Professional Documents

Culture Documents

HVAC Control Valves MOC

HVAC Control Valves MOC

Uploaded by

Praveen SagayarajOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HVAC Control Valves MOC

HVAC Control Valves MOC

Uploaded by

Praveen SagayarajCopyright:

Available Formats

CONTROLVALVESI

Materialof Gonstruction

By Arrwish Chopra

CEO - AnergyInstrwnentsPut. Ltd., Foridrtbad

callfor valvebodymade iron', but actually it is not a single material, it is a family of

anycontrolvalvespecifications

of brass,gunmetalor bronzefor sizes50mm diameter materialswhosemajor constituent is iron with varying amounts

and below,and castiron for sizes65mmdiameterand of carbon and silicon. Cast irons arenatural composite materials

whose properties are determined by their microstructures'

Cyey lron - Grey iron is an iron alloy characterizedby

its relatively high carbon content, usually 7o/oto 4o/o' When

molten iron solidifiessomeof the carbonprecipitatesasgraphite,

forming tiny, irregular flakeswithin the crystal sffucture of the

metal. The presenceof graphite flakesgive grey iron excellent

casting,machining and self-lubricating properties,but distrupt

the crystal structure providing a nucleation point for cracks,

leading to grey iron's characteristic brittleness.

Ductile lrut -lnductile iron the graphite is in the form of

sphericalnodulesrather than flakes,thuinhibitlng the creation

Gopper Alloys

Copper was the first metal used by man and it was soon of cracksand providing enhancedductility' It is alsoknown as

found that its propertiescould be improved by alloying' Brass, S.G. iron or nodular iron. It was invented around 1948.

Its high tensile strength, ductility and easeof casting

gunmetal and bronze are all alloys of copper with different

makes

it material of choice for applications where use of

percentages

of zinc, tin and lreadas alloying elements'

'

is

expensive. It has replaced many components in the

Early

steel

Brurie- Bronzewasthe fiist copper alloy usedby man.

industry.

automotive

together

that

occurs

bronze was an alloy of copper and arsenic

context, ductile iron can replace copper alloy

HVAC

In

and

was

favour

for

its

toxicity

fell

of

out

naturally. Later on, arsenic

without increasing the wall thickness and

valve

bodies

more

harder

and

makes

the

alloy

of

tin

Addition

by

tin.

replaced

component weight. It can alsobe usedto replacethe grey iron

corrosion resistant then the virgin metal, thus more useful.

Bronzewaswidely useduntil iron becamecheaperand more valve bodies with increasedstrength and pressurerating'

To summarise,all copper alloys have excellent resistance

plentiful. Bronze is harder and tougher than any other copper

to corrosion but eachhas its distinct advantages.Brassis most

alloy. In HVAC context bronze is more suitable for valves for

suitable for forged and die-casted valve bbdies, gunmetal is

high-pressurehot water and steam applications'

more suitable for sand casting and bronze is more suitable for

Brcss Brassesare copper alloys in which the principal

high pressureand temperatureapplications.

alloying element is zinc. Their properties depend primarily

Grey iron can be usedfor casting all kinds of valve bodies,

upon the proportion of zinc present. Most commonly

.

These

brasses

are

except of very imall sizeswith thin sections,whereasDuctile/

used brassescontain 30Vo 40o/oof zinc.

iron overcomesthis weaknessand can be usedto.

Nodular/S.G.

can

and

room

temperature,

characterizedby their ductility at

from lessthan 20 gramsto more than 200

produce

components

spinning,

bending,

rolling,

drawing,

by

be extensivelydeformed

as

small as 2mm to more than 500mm.

sizes

tons

of

section

forging.

and

deep-drawing

Going back to the specifications, the other most likely

The combination of ductility, machinability and strength

reasonsfor biasfavoring copper alloys could have been the easeof

makesthis material most suitable for small valve bodies,with

manufacturing,possibilityof usingthin wall sections,thusreducing

thin wall sections,which are either forged or die-casted.

component weight, and not very high price differential.

Qunmetal. It is a copper alloy containing both zinc and

But in today's scenario when, copper alloys have become

tin asalloying elements. It wasdevelopedby British admiralty

for ordnancepartsby adding zinc to bronze,to improve casting much more expensive,improved foundry practiceshave made

it possible and easierto cast small components of grey iron,

characteristics.

particularly

as

and development of ductile iron has made it possibleto cast

good

casting characteristics,

Gunmetal has

with thin sections,it is time to rewrite these

components

valve

bodies

casted

for

sand

It

is

most

suited

a sand casting.

and remove the unnecessarybias towardscopper

specifications

resistance

and

corrosion

pressure

tightness

high

strength,

where

alloys.

are important.

