_mbmNo ratings yet

- EOD Stanags Overview April 2021Document12 pagesEOD Stanags Overview April 2021den mas paratate leo egoNo ratings yet

- Advanced Anarchist Arsenal - Recipes For Improvised Incendiaries and Explosives PDFDocument50 pagesAdvanced Anarchist Arsenal - Recipes For Improvised Incendiaries and Explosives PDFJames100% (1)

- FireworksDocument30 pagesFireworksAdalberto MacdonaldNo ratings yet

- Industrial Catalogue 11 - 7 - 13 PDFDocument68 pagesIndustrial Catalogue 11 - 7 - 13 PDFCrisanto JeresanoNo ratings yet

- CIL Explosive TestingDocument43 pagesCIL Explosive TestingLalitkumar SableNo ratings yet

- Dyno Nobel Shock Tube PDFDocument27 pagesDyno Nobel Shock Tube PDFTeofilus Lanyo MathenaNo ratings yet

- Ieds Catalog 09-21-2017 Low CompressDocument40 pagesIeds Catalog 09-21-2017 Low Compresswhorne24No ratings yet

- 5.10 CDC List of Cargoes 4-05Document19 pages5.10 CDC List of Cargoes 4-05Goran JakelicNo ratings yet

- 01 BombsDocument46 pages01 BombsZenon Kłosiński100% (1)

- LM2000AVMDocument18 pagesLM2000AVMweter44No ratings yet

- Cyberpunk 2020 - Datafortress 2020 - Ultimate Heavy WeaponsDocument26 pagesCyberpunk 2020 - Datafortress 2020 - Ultimate Heavy WeaponsSokoliak 010010110No ratings yet

- Flash Powder - Wikipedia, The Free EncyclopediaDocument5 pagesFlash Powder - Wikipedia, The Free EncyclopediaRicardo Fontanari de CarvalhoNo ratings yet

- Catalogue KRUŠIK"Document80 pagesCatalogue KRUŠIK"Nash7777100% (2)

- EOD (Explosive Ordnance Disposal) Terminology AmmunitionDocument16 pagesEOD (Explosive Ordnance Disposal) Terminology AmmunitionCosmin Iulian IonescuNo ratings yet

- CB 130Document1 pageCB 130shomi86No ratings yet

- Chemistry of Powder and ExplosivesDocument12 pagesChemistry of Powder and Explosivesvnmaina100% (2)

- Smokeless GAP-RDX Composite Rocket Propellants Containing Diaminodinitroethylene (FOX-7)Document6 pagesSmokeless GAP-RDX Composite Rocket Propellants Containing Diaminodinitroethylene (FOX-7)K3LH EMCNo ratings yet

- ExplosiveDocument404 pagesExplosiveAndres FeherNo ratings yet

- Make Flash PowderDocument10 pagesMake Flash PowderBruno Prpić100% (1)

- AFEO Bulletin 12Document28 pagesAFEO Bulletin 12cpt_suzukiNo ratings yet

- Cargo UN NumberDocument440 pagesCargo UN NumberAndrey ShevchenkoNo ratings yet

- Them Bombs - Manual (English, Android Phone) 1.0Document27 pagesThem Bombs - Manual (English, Android Phone) 1.0Ganjamaru Jc Na0% (2)

- Prtik 123Document47 pagesPrtik 123SUBHASMITA PATRANo ratings yet

Us1797509 PDF

Us1797509 PDF

Uploaded by

checolonoskiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us1797509 PDF

Us1797509 PDF

Uploaded by

checolonoskiCopyright:

Available Formats

1,797,509

H. A. L E w E

ELECTRIC BLASTING CAP AND IGNITION MATERIAL FOR THE SAME

Filed March 18, 1929

HALEW/s, lnvznror

Lg/1%"?

Bq hisa?orne .

Patented Mar. 24, 1931

1,797,509

UNITED STATES PATENT OFFICE

HAROLD A. LEWIS, OF WOODBURY, NEW JERSEY, ASSIGNOR TO E. I. DU PONT DE

NEMOULS & COMPANY, OF WILMINGTON, DELAWARE, A CORPORATION OF DELA

WARE

WEIECTRICWBVLASTING CAP AND IGNITION MATERIAL FOR THE SAME

Application ?led March 18, 1929.

Serial No. 347,915.

