Professional Documents

Culture Documents

Tery PDF

Tery PDF

Uploaded by

Micontakt FainderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tery PDF

Tery PDF

Uploaded by

Micontakt FainderCopyright:

Available Formats

Proceedings of the Forth Annual Portable by Design Conference,

Electronics Design, March 24-27, pp 398-403

A NEW SUBSTATE FOR ELECTRONICS PACKAGING: ALUMINUM-SILICON

CARBIDE (AlSiC) COMPOSITES

Mark Occhionero, Richard Adams, and Kevin Fennessy

Ceramics Process Systems, Corp.

Chartley, MA 02712

Abstract

AlSiC is an ideal packaging material for todays high power density Si and GaAs chips.

AlSiCs unique set of material properties includes a high thermal conductivity and IC device

compatible coefficient of thermal expansion (CTE) that permits direct device attachment for

maximum thermal dissipation. The low material density of AlSiC is ideal for weight sensitive

applications such as portable devices. This paper reviews the AlSiC material properties

contrasted with the material properties of traditional electronic heat sinking materials.

Introduction

Maximum heat dissipation is a

requirement for todays higher power GaAs

and Si integrated circuit devices. The

maximum heat dissipation is achieved by

mounting active devices directly to high

thermal conductivity heat sinking substrates

or packages. Direct attachment requires a

compatible coefficient of thermal expansion

(CTE) value of the heat sink material to avoid

stress failure of the IC device.

Traditional thermal dissipation

materials like copper and aluminum have

CTE values that are much greater than IC

devices. To compensate, the IC device is

mounted on a stress reducing interface

material with a marginally compatible CTE

to the heat-sinking device. Interface

materials, such as highly thermally resistive

alumina substrates, result in a thermal

dissipation penalty.

Occhionero, Adams, Fennessy

The Fe-Ni alloy packaging materials

like Kovar have compatible CTE values but

offer no thermal dissipation advantage due to

low thermal conductivity values. Although

CuMo and CuW packaging materials have

high thermal conductivity and compatible

CTE values, these materials have high

densities that make them inappropriate for

weight sensitive applications such as portable

devices1,2.

The Aluminum Silicon-Carbide

(AlSiC) material system offers the packaging

designer a unique set of material properties

that are suited to high performance advanced

thermal management packaging designs.

AlSiC has a high thermal conductivity and

compatible CTE permitting direct IC device

attachment. AlSiC is also light weight,

making it appropriate for portable designs

and other weight sensitive applications.

Ceramics Process Systems

Proceedings of the Forth Annual Portable by Design Conference,

Electronics Design, March 24-27, pp 398-403

Additionally, the AlSiC material and

process system have two significant

advantages over traditional packaging

materials. The first is that packages can be

fabricated to net-shape during material

processing. Net-shape fabrication offers the

designer flexibility to develop complex tight

tolerance package geometries without the

need to machine these features. Secondly,

functional components such as feedthrus,

sealrings, and substrates can be hermetically

integrated in packages during AlSiC

processing3,4. This single step process,

termed Concurrent IntegrationTM, eliminates

the need for subsequent integration operations

such as brazing and soldering which can be

yield limiting. Net-shape fabrication and

Concurrent IntegrationTM, coupled with

thermal conductivity, compatible CTE , and

low material density are technology enabling

attributes of AlSiC that create improvements

in design opportunities for the packaging

engineer5.

on 0.010 inch material cross sections. This

hermeticity level allows fabricated AlSiC

packages to provide environmental protection

of functional components.

Figure 1. SiC Preform and Ni-Au

Plated AlSiC Lid and Ceramic

Feedthrus.

AlSiC Composite Material System

The AlSiC material is fabricated by

pressure infiltration of molten aluminum

metal into a SiC particulate preform. The SiC

preform and the infiltration tooling

incorporate all the features of the final

product allowing for the net-shape package

fabrication5,6,7. Figure 1 displays a SiC lid

preform with the corresponding Ni-Au plated

AlSiC lid and ceramic feedthrus. The

ceramic feedthrus were integrated in this lid

during the infiltration process using the

Concurrent IntegrationTM technique that is

discussed later in this text.

The AlSiC microstructure is

composed of a continuous Al-metal phase

with discrete SiC particulate phase, as shown

in Figure 2. The AlSiC composite

microstructure is fully dense with no void

space creating a hermetic material; He leak

rates are better than 10-9 atm cc/s measured

Occhionero, Adams, Fennessy

Figure 2. AlSiC Microstructure (SiC in

dark contrast).

The unique AlSiC material properties

result from a combination of the constituent

material properties; AlSiC properties are

tailored by varying the ratio of these

constituents. The IC CTE compatible AlSiC

compositions have a SiC particulate content

between 50-68 vol%. Table 1 compares the

material properties of AlSiC to Si, GaAs and

traditional packaging materials.

