Professional Documents

Culture Documents

Kaiflex-ST Catalogue 09.15

Kaiflex-ST Catalogue 09.15

Uploaded by

vhin84Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kaiflex-ST Catalogue 09.15

Kaiflex-ST Catalogue 09.15

Uploaded by

vhin84Copyright:

Available Formats

Made in

Germany!

Designed to prevent condensation and energy losses.

Flexible insulation with closed cell structure to save energy and stop condensation.

Fire rating Class O

Highly flame retardant B-s3,d0

Water vapour resistance factor 10.000

Thermal conductivity 0C 0,034 W/(mK)

UL- and FM-approved

Designed to prevent condensation and energy losses.

insulation reliably prevents condensa-

Closed cell structure

with in-built water vapour barrier

tion and reduces energy loss. By in-

Formed from thousands of independently water resistant

corporating a water vapour barrier into

cells, Kaiflex insulation is naturally resistant to moisture in-

the insulation cell structure Kaiflex ST

gress and requires no additional water vapour barrier.

Kaiflex ST flexible closed cell rubber

can effectively eliminate water vapour

migration and retain outstanding performance over the entire system life.

Inherently resistant to corrosion

Available in tube, coils and sheets for

With an inherent resistance to moisture ingress Kaiflex insu-

use on air-conditioning, refrigeration,

lation keeps pipes dry and helps to prevent corrosion under

chilled water, heating and hot water

insulation.

pipes and air-distribution ductwork,

Kaiflex ST is versatile insulation with

In addition to exceptional condensa-

Excellent thermal values

minimise energy loss

tion preventing performance, Kaiflex

Kaiflex features a low thermal conductivity that prevents the

ST also performs an acoustic func-

loss of energy from pipework making Kaiflex an excellent

tion, absorbing sound and dampening

insulating material.

consistent and reliable technical values.

duct wall vibration. With inherent antimicrobial resistance as standard and

a closed cell rubber structure that is

Flexible, dust and fibre free nature

completely dust and fibre free, Kaiflex

Dust & fibres can aggravate respiratory conditions and cre-

ST can be used in any kind of build-

ate an additional site hazard. Kaiflex is dust and fibre free

ing without impacting on health or the

making installation easier and healthier.

quality of air.

Kaiflex ST has been designed to meet

European fire regulations and is a self-

Inherent resistance to microbial growth

extinguishing foam that will not drip or

By effectively preventing moisture ingress, Kaiflex is inher-

support flame spread. With a Europe-

ently resistant to microbial and mould growth that otherwise

an Class BL-s3, d0 or Class B-s3, d0

compromise indoor air quality.

fire classification, Kaiflex ST can be

safely used with confidence in public,

commercial and industrial buildings.

2

Kaimann GmbH | Subject to alterations. | www.kaimann.com

Designed to prevent condensation and energy losses.

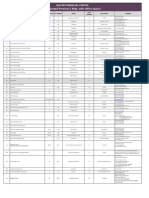

Kaiflex ST Technical Data

Material

Elastomeric foam based on synthetic rubber.

Flexible Elastomeric Foam (FEF)

in acc. with EN 14304

Cell structure

Closed cell

Colour

Black

Upper temperature limit

Pipe

+110 C

Flat surfaces

+85 C

Lower temperature limit

Thermal conductivity

50 C (200 C)

at 30 C

0,031 W/(mK)

at 20 C

0,032 W/(mK)

at 0 C

0,034 W/(mK)

at +10 C

0,035 W/(mK)

at +20 C

0,036 W/(mK)

at +40 C

0,038 W/(mK)

Moisture resistance factor

10.000

Tubes

BL-s3, d0

Sheets

B-s3, d0

Water vapour permeability

EuroClass

See remark (1)

Test acc. to

DIN EN ISO 8497

DIN EN 12667

Test acc. to

DIN EN 13469

DIN EN 12086

No separate vapour barrier required

Test acc. to DIN EN 13501-1

Practical fire behaviour

Self-extinguishing, no drips, does not support

flame spread

Fire performance

Class O

In acc. with UK building regulations

Surface spread of Flame

Class 1

Test acc. to BS 476-7

Fire propagation

Total index of performance

<12

Sub Index 1

<6

Corrosion resistance

Test acc. to BS 476-6

Satisfies requirements

Test acc. to DIN 1988

Dust & fibre free

Health aspects

Formaldehyde free

Cadmium free

Resistance to

Other attributes

Mould and bacteria

no growth

In acc. with VDI 6022

CE marked

pH-Value

Neutral

UL-approved (UL94)