This invention relates to electric blasting used, for example, mercury fulminate, either

caps, and more particularly to an improved alone or with potassium chlorate, mixtures of

ignition mixture for the same, and consists mercury fulminate, antimony sulphide, po

tassium chlorate, and gun cotton. A mixture

phocyanate, an oxidizing agent, and a low comprising eighty parts of mercury ful

?ash point fuel as an ignition material for minate and twenty parts of potassium chlo~

essentially in the use of a mixture of a sul

the blasting caps. -

Electric blasting caps, as commonly manu

rate has been, in most common use.

These mixtures heretofore used are expen

factured, comprise a metallic shell containing sive because of the high proportion of costly

a pressed explosive charge and an igniter.

In some cases the pressed explosive charge has

been a single charge of a primary detonat

ing compound such as mercury fulminate, or

15

20

mercury fulminate included; it has been

found in the past impractical to reduce the

cost materially by decreasing the proportion

of fulminate because of erratic performance.

a mixture of this material with an oxidizing In addition, the mercury fulminate cannot be

agent such as potassium chlorate; and in used in certain metallic shells because the

other cases it has consisted of two separate free mercury, almost invariably present as

charges, one a base charge and the other a impurity in fulminate, caused oxidation of

primer charge. Among the explosives used or an amalgamation with such metals; for

for the base charge have been, for example, example, mercury fulminate cannot be satis

trinitrotoluene, picric acid, tetranitromethyl factorily used in alumir'im shells, which

aniline (tetryl) tetranitropenterythrite, ery shells have been almos1 universally em

25

30

35

40

throl tetranitrate, nitrated ivory nut meal, ployed with lead azide primed detonators.

and ground smokeless powder. For the prim Also mixtures of mercury fulminate and

ing charge there have been used primary det potassium chlorate when used in contact

onating compounds, such as mercury ful with lead azide, have been generally con

minate, cyanurtriazide, and lead axide, va sidered responsible for spontaneous ex

rious oxidizing agents such as potassium plosions and therefore incompatible. F ur

chlorate being often mixed with the priming thermore, mercury fulminate and potassium

compound, and various ignition and binding chlorate mixtures are hydroscopic. In moist

compounds such as lead tritroresorcinate be

condition they exert a powerful corrosive ac

ing often mixed with or superimposed upon tion on certain metals and alloys whose other

the more di?icultly ignitible primers such as properties aresatisfactory for bridge wires;

lead azide. In some cases an inner capsule it has, therefore, been necessary in many cases

has been used with the primer charge in to use expensive metals, such as platinum, for

order to get additional con?nement, and bridge wires in order to overcome this cor

thereby increase the e?iciency of the det rosion. Also, when moist, these mixtures fre

onator, while in other cases no such capsule quently fail to ignite.

has been employed.

The object of my invention is to provide

For the ignition of these electric blasting an ignition compound for electric blasting

caps two general methods have been in use; caps which is cheaper than those most C0111

80

CO

one, a so called match head in which a wire is monly used heretofore. A further object

surrounded by a mass or bulk of ignitible ma is to provide an ignition compound which

terial; and, two, a bridge wire embedded in a

loose charge of ignitible material. In both

cases the ignition is a?'ected by heat gener

"ated in the bridge wire by passage of an.

may be used in any of the metals which have

heretofore been used for the manufacture of

blasting cap shells, and particularly one

which may be used in the presence of lead

electric current from an outside sourcev azide. Further objects will be apparent as

through leading wires attached to said the description proceeds.

bridge. For the loose charge, to which the , These objects are accomplished by the fol

50'

present invention relates, there have been lowing invention, in which I have found that

100

menace

an ignition com ound comprising a sulpho grammatic illustration merely of a satisfac

cyanate, an oxi izing agent and a low igni tory shell, constructed according to my in

tion-point fuel produces most satisfactory vention, reference may be had to the ac

results.

A suitable sulphocyanate for this purpose

companying drawing:

is lead sulphocyanate, although other sulpho

which a designates the metallic shell, 6 the

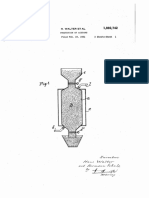

Figure 1 illustrates a sectional view in 70

cyanates may be used, such, for example, as leading wires, 0 the bridge wire, 03 a plug of

copper sulphocyanate. A suitable oxidizing sulphur or other suitable material, e a water

material for use in my composition is potas proo?ng compound, f a bridge plug, 9- the

sium chlorate, although I may use other oxi loose ignition mixture, h a capsule contain

dizing agents, such as potassium perchlorate ing 90-10 F. C. primer, designated z; and 3'

or barium nitrate.