Ceramics Process Systems

Proceedings of the Forth Annual Portable by Design Conference,

Electronics Design, March 24-27, pp 398-403

Si

GaAs

AlSiC

(60v% SiC)

Kovar

(Ni-Fe)

CuW

(10-20% Cu)

CuMo

(15-20%Mo)

Cu

Al

SiC

AlN

Alumina

Beryllia

Density

g/cm3

2.3

5.23

3.0

CTE

ppm/

25-150C

4.2

6.5

6.5 - 9

Thermal

Conduct

W/mK

151

54

170 - 200

8.1

5.2

11 - 17

15.7 17.0

10

6.5 - 8.3

180 - 200

7-8

160 - 170

8.96

2.7

3.2

3.3

3.98

3.9

17.8

23.6

2.7

4.5

6.5

7.6

398

238

200 - 270

170 - 200

20 - 30

250

Bend

Strngth

MPa

Youngs

Modulus

GPa

112

450

290

131

68

415

310

350

345

AlSiC composite materials have

thermal conductivity values that are similar to

aluminum metal, and CTE values that are

similar to alumina. These attributes make

AlSiC packages ideal for direct active device

attachment to maximize thermal dissipation

and improve product reliability.

Figure 3 displays graphically the

AlSiC instantaneous CTE values between -50

and 350C contrasted to alumina. The

average CTE values for IC compatible AlSiC

between room temperature and 150C is 6.8

ppm/ which is marginally higher than 6.5 and

4.2 ppm/, for GaAs and Si devices. This

marginal CTE difference between AlSiC and

the active devices is desirable and results in

placing the IC chips in slight compression

after attachment by brazing or soldering.

These compressive forces reduce the risk of

component cracking failure and increase

product reliability.

Occhionero, Adams, Fennessy

Alumina

3.00

-50

50

100

150

Temperature (C)

Thermal conductivity as a function of

temperature from room temperature to 400C

for AlSiC is plotted in Figure 4. These data

are compared with data for beryllia (BeO) and

aluminum nitride (AlN) which are known

high thermal conductivity substrate materials.

367

313

330

137-200

450

300

300

250

5.00

Figure 3. AlSiC Instantaneous CTE versus

Temperature.

131

1172

AlSiC

7.00

Thermal Conductivity

(W/mK)

Material

CTE (ppm/C)

TABLE 1: AlSiC Material Properties

Compared with Common Packaging,

Substrate and IC Materials.

(Typical Values)

250

AlSiC

BeO

200

AlN

150

100

100

200

300

400

Temperature C

.

Figure 4. Thermal Conductivity Versus

Temperature for AlSiC, AlN and BeO.

As shown in Figure 4 the thermal

conductivity values of AlSiC and AlN are

similar from room temperature to 150 C.

Above 150C, AlSiC performs better than

AlN for thermal dissipation with a slightly

higher thermal conductivity value. At room

temperature AlSiC thermal conductivity value

is well below beryllia which has room

temperature thermal conductivity values

ranging from 215 to 300 W/mK. At elevated

IC power chip operating temperatures BeO

Ceramics Process Systems

Proceedings of the Forth Annual Portable by Design Conference,

Electronics Design, March 24-27, pp 398-403

and AlSiC thermal conductivity values are

comparable.

AlSiC strength and stiffness compare

favorably to traditional packaging materials.

The ultimate bending strength of AlSiC is two

to three times greater than Al metal. The

Figure 6. AlSiC housing with Brazed Seal

Ring and 30 Pin Header Coaxial Feedthrus.

Figure 5. AlSiC BGA Lid with

Integral Heat Sink Fins.

AlSiC Youngs modulus - a measure of a

materials stiffness - is three times greater

than Al, and two times greater than Cu. The

high stiffness to low density ratio is

structurally desirable for larger parts with thin

cross sections. This attribute permits designs

to incorporate feature like fins to maximize

cooling surface area. Figure 5 shows an

AlSiC BGA lid with integral cooling fins.

Sealrings, feedthrus, and substrates

can be integrated in AlSiC packages during

the fabrication process3,4. Concurrent

IntegrationTM has the advantage of forming a

hermetic seal between the functional

component and AlSiC material in a single

process step6. An example of Concurrent

IntegratedTM AlSiC housing is shown in

Figure 7. In this housing a high thermal

conductivity aluminum nitride substrate is

captured in an AlSiC frame. In addition,

electrical traces of aluminum metal were also

incorporated on the AlN substrate surface

during the infiltration process. The housing

is Ni-plated to facilitate solder and wire

bonding.

