Professional Documents

Culture Documents

Membran Technology GMBH - Company Brochure E

Membran Technology GMBH - Company Brochure E

Uploaded by

stuntmanzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Membran Technology GMBH - Company Brochure E

Membran Technology GMBH - Company Brochure E

Uploaded by

stuntmanzCopyright:

Available Formats

BORSIG

MEMBRANE TECHNOLOGY

MEMBRANE

MEMBRANE TECHNOLOGY

TECHNOLOGY

FOR

FOR PROCESSES

PROCESSES AND

AND ENVIRONMENT

ENVIRONMENT

A Member of KNM Group Berhad

Our Products and Services

In many areas of the chemical, petrochemical, oil and gas industries,

membrane processes are the standard process that is used either as substitution or in combination with other process steps.

BORSIG Membrane Technology offers you modern, intelligent solutions for

new and existing processes. Taking the highest safety and quality standards

into consideration, our membranes, membrane modules and membrane

systems ensure safe plant operation and enable maximum efficiency and

optimum economic efficiency in the following applications:

EMISSION CONTROL

BORSIG Vapour Recovery Unit

VOC control for tank farms, marine loading and refineries

BORSIG Carbon Retrofit Unit

Retrofit of existing active carbon based recovery system

BORSIG Vent Recovery System

Product loss reduction at retail stations

10

PRODUCT RECOVERY

12

BORSIG Ethylene Recovery Unit

Ethylene recovery for production of polyethylene (PE) and

production of ethylene oxide (EO) and vinyl acetate monomer (VAM)

13

BORSIG Propylene Recovery Unit

Propylene recovery for production of polypropylene (PP)

14

BORSIG Hydrocarbon Recovery Unit

Recovery of valuable hydrocarbon products

15

GAS CONDITIONING

16

BORSIG Fuel Gas Conditioning

Gas treatment for pipeline, gas engine and turbine applications

17

BORSIG Oxygen Enrichment

Oxygen enrichment for combustion processes

18

BORSIG Gas Separation

Bulk separation of gas stream

18

BORSIG Biogas Processing

Membranes and systems for biogas treatment

19

LIQUID SEPARATION

20

BORSIG Nanofiltration

Innovative liquid filtration and separation by solvent resistant membrane

ENGINEERING AND SERVICES

24/25

BORSIG Membrane Technology GmbH, a member of the BORSIG Group,

About BORSIG

Membrane Technology

Berlin/Germany, is an internationally successful company that offers its

customers leading innovative membrane technology solutions for a wide

range of industrial applications.

Our products membranes, membrane modules and complete membrane

systems are synonymous for high quality, competence and reliability. Our

portfolio ranges from process simulation to the delivery of complete turnkey

systems and comprehensive after-sales services.

Our staff have been developing and offering intelligent process solutions for

more than 20 years. At two sites in Gladbeck/Germany and Rheinfelden/

Germany, highly qualified teams apply state-of-the-art production and engineering methods in order to produce membranes and to develop new tailormade solutions for your processes or to optimise processes already installed.

Our services focus on controlling the entire production processes and ensuring smooth workflows and time monitoring. Quality assurance, occupational health and safety, as well as environmental protection are top priorities at

all times. Our own staff co-ordinate all work steps, such as technical specifications, purchasing, production, assembly and commissioning.

With an expertise reflected by hundreds of industry-scale membrane systems

delivered to customers all over the world, BORSIG Membrane Technology is

the professional partner for your projects.

For other products and more information please visit our corporate website:

www.borsig.de

Membrane Technology

Today membrane-based separation processes are state-of-theart and in some areas this technology has become the leading

process solution. This was made possible by the development

and continuous improvement of efficient and selective polymer

membranes that ensure the thermal, chemical and mechanical

stability necessary for industrial use. Integrating the membranes

into suitable module designs ensure reliable and safe operation.

Membranes are used in many applications in the chemical,

petrochemical and oil/gas industries where liquid or gaseous

mixtures containing hydrocarbons must be treated. This can

serve recycling, emission protection or other operational requirements.

One milestone on this way was the successful implementation

of the gaspermeation process for selectively separating organic vapours from exhaust air, especially the treatment of

vapours released during the distribution and storage of highly

volatile hydrocarbons.

Accompanied by related environmental protection legislation in

the field of gasoline, a large number of membrane systems has

been installed and successfully operated since 1988, making

membrane technology today a leading technology in the field of

industrial gasoline vapour recovery.

Membrane Technology

Based on this experience, further gaspermeation applications

were successfully implemented in recent years, for example, in

the olefin industry. Today hundreds of industry-scale plants

using BORSIG technology are successfully in operation.

Besides gaspermeation BORSIG Membrane Technology

entered a new challenging technology - the treatment of liquid

hydrocarbons streams by the innovative organophilic nanofiltration process.

For all these applications BORSIG Membrane Technology offers

membranes and module types. Together with our partners and

within the framework of R&D programmes, we are pursuing

dedicated development efforts in order to continue offering our

customers innovative and cost saving solutions in the future.

BORSIG Membrane Technology offers:

Stability tests and permeation measurements

Targeted membrane screening and development

Membranes, modules and membrane systems for gas

separation

Membranes and modules for organophilic nanofiltration

Test modules and test systems

Comprehensive process solutions

Emission Control

Volatile Organic Compounds (VOC), defined as a large family of

hydrocarbons with high volatility, occur naturally and are produced in

many industrial processes. In a wide range of industrial applications,

e.g. such as oil & gas industry, chemical industry and petrochemical

industry the use of VOC leads to substantial emissions mainly caused

by evaporation, displacement and purge procedures.

These emissions of volatile organic compounds (VOC) can cause

significant health risks, e.g. they are toxic and carcinogenic.

Additionally they are known as precursor substances for ozone gas,

causing summer smog and thereby contributing to global warming. In

order to protect man and his environment, suitable measures must

hence be taken in order to minimise the resultant emissions.