I have found that for a represents the tetryl base load.

low ignition-point fuel nitrocellulose or pyro

15

75

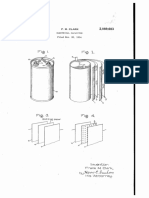

In Figure 2, like characters represent the

powder is very satisfactory, although any same elements as shown in Figure 1, except

of the low ignition-point fuels, for instance, i designates the lead azide-lead styphnate

80

salts of various organic acids, such as the lead compound in place of the 90-10 F. C. primer. I

As many apparently widely di?erent em

salts of styphnic acid or picric acid, may

be used. I have found, however, that the bodiments of this invention may be made

nitric esters are particularly well suited to

without departing from the spirit thereof,

my purpose, because of their availability. it is to be understood that I do not limit my

Another example of low ?ash point nitric self to the foregoing examples or descrip

esters having satisfactory properties for my tions except as indicated in the following

purpose is nitro-starch, tho-ugh this mate patent claims:

I claim:

rial is less satisfactory than ground smoke;

1. An electric blasting cap comprising a

less powder because of its tendency towards

instability and ready moisture absorption.

90

metallic shell, a pressed detonating charge,

By way of description, the following is a loose charge of ignition material consisting

given, but it is to be understood that this in

of a mixture of sulphocyanate, an oxidizing

vention is not to be limited to the materials compound and a low ignition point fuel, and

or proportions given below, and that this ex a bridge wire attached to current leading

95

ample is merely illustrative of one of the wires embedded in said loose charge.

preferred embodiments of my invention suit

2, An electric blasting cap comprising a

able for the purpose described:

metallic shell, a pressed charge of a sec

Lead sulphocyanate ______________ __ till-b0

ondary detonating compound, a pressed

charge of a primary detonating compound,

Potassium chlorate _______________ __ 10-30

a loose charge of ignition material consisting

Ground smokeless powder _________ __ 3050

of a mixture of sulphocyanate, an oxidizing

P r e nt

A. composition comprising the above mate compound and a low ignition point fuel, and

rials in essentiall the proportions given, a bridge wire attached to current leading

?res with approximately the same current wires embedded in said loose charge.

consumption, and hence at approximately 3. An electric blasting cap comprising a

101)

10E

the same temperature as a mixture of eighty metallic shell, a pressed charge of a sec

45

50

55

60

65

parts of mercury fulminate and twenty parts ondary detonating compound, a pressed

of potassium chlorate. Such a composition charge of a primary detonating compound,

may be used in any of the metallic shells em a loose charge of ignition material consisting

ployed in the industry, and is entirely com of a mixture of lead sulphocyanate, potas

patible with either mercury fulminate or sium chlorate and a low ignition point fuel,

lead azide priming compositions. Further and a bridge wire attached to current leading

1%

I

more, even after it has absorbed appreciable wires embedded in said loose charge.

4. An electric blasting cap comprising a 315

quantities of moisture, it will ?re with a cur

rent consumption approximating that re metallic shell, a pressed charge of a sec

detonating compound, a pressed

quired by dried material, and in this moist ondary

charge

of

a primary detonating compound, a

condition it exerts no corrosive action on com

loose

charge

of ignition material consisting

mon alloys used for bridge wires. Also, the

a mixture of lead sulphocyanate, potassium

scnsitiveness of this ignition mixture, to both of

chlorate and a low ignition point nitric ester,

shock and friction, is lower than that of ful and a bridge wire attached'to current lead

minate-chlorate mixtures, and for that rea ing wires embedded in said loose charge.

son it may be handled. and used with less

5. An electric blasting cap comprising a

hazard.

metallic shell, a pressed charge of a secondary

It will be understood, of course, that the detonating compound, a pressed charge of

new compositions comprising my invention a primary detonating compound, a loose.

may be arranged in the metallic shell in any charge of ignition material consisting of a

suitable manner according to the practice in mixture .of lead sulphocyanate, potassium

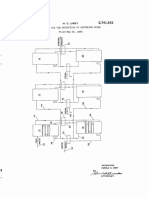

making electric blasting caps. For a dia chlorate and ground pyro powder, and a

I20

125

130

1,797,509

bridge wire attached to current leading wires

embedded in said loose charge.