AlSiC Plating and Integration

AlSiC packages and substrates can be

plated using similar plating processes as

traditional packaging materials including: Ni,

Ni-Au, anodization and plasma flame spray

coating. AlSiC packages can also be

assembled with sealrings, feedthrus, and

substrates using traditional low temperature

eutectic brazing and soldering techniques.

Figure 6 shows an Alloy-48 sealring and

planar ceramic feedthrus that were brazed to

an AlSiC housing.

Figure 7. Concurrently IntegratedTM

AlSiC Housing with AlN substrate.

Ceramics Process Systems

Occhionero, Adams, Fennessy

Proceedings of the Forth Annual Portable by Design Conference,

Electronics Design, March 24-27, pp 398-403

It is important to note that the great

geometrical variety of AlSiC substrates, heat

sinks and packages shown in the proceeding

figures were fabricated to net-shape.

Machined components from traditional

packaging materials, which are usually

provided in billet or sheet stock, would be

costly5.

Conclusions

AlSiC is an ideal packaging material

for components and devices that require

advanced thermal management performance.

The low density of AlSiC makes it an

appropriate choice for weight sensitive

applications such as portable devices.

Furthermore, net-shape fabrication, as well as

Concurrent IntegrationTM processing offers

significant design advantages over the

traditional packaging materials. These

attributes enable improvements in advanced

packaging and thermal management designs

that ultimately improve component reliability.

The significant process and material

advancements of AlSiC in past years has

gained the acceptance of AlSiC heat sinks,

packages and substrates in both military and

commercial applications. Product designs in

AlSiC are cost competitive and offer

significant performance value.

Acknowledgments:

The Authors would like to thank

Professor D.P.H. Hasselman of Virginia

Polytechnic Institute for Specific Heat and

Thermal Diffusivity measurements.

Additional thanks to Dr. James Forster of

Texas Instruments for CTE measurements.

References

[1] R.W. Adams, B.E. Novich, D.Kane, K.

Brantferger, R.Oberle and S.Chai, A

Lightweight High Thermal Conductivity

Metal Matrix Composite Microwave Module

Package For Airborne Applications,

Proceedings of Government Microcircuit

Applications Conference (GOMAC), Digest

of Papers , Vol. 20, pp 454-456 November

1994.

[2] B.E. Novich and R.W. Adams, Design

and Fabrication of Metal Matrix Composites

for Microwave and Millimeter Wave

Integrated Circuit Packages, Proceedings of

1994 International Symposium on

Microelectronics, ISHM Boston, MA

November 15-17, 1994, pp 590-595.

[3]R.W. Adams, B.E. Novich and K.P.

Fennessy, Concurrent IntegrationTM of

Al/SiC MMIC Packages, Proceedings of the

1995 International Symposium on

Microelectronics, ISHM, Los Angeles CA,

October 1995, pp 36-41.

[4] B.E. Novich , R.W. Adams, and M.A.

Occhionero, low Cost MCM-D Cavity

Substrates for Packaging High Density Si and

GaAs Devices , Proceedings of the 10th

European Microelectronics Conference,

ISHM, Copenhagen, Denmark, May 14-17,

1995, pp 475-481.

[5]R.W. Adams, M.A. Occhionero, and K.P.

Fennessy, CTE Compatible Thermal

Packaging Solutions - Net-Shape Fabricated

AlSiC and AlN, Proceedings of the Third

Annual Portable by Design Conference,

Electronic Design, March 25-29, 1996, pp

527-536

[6] B.E. Novich and R.W. Adams,

Aluminum/Silicon Carbide (AlSiC) Metal

Matrix Composites For Advanced Packaging

Applications, Proceedings of the 1995

International Electronics Packaging

Conference, IEPS, San Diego CA, September

24-27, 1995, pp 220-227.

Occhionero, Adams, Fennessy

Ceramics Process Systems

Proceedings of the Forth Annual Portable by Design Conference,

Electronics Design, March 24-27, pp 398-403

[7] B.E. Novich, R.W. Adams, and K.P.

Fennessy, Metal Matrix Composites for

Single Chip and Multichip Microprocessor

Packaging, Proceedings of the 1995

International Electronics Packaging

Conference, IEPS, San Diego CA, September

24-27, 1995.