The use, storage and distribution of solvents and petroleum products

have been identified as the most significant sources for VOC

emissions. Displacement and evaporation processes affect the

release of organic vapours, which are in most cases mixed with air or

other permanent gas. Typical products are

Solvents

All kind of gasoline

Additives

Diesel, jet fuel

Alcohols

Bio fuels

Crude oil

Worldwide corresponding regulations and emissions laws are implemented to drastically minimise the VOC emissions by the reduction of

VOC consumption and by the installation of emission control systems.

Parallel the industrial operators also focus on these topics to express

their ecologically oriented production philosophy.

Emission Control

Very often the installation of emission control systems goes

along with economic benefits, e.g. when installing vapour recovery units to recover or liquefy the VOC vapours for reuse.

The recovered product value or other associated effects can

affect the profitability and return on investment (ROI). One

example is the tax-refund, which will be granted in some countries, when the vapours of already taxed products are recovered

and returned into the distribution chain.

BORSIG Membrane Technology offers emission control solutions with maximum recovery rates of up to 99.9% and thereby

enables compliance with all customary emission standards

worldwide whilst also fulfilling the highest quality, safety and

reliability demands.

BORSIG Membrane Technology's portfolio in the field of

emissions protection includes:

BORSIG Vapour Recovery Unit (VRU)

VOC control for tank farms, marine loading and refineries

BORSIG Carbon Retrofit Unit (CRU)

Retrofit of existing active carbon based recovery system

BORSIG Vent Recovery System (VRS)

Product loss reduction at retail stations

Emission Control

BORSIG Vapour Recovery Unit

VOC control for tank farms, marine loading and refineries

The Application

During storage and distribution of petroleum products large

streams of vapours are released by evaporation and displacement procedures, e.g. by truck-, railcar- or ship loading applications. According to the common emission legislations and technical guidelines these vapours must be treated preferably in

vapour recovery units. Typical products include:

Gasoline (all grades)

ETBE, MTBE, all kind of additives

Diesel, jet fuel

Intermediate products, e.g. reformate, naphtha etc.

Ethanol, methanol

Chemicals, solvents

Due to the high volatility and therefore high concentration of the

vapours a substantial product loss is affected and also corresponding strict emission limits have been defined to avoid the

emission of these harmful substances, e.g.

European Directive 94/EC/63

German TA-Luft and BImSchG

Swiss LRV

US EPA

Modern vapour recovery units must fulfil all these latest requirements as well as further options to allow a flexible and most economical operation:

Fulfil highest safety demands to process explosive vapours

Recovery of pure product vapours but also of mixed products

vapours

Considering the pre-loading of vessels and railcars

Treatment of conventional gasoline vapours

Compatibility with new gasoline specifications,

e.g. Ethanol 85, bio fuels

Highest flexibility regarding future expansion of customers

product portfolio or changing specifications

Emission Control

BORSIG Vapour Recovery Unit

The BORSIG Solution

The BORSIG Vapour Recovery Unit (VRU) is based on a combination of

absorption or condensation and membrane separation. Main equipment

are liquid ring compressor, scrubber, membrane separation stage and

vacuum pump. The BORSIG VRU process enables an effective treatment

of the vapours meeting the required emission level.

The vapour/air mixture is taken into the VRU by the liquid ring compressor and is mixed with the membrane recycle stream. The compressor

compresses the mixture to the required discharge pressure using a part

of the absorbent stream as liquid hydrocarbon seal that creates a noncontact seal ring and removes the heat of compression from the gas

stream. The compressed gas is discharged together with the ring liquid

into the absorption column, where vapours get into contact with the external absorbent flow and the liquefaction of the vapours is effected by condensation and absorption effects. The non-liquefied vapour stream leaves

the column at the top and enters the membrane separation modules.

Supported by the vacuum pump the membrane stage enables a final

cleaning of the vapour stream and the separated enriched hydrocarbon

vapours are recycled to the compressor inlet, which enables an inherent

safety principle by enrichment of the VRU inlet stream. Further vapour

cleaning can also be achieved by additional polishing stages.

BORSIG VRUs are equipped with high quality machinery and materials

only. The combination with most reliable instrumentation and latest stateof-the-art control systems makes it suitable for all applications and

products.

Advantages & Benefits

Most compact and modular design

Unique inherent safety principle

High efficiency of recovery

Customised to meet individual applications

Considering customers codes & standards

Flexible and safe for all products

Flexible for emission changes due to modular process design

Low maintenance due to machinery and material selection

(e.g. use of stainless steel)

Highest reliability due to high quality equipment and control

Self-in-taking principle enables minimised costs for customers

vapour piping

Emission Control

BORSIG Carbon Retrofit Unit

Retrofit of existing active carbon based recovery system

The Application

In existing vapour recovery units based on active carbon adsorption technology the adsorbers are designed for a

maximum mass flow of hydrocarbons before being desorbed again. Practical experience has shown that operators

are facing frequently the following difficulties:

Customer needs more capacity, e.g. due to increased transshipment

The performance of the existing unit is not efficient enough to meet the required emission level

New product vapours have negative impact on the active carbon or cannot be adsorbed and must be separated

before entering the adsorbers

Safety risks related to potential dangerous exothermic reactions shall be prevented.

The BORSIG Solution

The Carbon Retrofit Unit significantly reduces the hydrocarbon concentration and mass flow entering the adsorbers. The separated enriched stream is bypassing the adsorbers and directly entering the existing absorption

system (scrubber). This enables adsorber performance increase and debottlenecking.

The Carbon Retrofit Unit is installed upstream the existing active carbon system. The vapour stream is separated

by the membrane unit into two streams. The stream passing through the membrane material is highly enriched with

hydrocarbons and is given directly into the existing scrubber part of the carbon unit, where the hydrocarbons are

liquefied. The light stream is entering the existing adsorbers. The integration of the Carbon Retrofit Unit is easy

and cost effective with only minor modifications of the existing active-carbon-based vapour recovery unit. The retrofit system mainly consists of the membrane unit, a vacuum pump and an optional blower.