6. An electric blasting cap comprising a

metallic shell, a pressed charge of a secondary

detonating compound, a pressed charge of a

primary detonating compound, a loose charge

of ignition material consisting of a mixture

of from 3050% lead sulphocyanate, 1030%

potassium chlorate and 3050% ground pyro

powder, and a bridge wire attached to cur

rent leading wires embedded in said loose

charge.

7 . An electric blasting cap comprising a

metallic shell, a pressed base charge of tetra

15

nitromethylaniline, a pressed priming charge

of lead azide together with an ignition and

binding material either mixed with or super

imposed upon said lead azide, a loose igni

tion charge consisting of a sulphocyanate, an

20

oxidizing compound and a low ignition point

fuel, and a bridged wire attached to current

leading Wires embedded in said loose charge.

8. An electric blasting cap comprising a

metallic shell, a pressed base charge of tetra

nitromethylaniline, a pressed priming charge

of lead azide together with an ignition and

binding material either mixed with or super

imposed upon said lead azide, a loose ignition

30

charge consisting of lead sulphocyanate, po

tassium chlorate, and ground pyro powder,

and a bridge wire attached to current lead

ing wires embedded in said loose charge.

In testimony whereof, I af?x my signature.

HAROLD A. LEWIS.

35

50

60

65

You might also like

- TM 9-1300-203, Artillery AmmunitionDocument486 pagesTM 9-1300-203, Artillery AmmunitionVlad VladNo ratings yet

- Explosives Akhavan PDFDocument196 pagesExplosives Akhavan PDFbbnchem86% (7)

- Electrowinning From Cupric Chloride SolutionDocument6 pagesElectrowinning From Cupric Chloride SolutionAwaken69100% (2)

- Preparing Perch Lo RatesDocument9 pagesPreparing Perch Lo Rateshussein_150666No ratings yet

- Separating The Six Platinum MetalsDocument9 pagesSeparating The Six Platinum MetalsAFLAC ............100% (1)

- Handbook of Ammunition Used in Irak and Surrounding AreasDocument319 pagesHandbook of Ammunition Used in Irak and Surrounding Areasmalone6993% (15)

- Tsar BombaDocument3 pagesTsar BombaDenish RamnarainNo ratings yet

- Us1928205 PDFDocument4 pagesUs1928205 PDFchecolonoskiNo ratings yet

- Us2473405 PDFDocument5 pagesUs2473405 PDFchecolonoskiNo ratings yet

- United States Patent Office.: Patented Feb. 22, 1916Document3 pagesUnited States Patent Office.: Patented Feb. 22, 1916JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Us1404687 PDFDocument2 pagesUs1404687 PDFchecolonoskiNo ratings yet

- Room Temperature Na-S Batteries With Sulfur Composite Cathode MaterialsDocument4 pagesRoom Temperature Na-S Batteries With Sulfur Composite Cathode MaterialsJahangir MalikNo ratings yet

- Us1399104 PDFDocument2 pagesUs1399104 PDFchecolonoskiNo ratings yet

- Georgia Tech Sponsored ResearchDocument51 pagesGeorgia Tech Sponsored ResearchChristian SmallenNo ratings yet

- Rcccivctl: Manning March RSTH, 1@3Document7 pagesRcccivctl: Manning March RSTH, 1@3Javier Andres Esteban MuñozNo ratings yet

- United States Patent (191Document11 pagesUnited States Patent (191Sushil Kumar RaoNo ratings yet

- Jan. 22, 1963 L.. Domash Etal 3,074,380: Improvement 1N Hydrodesulfurization With Filed Dec. 30, 1958Document5 pagesJan. 22, 1963 L.. Domash Etal 3,074,380: Improvement 1N Hydrodesulfurization With Filed Dec. 30, 1958deni.sttnNo ratings yet

- Appendix A Analysis by The BlowpipeDocument38 pagesAppendix A Analysis by The BlowpipeArsalan BalochNo ratings yet

- Chemical Studies of Polythionic Acid Stress - Corrosion CrackingDocument10 pagesChemical Studies of Polythionic Acid Stress - Corrosion Crackingqueno1No ratings yet

- Us 4570540Document3 pagesUs 4570540erwerNo ratings yet

- Aids Powder Metallurgy: Sintering inDocument12 pagesAids Powder Metallurgy: Sintering inSebastian Edison Muñoz GuerreroNo ratings yet

