Professional Documents

Culture Documents

QHSE Bulletin 51

QHSE Bulletin 51

Uploaded by

wrangularCopyright:

Available Formats

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Mil-Std-1235b 1981Document62 pagesMil-Std-1235b 1981karismaNo ratings yet

- StarDiesel Common Rail PDFDocument32 pagesStarDiesel Common Rail PDFaddelyn_robescu879488% (8)

- Wilhelm Fold 040115Document8 pagesWilhelm Fold 040115Michael Tayactac100% (1)

- Tweco Velocity: Medium and Heavy Duty MIG Welding ConsumablesDocument12 pagesTweco Velocity: Medium and Heavy Duty MIG Welding ConsumablesJoão GuilhermeNo ratings yet

- Cables and Wires CatalogueDocument16 pagesCables and Wires CatalogueVENITHA KNo ratings yet

- Elsewedy EgyptDocument7 pagesElsewedy EgyptshenshNo ratings yet

- IJSRMME18348Document7 pagesIJSRMME18348Kiran KumarNo ratings yet

- Anemo Projects Pvt. LTDDocument27 pagesAnemo Projects Pvt. LTDTILAK RAJ KambojNo ratings yet

- SB Drill Collar PDFDocument51 pagesSB Drill Collar PDFSiva GanaNo ratings yet

- 2015 Effect-of-activating-fluxes-on-weld-bead-morphology-of-P9 - Journal-of-MaDocument10 pages2015 Effect-of-activating-fluxes-on-weld-bead-morphology-of-P9 - Journal-of-MabhaskarNo ratings yet

- Welding Technology GTAW GMAW FCAW PAW Nov 2020Document87 pagesWelding Technology GTAW GMAW FCAW PAW Nov 2020ENZO PEREZNo ratings yet

- PTA Hardfacing: Arcraft Plasma IndiaDocument16 pagesPTA Hardfacing: Arcraft Plasma IndiaJimmy RodriguesNo ratings yet

- Export Product Hand BookDocument94 pagesExport Product Hand Bookamit singhNo ratings yet

- Tig English ProjectDocument11 pagesTig English Projectmourid trabelsiNo ratings yet

- 2.welding ProcessesDocument81 pages2.welding ProcessesP. M. ISAI VISAAHANNo ratings yet

- rAJURI sTEEL COMPANY PROFILEDocument59 pagesrAJURI sTEEL COMPANY PROFILEpankajkapse100% (1)

- Niras - PresentasjonDocument23 pagesNiras - PresentasjonDeny Tirta KusumaNo ratings yet

- Tig Welding ThesisDocument5 pagesTig Welding ThesisBrooke Heidt100% (3)

- Induction BendingDocument23 pagesInduction BendingstevenNo ratings yet

- Welding and Soldering - 25.11.21 - GrundgerüstDocument27 pagesWelding and Soldering - 25.11.21 - GrundgerüstAlexander HoffmannNo ratings yet

- Thesis On Welding and FabricationDocument4 pagesThesis On Welding and Fabricationmkdswzgig100% (2)

- L31a GtawDocument23 pagesL31a GtawCrocodileNo ratings yet

- Toroidal Transformers For Universal Application: NuvotemDocument16 pagesToroidal Transformers For Universal Application: NuvotemFidel Segundo Fernandez HuertaNo ratings yet

- TIG-welding Gases PDFDocument2 pagesTIG-welding Gases PDFwenigmaNo ratings yet

- STT & Alloy 625 PDFDocument4 pagesSTT & Alloy 625 PDFharan2000No ratings yet

- MK0042 Hydrostatic Testing (EPC) Application SheetDocument2 pagesMK0042 Hydrostatic Testing (EPC) Application SheetMoezNo ratings yet

- Welding Toolbox Talk FINALDocument18 pagesWelding Toolbox Talk FINALJohan CárdenasNo ratings yet

- A5-8 Tig WeldingDocument104 pagesA5-8 Tig Weldinghema_avraoNo ratings yet

- MCL-135-Welding and Allied Processes - Class 11-15Document58 pagesMCL-135-Welding and Allied Processes - Class 11-15mHmNo ratings yet

