Professional Documents

Culture Documents

Pda India Chapter Aseptic Processing Workshop Session 2

Pda India Chapter Aseptic Processing Workshop Session 2

Uploaded by

Nitin KashyapOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pda India Chapter Aseptic Processing Workshop Session 2

Pda India Chapter Aseptic Processing Workshop Session 2

Uploaded by

Nitin KashyapCopyright:

Available Formats

7/5/2014

Purpose of GMP

:Session 2:

Qualification/validation of aseptic

techniques dos and donts

Mr. Sanjay Singh, Sr. Vice President

Aurobindo Pharma

Aseptic Processing Workshop:

July 2014; Indore

Connecting People, Science and Regulation

Why Media Fill ?

The basic idea is that we run an aseptic process, substituting a

microbiologically inert placebo for product

And then test every unit for microbiological

contamination

It has been convenient that liquid microbiological media serve as

placebo

This is because we can inspect each filled unit by

eye for visible growth

Connecting People, Science and Regulation

Generally, good GMP-compliance is based on

good understanding

When you understand the reasons for a particular

GMP requirement, the chances are high that you

will be able to comply with it in procedures,

records and actions

In this session we will understand what GMP

intends to gain from media fills

Connecting People, Science and Regulation

The Underlying Principle

In aseptic processing it is intended that a

product and its containment system

(separately sterilized) are brought together

without them becoming microbiologically

contaminated

The media fill is an investigative tool which

can show us if the aseptic process actually

does what it is intended to do

Connecting People, Science and Regulation

7/5/2014

Simulation

In other words we are simulating the aseptic

process in order to find out if it is safe

Commercial airline pilots are trained on flight

simulators to ensure that they are safe to be in

charge of aircraft

Commercial airline pilots are also trained for

emergency landings on flight simulators because

obviously you cannot practice crash landings in

real situations.

Connecting People, Science and Regulation

Media Fill Failure

Only failed media fills trigger the process

improvement cycles

Investigate

Find root cause

Fix root cause

Confirm fix was correct

However there are severe commercial and

regulatory consequences from failed media

fills

Therefore triggering the process improvement cycle

through failed media fills has disproportionate costs

Connecting People, Science and Regulation

Media Fill Simulation

The unsatisfactory part of media fill simulation is this:

There are lots of reasons why unsafe aseptic processes

could still give perfect media fill results (zero

contaminants)

Media does not support growth

Media Fill done in best conditions which do not reflect reality

Routine risks omitted (accidentally or deliberately)

The only way media fills give us any useful information

about our aseptic processes is when they fail, we

investigate, we find a fault in the process, and then we fix

the faults

Connecting People, Science and Regulation

Commercial ConsequencesValidation Media Fills

At validation we know very little about the

performance of a new line (or new size):

We do not know very much about the equipment except

what the supplier tells us (the best for the price)

We have limited experience of working with the

equipment (what are its difficulties?)

We have had little practice working in new surroundings

Therefore we perform media fills on every size and in

replicates

Failure helps us de-bug any problems before they turn

up in commercial production

Connecting People, Science and Regulation

7/5/2014

Commercial Consequences Validation

Media Fills

We prepare our protocol from a tentative Study Design to

help us find out if there is anything going to go wrong that we

need to get fixed

Because it is better to do it in validation than discover it in routine

operation

In validation it may delay release of the line but it has no other costs to the

patient or to the commercial supply chain

The tentative Study Design is the list of interventions tested at

worst case which could lead to contamination on the line.

We should make the tentative Study Design as tough as possible

because the regulatory submissions will be scrutinised and inspected

to ensure we have done this

Connecting People, Science and Regulation

Commercial Consequences Routine

Media Fills

We are required to repeat media fills on each line at 6

month intervals

In routine media fills, failure means we have either:

Missed something out when we did the Validation Media

Fill, or

Some aspect of the equipment or facility has broken

down or changed, or

Our personnel have begun to do something differently, or

We are experiencing bad luck (but inspectors do not

acknowledge bad luck)

Connecting People, Science and Regulation

Commercial Consequences

Routine Media Fills

Day 0 begin Media Fill

Day 14 confirm contamination in Media Fill. Stop all further manufacture

Quarantine product

Start Investigation

Day 17 obtain Identification of contaminants

Day 25 finalise investigation by confirming root cause

Day 30 CAPA agreed and confirmed. Order placed for parts

Day 35 Parts fitted and tested

Days 36-38 Confirmatory Media Fills set up

Days 50-52 Obtain Media Fill Results

Day 53 Resume Manufacture

Day 67 Resume Releasing Product

Connecting People, Science and Regulation

Routine Media Fills

So the routine media fill is NOT A SAFE

SIMULATION

It is not like the commercial airline pilots

emergency landing simulation which is completely

safe

But can we make it safe ?