- Oct. 16, 1934. P. R. Judy Et A 1,977.277: 76e 7727 6&éezze AveDocument3 pagesOct. 16, 1934. P. R. Judy Et A 1,977.277: 76e 7727 6&éezze AveJEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- Wilder GetterDocument13 pagesWilder GetterFerhat Bozduman100% (1)

- (1994) - Shen - Development of An Aluminiumhea Water Battery For Subsea ApplicationsDocument9 pages(1994) - Shen - Development of An Aluminiumhea Water Battery For Subsea ApplicationsK A ThomasNo ratings yet

- United States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsenDocument5 pagesUnited States Patent: Primary Examiner-G. L. Kaplan Attorney, Agent, or Firm-Wa!ter G. NilsencicerojoiasNo ratings yet

- Smoke Suppressant For Copolymers of Ethylene and Cholortrifluoro EthyleneDocument2 pagesSmoke Suppressant For Copolymers of Ethylene and Cholortrifluoro EthyleneVansala GanesanNo ratings yet

- EP0070932B1Document5 pagesEP0070932B1bayuNo ratings yet

- United States Patent: Patented June 15, 1971Document3 pagesUnited States Patent: Patented June 15, 1971cantikNo ratings yet

- Catalytic Isomerization of Light Alkanes - T.loftenDocument133 pagesCatalytic Isomerization of Light Alkanes - T.loftenIrina Ammosova100% (2)

- Apl XGDocument3 pagesApl XGPravin ShindeNo ratings yet

- 135 137 PMR Jul09Document3 pages135 137 PMR Jul09syaNo ratings yet

- RebeccaDocument133 pagesRebeccabennetNo ratings yet

- Us2487906 PDFDocument2 pagesUs2487906 PDFchecolonoskiNo ratings yet

- Electrodeposition Palladium-Silver Alloys Arnrnoniacal ElectrolytesDocument8 pagesElectrodeposition Palladium-Silver Alloys Arnrnoniacal ElectrolytescicerojoiasNo ratings yet

- Final Paper Laporte BalfourDocument52 pagesFinal Paper Laporte Balfourapi-249533478No ratings yet

- Electrode Position of PT PMR v32 I4 188 197Document10 pagesElectrode Position of PT PMR v32 I4 188 197bissonaNo ratings yet

- Cat Forklift Tc30 Spare Parts ManualDocument22 pagesCat Forklift Tc30 Spare Parts Manualandrewbell190802bfe100% (26)

- Effect of Alumina - Titania Supports On The Activity of PD, PT and Bimetallic PD - PT Catalysts For Hydrorefining ApplicationsDocument5 pagesEffect of Alumina - Titania Supports On The Activity of PD, PT and Bimetallic PD - PT Catalysts For Hydrorefining ApplicationssaraseeNo ratings yet

- Arc Plasma Processing of PT and PD Catalysts SupportedDocument4 pagesArc Plasma Processing of PT and PD Catalysts SupportedFei ZhouNo ratings yet

- Jan. 3, 1933. H. Walter Et Al: Filed Feb. 19, 1931 2 Sheets-Sheet 1Document5 pagesJan. 3, 1933. H. Walter Et Al: Filed Feb. 19, 1931 2 Sheets-Sheet 1Rzn LaviNo ratings yet

- Us3437534 PDFDocument3 pagesUs3437534 PDFchecolonoskiNo ratings yet

- United States Patento: Ratented Nov. 4, 1$I58Document7 pagesUnited States Patento: Ratented Nov. 4, 1$I58Stella AguirreNo ratings yet

- Pure Titanium: Metallurgy of T Itanium and Its AlloysDocument8 pagesPure Titanium: Metallurgy of T Itanium and Its AlloysLowry GuettaNo ratings yet

- Japan Sea WaterDocument8 pagesJapan Sea WaterVikk SuriyaNo ratings yet

- Referencia 74Document5 pagesReferencia 74XDEWSZAQNo ratings yet

- Isomer CatalystDocument133 pagesIsomer CatalystSoran SabirNo ratings yet

- The Direct Electrochemical Synthesis of ( (C6H5) 3Ph) 2 (CoCl4)Document2 pagesThe Direct Electrochemical Synthesis of ( (C6H5) 3Ph) 2 (CoCl4)Pavle RadojkovićNo ratings yet