- PTA Welding and HardfacingDocument16 pagesPTA Welding and Hardfacingpavi32No ratings yet

- Laser Cladding Vs Other TechnologiesDocument17 pagesLaser Cladding Vs Other Technologiesvenkat200a100% (2)

- M09 - Gtaw & PawDocument34 pagesM09 - Gtaw & Pawசுரேஷ் பாலமுருகன்No ratings yet

- Tungsten Inert Gas WeldingDocument47 pagesTungsten Inert Gas Weldingravi00098No ratings yet

- Applying Tig Techniques Hand-OutDocument12 pagesApplying Tig Techniques Hand-Outjuvy may esbanNo ratings yet

- GMAWDocument9 pagesGMAWMathias NsimbeNo ratings yet

- EEW Clad Steel PipesDocument4 pagesEEW Clad Steel PipesstevenNo ratings yet

- Espey WD200: Carbon Floating Ring Seals - Shaft SealsDocument5 pagesEspey WD200: Carbon Floating Ring Seals - Shaft SealsJose Vega VelascoNo ratings yet

- Seminar Report TIGDocument13 pagesSeminar Report TIGRahul ShawNo ratings yet

- Thesis Tig WeldingDocument8 pagesThesis Tig Weldingafknlmzok100% (2)

- Turbine Services, Ltd. Group: Delivering Quality Anywhere in The WorldDocument11 pagesTurbine Services, Ltd. Group: Delivering Quality Anywhere in The WorldHANIF AKBARNo ratings yet

- Turbine Blade and Nozzle Ring RepairsDocument2 pagesTurbine Blade and Nozzle Ring Repairsamir moniriNo ratings yet

- TS200 Manual SML 1 PDFDocument32 pagesTS200 Manual SML 1 PDFTimNo ratings yet

- Cast Resin Dry Transformers BrochureDocument12 pagesCast Resin Dry Transformers Brochuremohamedelshrpeni0No ratings yet

- VentureClad 1577CWDocument2 pagesVentureClad 1577CWUmen AryanNo ratings yet

- Gouging Processes: Arc-Air Gouging Plasma GougingDocument4 pagesGouging Processes: Arc-Air Gouging Plasma GougingMika VelinovNo ratings yet

- Gouging PDFDocument4 pagesGouging PDFEkhaSoemarnoNo ratings yet

- Amta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesDocument115 pagesAmta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesAbu RectifyNo ratings yet

- THE Tri-Con SeriesDocument6 pagesTHE Tri-Con Seriespablopasqualini18No ratings yet

- Mec 602 Bearing DesignDocument148 pagesMec 602 Bearing DesignJonnalgadda Sameer KumarNo ratings yet

- Welding ProcessDocument42 pagesWelding ProcessPankaj KumbhareNo ratings yet

- UNIT 2 MP NewDocument71 pagesUNIT 2 MP Newvrinda.bhardwaj.52No ratings yet

- EagleBurgmann EMG Flyer en 22-12Document4 pagesEagleBurgmann EMG Flyer en 22-12Hakan TekelNo ratings yet

- Hard FacingDocument4 pagesHard FacingKassya SchunkNo ratings yet

- A New Perception of Activated Flux Tungsten Inert Gas (A-TIG) Welding Techniques For Various MaterialsDocument14 pagesA New Perception of Activated Flux Tungsten Inert Gas (A-TIG) Welding Techniques For Various MaterialsTibor KeményNo ratings yet

- Gantrail Crane Rail WeldingDocument2 pagesGantrail Crane Rail WeldingJorge Cruz RodriguezNo ratings yet

- Welding Productivity 5Document1 pageWelding Productivity 5atulNo ratings yet

- StainTrode DDocument2 pagesStainTrode DGyanaranjan2011No ratings yet

- EDS 105 Introduction To Welding Rev 1Document29 pagesEDS 105 Introduction To Welding Rev 1kevin.machado6317No ratings yet

- CMP Products Cable Gland Accessory CatalogueDocument1 pageCMP Products Cable Gland Accessory CatalogueElliza IshakNo ratings yet