Other certificates/approvals

In acc. with UL94 V-0,HF-1

FM-approved

DNV, Lloyd's Register, See BG

1 year

Store in a dry room at a typical relative

humidity (between 50 % and 70 %)

and room temperature (between 0 C

and +35 C)

Tolerances

Consult table Tolerances

In acc. with DIN EN 14304:2013-04

Outdoor applications

Needs protection against UV-radiation

See remark (2)

Lifespan

Self-adhesive products

Remark (1) For temperatures below 50 C please contact our Technical Support Team for advice.

Remark (2) To protect against UV-induced deterioration Kaiflex should be either painted using Kaifinish paint or covered with a suitable UV resistant cladding system within 3 days of being installed outdoors.

The Euroclass rating applies to metalic or solid mineral substrates.

UL94

Kaimann GmbH | Subject to alterations. | www.kaimann.com

V-0, HF-1

Designed to prevent condensation and energy losses.

Kaiflex ST Tube

Colour: Black Length: 2 m

Copper pipe

Cu

OD

mm

Nom

width

DN

6,0

10,0

12,0

10

15,0

10

Inch

/8

/4

Nom

width

DN

10,2

13,5

Reference

Order No.

m/

carton

Reference

Order No.

m/

carton

ST-06x006

17006006

600

ST-09x006

17009006

360

ST-06x010

17006010

430

ST-09x010

17009010

320

ST-06x012

17006012

350

ST-09x012

17009012

280

ST-06x015

17006015

300

ST-09x015

17009015

240

ST-06x020

17006020

250

ST-09x020

17009020

160

21,3

15

ST-06x022

17006022

216

ST-09x022

17009022

156

/4

26,9

20

ST-06x028

17006028

150

ST-09x028

17009028

124

33,7

25

ST-06x035

17006035

120

ST-09x035

17009035

92

1 1 /4

42,4

32

ST-09x042

17009042

70

1 1 /2

48,3

40

ST-09x048

17009048

60

ST-09x054

17009054

60

ST-09x060

17009060

60

28,0

25

35,0

32

42,0

40

50

54,0

2

Copper pipe

Cu

60,3

50

13 mm

Insulation thickness

Iron & steel pipe

Fe

Nom

width

DN

6,0

10,0

12,0

10

15,0

10

9 mm

Insulation thickness

/2

20

OD

mm

OD

mm

12,5

22,0

54,0

6 mm

Insulation thickness

Iron & steel pipe

Fe

Inch

/8

OD

mm

10,2

Nom

width

DN

Reference

ST-13x006

17013006

240

ST-19x006

17019006

126

ST-13x010

17013010

190

ST-19x010

17019010

106

ST-13x012

17013012

172

ST-19x012

17019012

100

ST-13x015

17013015

154

ST-19x015

17019015

86

ST-13x020

17013020

120

ST-19x020

17019020

76

12,5

/4

13,5

19 mm

Insulation thickness

Order No.

m/

carton

Reference

Order No.

m/

carton

/2

21,3

15

ST-13x022

17013022

110

ST-19x022

17019022

74

/4

26,9

20

ST-13x028

17013028

86

ST-19x028

17019028

58

22,0

20

28,0

25

35,0

32

33,7

25

ST-13x035

17013035

76

ST-19x035

17019035

48

42,0

40

1 /4

42,4

32

ST-13x042

17013042

56

ST-19x042

17019042

40

1 1 /2

48,3

40

ST-13x048

17013048

48

ST-19x048

17019048

30

ST-13x054

17013054

46

ST-19x054

17019054

30

ST-13x060

17013060

40

ST-19x060

17019060

28

ST-13x067

17013067

40

ST-19x067

17019067

28

ST-13x076

17013076

34

ST-19x076

17019076

28

ST-13x080

17013080

30

ST-19x080

17019080

26

ST-13x089

17013089

30

ST-19x089

17019089

22

ST-13x108

17013108

28

ST-19x108

17019108

20

ST-13x114

17013114

28

ST-19x114

17019114

18

54,0

50

54,0

2

60,3

50

67,0

65

2 1 /2

76,1

65

88,9

80

88,9

80

108,0

100

114,0

100

76,1

80,0

108,0

4

114,3

100

9 mm tubes are available upon request for the pipe dimensions: 9 x 64, 9 x 70, 9 x 76, 9 x 80, 9 x 89, 9 x 102, 9 x 108, 9 x 114, 9 x 125, 9 x 133, 9 x 140 and 9 x 160.