Advantages and Benefits

Tremendous reduction of hydrocarbon mass flow to the carbon beds

Increased safety of the carbon VRU due to the reduction of exothermic reactions in the carbon beds

Substantial increase of the capacity of the retrofitted system

Increased efficiency and lower emission level

Pre-assembled skid-mounted design

Easy implementation

Low maintenance

Reduced specific power consumption

10

Emission Control

BORSIG Vent Recovery System

Product loss reduction at retail stations

The Application

On car filling stations three main sources for VOC emissions are

identified:

Emissions caused by storage tank filling

Typically these emissions can be minimised by so-called

Stage I measures, by balancing the vapours released

during the filling between the underground storage tank and

the filling truck.

Emissions caused by car tank filling

The emissions caused by released vapours from car tank

can be reduced by a conventional Stage II vapour return to

the storage tank enabled by vapour suction integrated in

the filling nozzle. Sometimes a limited efficiency of vapour

collection affects the suction of air into the storage tank and

therefore leads to further evaporation of the storage product.

Storage Tank Breathing

Temperature affected breathing and vaporisation in the

storage tank leads to increased tank pressure and therefore

to vent stack emissions to the atmosphere.

11

Emission Control

BORSIG Vent Recovery System

Nowadays more and more local regulations require the control of the entire sealing of car filling stations and the reduction of corresponding leakage losses,

which can cause a product loss (wet stock loss) of up to 0,5% of the car filling

stations throughput and sometimes more. Furthermore these losses have an

impact on our environment as well as on the safety in operating car filling

stations, while hazardous products and the vapours are handled and emitted.

The BORSIG Solution

BORSIG Membrane Technology developed an innovative enhanced add-on

system enabling the increase of the vapour return ratio from the car nozzle to

the storage tank for more efficient vapour collection. The BORSIG VRS is connected to the vent stack to treat the vented air/gasoline vapours. Proven membrane technology generates two streams and selectively separates the air from

the hydrocarbon molecules. The valuable gasoline fraction is returned to the storage to keep the gas phase saturated and even to liquefy the gasoline vapours

when the due point is reached. The cleaned air is released to the atmosphere.

Advantages and Benefits

Proven reduction of wet stock losses by 95%, measured by third party

Increased safety of car filling stations

Better prospects of obtaining planning permission from the authorities

and improved neighbourhood acceptance for filling stations

Reduced exposure of customers to hydrocarbon vapours during car fuelling.

Substantial pay back related to the yearly gasoline throughput

Improved marketing image of the operator

Elimination of direct stack emission

Monitoring of the car filling station tightness and function

12

Product Recovery

Product recovery systems must meet with evermore demanding efficiency

requirements. Economic efficiency, productivity, improved sustainability of

technological processes, as well as optimum utilisation of our resources are

key challenges in this for the industry.

BORSIG Membrane Technology offers optimum solutions here which helps

minimising losses, to recover valuable raw materials or products from

exhaust air or process gas flows and their recycling into the production process and therefore enables:

- Recovery of valuable feedstock and product

- Significant reduction of waste and flare gas capacities

Important products and applications include:

Ethylene monomer from polyethylene (HDPE, LDPE, etc.), EO or VAM

productions

Propylene monomer from polypropylene production

Solvent (Butane, Hexane etc.) from slurry-type polymer production

processes

Vinyl chloride monomer (VCM) from PVC production

Aromatics (Benzene, Toluene, Xylene etc.) from production and storage

MTBE, ETBE

Fluoro & Chloro Hydrocarbons from any related processes

Methanol, Ethanol

Bio-Fuels from production & storage

Our products include:

BORSIG Ethylene Recovery Unit

Ethylene monomer recovery for polyethylene (PE), ethylene oxide (EO) production

BORSIG Propylene Recovery Unit

Propylene monomer recovery for polypropylene (PP) production

BORSIG Hydrocarbon Recovery Unit

Recovery of valuable hydrocarbon products

13

Product Recovery

BORSIG Ethylene Recovery Unit

Ethylene recovery for production of polyethylene (PE) and

production of ethylene oxide (EO) and vinyl acetate monomer (VAM)

The Application

During the production of polyethylene (PE) one typical process

step is the degassing of PE powder and downstream pressure

condensation to condensate hydrocarbons. The residual purge

gas stream is still rich on non-condensable hydrocarbons and

monomer. To prevent enrichment of inert gas a side stream is

typically sent to the flare and also effects a loss of monomer and

hydrocarbons.

Similar purge gas streams can be identified in vinyl acetate

monomer (VAM) and ethylene oxide (EO) processes. For example the inert gas Argon must be purged out of the process to

prevent enrichment. Furthermore internal distillation overhead

vents and other reactor purges can be treated.

All these procedure effect

- substantial loss of ethylene monomer and of other solvents

- increased flare gas streams and therefore secondary

emissions to the atmosphere

The BORSIG Solution

The BORSIG Ethylene Recovery technology is an easy add-on

system and can be considered in existing and new process

installations. The purge gas stream, typically pressurized and

containing the ethylene monomer and disturbing inert gas, is fed

into the membrane system, while the permeate side of the membrane separation stage is fed back to the existing process gas

compressors suction side. By means of the resulting pressure

difference and the hydrocarbon selective membrane material,

the purge gas stream is separated into the inert gas enriched off

gas and the recycled ethylene-rich permeate stream. Typically

no other equipment or machinery is required, which results in a

very simple and reliable process solution.