- Advanced Gas Tungsten Arc Weld Surfacing Current Status and ApplicationDocument16 pagesAdvanced Gas Tungsten Arc Weld Surfacing Current Status and ApplicationGabriel FajardoNo ratings yet

- CC607 T4 Water Distribution System New 2Document40 pagesCC607 T4 Water Distribution System New 2Nursyahira Abd Ghani100% (2)

- 03 Junit4Document16 pages03 Junit4Anil KumarNo ratings yet

- Article - Explaining Peak Pressure Prediction Using Vds or FssaDocument2 pagesArticle - Explaining Peak Pressure Prediction Using Vds or FssaFreddy BelizarioNo ratings yet

- Metodologia de La InvestigacionDocument40 pagesMetodologia de La InvestigacionparpejoNo ratings yet

- Unit - I-3Document9 pagesUnit - I-3Saheer ShaikNo ratings yet

- Rent Payment Schedule - FDocument3 pagesRent Payment Schedule - FTom CatNo ratings yet

- Exide A7Document12 pagesExide A7Sebastian NarvaezNo ratings yet

- STM PresentationDocument22 pagesSTM PresentationPritish MoharirNo ratings yet

- BMC Group Raw MaterialDocument14 pagesBMC Group Raw MaterialSyedur RahmanNo ratings yet

- Company Presentation NewDocument13 pagesCompany Presentation NewNaveen PradeepanNo ratings yet

- Modul InoerpDocument5 pagesModul InoerpFatoni SiSahabat NoahNo ratings yet

- Accomplishment Report (January-April2021) Lovilyn EncarnacionDocument4 pagesAccomplishment Report (January-April2021) Lovilyn EncarnacionLovilyn EncarnacionNo ratings yet

- ResumeDocument3 pagesResumeanon-936858No ratings yet

- Hazard and Operability Study (HAZOP) Safety Assessment On: University of Nottingham Malaysia Campus H82PLD Coursework 2Document127 pagesHazard and Operability Study (HAZOP) Safety Assessment On: University of Nottingham Malaysia Campus H82PLD Coursework 2KongWeiHern100% (2)

- Teleportation Ece Seminar ReportDocument24 pagesTeleportation Ece Seminar ReportSudheesh Vs100% (1)

- Appendix D.4 Intake Design ConsiderationsDocument4 pagesAppendix D.4 Intake Design Considerationsnikom kraitadNo ratings yet

- Bhushan Power & Steel Ltd.Document17 pagesBhushan Power & Steel Ltd.navdeeplakheraNo ratings yet

- Anansi The SpiderDocument2 pagesAnansi The SpideramypeabodyNo ratings yet

- HST Pines Komatsu Wa320Document1 pageHST Pines Komatsu Wa320Victor Rodrigo Cortes YañezNo ratings yet

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- .Planning Designing and Estimation of A Ba PDFDocument7 pages.Planning Designing and Estimation of A Ba PDFRusscelNo ratings yet

- Ek101 & Ea301 Engineers in Society (Eis) Group Assignment: Name Student IDDocument12 pagesEk101 & Ea301 Engineers in Society (Eis) Group Assignment: Name Student IDLeeMayYanNo ratings yet

- Tesis OffshoreDocument265 pagesTesis OffshoreRosalita Cordaro100% (1)

- Architectural Design: Francis Cauffman Foley HoffmannDocument4 pagesArchitectural Design: Francis Cauffman Foley HoffmannLTE002No ratings yet

- Material Selection Guide - MILD STEELDocument1 pageMaterial Selection Guide - MILD STEELlouis donyNo ratings yet

- Gianduzzo Robert 1059876 Task2 Edu400Document6 pagesGianduzzo Robert 1059876 Task2 Edu400api-297391450No ratings yet

- GT02 Protocol en NeutralDocument16 pagesGT02 Protocol en NeutralLorocopeyNo ratings yet

- Mind Map Tutor HandbookDocument24 pagesMind Map Tutor HandbookWalter100% (1)

QHSE Bulletin 51

QHSE Bulletin 51

Uploaded by

wrangularOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QHSE Bulletin 51

QHSE Bulletin 51

Uploaded by

wrangularCopyright:

Available Formats

QHSE Bulletin

DESCON ENGINEERING LIMITED

Issue No. 51 \\\\ Jan, Feb 2009

TIP of

THE MONTH

NewsCORNER

QHSE

Protect Yourself from

Pollution

Safe Sub-Contractor of the Month: If you can't live in a smog-free

Technip once again awarded Descon as a Safe Sub- environment, at least avoid

Contractor for the month (January, 2009) at Olefin Project smoke-filled rooms, high traffic

Qatar. Our HSE team has received this award areas, breathing in highway

5th time at Olefin Project. We fumes and exercising near

congratulate our project team on busy thoroughfares.

achieving this award. Exercise outside when

the smog rating is low.

One hundred thousand Man- Exercise indoors in air

Hours with out LTI at TRL conditioning when air

Project (P#1129): quality is good. Plant

lots of shrubbery in

Our Project HSE team has

your yard.

achieved LTI free One hundred

Thought for the day:

thousand Man-hours at TRL Project

'Smoke gets in your

(P#1129). We congratulate our Project

eyes'…and your mouth, and

Team on reaching this milestone

your nose and your lungs as do

successfully. Achievement of this milestone is

pollutants….hum the tune daily.

the result of joint effort of HSE & Execution Team. We

wish them good luck and hope that they will complete this

project without LTI.

Eight Million Man-hours without LTI at Pearl GTL FAITH AND BELIEF

Project:

On 11th February, 2009 our Project HSE team at Pearl GTL “Only the person who has

has completed Eight Million Man-hours without any OHSA faith in himself is able to be

Recordable Injury. We congratulate our project team on faithful to others.”

achieving this milestone and hope that same stride will be

followed by the end of project. Erich Fromm

QHSE Monthly Bulletin 01

Issue No. 51 \\\\ Jan, Feb 2009

Gas Tungsten Arc

QUALITY Welding (GTAW)

GAS TUNGSTEN ARC WELDING IS ONE OF

THE WELDING PROCESS TYPE AND IT’S

ALSO CALLED TIG WELDING PROCESS

The arc is initiated Welding is the joining of multiple pieces of metal by the use of

between the tip of the heat and or pressure. A union of the parts is created by fusion or

electrode and work to melt

the metal being welded, as re-crystallization across the metal interface. Welding can involve

well as the filler metal, the use of filler material, or it can involve no filler.

when used. A gas shield

protects the electrode and There are many types of welding processes out of that one is Gas

the molten weld pool, and Tungsten Arc Welding also called TIG Welding process.

provides the arc

characteristics.

GTAW uses a non-consumable tungsten electrode which must be

shielded with an inert gas. The arc is initiated between the tip of

the electrode and work to melt the metal being welded, as well as

the filler metal, when used. A gas shield protects the electrode and

the molten weld pool, and provides the arc characteristics.

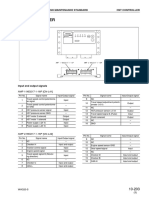

GTAW tools and equipments:

• Welding Torch

• Tungsten Electrode

• Inert Gas

• Pressure regulators and flow meters

• Welding face shield

• Protective clothing

• Gas Nozzle on gun

• A source of shielding gas.

• Power Source (8KW to 30 KW) Current range (200A to

500A)

• High Frequency Oscillator

• Welding wire

Advantages:

• Welds with or without filler metal

• Precise control of welding variables

• Low distortion

• Higher quality root pass.

• Accommodate wide range of thickness, positions and

geometries.

• Portable Equipment

• Combination with GMAW or SMAW (Shielded Metal Arc

Welding) produces good results

for pipe welding.

Limitations:

• More training time required as GMAW & SMAW.

• More expensive than SMAW

• Requires greater welder dexterity than MIG or stick welding

• Lower deposition rate

• More costly for welding thick sections

TIG/GTAW butt weld in 3/8-in.

thick 4140 aluminum alloy using Applications:

Alumaxx Plus gas.

Most commonly used for Aluminum, Steel and Stainless steel.

Except for thin sections or where very high quality is needed.

Common Defects:

• Porosity

• Incomplete Fusions

• Inadequate joint penetration.