13 mm tubes are available upon request for the pipe dimensions: 13 x 125, 13 x 133, 13 x 140 and 13 x 160.

19 mm tubes are available upon request for the pipe dimensions: 19 x 125, 19 x 133, 19 x 140 and 19 x 160.

Kaimann GmbH | Subject to alterations. | www.kaimann.com

Designed to prevent condensation and energy losses.

Kaiflex ST Tube

Colour: Black Length: 2 m

Copper pipe

Cu

OD

mm

Nom

width

DN

6,0

10,0

12,0

10

15,0

10

Inch

/8

OD

mm

Nom

width

DN

10,2

12,5

1

/4

13,5

Reference

Order No.

m/

carton

ST-25x006

17025006

80

ST-25x010

17025010

72

ST-25x012

17025012

60

ST-32x012

17032012

36

ST-25x015

ST-25x020

17025015

60

ST-32x015

17032015

32

17025020

50

17025022

42

ST-32x022

17032022

32

/4

26,9

20

ST-25x028

17025028

40

ST-32x028

17032028

24

33,7

25

ST-25x035

17025035

32

ST-32x035

17032035

24

1 1/4

42,4

32

ST-25x042

17025042

24

ST-32x042

17032042

24

1 1/2

48,3

40

ST-25x048

17025048

24

ST-32x048

17032048

18

ST-25x054

17025054

22

ST-32x054

17032054

18

ST-25x060

17025060

22

ST-32x060

17032060

16

ST-25x067

17025067

18

ST-32x067

17032067

14

ST-25x076

17025076

18

ST-32x076

17032076

12

ST-25x080

17025080

14

ST-32x080

17032080

12

ST-25x089

17025089

14

ST-32x089

17032089

10

ST-25x108

17025108

10

ST-32x108

17032108

ST-25x114

17025114

10

ST-32x114

17032114

ST-32x133

17032133

28,0

25

35,0

32

42,0

40

50

54,0

2

60,3

50

67,0

65

2 1/2

76,1

65

88,9

80

88,9

80

108,0

100

114,0

100

133,0

125

80,0

108,0

4

114,3

100

133,0

5

150

139,7

125

160,0

Copper pipe

Cu

Nom

width

DN

m/

carton

ST-25x022

OD

mm

Order No.

15

159,0

Reference

21,3

20

76,1

32 mm

Insulation thickness

/2

22,0

54,0

25 mm

Insulation thickness

Iron & steel pipe

Fe

ST-25x140

17025140

ST-32x140

17032140

ST-25x160

17025160

ST-32x160

17032160

40 mm

Insulation thickness

Iron & steel pipe

Fe

Inch

OD

mm

50 mm

Insulation thickness

Nom

width

DN

Reference

Order No.

m/

carton

Reference

Order No.

m/

carton

/2

21,3

15

ST-40x022

17040022

22

ST-50x022

17050022

14

/4

26,9

20

ST-40x028

17040028

16

ST-50x028

17050028

10

22,0

20

28,0

25

35,0

32

33,7

25

ST-40x035

17040035

16

ST-50x035

17050035

42,0

40

1 1/4

42,4

32

ST-40x042

17040042

16

ST-50x042

17050042

1 1/2

48,3

40

ST-40x048

17040048

16

ST-50x048

17050048

54,0

ST-40x054

17040054

10

ST-50x054

17050054

60,3

50

ST-40x060

17040060

10

ST-50x060

17050060

50

54,0

76,1

65

2 /2

76,1

65

ST-40x076

17040076

10

ST-50x076

17050076

88,9

80

88,9

80

ST-40x089

17040089

10

ST-50x089

17050089

108,0

100

ST-40x108

17040108

ST-50x108

17050108

114,0

100

ST-40x114

17040114

ST-50x114

17050114

108,0

4

114,3

100

40 mm and 50 mm tubes are available upon request for the pipe dimensions: 40 x 140, 40 x 160, 40 x 168, 50 x 140, 50 x 160 and 50 x 168.