- United States Patent (19) (11) Patent Number: 4,717,459: Nakazawa Et Al. (45) Date of Patent: Jan. 5, 1988Document6 pagesUnited States Patent (19) (11) Patent Number: 4,717,459: Nakazawa Et Al. (45) Date of Patent: Jan. 5, 1988cicerojoiasNo ratings yet

- Practice Problem Set 4 Atomic Absorption SpectrosDocument14 pagesPractice Problem Set 4 Atomic Absorption SpectrosKassimNo ratings yet

- Us2589532 PDFDocument7 pagesUs2589532 PDFchecolonoskiNo ratings yet

- Of Of: by John A. Scherrer. Rosemond K. Bell. and William D. MogermanDocument4 pagesOf Of: by John A. Scherrer. Rosemond K. Bell. and William D. MogermanMahmood UllahNo ratings yet

- Electrolytic Concentration of Aqueous Solutions of Nitric Acid. I. Henry Jermain Maude CreightonDocument7 pagesElectrolytic Concentration of Aqueous Solutions of Nitric Acid. I. Henry Jermain Maude Creightoneduard morarNo ratings yet

- 07 - Chapter 1Document46 pages07 - Chapter 1jakinNo ratings yet

- A Mechanism For The Oxidation-Related in Uence On The Thermoelectric Behavior of PalladiumDocument32 pagesA Mechanism For The Oxidation-Related in Uence On The Thermoelectric Behavior of PalladiumGlobal QualityNo ratings yet

- Bu77.2/4/ É. Sucée: Fig. 5. Hig 4Document5 pagesBu77.2/4/ É. Sucée: Fig. 5. Hig 4k-groupNo ratings yet

- Lead Metallurgy (From Heavy Non Ferrous Metals N. SEVRYUKOV)Document24 pagesLead Metallurgy (From Heavy Non Ferrous Metals N. SEVRYUKOV)Tsakalakis G. KonstantinosNo ratings yet

- Photoelectrochemical Water Splitting in Separate Oxygen and Hydrogen CellsDocument7 pagesPhotoelectrochemical Water Splitting in Separate Oxygen and Hydrogen Cellskhan47pkNo ratings yet

- 1 s2.0 002207289280421Y MainDocument11 pages1 s2.0 002207289280421Y MainananthuNo ratings yet

- Awad 2007Document7 pagesAwad 2007Ben Duncan Málaga EspichánNo ratings yet

- Ethylene Oxide Kinetics and MechanismDocument10 pagesEthylene Oxide Kinetics and MechanismjohnNo ratings yet

- Method For Producing Methyl Chloride PattenDocument23 pagesMethod For Producing Methyl Chloride PattenMufita RamadhinaNo ratings yet

- Patent US2960558 - Dry Cell - Google PatentsDocument5 pagesPatent US2960558 - Dry Cell - Google PatentsAyasmitaPadhiaryNo ratings yet

- A System of Instruction in the Practical Use of the Blowpipe Being A Graduated Course Of Analysis For The Use Of Students And All Those Engaged In The Examination Of Metallic CombinationsFrom EverandA System of Instruction in the Practical Use of the Blowpipe Being A Graduated Course Of Analysis For The Use Of Students And All Those Engaged In The Examination Of Metallic CombinationsNo ratings yet

- A System of Instruction in the Practical Use of the BlowpipeFrom EverandA System of Instruction in the Practical Use of the BlowpipeNo ratings yet

- Benzocaine (2 Steps)Document11 pagesBenzocaine (2 Steps)checolonoski0% (1)

- Anti-Corrosion Methods and Materials: Article InformationDocument6 pagesAnti-Corrosion Methods and Materials: Article InformationchecolonoskiNo ratings yet

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsDocument9 pagesPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiNo ratings yet

- Us2589532 PDFDocument7 pagesUs2589532 PDFchecolonoskiNo ratings yet

- Us4278480 PDFDocument3 pagesUs4278480 PDFchecolonoskiNo ratings yet

- جورنال عراقى (جامعة تكريت) PDFDocument10 pagesجورنال عراقى (جامعة تكريت) PDFchecolonoskiNo ratings yet