• Cracks

QHSE Monthly Bulletin 02

Issue No. 51 \\\\ Jan, Feb 2009

What Does Safety

SAFETY Success Look Like?

IT IS VERY IMPORTANT TO KNOW THAT

ON WHICH POINTS TO BE

FOCUSED TO ACHIEVE

SUCCESSFUL SAFETY SYSTEM

Safety is a condition of Following areas to be focused to achieve successful safety system:

operations that has certain

qualities. When you

1. Proactive

achieve the qualities, the Truly successful safety efforts have begun to max out traditional

numbers follow. If you reactive safety and go well beyond these minimal efforts to “get

think of safety as a vacuum

ahead of the curve” in safety efforts. Success in reactive safety

in which accidents have all

been sucked out, you fall in generates the necessity for proactive safety. When you use

to the trap of avoiding accident investigation data to improve safety, the more you

failure and your efforts succeed, the less data you have. Before the accident data

become negative and disappears it does another nasty trick: it loses its statistical

ineffective. It is very

significance that last bit of accident data tells you that you are not

important to know that on

which points to be focus to perfect; but it doesn’t tell you how to get better.

achieve successful safety 2. Focused

system.

Truly successful safety efforts generate a focus on the most

important dangers and the precautions that can best avoid them.

The narrow focus needs to be communicated relentlessly until

workers actually memorize the list.

Many sites create acronyms or other mnemonics to aid the

learning and retention of the focus list then they reinforce the list

until it becomes second nature or even habitual. Once workers

automatically take the most critical precautions, the accidents

rate go down and stay down. FOCUS is an acronym for Forming

One Common Understanding of Safety.

3. Transformation

Precautions that can potentially have a significant impact on

accidents are called transformation precautions. Truly excellent

safety efforts are not striving for modest gains, but working

toward goals that can truly transform the accident rates with a

minimal effort.

All truly successful safety

4. Involves Workers

Management efforts to improve efforts have all or most of

safety can be highly effective, but the following qualities in

almost inevitably are limited if common. The more of these

worker involvement is not qualities, the more

increased. Deming said that you

successful the effort.

should always involve the people

who know the most when solving

organizational problems. Truly excellent safety efforts attack risks

on two fronts: the management front and the cultural (or worker-

involved) front. Managers should dictate compliance with laws

and company policies as a condition of employment and enforce

them accordingly. Workers should identify precautions that go

beyond compliance and tap into worker discretional efforts to

further move safety efforts toward excellence.

5. Clearly Communicated

Effective communication is a trademark of safety success. Both

the quantity and quality of safety communication are critical to

safety success. When managers and supervisors talk about

productivity much more often than safety, this tends to create the

perception that productivity is important and safety is a lesser

goal. Because of changing priorities and changing perceptions,

many have suggested that safety should be a value and not a

priority. If this goal is to be accomplished, it will require a steady

flow of communication that does not waiver or bend and

management decisions that demonstrate the commitment.

Everyone in the organization should self-monitor their level of

safety communication in both word and deed to determine if

safety is truly clearly communicated.

6. Results Oriented

Processes that do not produce downstream results are not

working and should be revised or scrapped. The true value of

process metrics is to determine if the process is being worked and

if the process is working. Profound knowledge of safety is neither

process or result metrics; it includes knowledge of the process

and result metrics as well as having an understanding of the

relationship between the two. Many safety programs and

processes create a process mentality.

7. Multi-dimensional

The safety world is full of subject-matter experts trying to disguise

science as technology. We constantly are being exposed to new or

revised processes that are largely one-dimensional, one-science

approaches to one symptom of safety failure.

8. Integrated

Truly successful safety efforts are not something else you do; they

are the way you do everything. The more “apart” safety efforts are

from day-to-day functions, the less successful they are. If your

organization practices Six Sigma, your safety processes should

parallel or even piggy-back on these methods and efforts. Safety is

a quality issue and a staffing issue. When we integrate safety into

everything else, we can truly make it a value and not just a

changeable value.

9. Practical

Safety success can be advanced by theories, but it ultimately is not

a theory. Safety success is impossible if it does not fit the cultural,

procedural and conditional realities of the workplace.