Connecting People, Science and Regulation

7/5/2014

Making Routine Media Fills Safe !

1. We can cheat.

But cheating might give us an unsafe process and we

might be endangering the patient !

If we get caught cheating it will cost us more than 6-8

weeks lost production

2. We can make sure that we discover and address

every risk BEFORE we test the process by media

fill: this is sensible Risk Management

Connecting People, Science and Regulation

Case Study

A firm filled 3 media fill batches and on daily

observation found :

Batch A all containers OK after 7 days

Batch B all containers Ok after 5 days

Batch C All containers contaminated after

2 days.

Connecting People, Science and Regulation

Compliance with Media Fill

Requirements

Observe the process and correct all areas of doubtful control

Create a Study Design for Media Fills including the worst risks

we have identified but have been unable to correct

Replicate worst risks in every media fill

Protocol and include all other risks

Ensure that a worst case process is included

each 6-months in Routine Media Fill Matrix

Ensure that any Investigation of media fill failure is

intensively done and comprehensively documented

Connecting People, Science and Regulation

Case Study

Investigation begins :

Identification of the contaminating organism

started.

During the process 26 contaminations

observed in Batch A after 12 days and 6

contaminants were observed in Batch B

also after 10 days

Connecting People, Science and Regulation

7/5/2014

Case Study

Case Study

Initials information and investigations suggest that :

Batch A is contaminated at point of fill by

environmental flora

Batch B is contaminated at point of fill by

environmental flora and surviving spore formers

Batch C is contaminated at point of fill by

environmental flora and surviving spore formers

also the filling path was contaminated with

spore former

Connecting People, Science and Regulation

This indicates the following :

1. Improper aseptic practices

2. Improper equipment design

3. Improper systems

Connecting People, Science and Regulation

Case Study

Case Study

Conjecture

Conclusion

Direct Evidence

There were lapses in

performing aseptic

manipulations

This conjecture is correct

Video of media fill activities

shows , operator leaning

over open vials at many

occasions.

There were process or

equipment deficiencies

which could account for

all media fill failures

The conjecture is definitely

correct

Steam trap mounted

horizontally on drain line

(not self draining)

No validation of CIP Done to

ensure absence of TSB from

the line.

No barrier filter on drain line

SIP not thermometrically and

biologically validated at low

point (drain)

The types of microorganisms

recovered from Batch A

were distinctly different from

those recovered from Batch

B and C

The types of contaminants in

Batch B were intermediate

between those identified for

Batches A and C.

The contamination in all 3

batches originated from

the same source

The process is conducted

in a closed system,

subject to SIP.

The conjecture is most

probably incorrect

The conjecture is incorrect

Connecting People, Science and Regulation

Indirect

Evidence/Comment

Supervisor has not observed

this in 1 st run and did not

inform the operator/s

The fluid path was visibly

contaminated in Batch C at

all sample pints from the

product drain downstream,

but there were no such

indications for Batch A.

It would appear that

something may have

happened in the system

after its first exposure to

TSB when running Batch A,

which led to the fluid path

contamination seen in Batch

C.

The drain was not

adequately protected from

possible microbiological

ingress into the system

A diaphragm valve and a

horizontally mounted steam

trap do not present an antimicrobial barrier.

Conjecture

Conclusion

Direct Evidence

The source of

contamination of the fluid

path (Batch C) is

downstream of the

holding vessel

The contamination of the

fluid path in Batch c

resulted from a failure in

the SIP

The conjecture is most

probably correct

Visible contamination in

Batch C throughout the

system from the drain point

to all points downstream

Indirect

Evidence/Comment

Contamination observed in

all samples and vials

The conjecture is possibly

correct

The contaminants from

Batch C were aerobic spore

formers which would be

expected to be somewhat

heat resistant.