Kaimann GmbH | Subject to alterations. | www.kaimann.com

Designed to prevent condensation and energy losses.

Kaiflex ST Sheet continuous

Colour: Black

Insulation

thickness

mm

Sheet continuous

1 m width

Reference

Sheet continuous self-adhesive

1 m width

Order No.

m/

carton

Reference

Order No.

m/

carton

ST-03-RL

18003000

30

ST-03-RL-SK

18203000

30

ST-06-RL

18006000

30

ST-06-RL-SK

18206000

30

10

ST-10-RL

18010000

20

ST-10-RL-SK

18210000

20

13

ST-13-RL

18013000

14

ST-13-RL-SK

18213000

14

16

ST-16-RL

18016000

12

ST-16-RL-SK

18216000

12

19

ST-19-RL

18019000

10

ST-19-RL-SK

18219000

10

25

ST-25-RL

18025000

ST-25-RL-SK

18225000

32

ST-32-RL

18032000

ST-32-RL-SK

18232000

40

ST-40-RL

18040000

ST-40-RL-SK

18740000

50

ST-50-RL

18650000

ST-50-RL-SK

18750000

Tolerances DIN EN 14304:2010-03 Flexible Elastomeric Foam (FEF)

Supplied as

Length

Tubes

1,5%

Flat sheets

1,5%

Continous sheets

Tapes

Width

Thickness

Perpendicularity

Inner diameter

Di 100

Di > 100

3,0 mm

Di,D + 1 Di Di,D + 4

Di,D + 1 Di Di,D + 6

1,0

1,5

2,0

3,0 mm/m (length/width)

3,0 mm (Thickness)

dD 6

6 < dD 19

dD > 19

1,0

1,5

2,0

3,0 mm/m (length/width)

3,0 mm (Thickness)

dD = 3

0,1

+1,5

Stated

Limits

dD 8

8 < dD 18

18 < dD 31

dD > 31

1,0

1,5

2,5

3,0

2,0%

dD 6

6 < dD 19

dD > 19

+5,0%

1,5%

2,0%

+5,0%

1,5%

2,0%

Measurements in mm Di = inner diameter dD = Nominal thickness of product Di,D = Nominal thickness of a tube

Kaimann GmbH | Subject to alterations. | www.kaimann.com

Adhesive Cleaner Protective Coating

Description

Order No.

Can

content

Carton

content

Adhesive

Adhesive 414 toluene free can

299-0.20

220 g

24

Adhesive 414 toluene free

299-0.75

660 g

20

Adhesive 414 toluene free

299-2.50

2.200 g

Adhesive 494 LEED-compliant

299-2300

2.300 g

299REINI

1,0 l

12

Kaifinish Protective Coating pure white RAL 9010

299KAFI1

0,75 l

12

Kaifinish Protective Coating grey RAL 7035

299KAFI5

0,75 l

12

Cleaner

Cleaner

Protective Coating

Tools

Description

Order No.

Content

/PU

Glue pump

Glue pump short spout Brush 17 mm

299KABI4

Glue pump long spout Brush 17 mm

299KABI1

Brush 11 mm

299KABI2

Brush 17 mm

299KABI3

Ceramic knife knife with ceramic blade (12 cm) and plastic handle (12 cm)

299SMES6

Sheet knife

299SMES3

Kaiflex set of knives 3 knives, 1 whetstone

299SMES5

V-Cutter

299SMES2

Spare blades for V-Cutter

299KLIFU

Knives

Tape

Description

Order No.

Length

m

Width

mm

Thickness

Rolls/

carton

1891BAND

15

50

3 mm

12

Tape self-adhesive

ST Tape self-adhesive

Kaimann GmbH | Subject to alterations. | www.kaimann.com

Kaimann technology. engineering. solutions.

For over 50 years Kaimann has looked

technology.

to build for the future without ever

Over 50 years Kaimann has developed

forgetting the lessons of the past. The

an intimate understanding of the physi-

success of our company has always

cal and chemical processes that make

been based on a reputation for quality

flexible elastomeric foams such a

and a commitment to establishing fair,

uniquely versatile material. Through an

long-term business partnerships with

unrivalled mastery of this technology,

all of our customers.