Send your comments and suggestions to 10. Humanistic

qhse@descon.com.pk

quality@descon.com.pk

Ultimately, the reason for working on safety is as important as

how you work on it. If your goals are all financial and bench

We welcome all useful information

regarding Quality, Health, Safety, & marking in their orientation, you will not win the hearts of the

Environment for inclusion in the people who can make you successful.

forthcoming Issues.

QHSE Monthly Bulletin 03

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Mil-Std-1235b 1981Document62 pagesMil-Std-1235b 1981karismaNo ratings yet

- StarDiesel Common Rail PDFDocument32 pagesStarDiesel Common Rail PDFaddelyn_robescu879488% (8)

- Wilhelm Fold 040115Document8 pagesWilhelm Fold 040115Michael Tayactac100% (1)

- Tweco Velocity: Medium and Heavy Duty MIG Welding ConsumablesDocument12 pagesTweco Velocity: Medium and Heavy Duty MIG Welding ConsumablesJoão GuilhermeNo ratings yet

- Cables and Wires CatalogueDocument16 pagesCables and Wires CatalogueVENITHA KNo ratings yet

- Elsewedy EgyptDocument7 pagesElsewedy EgyptshenshNo ratings yet

- IJSRMME18348Document7 pagesIJSRMME18348Kiran KumarNo ratings yet

- Anemo Projects Pvt. LTDDocument27 pagesAnemo Projects Pvt. LTDTILAK RAJ KambojNo ratings yet

- SB Drill Collar PDFDocument51 pagesSB Drill Collar PDFSiva GanaNo ratings yet

- 2015 Effect-of-activating-fluxes-on-weld-bead-morphology-of-P9 - Journal-of-MaDocument10 pages2015 Effect-of-activating-fluxes-on-weld-bead-morphology-of-P9 - Journal-of-MabhaskarNo ratings yet

- Welding Technology GTAW GMAW FCAW PAW Nov 2020Document87 pagesWelding Technology GTAW GMAW FCAW PAW Nov 2020ENZO PEREZNo ratings yet

- PTA Hardfacing: Arcraft Plasma IndiaDocument16 pagesPTA Hardfacing: Arcraft Plasma IndiaJimmy RodriguesNo ratings yet

- Export Product Hand BookDocument94 pagesExport Product Hand Bookamit singhNo ratings yet

- Tig English ProjectDocument11 pagesTig English Projectmourid trabelsiNo ratings yet

- 2.welding ProcessesDocument81 pages2.welding ProcessesP. M. ISAI VISAAHANNo ratings yet

- rAJURI sTEEL COMPANY PROFILEDocument59 pagesrAJURI sTEEL COMPANY PROFILEpankajkapse100% (1)

- Niras - PresentasjonDocument23 pagesNiras - PresentasjonDeny Tirta KusumaNo ratings yet

- Tig Welding ThesisDocument5 pagesTig Welding ThesisBrooke Heidt100% (3)

- Induction BendingDocument23 pagesInduction BendingstevenNo ratings yet

- Welding and Soldering - 25.11.21 - GrundgerüstDocument27 pagesWelding and Soldering - 25.11.21 - GrundgerüstAlexander HoffmannNo ratings yet

- Thesis On Welding and FabricationDocument4 pagesThesis On Welding and Fabricationmkdswzgig100% (2)

- L31a GtawDocument23 pagesL31a GtawCrocodileNo ratings yet

- Toroidal Transformers For Universal Application: NuvotemDocument16 pagesToroidal Transformers For Universal Application: NuvotemFidel Segundo Fernandez HuertaNo ratings yet

- TIG-welding Gases PDFDocument2 pagesTIG-welding Gases PDFwenigmaNo ratings yet

- STT & Alloy 625 PDFDocument4 pagesSTT & Alloy 625 PDFharan2000No ratings yet

- MK0042 Hydrostatic Testing (EPC) Application SheetDocument2 pagesMK0042 Hydrostatic Testing (EPC) Application SheetMoezNo ratings yet

- Welding Toolbox Talk FINALDocument18 pagesWelding Toolbox Talk FINALJohan CárdenasNo ratings yet