SIP records were all in order

SIP was not

thermometrically and

biologically qualified at drain

The contamination in

Batch A arose at point of

fill

The conjecture is most

probably correct

The microorganisms

identified in Batch A were all

common environmental and

human types, the same as or

similar to those found in

routine monitoring.

Poor aseptic techniques

The contamination in

Batch C did not arise at

point of fill

The conjecture is most

probably correct

The fluid path was visibly

contaminated within a few

days of starting Batch C at

all points in the system

downstream of the drain.

It is unlikely that

contamination would move

upstream against the flow of

product over this distance in

such a short time.

The microorganisms

identified in Batch C had

never been identified in

routine environmental or

personnel monitoring

It is unlikely that this

concentration of

contaminants could have

developed from incidental

environmental sources

Connecting People, Science and Regulation

7/5/2014

Case Study

Considering this Hypothesis, process simulation

studies were conducted after

Correction in equipment design

Correction of product path

Training of operating personnel

Requalification of the system

Thank You

This resulted into a successful simulation of the

aseptic process.

Connecting People, Science and Regulation

Connecting People, Science and Regulation

You might also like

- Microbial OOS InvestigationsDocument12 pagesMicrobial OOS InvestigationsSairam EdupugantiNo ratings yet

- CAPA in Medical Devices ManufacturingDocument7 pagesCAPA in Medical Devices ManufacturingShantha Kumar Parameswaran100% (1)

- Pharmaceutical and Medical DeviceDocument272 pagesPharmaceutical and Medical Devicemodava100% (1)

- FDA and Industry Collaboration On Computer Software AssuranceDocument56 pagesFDA and Industry Collaboration On Computer Software AssuranceNitin Kashyap100% (5)

- V Model - GampDocument2 pagesV Model - GampNitin Kashyap100% (1)

- 21 Questions On 21 CFR Part 820Document2 pages21 Questions On 21 CFR Part 820Nitin KashyapNo ratings yet

- Iq/Oq: Iq/Oq For Vaisala Viewlinc Monitoring System Page 1 of 161Document23 pagesIq/Oq: Iq/Oq For Vaisala Viewlinc Monitoring System Page 1 of 161Nitin KashyapNo ratings yet

- Risk Based Environmental Monitoring ProgrammeDocument51 pagesRisk Based Environmental Monitoring ProgrammeAugustine KoomsonNo ratings yet

- Englishtec 2st Partial - Melvin González - 2183612Document5 pagesEnglishtec 2st Partial - Melvin González - 2183612Melvin GonzalezNo ratings yet

- Polygraph ProcedureDocument38 pagesPolygraph ProcedureDaniel Besina Jr.No ratings yet

- 2008 Jan All - NoRestrictionDocument24 pages2008 Jan All - NoRestrictionRobertProsser19No ratings yet

- Questions and Answers: 2012 Annual Ambulatory Care Conference MiscellaneousDocument3 pagesQuestions and Answers: 2012 Annual Ambulatory Care Conference MiscellaneousMa J OngNo ratings yet

- The Concept of "Patient Safety" Applies Most Appropriately ToDocument77 pagesThe Concept of "Patient Safety" Applies Most Appropriately Toshreefmohammed2007No ratings yet

- Examples of Critical and Major Observations From GMP Inspections of Manufacturing, QC and Contract Research OrganisationsDocument59 pagesExamples of Critical and Major Observations From GMP Inspections of Manufacturing, QC and Contract Research OrganisationsMusab HashmiNo ratings yet

- Supply Chain MGMTDocument21 pagesSupply Chain MGMTHaricharan Conjeevaram NarayananNo ratings yet

- How To Recognize Effective CAPAs and A Culture of Quality (Caso #3)Document9 pagesHow To Recognize Effective CAPAs and A Culture of Quality (Caso #3)A. MorilloNo ratings yet

- Ethics Laboratory PDFDocument49 pagesEthics Laboratory PDFAnne Dewi SiagianNo ratings yet

- Pharmacia Upjohn Facility Receives Second FDA Form 483 in Almost Five YearsDocument21 pagesPharmacia Upjohn Facility Receives Second FDA Form 483 in Almost Five YearsPiruzi MaghlakelidzeNo ratings yet