Advantages & Benefits

Easy installation in new plants and easy retrofit of existing

systems

Easiest solution Key equipment membrane separator only

Quick installation and easy implementation by skid-mounted

modular design

Very short payback period

Low maintenance

Safe and reliable operation

Tailor-made design to meet customers codes and

specifications

14

Product Recovery

BORSIG Propylene Recovery Unit

Propylene recovery for production of polypropylene (PP)

The Application

During the production of polypropylene (PP) one typical process

step is the degassing of PP resin in the resin bin in order to

purge out non-reacted propylene monomer. Typically nitrogen is

used and continuous purge streams containing substantial content of monomer have to processed to minimise the loss of profit and the required flare gas capacities:

-

Substantial loss of propylene monomer

Increased flare gas streams and therefore secondary

emissions to the atmosphere

The BORSIG Solution

The BORSIG Propylene Recovery technology is an easy add-on

system and can be considered in existing and new process

installations. The purge gas stream compressed and condensed

in the downstream condenser stage, which might be cooled with

cooling agent or liquid propylene. For some PP production

licenses an additional dryer system must be installed prior to

condensation. After separating the condensate the remaining

purge gas is fed into the membrane system, while the permeate side of the membrane separation stage is fed back to

compressors suction side. By means of the resulting pressure

difference and the hydrocarbon selective membrane material,

the purge gas stream is separated into the purified nitrogen

stream and the recycled propylene-rich permeate stream. A

small part of the separated stream is sent to the flare to prevent

accumulation of lighter components.

The process system consists beside the required membrane

stage, mainly of compressor and condensation unit, fully designed as package unit with dedicated PLC. Sometimes dryers

and transfer liquid pumps are installed to meet specific clients

requirements.

Advantages & Benefits

Recovery rates > 95% Propylene and purity > 99 mol.%

Nitrogen

Short payback periods in order of 1-3 years

Safe operation, high reliability, low maintenance

Tailor-made design to specific plants conditions and local

regulations

Quick installation and easy implementation through package

unit design

Feasibility for adaption into existing plants (retrofit design)

15

Product Recovery

BORSIG Hydrocarbon Recovery Unit

Recovery of valuable hydrocarbon products

The Application

In many petrochemical/chemical productions process streams

are generated containing significant amounts of hydrocarbons,

such as solvents, alcohols, aromatics etc. Typically these hydrocarbons are mixed in inert gas streams and must be treated in

order to meet following typical targets:

-

to meet off-gas conditions according to emission legislations

to recover the valuable hydrocarbon content and therefore

minimise the loss of product and profit

to meet the inlet conditions of any downstream process steps

and systems

The BORSIG Solution

The BORSIG Hydrocarbon Recovery technology is a portfolio of

specially developed and customised process solution to meet

the targets. Typically the membrane separation is combined with

other unit operations, such as absorption, condensation, extraction etc. These hybrid processes are very efficient and enable

the customer to operate his process with highest economically

and ecologically efficiency.

A typical application is the powder degassing in slurry-type PE

plants. Polymer is flashed and stripped with hot nitrogen and the

released purge gas existing of nitrogen and solvents like butane, pentane or hexane can be processed by a sophisticated

BORSIG Hydrocarbon Recovery process.

The liquefied solvent and the nitrogen can be provided for reuse with highest purity.

Advantages & Benefits

Flexible system for multiple components handling

Highest product purities

Stand-alone solution possible

Moderate pressures and temperatures applied for required

condensation

Safe operation, high reliability, low maintenance

Modular design to meet specific plants conditions and local

regulations

Quick installation and easy implementation by package unit

design

Feasibility for adoption to existing plants (retrofit design)

16

Gas Conditioning

BORSIG Membrane Technology offers the possibility to treat

gas flows in oil and gas production applications. The aim is to

condition raw gas flows or to improve product quality to comply

with customers gas specifications, pipeline specifications or

calorific-value requirements.

The required gas quality is typically specified by defining

methane content, pressure dew points, calorific values or a minimum methane number. These quality parameters are typically

determined by the share of higher hydrocarbons (C3+), CO2 or

O2 in the gas.

The possibilities offered by BORSIG Membrane Technology at a

glance:

BORSIG Fuel Gas Conditioning

Gas treatment for pipeline, gas engine and turbine

applications

BORSIG Oxygen Enrichment

Oxygen enrichment for combustion processes

BORSIG Gas Separation

Bulk separation of gas stream

BORSIG Biogas Processing

Membranes and systems for biogas treatment

Process concepts in addition or as an alternative to conventional process solutions.

17

Gas Conditioning

BORSIG Fuel Gas Conditioning

Gas treatment for pipeline, gas engine and turbine applications

Fuel gas taken from the sources available at site and in particular in remote production locations often does not meet the high quality standards

required for pipeline injection or for utilisation in modern high efficiency

gas turbines or engines.

The Application

The fuel gas quality is typically specified in terms of minimum methane

content, methane number, dew point or calorific value or other closely related parameters. All these parameters are determined by the content of

higher hydrocarbons in the fuel gas. Hence in order to increase the fuel

gas quality with respect to these parameters a selective removal or significant reduction of the content of these C3+ components is desired.

The BORSIG Solution

The BORSIG membrane technology for hydrocarbon separation provides

a simple, cost saving and highly reliable solution for fuel gas upgrading

and calorific value control.

The raw gas is taken directly out of a high pressure line at site or compressed by a separate compressor and routed to the membrane unit.

The heavier hydrocarbons (C3+) are separated preferentially and are concentrated on the low pressure side of the membrane, whereas the lighter

components, mainly the methane and ethane, remain at high pressure.

This lean residue of the membrane provides the high quality fuel gas to

be utilised in the gas motor or turbine or to be injected into a respective

pipeline. The enriched permeate stream is routed to a low pressure line at

site or typically recycled to the compressor suction.

Because the membrane provides also a separation capability for water

the membrane will also allow a certain degree of dehydration simultaneously with the hydrocarbon separation. This may be sufficient to

achieve the required water dewpoint specification and to reduce the risk

of hydrate formation.

Advantages & Benefits

High C3+ removal

High equipment reliability and on-stream availability

Completely assembled compact process units

Easy integration into existing facilities

Minimum of supervision and maintenance

Prolonged life time of gas turbines or engines and related components

Particularly suitable for offshore applications and remote locations

18

Gas Conditioning

BORSIG Oxygen Enrichment

BORSIG Gas Separation

Oxygen enrichment for combustion processes

Various processes requiring oxygen are just being fed with air.