Kaimann's team of leading research

chemists has taken Kaiflex into new

Since Kaimann was founded in 1959

spheres of performance without mak-

the company has constantly sought

ing any compromise.

to improve the quality of products and

services we are able to offer to the

engineering.

market. This long and continuous pro-

Absolute dedication to quality manu-

gramme of development has led to our

facturing has seen Kaimann establish

manufacturing plant in Hvelhof being

itself as an expert on engineering plant

recognised as a centre for the produc-

equipment for the production of flexi-

tion and development of flexible elas-

ble elastomeric insulation materials.

tomeric and polyethylene insulation.

Through a continually ongoing programme of improvement and optimisa-

Kaiflex, our Europe-wide established

tion of all manufacturing components

insulation brand, has grown to be-

Kaimann is able to realise the full ben-

come known as very reliable and

efits of superior engineering to deliver

trusted brand of flexible insulation for

the highest quality products.

air-conditioning, refrigeration, heating,

hot water and solar hot water appli-

solutions.

cations. Today Kaiflex continues to set

With an already diverse range of solu-

the standard for elastomeric foam in-

tions that combine exceptionally high

sulation with a series of sophisticated

quality foam technology together with

product innovations.

the insights offered by an in-depth understanding of the challenges technical

insulation must overcome, Kaimann

is constantly working with partners

worldwide to realise the cutting edge

insulation solutions of tomorrow.

Kaimann Middle East FZE P.O. Box 341217 Dubai Silicon Oasis Dubai, U.A.E. Tel.: +97143712590 Fax: +97143712591 info.dubai@kaimann.com www.kaimann.com

08/15 - MAED2CSB

Kaimann GmbH Hansastrae 2-5 D-33161 Hvelhof Germany Tel.: +49 5257 9850-0 Fax: +49 5257 9850-590 info@kaimann.com www.kaimann.com 2015 Kaimann GmbH Subject to alterations.

Kaimann GbmH provides this information as a technical service. Where information is provided that is a direct result of Kaimanns own technical analysis and testing, the information displayed is an interpretation of the data accurate

to the extent of our knowledge and ability as of date of printing. Standardised methods and procedures are used wherever possible. Some information presented may be derived from sources other than Kaimann and in these cases

Kaimann is substantially, if not wholly, relying upon the other source(s) to provide accurate information.

Actual technical performance may be dependent on the specific installation and site conditions. Since Kaimann cannot control installation or site conditions, Kaimann does not guarantee that the user will obtain the same results as

published in this document. It is the responsibility of each user to perform their own tests in order to determine the safety, fitness and suitability of the products, or combination of products, for any foreseeable purposes, applications

and uses by the user and/or any third party to which the user may convey the products.

Kaiflex is a registered trademark of the Kaimann GmbH.

You might also like

- Method Statement For Installation, Testing & Commissioning of VRF & Split System Rev.01Document36 pagesMethod Statement For Installation, Testing & Commissioning of VRF & Split System Rev.01vhin8467% (6)

- Afico Faceed InsulationDocument4 pagesAfico Faceed Insulationhello1230No ratings yet

- Ward Product SelectorDocument32 pagesWard Product SelectorvgchgchgcNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Knauf Installation Guide 2012 WEBDocument52 pagesKnauf Installation Guide 2012 WEBamazonfedNo ratings yet

- Checklist For Installation Testing & Commissioning of AHU's & FAHU's Rev.02Document16 pagesChecklist For Installation Testing & Commissioning of AHU's & FAHU's Rev.02vhin84No ratings yet

- Checklist For Installation Testing & Commissioning of AHU's & FAHU's Rev.02Document16 pagesChecklist For Installation Testing & Commissioning of AHU's & FAHU's Rev.02vhin84No ratings yet

- Condensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHDocument41 pagesCondensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHMilton UrrozNo ratings yet

- Astm C165Document5 pagesAstm C165Lakruwan100% (1)

- KflexDocument8 pagesKflexEddie BoyzNo ratings yet

- Kaiflex MasterSpecificationDocument8 pagesKaiflex MasterSpecificationnaseema1No ratings yet

- Kaiflex Specification DomesticDocument5 pagesKaiflex Specification Domesticnaseema1No ratings yet