- 11 To 20Document4 pages11 To 2020-CFIS-1038-Ravuri shanmukhaNo ratings yet

- CAPA Best PracticeDocument37 pagesCAPA Best PracticePutra Wijaya100% (1)

- Quality Assurance SystemsDocument7 pagesQuality Assurance SystemsJagtar Singh ChandelNo ratings yet

- When U Have A Bowie Dick TestDocument6 pagesWhen U Have A Bowie Dick TestboddarambabuNo ratings yet

- Cleaning Validation ThesisDocument6 pagesCleaning Validation Thesisaliciabrooksbeaumont100% (2)

- Drug Accountability in The Electronic AgeDocument4 pagesDrug Accountability in The Electronic AgeNaresh KumarNo ratings yet

- Lecture 1Document131 pagesLecture 1Varun SinghNo ratings yet

- Risk-Based Approach To Near Miss: Safety ManagementDocument0 pagesRisk-Based Approach To Near Miss: Safety ManagementLoveNo ratings yet

- EnvMonitoringHygieneGuideforEHOs PDFDocument16 pagesEnvMonitoringHygieneGuideforEHOs PDFPramod SivanandanNo ratings yet

- When Systems Fail, CAPA Validation BeginsDocument9 pagesWhen Systems Fail, CAPA Validation BeginsDarren TanNo ratings yet

- Oei 05 94 00100Document29 pagesOei 05 94 00100Sachin ChalkeNo ratings yet

- Cleaning Validation To Be Developed From This Article On Metformin TabletsDocument9 pagesCleaning Validation To Be Developed From This Article On Metformin TabletsPramba Kumar AhujaNo ratings yet

- Forum - Test SafetyDocument2 pagesForum - Test SafetyhhhNo ratings yet

- The Safe Way ForwardDocument37 pagesThe Safe Way ForwardTHROnlineNo ratings yet

- SOP On Deviation and Out-Of-Specification InvestigationDocument6 pagesSOP On Deviation and Out-Of-Specification InvestigationAngel Flores0% (1)

- Failure Mode and Effects AnalysisDocument24 pagesFailure Mode and Effects AnalysisHasyim PurwadiNo ratings yet

- Monitoring Plan 4 WebsiteDocument5 pagesMonitoring Plan 4 WebsitejohncuyNo ratings yet

- Microbiological Testing of Fresh ProduceDocument18 pagesMicrobiological Testing of Fresh ProducerohishaakNo ratings yet

- US FDA WL To Hanlim Pharm Co., LTD., South KoreaDocument5 pagesUS FDA WL To Hanlim Pharm Co., LTD., South Koreavijay narayanNo ratings yet

- Linne Ringsruds Clinical Laboratory Science 7th Edition Turgeon Test BankDocument35 pagesLinne Ringsruds Clinical Laboratory Science 7th Edition Turgeon Test Bankjerrybriggs7d5t0v100% (25)

- Final Poly 2.aDocument19 pagesFinal Poly 2.akimberlyn odoñoNo ratings yet

- CH10 Recall WebDocument32 pagesCH10 Recall WebPoulami DeNo ratings yet

- The Changing Face of Testing: WeblinksDocument3 pagesThe Changing Face of Testing: WeblinkstakazamyNo ratings yet

- Site Monitoring Plan TemplateDocument5 pagesSite Monitoring Plan TemplaterajuNo ratings yet

- Case Study 4 - CIP - SIP - Automation PDFDocument4 pagesCase Study 4 - CIP - SIP - Automation PDFManish BhatkarNo ratings yet

- SCRM Part 3 - Examples Draft2 PDFDocument14 pagesSCRM Part 3 - Examples Draft2 PDFElena StoevaNo ratings yet

- Part 3 - Risk Management ExamplesDocument14 pagesPart 3 - Risk Management ExamplesElena StoevaNo ratings yet

- A Cleanroom Contamination Control SystemDocument8 pagesA Cleanroom Contamination Control SystemTorres XiaNo ratings yet

- Investigation Guidelines by IpaDocument96 pagesInvestigation Guidelines by Ipabharat_sasiNo ratings yet

- Engineering As Social Experimentation: Chapter - 3Document10 pagesEngineering As Social Experimentation: Chapter - 3Sayan Kumar KhanNo ratings yet

- GLPDocument6 pagesGLPabhijit612No ratings yet

- Safe Work Practices: What Can You Do? Did You Know?Document1 pageSafe Work Practices: What Can You Do? Did You Know?AsimNo ratings yet