Typically higher process efficiency or product yields can be

achieved when operating these processes with a gas stream

with higher oxygen content than provided by ambient air.

The BORSIG membrane technology provides an attractive solution to generate oxygen enriched feed gas streams utilised for

instance in combustion or chemical process applications.

Bulk separation of gas stream

CO2 SEPARATION

CO2 gas separation applications are found within a wide range

of operating pressures and feed gas compositions. Typically in

dependence on the actual application also the requirements

regarding product purity and separation efficiency do vary within

a wide range. Main applications are for instance biogas and

natural gas treatment or more general CO2 separation/recovery

from process off gas streams. The membrane technology provides efficient and cost effective solutions for CO2 separation in

a wide range of these applications.

Natural Gas Treatment

Nowadays a significantly increased percentage of worldwide

gas production is dealing with natural gas containing considerable amounts of CO2. A typical CO2 content is within the

range of 5 to 15 %. In order to maintain the gas quality and to

meet pipeline specification requirements efficient and economically viable CO2 separation technologies have to be applied.

For a wide range of applications in particular for small and medium gas flow rates the membrane technology can provide

interesting process concepts in addition or as an alternative to

conventional process solutions.

Biogas

Plant

Biogas

Treatment / U

Raw

Bio-gas

Biogas

production

Filter/

Coalescer

free water

removal

Gas

compression

19

Gas Conditioning

BORSIG Biogas Processing

Membranes and systems for biogas treatment

With the recently increasing efforts to utilise renewable energy

sources biogas is considered to be one of the major options for

providing a significant share in the modern energy mix. To use

this source the produced raw-biogas is processed and treated in

order to meet the gas specifications required for utilisation.

The Application

A raw-biogas generated by fermentation contains methane (typically 50 to 60 %) and CO2. In order to utilise the bio-methane

for the injection in the gas distribution network or as fuel gas for

motors or turbines for energy production the raw biogas is treated and upgraded accordingly.

The BORSIG Solution

The BORSIG membrane and process technology enables an

efficient CO2/methane separation process to provide the product gas at the required purity while reducing the loss of methane.

s

pgrade

Product Gas

Bio-Methane

CO2/

methane

separation

Membrane

Unit

Lean

Off-gas

Utilisation /

Treatment

Network

Operator

Gas Network

Compression,

meetering,

odoration etc

The biogas treatment process set-up comprises

Filter/coalescer for free water removal

Desulphurisation if required to meet respective pipeline

specifications of network operator

Gas compression

Membrane separation

Product gas metering and conditioning (odoration, etc.)

to be provided by network operator

Advantages & Benefits

Reduced scope of equipment, reduced size and weight

Minimum mechanical complexity:

Static system / no moving parts / easy to operate

No additional chemicals or refrigerants required

Flexible modular design

Completely prefabricated containerised solution ready for

installation and operation

These advantages allow attractive process solutions for biogas

processing already for operators of biogas plants within the

lower capacity range.

20

Liquid Separation

BORSIG Nanofiltration

Innovative liquid filtration and separation by solvent resistant membrane

Chemical resistant membrane materials, in combination with innovative technology to

modify surfaces for specific purposes, enable a wide range of new promising applications for membrane separation processes.

Based on these developments Organophilic Nanofiltration (oNF) offers attractive solutions for challenging separations in the molecular range between ultrafiltration and reverse osmosis, focusing on treatment of organic liquids.

As alternative to or in combination with conventional separation operations, solvent resistant membranes provide the opportunity of highly efficient process installations for the

selective separation of liquid organic mixtures.

BORSIG Membrane Technology provides composite membranes with excellent performance to meet high requirements in nanofiltration applications. Based on our know-how

and experience in process design and engineering various applications have been already implemented.

Features and Advantages of our oNF-Membranes:

Outstanding performance with regard to permeability and selectivity

Chemical resistance to organic media e.g.:

Alkanes (Hexane, etc.)

Aromatics (Toluene, etc.)

Alcohols (Ethanol, etc.)

Ether

(THF, etc.)

Ketones (Acetone, etc.)

Ester

(Ethylacetate, etc.)

Long-term durability

Mechanical stability in a wide range of pressures and temperatures

Easy configuration for different types of modules

21

Applications (Examples)

Recovery of homogenous catalysts from reaction mixtures

Conditioning of liquid hydrocarbons

Purification of organic solvents

Product separation in edible oil industries

The cooperation with our partner enables us to provide tailor-made membranes for specific applications. This is accomplished using comprehensive know-how on molecular

surface design (MSE-Technology: Molecular Surface Engineering).

Highly sophisticated test units and advanced analytics ensure the optimised selection

and reliable evaluation of membranes.

Membrane production and supply of required membrane modules in envelope or spiral

wound type design is provided by BORSIG Membrane Technology to all international

codes and standards.

Our Services at a glance

Evaluation of your separation problem and technical support by our experts

Lab-scale membrane tests (chemical resistance, membrane screening, feasibility

studies)

Development and optimisation of nanofiltration membranes for your specific

application

In-house membrane and module manufacturing

Pilot scale field tests

Process design (basic engineering)

Detail engineering and construction

Process units (pilot scale, production process systems)

22

Liquid Separation

BORSIG Nanofiltration

Organophilic Nanofiltration Test Rig

Features

Cell design enables defined cross-flow velocities

Reproducible test results

Simultaneous testing of two membranes possible

Feed, retentate and permeate sampling (during unit operating)

Automated unit control & monitoring

Computer-aided data processing & documentation

Temperature-controlled tests

Scope of Applications

Membrane screening & characterisation

Long-term performance tests

Determination of reliable scale-up parameters for industrial

modules

Optimisation tests for industrial process parameters

Small-scale production and processing for product evaluation

(purification, concentration)

Operating Conditions

Pressure range:

Temperature range:

Feed flow rate:

Feed volume:

0-40 bar

0-100 C

up to 200 l/h

7.5 l

23

24

Engineering and Services

BORSIG Membrane Technology offers its customers in the

oil/gas-, petrochemical and chemical industry a comprehensive

service package or individual services, so that you can fully

focus on your core competence.