- AFICO Heavy Density Pipe Insulation - NewDocument4 pagesAFICO Heavy Density Pipe Insulation - NewNickolas HeadNo ratings yet

- Superlon 16 Pages CatalogDocument16 pagesSuperlon 16 Pages CatalogDevan SanmugamNo ratings yet

- Aspen Aerogels Pyrogel XT PDFDocument4 pagesAspen Aerogels Pyrogel XT PDFBTconcordNo ratings yet

- Proflex CatalogueDocument8 pagesProflex Catalogueapi-291585305No ratings yet

- Marine-Offshore Cable & Pipe Penetration DossierDocument39 pagesMarine-Offshore Cable & Pipe Penetration DossierHonka VoxNo ratings yet

- Cable Repairs From NETDocument8 pagesCable Repairs From NETsonotiumNo ratings yet

- Recotec Rotafil enDocument16 pagesRecotec Rotafil enJordan RileyNo ratings yet

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbNo ratings yet

- Chapter 3 Datasheets Roof PanelsDocument16 pagesChapter 3 Datasheets Roof PanelsMladen BilincNo ratings yet

- Pipe InsulationDocument50 pagesPipe InsulationSam WeberNo ratings yet

- BroucherDocument8 pagesBroucherSiangRelNo ratings yet

- Euro Therma TR27 2ppDocument2 pagesEuro Therma TR27 2ppbakkakraljNo ratings yet

- Insulation Engineered For: Cold SystemsDocument0 pagesInsulation Engineered For: Cold SystemsjeewanaaNo ratings yet

- Insulation ContraThermDocument16 pagesInsulation ContraThermmarcins85No ratings yet

- Fire Security NGOAFRDocument5 pagesFire Security NGOAFRseeker05No ratings yet

- Rockwool 3Document28 pagesRockwool 3deerajksNo ratings yet

- SUNSHADE Junction Boxes and SunshadesDocument20 pagesSUNSHADE Junction Boxes and Sunshadesfaisal84inNo ratings yet

- Advanced ContraFlame 02 09 2011 - 12pp PDFDocument12 pagesAdvanced ContraFlame 02 09 2011 - 12pp PDFfredo405No ratings yet

- Catalogue Băng Keo Alberta 80 FusionDocument2 pagesCatalogue Băng Keo Alberta 80 FusionHà Trần MạnhNo ratings yet

- TIMSA Elements of Insulation DesignDocument6 pagesTIMSA Elements of Insulation DesignmombarreNo ratings yet

- Eng Trocellen DuctDocument6 pagesEng Trocellen DuctjacksonliNo ratings yet

- CONTRAFLEX Advanced Insulation PDFDocument32 pagesCONTRAFLEX Advanced Insulation PDFYadira MarquezNo ratings yet

- Armaflex Self Seal Leaflet DigitalDocument4 pagesArmaflex Self Seal Leaflet Digitallilama45-1No ratings yet

- Coltlite: Natural Glass Louvred VentilatorDocument12 pagesColtlite: Natural Glass Louvred VentilatorAdnan KhanNo ratings yet

- Glasswool Spec PDFDocument3 pagesGlasswool Spec PDFabhishek198327No ratings yet

- Bondor BondorPanel Insulated Walling Technical DataDocument2 pagesBondor BondorPanel Insulated Walling Technical DataSvan Dxi ArulNo ratings yet

- Composite InsulatorsDocument8 pagesComposite InsulatorsHillary McgowanNo ratings yet

- Geolan CatalogueDocument20 pagesGeolan CataloguelajharkaNo ratings yet

- LIL-Products-PUF-PIR Pipesection For Insulation Res17 PDFDocument2 pagesLIL-Products-PUF-PIR Pipesection For Insulation Res17 PDFJoshua FernandezNo ratings yet

- Piping Equipment IsolationDocument14 pagesPiping Equipment IsolationLữ Hành ShutoNo ratings yet

- Heraklith C ENG 2012 11Document2 pagesHeraklith C ENG 2012 11Calin AncutaNo ratings yet

- Insulation Application GuideDocument33 pagesInsulation Application GuideNath BoyapatiNo ratings yet

- ARIFLEXDocument8 pagesARIFLEXRiyas Udheen50% (2)