- Us2344840 PDFDocument3 pagesUs2344840 PDFchecolonoskiNo ratings yet

- Us2942965 PDFDocument2 pagesUs2942965 PDFchecolonoskiNo ratings yet

- Us857580 PDFDocument2 pagesUs857580 PDFchecolonoskiNo ratings yet

- Us2741543 PDFDocument6 pagesUs2741543 PDFchecolonoskiNo ratings yet

- Ravi2011 PDFDocument11 pagesRavi2011 PDFchecolonoskiNo ratings yet

- Urey1931 PDFDocument9 pagesUrey1931 PDFchecolonoskiNo ratings yet

- Nitrate Solid Solution. I: Distributed byDocument37 pagesNitrate Solid Solution. I: Distributed bychecolonoskiNo ratings yet

- Forensic 103Document6 pagesForensic 103Francheska Kate LabiosNo ratings yet

- Firecracker: For Other Uses, SeeDocument4 pagesFirecracker: For Other Uses, SeeJrPelayoNo ratings yet

- Protocol For Explosive Related Incidents Investigation: Seminar: A.B.K.D CECU ButuanDocument18 pagesProtocol For Explosive Related Incidents Investigation: Seminar: A.B.K.D CECU ButuanBowie DanoNo ratings yet

- Nonel ManualDocument56 pagesNonel Manuallaxman_mbmNo ratings yet

- EOD Stanags Overview April 2021Document12 pagesEOD Stanags Overview April 2021den mas paratate leo egoNo ratings yet

- Advanced Anarchist Arsenal - Recipes For Improvised Incendiaries and Explosives PDFDocument50 pagesAdvanced Anarchist Arsenal - Recipes For Improvised Incendiaries and Explosives PDFJames100% (1)

- FireworksDocument30 pagesFireworksAdalberto MacdonaldNo ratings yet

- Industrial Catalogue 11 - 7 - 13 PDFDocument68 pagesIndustrial Catalogue 11 - 7 - 13 PDFCrisanto JeresanoNo ratings yet

- CIL Explosive TestingDocument43 pagesCIL Explosive TestingLalitkumar SableNo ratings yet

- Dyno Nobel Shock Tube PDFDocument27 pagesDyno Nobel Shock Tube PDFTeofilus Lanyo MathenaNo ratings yet

- Ieds Catalog 09-21-2017 Low CompressDocument40 pagesIeds Catalog 09-21-2017 Low Compresswhorne24No ratings yet

- 5.10 CDC List of Cargoes 4-05Document19 pages5.10 CDC List of Cargoes 4-05Goran JakelicNo ratings yet

- 01 BombsDocument46 pages01 BombsZenon Kłosiński100% (1)

- LM2000AVMDocument18 pagesLM2000AVMweter44No ratings yet

- Cyberpunk 2020 - Datafortress 2020 - Ultimate Heavy WeaponsDocument26 pagesCyberpunk 2020 - Datafortress 2020 - Ultimate Heavy WeaponsSokoliak 010010110No ratings yet

- Flash Powder - Wikipedia, The Free EncyclopediaDocument5 pagesFlash Powder - Wikipedia, The Free EncyclopediaRicardo Fontanari de CarvalhoNo ratings yet

- Catalogue KRUŠIK"Document80 pagesCatalogue KRUŠIK"Nash7777100% (2)

- EOD (Explosive Ordnance Disposal) Terminology AmmunitionDocument16 pagesEOD (Explosive Ordnance Disposal) Terminology AmmunitionCosmin Iulian IonescuNo ratings yet

- CB 130Document1 pageCB 130shomi86No ratings yet

- Chemistry of Powder and ExplosivesDocument12 pagesChemistry of Powder and Explosivesvnmaina100% (2)

- Smokeless GAP-RDX Composite Rocket Propellants Containing Diaminodinitroethylene (FOX-7)Document6 pagesSmokeless GAP-RDX Composite Rocket Propellants Containing Diaminodinitroethylene (FOX-7)K3LH EMCNo ratings yet

- ExplosiveDocument404 pagesExplosiveAndres FeherNo ratings yet

- Make Flash PowderDocument10 pagesMake Flash PowderBruno Prpić100% (1)

- AFEO Bulletin 12Document28 pagesAFEO Bulletin 12cpt_suzukiNo ratings yet

- Cargo UN NumberDocument440 pagesCargo UN NumberAndrey ShevchenkoNo ratings yet

- Them Bombs - Manual (English, Android Phone) 1.0Document27 pagesThem Bombs - Manual (English, Android Phone) 1.0Ganjamaru Jc Na0% (2)

- Prtik 123Document47 pagesPrtik 123SUBHASMITA PATRANo ratings yet