Our service team is trained according to SCC and VCA and consists of seasoned engineers and technicians who are in charge

of plants and installations worldwide. Thanks to our many years

of experience in servicing industrial plants and the required

multidisciplinary competence in process engineering, plant

design, control and instrumentation, as well as explosion protection, we know what matters.

We offer you reliability, economic efficiency and protection for

your assets. We can perform or co-ordinate all services ourselves and are hence capable of making optimum use of synergies. The basic requirement for optimum plant efficiency and for

avoiding non-scheduled downtime is regular inspections and the

checking of all functions and installation parts subject to wear by

competent experts. Innovative measuring and analysis methods

help to avoid failures and breakdowns. Using software-supported systems for maintenance and service scheduling, we

develop with you specific strategies for your particular application in order to establish perfectly timed and cost saving maintenance and service intervals. These made-to-measure concepts ensure that plant availability and productivity increase,

environmental burdens become fewer, and maintenance costs

drop significantly.

Vapour

Recovery

Unit

Feed

20,00 C

1,010 kg/cm2

1000 ACT_m3/h

Gasoline

Vapours

440,6 C

7,138 kg/cm2

5,199 m3/h

10,00 C

7,036 kg/cm2

Valve-01

Feed

Compressor

Mixer-01

Absorbent

Mixe

in

25,13 C

1,050 kg/cm2

23,36 m3/h

25,13 C

1,050 kg/cm2

1306 kgmole/h

Mixer-03

Mixer-02

Heat

Exchanger-100 Vessel-01

23,00 C

1,050 kg/cm2

1,000 kg/h

Makeup

water

Gas

in

Pump-01

35,30

140,4

35,30 C

7,138 kg/cm

89,50 kg/h

Vesse

Tee-01

47,95 m3/h

20,00 C

1,033 kg/cm2

Cooling

water

in

20,00 C

0,9310 kg/cm2

Cooling

water

out

35,30 C

7,138 kg/cm2

11,98 kg/h

25

Engineering and Services

Performance

VRU Feed g/Nm 597,7

Retentate g/Nm 6,829

15,18 C

7,036 kg/cm2

124,4 m3/h

HC (Vol.)

19,99

HC Recovery

99,95

Retentate

Gas

out Membrane-01

er-05

11,15

0,1530

240,5

1688

0 C

4 ACT_m3/h

C

kg/cm2

Nm3/h

ACT_m3/h

Permeate

2,910 kg/h

24,05 C

7,138 kg/cm2

m2

Off

Gas

Valve-04

Absorber

Absorbent

out

9,810 C

6,832 kg/cm2

89,78 ACT_m3/h

3629 kg/h

Valve-02 633,3 kg/m3

el-02

Recovered

Hydrocarbon

14,89 kg/h

33,10 C

7,138 kg/cm2

24,32 C

7,138 kg/cm2

Mixer-04

Valve-03

Process

water

out

Process development and optimisation

Basic- and detail engineering

Process control and visualisation

Erection and commissioning of plants and systems

Operator training

After-sales-services, maintenance and trouble-shooting

in accordance with DIN EN 13306

Maintenance and trouble-shooting of third-party vapour

recovery units

Plant-specific maintenance contracts and spare-parts

management

Standby service and remote-service for software

updates and trouble-analyses

Process optimisation of existing plants and systems

Hazard and operability studies (HAZOP) of BORSIG and

third-party VRUs and other plants and systems, IPF analysis

Pressure vessel tests in co-operation with responsible

authorities

Performance tests of BORSIG and third-party plants and

systems, including gas and emission- and capacity

measurement, gas analyses

Emission reports for refineries and tank farms

BORSIG Membrane Technology GmbH

Bottroper Strasse 279

D-45964 Gladbeck/Germany

Am Rhein 5

D-79618 Rheinfelden/Germany

Phone +49 (0) 2043 / 4006-01

Fax

+49 (0) 2043 / 4006-6299

E-mail info@borsig-mt.com

Phone +49 (0) 7623 / 96609-0

Fax

+49 (0) 7623 / 96609-50

http:// www.borsig.de

Edition: BMT-EN-2010-09

You might also like

- How CPRS WorksDocument19 pagesHow CPRS WorksAnonymous i3xDz4TNo ratings yet

- Biological Treatment WastewaterDocument183 pagesBiological Treatment WastewaterAgentia Imobiliara InterestNo ratings yet

- TorayDocument8 pagesTorayWildan Novaldi IrawanNo ratings yet

- Anaerobic Digestion - Collins GavinDocument152 pagesAnaerobic Digestion - Collins Gavinivmc1985100% (1)

- Fixed Bed ReactorDocument63 pagesFixed Bed ReactorVishal Goswami100% (1)

- ASPEN Design of Vap-Liq Separator EdtDocument6 pagesASPEN Design of Vap-Liq Separator EdtethanNo ratings yet

- Fundamentals of Biological Wastewater Treatment - PrefaceDocument4 pagesFundamentals of Biological Wastewater Treatment - Prefaceabhi_nddNo ratings yet

- Advanced Chlor Alkali Electrolyzer With Cover Page v2Document101 pagesAdvanced Chlor Alkali Electrolyzer With Cover Page v2pmarteeneNo ratings yet

- DOWEXDocument93 pagesDOWEXjose antonio daza cedeñoNo ratings yet

- Wet Air OxidationDocument42 pagesWet Air OxidationSiddharth ChoksiNo ratings yet

- 2010 SMR ClarifierDocument60 pages2010 SMR ClarifierRohan Kakde100% (1)

- Practical Guide To The Optimisation of Chemical Dosing, Coagulation, Flocculation and ClarificationDocument5 pagesPractical Guide To The Optimisation of Chemical Dosing, Coagulation, Flocculation and ClarificationAdit JuliansyahNo ratings yet