Small valves of forgedbrassare likely to remain popular for

lrcn Alloys

'grey

'cast

{'

the easeof manufacturing, thus low overall cost.

iron' generally refers to

Cast lron - The terms

above. These specificationsseemto have been in usefor over

half-a-century and show a bias towardscopper alloys over cast

iron for small sizedvalves.

The reasonsfor this bias could be many, the easiestbeing

the better corrosion resistanceof copper alloys,but that seems

unlikely in HVAC systemswhere most of the piping itself is of

mild-steel,prone to corrosion.

The intent of this article is to go through the characteristics

and physical propertiesof someof the copper and iron alloys to

find out other reasonsfor this bias and its relevance today.

* January'March2009

134 AirConditioningandRefrigerationJournal

You might also like

- 04 ws2 Baleq2-KeyDocument2 pages04 ws2 Baleq2-KeyFerni Nishizaki70% (10)

- Testing and Commissioning Procedure For Air-Conditioning, Refrigeration, VentilationDocument247 pagesTesting and Commissioning Procedure For Air-Conditioning, Refrigeration, VentilationPraveen KasrottaranNo ratings yet

- Advantages of Oil-Free Screw CompressorsDocument4 pagesAdvantages of Oil-Free Screw CompressorsMANIU RADU-GEORGIANNo ratings yet

- Cable Glands REV and REVD SeriesDocument20 pagesCable Glands REV and REVD SeriesTh Nattapong100% (1)

- Cast Iron - WikipediaDocument11 pagesCast Iron - WikipediaBhumikNo ratings yet

- Composition and Grades of Cast IronDocument5 pagesComposition and Grades of Cast IronahmedNo ratings yet

- Grey Cast IronDocument43 pagesGrey Cast IronVasanth PrasadNo ratings yet

- Engineering Materials NotesDocument25 pagesEngineering Materials NotesRoobanesh ManoharanNo ratings yet

- 150 Sample-Chapter PDFDocument25 pages150 Sample-Chapter PDFMochammad Waris SNo ratings yet

- Ferrous Alloys & Non - Ferrous AlloysDocument11 pagesFerrous Alloys & Non - Ferrous AlloysMuath A, RadhwanNo ratings yet

- Engineering Materials: (Hi) Wrought IronsDocument1 pageEngineering Materials: (Hi) Wrought Ironsyashvirsingh21No ratings yet

- Cast Iron: Cast Iron Is A Group of Iron-Carbon Alloys With A Carbon Content Greater ThanDocument8 pagesCast Iron: Cast Iron Is A Group of Iron-Carbon Alloys With A Carbon Content Greater ThanspibluNo ratings yet

- Cast Iron PropertiesDocument8 pagesCast Iron PropertiesGerardo JM Palacios100% (1)

- Cast Iron: Gray Iron Ferrous Alloys Eutectic CarbideDocument12 pagesCast Iron: Gray Iron Ferrous Alloys Eutectic CarbideMANOJ MNo ratings yet

- Bcme Textbook Important QuestionsDocument13 pagesBcme Textbook Important QuestionsMahindra ChelliNo ratings yet

- Bgtech 1 Research Paper Ferrous and Non Ferrous Metals: Far Eastern University Institute of Architecture and Fine ArtsDocument23 pagesBgtech 1 Research Paper Ferrous and Non Ferrous Metals: Far Eastern University Institute of Architecture and Fine ArtsRousseau Pierre LouisNo ratings yet

- BMC MergedDocument93 pagesBMC Mergedkevin tomNo ratings yet

- MicroprojectDocument13 pagesMicroprojectomkar digamabar sonone0% (1)

- Cast Iron: A Widely Used MaterialDocument19 pagesCast Iron: A Widely Used MaterialHarshaDesuNo ratings yet

- MetalsDocument39 pagesMetalsVipin Kumar SharmaNo ratings yet

- Cast IronDocument9 pagesCast Ironedward biwottNo ratings yet

- Material Technology IInd SemDocument262 pagesMaterial Technology IInd SemvinayakNo ratings yet

- Grey Iron A Unique MaterialDocument13 pagesGrey Iron A Unique MaterialmetkarthikNo ratings yet

- Iron CastingDocument23 pagesIron CastingDiego MoralesNo ratings yet

- Course Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineDocument63 pagesCourse Prepared by M.Jayaprasad Materials, Manufacturing and Testing of EngineGopi GopinathNo ratings yet