- A5-8 Tig WeldingDocument104 pagesA5-8 Tig Weldinghema_avraoNo ratings yet

- MCL-135-Welding and Allied Processes - Class 11-15Document58 pagesMCL-135-Welding and Allied Processes - Class 11-15mHmNo ratings yet

- PTA Welding and HardfacingDocument16 pagesPTA Welding and Hardfacingpavi32No ratings yet

- Laser Cladding Vs Other TechnologiesDocument17 pagesLaser Cladding Vs Other Technologiesvenkat200a100% (2)

- M09 - Gtaw & PawDocument34 pagesM09 - Gtaw & Pawசுரேஷ் பாலமுருகன்No ratings yet

- Tungsten Inert Gas WeldingDocument47 pagesTungsten Inert Gas Weldingravi00098No ratings yet

- Applying Tig Techniques Hand-OutDocument12 pagesApplying Tig Techniques Hand-Outjuvy may esbanNo ratings yet

- GMAWDocument9 pagesGMAWMathias NsimbeNo ratings yet

- EEW Clad Steel PipesDocument4 pagesEEW Clad Steel PipesstevenNo ratings yet

- Espey WD200: Carbon Floating Ring Seals - Shaft SealsDocument5 pagesEspey WD200: Carbon Floating Ring Seals - Shaft SealsJose Vega VelascoNo ratings yet

- Seminar Report TIGDocument13 pagesSeminar Report TIGRahul ShawNo ratings yet

- Thesis Tig WeldingDocument8 pagesThesis Tig Weldingafknlmzok100% (2)

- Turbine Services, Ltd. Group: Delivering Quality Anywhere in The WorldDocument11 pagesTurbine Services, Ltd. Group: Delivering Quality Anywhere in The WorldHANIF AKBARNo ratings yet

- Turbine Blade and Nozzle Ring RepairsDocument2 pagesTurbine Blade and Nozzle Ring Repairsamir moniriNo ratings yet

- TS200 Manual SML 1 PDFDocument32 pagesTS200 Manual SML 1 PDFTimNo ratings yet

- Cast Resin Dry Transformers BrochureDocument12 pagesCast Resin Dry Transformers Brochuremohamedelshrpeni0No ratings yet

- VentureClad 1577CWDocument2 pagesVentureClad 1577CWUmen AryanNo ratings yet

- Gouging Processes: Arc-Air Gouging Plasma GougingDocument4 pagesGouging Processes: Arc-Air Gouging Plasma GougingMika VelinovNo ratings yet

- Gouging PDFDocument4 pagesGouging PDFEkhaSoemarnoNo ratings yet

- Amta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesDocument115 pagesAmta5 8 Applying Tungsten Inert Gas Tig Welding TechniquesAbu RectifyNo ratings yet

- THE Tri-Con SeriesDocument6 pagesTHE Tri-Con Seriespablopasqualini18No ratings yet

- Mec 602 Bearing DesignDocument148 pagesMec 602 Bearing DesignJonnalgadda Sameer KumarNo ratings yet

- Welding ProcessDocument42 pagesWelding ProcessPankaj KumbhareNo ratings yet

- UNIT 2 MP NewDocument71 pagesUNIT 2 MP Newvrinda.bhardwaj.52No ratings yet

- EagleBurgmann EMG Flyer en 22-12Document4 pagesEagleBurgmann EMG Flyer en 22-12Hakan TekelNo ratings yet

- Hard FacingDocument4 pagesHard FacingKassya SchunkNo ratings yet

- A New Perception of Activated Flux Tungsten Inert Gas (A-TIG) Welding Techniques For Various MaterialsDocument14 pagesA New Perception of Activated Flux Tungsten Inert Gas (A-TIG) Welding Techniques For Various MaterialsTibor KeményNo ratings yet

- Gantrail Crane Rail WeldingDocument2 pagesGantrail Crane Rail WeldingJorge Cruz RodriguezNo ratings yet

- Welding Productivity 5Document1 pageWelding Productivity 5atulNo ratings yet

- StainTrode DDocument2 pagesStainTrode DGyanaranjan2011No ratings yet

- EDS 105 Introduction To Welding Rev 1Document29 pagesEDS 105 Introduction To Welding Rev 1kevin.machado6317No ratings yet