- Coalesce RDocument4 pagesCoalesce Rrieza_fNo ratings yet

- Forward Osmosis System AnalysisDocument27 pagesForward Osmosis System AnalysisSyed Muztuza AliNo ratings yet

- Millipore MicrofiltrationDocument8 pagesMillipore MicrofiltrationMichael McNeelyNo ratings yet

- 10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)Document6 pages10.6. Liquid-Liquid Separation: 10.6.1. Decanters (Settlers)ashishkapoorsrmNo ratings yet

- Exploration & Production: TechnologyDocument36 pagesExploration & Production: Technologyidzham78No ratings yet

- Atmospheric CO2 To MethanolDocument16 pagesAtmospheric CO2 To MethanolMUTHU KESHAV KNo ratings yet

- D3860 Determination of Adsorptive Capacity of Activated Carbon by Aqueous Phase Isotherm TechniqueDocument4 pagesD3860 Determination of Adsorptive Capacity of Activated Carbon by Aqueous Phase Isotherm TechniqueLaura Torres ArtunduagaNo ratings yet

- Ultrafiltration For Oily Industrial Water: Separation Dynamics Paper SeriesDocument13 pagesUltrafiltration For Oily Industrial Water: Separation Dynamics Paper SeriesböhmitNo ratings yet

- Gas Sweetening and Processing FieldDocument6 pagesGas Sweetening and Processing FieldEdwin AguilarNo ratings yet

- Griffin LanzaTech - 20 July 2011 MASDocument17 pagesGriffin LanzaTech - 20 July 2011 MASNitin ThakurNo ratings yet

- Membrane MBR - Depliant 1Document8 pagesMembrane MBR - Depliant 1gsaviNo ratings yet

- Anaerobic Biological Wastewater TreatmentDocument4 pagesAnaerobic Biological Wastewater TreatmentKhalilRoumaniNo ratings yet

- PuROMax Commercial RO Instructions 2015Document49 pagesPuROMax Commercial RO Instructions 2015Jcc ChoNo ratings yet

- Concepts of GCDocument187 pagesConcepts of GCanoiring55No ratings yet

- What Does Choke Valve MeanDocument5 pagesWhat Does Choke Valve MeanWael_Barakat_3179No ratings yet

- Water Treatment For HemodialysisDocument3 pagesWater Treatment For Hemodialysismisya23No ratings yet

- CECO Filters - Ammonium Nitrate Applications ManualDocument35 pagesCECO Filters - Ammonium Nitrate Applications ManualabsahkahNo ratings yet

- Amberjet 4200 DatasheetDocument2 pagesAmberjet 4200 DatasheetXiaLUNo ratings yet

- TDM User GuideDocument133 pagesTDM User Guidemfruge7No ratings yet

- Understanding On Line Amperometric Chlorine MeasurementsDocument15 pagesUnderstanding On Line Amperometric Chlorine MeasurementsAndrea GómezNo ratings yet

- Melt CrystallizationDocument10 pagesMelt Crystallizationarsh19706636No ratings yet

- Bachmann Sheehan 71: and TR Lzs-A 7-Pregnadiene-3Document4 pagesBachmann Sheehan 71: and TR Lzs-A 7-Pregnadiene-3wakanda foreverNo ratings yet

- Lys Ark Rusten 2010Document26 pagesLys Ark Rusten 2010mbsahgNo ratings yet

- GBH Enterprises, LTD.: GBHE-PEG-RXT-806Document7 pagesGBH Enterprises, LTD.: GBHE-PEG-RXT-806Sankar SasmalNo ratings yet

- Colloidal Silica Removal in Coagulation - PubMed MobileDocument1 pageColloidal Silica Removal in Coagulation - PubMed MobileSandeep MishraNo ratings yet

- Drilling Formulas Calculation Sheet Verson 1.3Document189 pagesDrilling Formulas Calculation Sheet Verson 1.3Manosay IgnatiusNo ratings yet

- CES - Safe Handling of ChlorosilanesDocument26 pagesCES - Safe Handling of ChlorosilanesWilliam ChangNo ratings yet

- Tittel: A/S Norske Shell E&P Ormen LangeDocument15 pagesTittel: A/S Norske Shell E&P Ormen LangeArchanaa RaghuramanNo ratings yet

- Thesis M. DaftaribesheliDocument170 pagesThesis M. Daftaribesheliindramani100% (1)

- Rev 2 Tank Volumen Calculation SheetsDocument11 pagesRev 2 Tank Volumen Calculation SheetsAb de VriesNo ratings yet

- Packed Bed2Document61 pagesPacked Bed2rvsingh100% (4)

- Aqua BaseDocument8 pagesAqua BasejpfamiliabNo ratings yet

- Taste Masking by Ion Exchange Resin and Its New Applications A ReviewDocument16 pagesTaste Masking by Ion Exchange Resin and Its New Applications A ReviewNhonPhanThanhNo ratings yet

- Hosokawa Micron Develop Mikro ACM Mills For Processing High Fat Content Cocoa or Other Sticky Food ProductsDocument1 pageHosokawa Micron Develop Mikro ACM Mills For Processing High Fat Content Cocoa or Other Sticky Food ProductsRaza Un NabiNo ratings yet

- Reverse Osmosis: Pavanmandapaka Asst. Professor Dept. of Civil & Envt. Engg. Upes, DehradunDocument21 pagesReverse Osmosis: Pavanmandapaka Asst. Professor Dept. of Civil & Envt. Engg. Upes, DehradunKetan BajajNo ratings yet

- DEMCON Method (For Evaluating Demulsifier Performance)Document17 pagesDEMCON Method (For Evaluating Demulsifier Performance)odracir091865No ratings yet

- CPVCDocument3 pagesCPVCGraceNo ratings yet

- DESULFURIZATIONDocument58 pagesDESULFURIZATIONMukul GoyalNo ratings yet

- Catrdige Filter Cost Chang OutDocument4 pagesCatrdige Filter Cost Chang OutmigelNo ratings yet