- Cast Iron - WikipediaDocument48 pagesCast Iron - WikipediaLAliNo ratings yet

- Cast Iron - WikipediaDocument17 pagesCast Iron - Wikipedia257 Satyam YadavNo ratings yet

- Types of Cast IronDocument7 pagesTypes of Cast IronEddy VëraNo ratings yet

- Corrosion Behaviour of CIDocument1 pageCorrosion Behaviour of CIBaher ElsheikhNo ratings yet

- Structure and PropertiedDocument43 pagesStructure and PropertiedJalaj GaurNo ratings yet

- BrassesDocument7 pagesBrassesClaudia MmsNo ratings yet

- Types of Cast IronDocument5 pagesTypes of Cast Ironmanas310jntuhNo ratings yet

- ReportDocument3 pagesReportShamRock CasasNo ratings yet

- Iron (Pig Iron, Cast Iron, Wrought Iron)Document18 pagesIron (Pig Iron, Cast Iron, Wrought Iron)Bhanu Pratap SinghNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Ferrous MaterialsDocument151 pagesFerrous MaterialsAli RayyaNo ratings yet

- SOLUTIONS: Cast IronDocument26 pagesSOLUTIONS: Cast IronHanif SamsiNo ratings yet

- Chapter ThreeDocument38 pagesChapter ThreeAbi DemNo ratings yet

- Cast IronDocument12 pagesCast IronMANOJ MNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- Iron and It's TypesDocument12 pagesIron and It's TypesSakshi SharmaNo ratings yet

- Conmatest 7Document46 pagesConmatest 7Ian BondocNo ratings yet

- The Smith's Pocket Companion, Containing Useful Information and Tables On Iron and Steel, For The Use of Smiths and Steel WorkersDocument156 pagesThe Smith's Pocket Companion, Containing Useful Information and Tables On Iron and Steel, For The Use of Smiths and Steel WorkersArtisan Ideas100% (1)

- Processing Techniques and Productions of Ductile Iron A ReviewDocument27 pagesProcessing Techniques and Productions of Ductile Iron A ReviewChaitanyaNo ratings yet

- Zinc Alloy BearingsDocument6 pagesZinc Alloy BearingsJeff DunningNo ratings yet

- Heat Treatment of Cast IronDocument37 pagesHeat Treatment of Cast IronMothana RawashdehNo ratings yet

- Part 2-Materials and Heat Treatment-1Document42 pagesPart 2-Materials and Heat Treatment-1ALFRED BONAHNo ratings yet

- Welding of Cast IronDocument12 pagesWelding of Cast IronwalitedisonNo ratings yet

- Copper and Its Alloys PresentationDocument50 pagesCopper and Its Alloys PresentationIranthaShalindaJayawardanaNo ratings yet

- CH 01Document60 pagesCH 01tazebNo ratings yet

- Non Ferrous Metals and Alloys CH5 DDUDocument97 pagesNon Ferrous Metals and Alloys CH5 DDUPratik ThakerNo ratings yet

- Basic Maintenance Aspects PDFDocument194 pagesBasic Maintenance Aspects PDFHumaid ShaikhNo ratings yet

- Esc 36 Quiz 3 Notes CompilationDocument98 pagesEsc 36 Quiz 3 Notes CompilationkbgainsanNo ratings yet

- IRON - Module - 02Document27 pagesIRON - Module - 02Asna AbbasNo ratings yet

- DZR BrassDocument3 pagesDZR BrassAlfredo Cumbi CumbiNo ratings yet

- Ferrous and Non-Ferrous MetalDocument36 pagesFerrous and Non-Ferrous MetalakinyemioaNo ratings yet

- Mechanical MaterialDocument19 pagesMechanical MaterialcacaNo ratings yet

- Materials For Automobiles15Document25 pagesMaterials For Automobiles15Er. DevendraNo ratings yet

- Modern Steel - Lecture 1Document54 pagesModern Steel - Lecture 1Jojo Hany100% (1)

- GCE3135 AssignmentDocument10 pagesGCE3135 AssignmentBilal MishoryNo ratings yet

- Processing Techniques and Productions ofDocument27 pagesProcessing Techniques and Productions ofArindam DasNo ratings yet

- Metallographic Properties: 1. Mild SteelsDocument4 pagesMetallographic Properties: 1. Mild SteelsmuralidharanNo ratings yet