- Human ErrorDocument19 pagesHuman ErrorTumma RamaraoNo ratings yet

- BFS-FRIEDMAN - Contamination Case Studies Paper PDFDocument9 pagesBFS-FRIEDMAN - Contamination Case Studies Paper PDFipatoffNo ratings yet

- Introduction To Clinical Research IIDocument26 pagesIntroduction To Clinical Research IIkundagolNo ratings yet

- Pharmaceutical Cleaning A Comprehensive Approach - 0Document15 pagesPharmaceutical Cleaning A Comprehensive Approach - 0Mina Maher MikhailNo ratings yet

- Cccure 06. Security Assessment and Testing Cissp Practice Test With Answer and ExplanationDocument63 pagesCccure 06. Security Assessment and Testing Cissp Practice Test With Answer and ExplanationMona AdelNo ratings yet

- Polaroid GROUP 7Document3 pagesPolaroid GROUP 7Saif Ul Islam0% (1)

- CPHQ ControlDocument26 pagesCPHQ ControlibmNo ratings yet

- Design Fabrication, Assembly, Physical Tests, Simulation Prototype, Pilot Study, ModeltestDocument11 pagesDesign Fabrication, Assembly, Physical Tests, Simulation Prototype, Pilot Study, ModeltestramyaNo ratings yet

- Mid Atlantic Region Inspection Guide May 2003 FDA199305ADocument9 pagesMid Atlantic Region Inspection Guide May 2003 FDA199305AGirgis AiadNo ratings yet

- V ALIDATIONDocument7 pagesV ALIDATIONajitjoshi950No ratings yet

- Report On Rapid Site Access Program (Replacement of Pre Access Drug Testing With Random)Document9 pagesReport On Rapid Site Access Program (Replacement of Pre Access Drug Testing With Random)Michael ThomasNo ratings yet

- Good Cleanroom Practices - A Manual For Cleanroom PersonnelDocument208 pagesGood Cleanroom Practices - A Manual For Cleanroom PersonnelChandersekhar K MoorthyNo ratings yet

- Clinical Trials Audit Preparation: A Guide for Good Clinical Practice (GCP) InspectionsFrom EverandClinical Trials Audit Preparation: A Guide for Good Clinical Practice (GCP) InspectionsNo ratings yet

- Computer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Document12 pagesComputer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Nitin KashyapNo ratings yet

- Thinking Cap 21 CFR AssessmentDocument5 pagesThinking Cap 21 CFR AssessmentNitin KashyapNo ratings yet

- Computersystemsvalidation BlogspotDocument7 pagesComputersystemsvalidation BlogspotNitin KashyapNo ratings yet

- 4541 PDFDocument372 pages4541 PDFNitin Kashyap100% (2)

- Guide To CFR Part 11Document8 pagesGuide To CFR Part 11Nitin KashyapNo ratings yet

- Validation of COTS Using Single Life Cycle Approach - RD McDowallDocument15 pagesValidation of COTS Using Single Life Cycle Approach - RD McDowallNitin KashyapNo ratings yet

- A Road Map To: Computer System ValidationDocument29 pagesA Road Map To: Computer System ValidationNitin KashyapNo ratings yet

- 21 CFR 11 Compliance - WatersDocument12 pages21 CFR 11 Compliance - WatersNitin KashyapNo ratings yet

- ECA Annex11 CompSysDocument6 pagesECA Annex11 CompSysNitin KashyapNo ratings yet

- Gap Analysis & Risk AssessmentDocument47 pagesGap Analysis & Risk AssessmentKevin Thomas100% (2)

- Praxis CSV BasicsDocument17 pagesPraxis CSV BasicsNitin KashyapNo ratings yet

- Ranbaxy Case StudyDocument12 pagesRanbaxy Case StudyNitin KashyapNo ratings yet

- Gamp 4 To Gamp 5Document3 pagesGamp 4 To Gamp 5Nitin KashyapNo ratings yet

- Article Ejbps Volume 2 June Issue 3 1433741132Document25 pagesArticle Ejbps Volume 2 June Issue 3 1433741132Nitin KashyapNo ratings yet