- Expansion JointsDocument8 pagesExpansion Jointsterencejustine100% (1)

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- Rip Bushing PDFDocument38 pagesRip Bushing PDFTravis Wood100% (1)

- Firebox T-Serie en PDFDocument16 pagesFirebox T-Serie en PDF2zeceNo ratings yet

- IsoTek Manual 8-18-14Document13 pagesIsoTek Manual 8-18-14usamazarifehNo ratings yet

- Anticorrosion Treatment AlucoastDocument7 pagesAnticorrosion Treatment Alucoastznim04No ratings yet

- Introduction To InsulationDocument43 pagesIntroduction To InsulationHaridev Moorthy100% (2)

- Insulation GuideDocument5 pagesInsulation GuideJessie PimentelNo ratings yet

- InsulationDocument23 pagesInsulationchesspupilNo ratings yet

- Thermazone Foilboard Insulation DatasheetDocument3 pagesThermazone Foilboard Insulation DatasheetSuthirak SumranNo ratings yet

- K450 Plus Updated PDFDocument138 pagesK450 Plus Updated PDFCongson JeffNo ratings yet

- Flange Management GuideDocument8 pagesFlange Management GuidekeronsNo ratings yet

- Usi SectionaleDocument18 pagesUsi SectionaleFlorian MihaleNo ratings yet

- Thermal Products - Materiais LizDocument8 pagesThermal Products - Materiais LizRui Carlos Delgado Lopes AlvesNo ratings yet

- Insulation Solutions For LNG and Other Cold/Cryogenic ApplicationsDocument4 pagesInsulation Solutions For LNG and Other Cold/Cryogenic Applicationsalex_E_bondNo ratings yet

- Construction Machinery Brochur IGUSDocument24 pagesConstruction Machinery Brochur IGUSjorgew2050No ratings yet

- K-Flex Tapes BrochureDocument16 pagesK-Flex Tapes BrochuregetashishvaidNo ratings yet

- K-Flex India Brochure 2023Document6 pagesK-Flex India Brochure 2023Ishan PereraNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Constitution and By-Laws: Asme Manual Mm-1Document56 pagesConstitution and By-Laws: Asme Manual Mm-1vhin84No ratings yet

- Q14120-0100D-Detailed Design Phase - Part 2 - REV 00 - Nov 15Document376 pagesQ14120-0100D-Detailed Design Phase - Part 2 - REV 00 - Nov 15vhin84No ratings yet

- Training Survey Procedure For Strategic MarketingDocument8 pagesTraining Survey Procedure For Strategic Marketingvhin84No ratings yet

- CDC/Boom-JV NPP0047-CCIA: Material Approval Submittal SampleDocument2 pagesCDC/Boom-JV NPP0047-CCIA: Material Approval Submittal Samplevhin84No ratings yet

- QFC Designated Premises - 032016Document1 pageQFC Designated Premises - 032016vhin84No ratings yet

- LEED v4 For Operations & Maintenance: Existing Buildings: Project Checklist Project Name: DateDocument18 pagesLEED v4 For Operations & Maintenance: Existing Buildings: Project Checklist Project Name: Datevhin84No ratings yet

- UKR1 MGMT 00003 Unit05 Crawford NahmiasDocument8 pagesUKR1 MGMT 00003 Unit05 Crawford Nahmiasvhin84No ratings yet

- Purchase Order LetterDocument1 pagePurchase Order Lettervhin84No ratings yet

- CMP Guide: Credential Maintenance ProgramDocument10 pagesCMP Guide: Credential Maintenance Programvhin84No ratings yet

- Pages From ISO IEC 17021 2006Document1 pagePages From ISO IEC 17021 2006vhin84No ratings yet

- BDC PosterDocument1 pageBDC Postervhin84No ratings yet

- 2 PDFDocument1 page2 PDFvhin84No ratings yet

- Method Statement Material Submittal Pre-Qualification Inspection Request NCRDocument1 pageMethod Statement Material Submittal Pre-Qualification Inspection Request NCRvhin84No ratings yet

- QCD-FS-G.Annex Rev2015 PDFDocument1 pageQCD-FS-G.Annex Rev2015 PDFvhin84No ratings yet

- PDS Foster 30 45 Foamseal SealantDocument4 pagesPDS Foster 30 45 Foamseal SealantKumarNo ratings yet