- CMP Products Cable Gland Accessory CatalogueDocument1 pageCMP Products Cable Gland Accessory CatalogueElliza IshakNo ratings yet

- Advanced Gas Tungsten Arc Weld Surfacing Current Status and ApplicationDocument16 pagesAdvanced Gas Tungsten Arc Weld Surfacing Current Status and ApplicationGabriel FajardoNo ratings yet

- CC607 T4 Water Distribution System New 2Document40 pagesCC607 T4 Water Distribution System New 2Nursyahira Abd Ghani100% (2)

- 03 Junit4Document16 pages03 Junit4Anil KumarNo ratings yet

- Article - Explaining Peak Pressure Prediction Using Vds or FssaDocument2 pagesArticle - Explaining Peak Pressure Prediction Using Vds or FssaFreddy BelizarioNo ratings yet

- Metodologia de La InvestigacionDocument40 pagesMetodologia de La InvestigacionparpejoNo ratings yet

- Unit - I-3Document9 pagesUnit - I-3Saheer ShaikNo ratings yet

- Rent Payment Schedule - FDocument3 pagesRent Payment Schedule - FTom CatNo ratings yet

- Exide A7Document12 pagesExide A7Sebastian NarvaezNo ratings yet

- STM PresentationDocument22 pagesSTM PresentationPritish MoharirNo ratings yet

- BMC Group Raw MaterialDocument14 pagesBMC Group Raw MaterialSyedur RahmanNo ratings yet

- Company Presentation NewDocument13 pagesCompany Presentation NewNaveen PradeepanNo ratings yet

- Modul InoerpDocument5 pagesModul InoerpFatoni SiSahabat NoahNo ratings yet

- Accomplishment Report (January-April2021) Lovilyn EncarnacionDocument4 pagesAccomplishment Report (January-April2021) Lovilyn EncarnacionLovilyn EncarnacionNo ratings yet

- ResumeDocument3 pagesResumeanon-936858No ratings yet

- Hazard and Operability Study (HAZOP) Safety Assessment On: University of Nottingham Malaysia Campus H82PLD Coursework 2Document127 pagesHazard and Operability Study (HAZOP) Safety Assessment On: University of Nottingham Malaysia Campus H82PLD Coursework 2KongWeiHern100% (2)

- Teleportation Ece Seminar ReportDocument24 pagesTeleportation Ece Seminar ReportSudheesh Vs100% (1)

- Appendix D.4 Intake Design ConsiderationsDocument4 pagesAppendix D.4 Intake Design Considerationsnikom kraitadNo ratings yet

- Bhushan Power & Steel Ltd.Document17 pagesBhushan Power & Steel Ltd.navdeeplakheraNo ratings yet

- Anansi The SpiderDocument2 pagesAnansi The SpideramypeabodyNo ratings yet

- HST Pines Komatsu Wa320Document1 pageHST Pines Komatsu Wa320Victor Rodrigo Cortes YañezNo ratings yet

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- .Planning Designing and Estimation of A Ba PDFDocument7 pages.Planning Designing and Estimation of A Ba PDFRusscelNo ratings yet

- Ek101 & Ea301 Engineers in Society (Eis) Group Assignment: Name Student IDDocument12 pagesEk101 & Ea301 Engineers in Society (Eis) Group Assignment: Name Student IDLeeMayYanNo ratings yet

- Tesis OffshoreDocument265 pagesTesis OffshoreRosalita Cordaro100% (1)

- Architectural Design: Francis Cauffman Foley HoffmannDocument4 pagesArchitectural Design: Francis Cauffman Foley HoffmannLTE002No ratings yet

- Material Selection Guide - MILD STEELDocument1 pageMaterial Selection Guide - MILD STEELlouis donyNo ratings yet

- Gianduzzo Robert 1059876 Task2 Edu400Document6 pagesGianduzzo Robert 1059876 Task2 Edu400api-297391450No ratings yet

- GT02 Protocol en NeutralDocument16 pagesGT02 Protocol en NeutralLorocopeyNo ratings yet

- Mind Map Tutor HandbookDocument24 pagesMind Map Tutor HandbookWalter100% (1)