- Ceca Newsletter April 2012Document1 pageCeca Newsletter April 2012ghasem_726990287No ratings yet

- Growth Kinetics of Oleaginous Yeast, Rhodosporidium Toruloides, in High Salinity ConditionDocument79 pagesGrowth Kinetics of Oleaginous Yeast, Rhodosporidium Toruloides, in High Salinity ConditionShimme7No ratings yet

- 1.3 Coriollis PDFDocument12 pages1.3 Coriollis PDFAsahel NuñezNo ratings yet

- Mono BeltDocument4 pagesMono BeltAlexandru IgnatNo ratings yet

- BORSIG Membrane Technology GMBH EDocument52 pagesBORSIG Membrane Technology GMBH Estalindcunha1No ratings yet

- BREAXIT Emulsion Breakers: Oilfield Separation TechnologiesDocument8 pagesBREAXIT Emulsion Breakers: Oilfield Separation TechnologiesptstradingNo ratings yet

- KVTBrochure 19122012 PDFDocument12 pagesKVTBrochure 19122012 PDFvb_pol@yahooNo ratings yet

- Submerged OverviewDocument3 pagesSubmerged OverviewkapasomiraNo ratings yet

- 57 240.0 SingleDualSealStandardsDocument4 pages57 240.0 SingleDualSealStandardsstuntmanzNo ratings yet

- FIN CatalogDocument2 pagesFIN CatalogstuntmanzNo ratings yet

- Reindl PDFDocument6 pagesReindl PDFstuntmanzNo ratings yet

- Aace Classification SystemDocument11 pagesAace Classification SystemstuntmanzNo ratings yet

- Design of Compressor Suction Scrubbers - Noijen - ClintonDocument44 pagesDesign of Compressor Suction Scrubbers - Noijen - ClintonNirma Afrisanti KinasihNo ratings yet

- The History of SRMDocument9 pagesThe History of SRMstuntmanzNo ratings yet

- Model: Smartstat: Feature Table - Thermostat ModeDocument1 pageModel: Smartstat: Feature Table - Thermostat ModestuntmanzNo ratings yet

- Astm f1155 1998Document25 pagesAstm f1155 1998nerissaloveNo ratings yet

- Sa 7930Document2 pagesSa 7930stuntmanzNo ratings yet

- Offshore Kurz SolarDocument28 pagesOffshore Kurz Solarstuntmanz100% (1)

- ct2201505 DLDocument100 pagesct2201505 DLstuntmanzNo ratings yet

- SteamlocDocument8 pagesSteamlocstuntmanzNo ratings yet

- BW Inside CiscoDocument3 pagesBW Inside CiscoMunkhbayar BaadgaiNo ratings yet

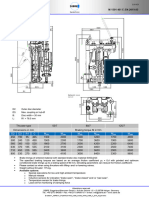

- Gas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11ADocument4 pagesGas Pressure Reducing: Gas Pressure Reducing & Shut-Off Valve & Shut-Off Valve Series 71P11A Series 71P11AĐình Sơn HoàngNo ratings yet

- Data Sheet USB5 II 2019 05 ENDocument1 pageData Sheet USB5 II 2019 05 ENJanne LaineNo ratings yet

- Straumann Product Catalogue 2018 2019Document260 pagesStraumann Product Catalogue 2018 2019kllasikalleNo ratings yet

- Schiavi Enc Met Page015Document1 pageSchiavi Enc Met Page015Adel AdelNo ratings yet

- Tac85 11Document32 pagesTac85 11TateNo ratings yet

- Quarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)Document11 pagesQuarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)hakkensNo ratings yet

- Edible Oil - Case StudyDocument8 pagesEdible Oil - Case StudyVansh Raj GautamNo ratings yet

- UntitledDocument4 pagesUntitleddwky KrnwnNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Asma G.SDocument5 pagesAsma G.SAfia FaheemNo ratings yet

- Everlast INTERVAL TRAINING ROUND TIMER PDFDocument1 pageEverlast INTERVAL TRAINING ROUND TIMER PDFanniaanniaNo ratings yet

- Gds Manual Flo2d ProDocument182 pagesGds Manual Flo2d ProbycmNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- Recycling Hexane and EtOAcDocument1 pageRecycling Hexane and EtOAcjmiscNo ratings yet

- Tiny Talk 2 Teacher's BookDocument15 pagesTiny Talk 2 Teacher's BookAtena RaeisiNo ratings yet

- BDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPDocument2 pagesBDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPluis manuelNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Anjana Seminar SlideshareDocument38 pagesAnjana Seminar SlideshareAnjana kpNo ratings yet

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Document42 pagesBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNo ratings yet

- Background of Philippine Art and Literature in Romantic RealismDocument2 pagesBackground of Philippine Art and Literature in Romantic RealismRaldz CoyocaNo ratings yet

- Anthropological Thought Session by DR G. VivekanandaDocument277 pagesAnthropological Thought Session by DR G. Vivekanandahamtum7861No ratings yet

- Final Firefly Reading & Writing AnswerDocument70 pagesFinal Firefly Reading & Writing AnswerVamshidhar ReddyNo ratings yet

- CD Dye RD0005Document7 pagesCD Dye RD0005Juan CarlosNo ratings yet

- Premium HC: 120 Halfcell Monocrystalline High Performance Solar ModuleDocument2 pagesPremium HC: 120 Halfcell Monocrystalline High Performance Solar ModuleMujahed Al-HamatiNo ratings yet

- Brochure Keor S GBDocument8 pagesBrochure Keor S GBFernando CespedesNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- Md. Rizwanur Rahman - CVDocument4 pagesMd. Rizwanur Rahman - CVHimelNo ratings yet

- W8 Module08 Meaning and Relevance of History Presentation 1Document22 pagesW8 Module08 Meaning and Relevance of History Presentation 1Jessa UdtohanNo ratings yet

- AbseilingDocument12 pagesAbseilingMurah Rezeki Cikgu WafiNo ratings yet