- LNG 26-62Document37 pagesLNG 26-62mohkal1260No ratings yet

- Efficient Technology For Major Tasks: Hot Water BoilersDocument32 pagesEfficient Technology For Major Tasks: Hot Water BoilersJosé Pedro MagalhãesNo ratings yet

- Thermal and Electrical Insulation Termotisa For Electrical Cabinets en v.1.0-17Document7 pagesThermal and Electrical Insulation Termotisa For Electrical Cabinets en v.1.0-17Beganović DinoNo ratings yet

- Water Plumbing Lect 3 2015 EDUDocument80 pagesWater Plumbing Lect 3 2015 EDUMoudi Houri100% (3)

- Keflex Braided Hose Installation Recommendations - Bpump-con-InsDocument2 pagesKeflex Braided Hose Installation Recommendations - Bpump-con-Insgary_robinson100% (1)

- Symposium ThermalDocument124 pagesSymposium Thermaly2kareinNo ratings yet

- An Anisotropically High Thermal Conductive Boron Nitride - Epoxy Composite Based On Nacre Mimetic 3D Network (Advanced Functional Materials) (2019)Document9 pagesAn Anisotropically High Thermal Conductive Boron Nitride - Epoxy Composite Based On Nacre Mimetic 3D Network (Advanced Functional Materials) (2019)Muhammad Hamza 1710-FBAS/BSPHY/F19No ratings yet

- WHP1017 Super Padg HD Perf SpecsDocument1 pageWHP1017 Super Padg HD Perf SpecsSterlingNo ratings yet

- Geofoam IntrusionsDocument24 pagesGeofoam IntrusionsECEOCETNo ratings yet

- Aspen Aerogel Pyrogel XT-DSDocument2 pagesAspen Aerogel Pyrogel XT-DSkflimNo ratings yet

- Tank Heat LossDocument25 pagesTank Heat Lossdanmaltais100% (3)

- Painting Insulation WorkDocument47 pagesPainting Insulation WorkRjeb mohamed100% (1)

- D5298 Curva Característica Do SoloDocument6 pagesD5298 Curva Característica Do SoloDenny SantanaNo ratings yet

- Induction Motor Manual (E)Document60 pagesInduction Motor Manual (E)sizmaruNo ratings yet

- Heat Transfer 1990-2003 1643994287402Document22 pagesHeat Transfer 1990-2003 1643994287402Anshu MeenaNo ratings yet

- Brochure FPE Sale Straight Tunnel Freezer 2009Document4 pagesBrochure FPE Sale Straight Tunnel Freezer 2009Aries RezpectorNo ratings yet

- Foamglas Data Sheet EngDocument2 pagesFoamglas Data Sheet EngAnonymous yQ7SQrNo ratings yet

- Boil Off GasDocument6 pagesBoil Off GasJitendra singh palNo ratings yet

- Inspection and Test Plan - Cold Insulation Application & MaterialsDocument1 pageInspection and Test Plan - Cold Insulation Application & MaterialsDineshNo ratings yet

- Home About Us Products Process Application Quality Standards Enquiry Contact UsDocument1 pageHome About Us Products Process Application Quality Standards Enquiry Contact UsSravan DasariNo ratings yet

- Terms of Reference For Foundry RoofingDocument25 pagesTerms of Reference For Foundry RoofingImags GamiNo ratings yet

- Comprehensive Procurement Guidelines For Construction Products - US EPADocument19 pagesComprehensive Procurement Guidelines For Construction Products - US EPAAalaaNo ratings yet

- HMT Unit 1Document33 pagesHMT Unit 1Muthuvel MNo ratings yet

- SPD0007ERN - 2 - Basic Design PackageDocument16 pagesSPD0007ERN - 2 - Basic Design Packagechuntao fengNo ratings yet

- Traning On Building InsulationDocument48 pagesTraning On Building Insulationnaveen jainNo ratings yet

- 2017-02 ENG TECMAN Manuel-Technique-Pex-System COMAP-C Web PDFDocument56 pages2017-02 ENG TECMAN Manuel-Technique-Pex-System COMAP-C Web PDFDieter PolletNo ratings yet

- Examen+1+calor+th 16Document4 pagesExamen+1+calor+th 16Denisse M. ZamoraNo ratings yet