- Cast IronDocument12 pagesCast IronCarlos EsparzaNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Specialty Acrylics Various TDS FormulationsDocument2 pagesSpecialty Acrylics Various TDS Formulationsfranchise.adajanNo ratings yet

- Metal 2019 Proceedings of The Interim Meeting of The Icom CC Metals Working Group September 2 6 2019 Neuchâtel Switzerland Ebook PDFDocument493 pagesMetal 2019 Proceedings of The Interim Meeting of The Icom CC Metals Working Group September 2 6 2019 Neuchâtel Switzerland Ebook PDFsanthicocoNo ratings yet

- Use of Waste Plastic Use of Waste PlastiDocument8 pagesUse of Waste Plastic Use of Waste PlastiRayhan MazumderNo ratings yet

- Single Aisle Technical Training Manual Maintenance Course - T1 (V2500-A5/Me) OxygenDocument60 pagesSingle Aisle Technical Training Manual Maintenance Course - T1 (V2500-A5/Me) OxygenEvanildoLealNo ratings yet

- SHS-Physical Science (Active Ingredients of Cleaning Products)Document10 pagesSHS-Physical Science (Active Ingredients of Cleaning Products)KNBA VNHSNo ratings yet

- Catalogo Polea Dentada Polea Sincronica PDFDocument35 pagesCatalogo Polea Dentada Polea Sincronica PDFJuan Alberto JuannNo ratings yet

- 3 (B) Photochemistry EnglishDocument10 pages3 (B) Photochemistry EnglishRobert SmithNo ratings yet

- Protein Digestibility Corrected Amino Acid ScoreDocument4 pagesProtein Digestibility Corrected Amino Acid Scorekto1mntn2No ratings yet

- General Multi - Choice 1Document6 pagesGeneral Multi - Choice 1AnandNo ratings yet

- Product CertificateDocument1 pageProduct CertificateGonzalo TelleríaNo ratings yet

- SRJC Promo 2009 Paper 1Document16 pagesSRJC Promo 2009 Paper 1gretchen92No ratings yet

- CHE 321 Lecture NotesDocument90 pagesCHE 321 Lecture NotesCharles BaileyNo ratings yet

- Humanities-Impact of Industrialization On Soil Resources, A Study On Kanjikode Industrial Region, Palakkad-Richard ScariaDocument8 pagesHumanities-Impact of Industrialization On Soil Resources, A Study On Kanjikode Industrial Region, Palakkad-Richard ScariaBESTJournalsNo ratings yet

- Preparation of 4-Methylcyclohexene: BackgroundDocument4 pagesPreparation of 4-Methylcyclohexene: BackgroundVanila AisNo ratings yet

- New J. Chem., 2012, 36, 2292-2301Document10 pagesNew J. Chem., 2012, 36, 2292-2301yokeshNo ratings yet

- 1.SolidState KCET PYQsDocument1 page1.SolidState KCET PYQsgangi reddy100% (1)

- Anti Seize Compound - TDSDocument2 pagesAnti Seize Compound - TDSfahreezNo ratings yet

- Chemistry Textbook 10 - 12 PDFDocument86 pagesChemistry Textbook 10 - 12 PDFMusanta Simmon SimzNo ratings yet

- PUMP2Document7 pagesPUMP2Cesario GillasNo ratings yet

- Nuclear Fuel ReprocessingDocument33 pagesNuclear Fuel ReprocessingMuhamed FahadNo ratings yet

- Csio-Aist Brochure (25 Aug 09)Document69 pagesCsio-Aist Brochure (25 Aug 09)Prashant BansalNo ratings yet

- 93 PDFDocument20 pages93 PDFMariusDragoescuNo ratings yet

- Omega 99Document3 pagesOmega 99Badeng LawotNo ratings yet

- Multiphase Separation Processes: AdsorptionDocument45 pagesMultiphase Separation Processes: AdsorptionRahul SahuNo ratings yet

- WINSEM2023-24 BCSE354E ETH VL2023240503344 2024-03-19 Reference-Material-IIDocument38 pagesWINSEM2023-24 BCSE354E ETH VL2023240503344 2024-03-19 Reference-Material-IIDiya RamaniNo ratings yet

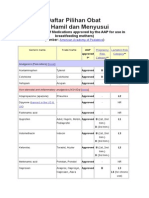

- Daftar Pilihan Obat Ibu Hamil Dan MenyusuiDocument12 pagesDaftar Pilihan Obat Ibu Hamil Dan MenyusuiHarryDodorotoNo ratings yet