Occhionero, Adams, Fennessy

Ceramics Process Systems

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Oled TV: Service ManualDocument51 pagesOled TV: Service Manualed pwtNo ratings yet

- TD1005 Free and Forced Convection Datasheet 0518 PDFDocument3 pagesTD1005 Free and Forced Convection Datasheet 0518 PDFAmier AziziNo ratings yet

- Task: 2 Assembling and Disassembling of PC AimDocument16 pagesTask: 2 Assembling and Disassembling of PC AimEsther ReddyNo ratings yet

- Thermal Analysis of Splayed Pin Fin Heat Sink: April 2014Document7 pagesThermal Analysis of Splayed Pin Fin Heat Sink: April 2014assia maziNo ratings yet

- Dell Inspiron 2350 Owner's Manual En-UsDocument73 pagesDell Inspiron 2350 Owner's Manual En-UsAttila KissNo ratings yet

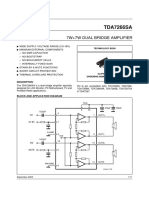

- TDA7266SA: 7W+7W Dual Bridge AmplifierDocument11 pagesTDA7266SA: 7W+7W Dual Bridge AmplifierWilman RengelNo ratings yet

- Texas - Instruments LM2940CT 5.0 - NOPB DatasheetDocument20 pagesTexas - Instruments LM2940CT 5.0 - NOPB Datasheetcarlos duranNo ratings yet

- 2009 10 Otti Solarcooling PalermoDocument6 pages2009 10 Otti Solarcooling PalermoKelvinVelasquezPascualNo ratings yet

- Tda2050 PDFDocument13 pagesTda2050 PDFmarcioulguimNo ratings yet

- MagPi101 PDFDocument100 pagesMagPi101 PDFTimothy NugentNo ratings yet

- Heat Transfer Characteristics of MWCNT Nano Uid in Rectangular Mini ChannelsDocument8 pagesHeat Transfer Characteristics of MWCNT Nano Uid in Rectangular Mini ChannelsSrynnENo ratings yet

- Make A Cloud Chamber Using Peltier CoolersDocument12 pagesMake A Cloud Chamber Using Peltier CoolersdontnubblemebroNo ratings yet

- Electronics CoolingDocument31 pagesElectronics Coolingvicky3000No ratings yet

- HiRef Chiller CDA Brochure-EnDocument4 pagesHiRef Chiller CDA Brochure-EnFranklin FernandezNo ratings yet

- Nmos350 500ConstructionGuideDocument3 pagesNmos350 500ConstructionGuidetrkonjicNo ratings yet

- CM200RXL 24SDocument15 pagesCM200RXL 24SMostafa ShannaNo ratings yet

- 2A Ultra Low Dropout Linear Regulator TJ4320Document20 pages2A Ultra Low Dropout Linear Regulator TJ4320Rizky GultomNo ratings yet

- L200 Design GuideDocument21 pagesL200 Design Guidetxe_scientistNo ratings yet

- CSS Grade 9 Week 2 FinalDocument20 pagesCSS Grade 9 Week 2 FinalHarlet Grace Basiao100% (1)

- 0 .. 30V/0 .. 10A Laboratory Power Supply: L L L L L LL LDocument10 pages0 .. 30V/0 .. 10A Laboratory Power Supply: L L L L L LL LMinh TrầnNo ratings yet

- Ansaldo: Repetitive Voltage Up To Mean On-State Current Surge CurrentDocument4 pagesAnsaldo: Repetitive Voltage Up To Mean On-State Current Surge CurrentAlex RamirezNo ratings yet

- A Square Guarded Hot Plate ApparatusDocument9 pagesA Square Guarded Hot Plate ApparatusJonatanLussolliNo ratings yet

- Icmax Thermal Analysis of Perforated Fin Arrays Applying Taguchi MethodDocument7 pagesIcmax Thermal Analysis of Perforated Fin Arrays Applying Taguchi MethodDHANAWADE HanamantNo ratings yet

- LG 20LB45xxT - Chassis LB45SDocument35 pagesLG 20LB45xxT - Chassis LB45SHarty LenyNo ratings yet

- EtraLED-EDI-7050 Edison Modular Passive Star LED Heat Sink Φ70mmDocument3 pagesEtraLED-EDI-7050 Edison Modular Passive Star LED Heat Sink Φ70mmleoNo ratings yet

- ShinEtsuLiquidSiliconeRubbers-ele EDocument32 pagesShinEtsuLiquidSiliconeRubbers-ele Eana.luiza.nanyNo ratings yet

- T-Top800 T-Top800 Top81Document1 pageT-Top800 T-Top800 Top81CADTDDNo ratings yet

- Deng Et Al. 2019 PDFDocument13 pagesDeng Et Al. 2019 PDFMontse Vilarrubí PortaNo ratings yet

- Aalborg Universitet: Shen, Yanfeng Wang, Huai Blaabjerg, Frede Zhao, Hui Long, TengDocument20 pagesAalborg Universitet: Shen, Yanfeng Wang, Huai Blaabjerg, Frede Zhao, Hui Long, TengLeandro GagliardiNo ratings yet