- Jøker Bjerre - Chomsky, Wittgenstein Og LacanDocument17 pagesJøker Bjerre - Chomsky, Wittgenstein Og LacanEub HansenNo ratings yet

- 2014-03-26 Dennis Montgomery Declaration (Atigeo V Offshore Limited)Document7 pages2014-03-26 Dennis Montgomery Declaration (Atigeo V Offshore Limited)Jack RyanNo ratings yet

- PERSEREC Espionage Cases August2009Document78 pagesPERSEREC Espionage Cases August2009renebavard100% (1)

- Enquiry On Results Form (NEW)Document3 pagesEnquiry On Results Form (NEW)Phuong Nguyen Chau ThaoNo ratings yet

- Lumanog vs. People (G.R. No. 182555)Document53 pagesLumanog vs. People (G.R. No. 182555)Raphael Nasol MalubagNo ratings yet

- Ch05 - Audit Risk and MaterialityDocument18 pagesCh05 - Audit Risk and MaterialitySamit Tandukar100% (1)

- Jpmorgan Chase Bank, N.A. P O Box 659754 San Antonio, TX 78265 - 9754 August 17, 2015 Through September 14, 2015 Account NumberDocument2 pagesJpmorgan Chase Bank, N.A. P O Box 659754 San Antonio, TX 78265 - 9754 August 17, 2015 Through September 14, 2015 Account NumberShorav SuriyalNo ratings yet

- Edexcel Recheck-Remark Letter May-June - 2015Document2 pagesEdexcel Recheck-Remark Letter May-June - 2015Abrar JahinNo ratings yet

- Igcse Sample 3hDocument20 pagesIgcse Sample 3hviclenNo ratings yet

- Commander's Sexual Assault Victim Assistance ChecklistDocument6 pagesCommander's Sexual Assault Victim Assistance ChecklistbobbysingersyahooNo ratings yet

- Agm 15 MinsDocument6 pagesAgm 15 Minsapi-253238145No ratings yet

- IOT Smart City PowerPoint TemplatesDocument7 pagesIOT Smart City PowerPoint Templatessaid setiawanNo ratings yet

- Fraud Risk Assessment Procedures PKFDocument3 pagesFraud Risk Assessment Procedures PKFCool DudeNo ratings yet

- Applying The ASME OM CodeDocument31 pagesApplying The ASME OM Codemajor_duanNo ratings yet

- Dr. Estrellita B. Lacuesta, R.Crim ,,CSP, CSTDocument203 pagesDr. Estrellita B. Lacuesta, R.Crim ,,CSP, CSTMary Rose BaluranNo ratings yet

- Applying The Principles To Criminal InvestigationDocument3 pagesApplying The Principles To Criminal Investigationmarz sidNo ratings yet

- United States v. Eric Virden, 488 F.3d 1317, 11th Cir. (2007)Document7 pagesUnited States v. Eric Virden, 488 F.3d 1317, 11th Cir. (2007)Scribd Government DocsNo ratings yet

- Bulacan InvestigationDocument12 pagesBulacan InvestigationAnonymous tyY1qUNo ratings yet

- Hedge Fund Insider TradingDocument15 pagesHedge Fund Insider TradingToral ShahNo ratings yet

- Thomas RenyardDocument11 pagesThomas Renyardapi-250954522No ratings yet

- Isabella I of CastileDocument20 pagesIsabella I of CastileJay RonssonNo ratings yet

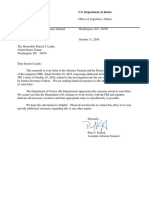

- Read The Letter The Justice Department Sent ToDocument4 pagesRead The Letter The Justice Department Sent ToJohn HinderakerNo ratings yet

- Critical Analysis of Lokpal Lokayuktas ActDocument30 pagesCritical Analysis of Lokpal Lokayuktas Acttayyaba redaNo ratings yet

- Citizens Against UFO SecrecyDocument10 pagesCitizens Against UFO Secrecymary engNo ratings yet

- Unit 1: On The Way To Work: Vocabulary ReviewDocument19 pagesUnit 1: On The Way To Work: Vocabulary ReviewMr. SimpsonNo ratings yet

- Post Blast GuideDocument8 pagesPost Blast GuideAmministratore Eod-ieddNo ratings yet

- Copyreading English Exercises by Tala PDFDocument48 pagesCopyreading English Exercises by Tala PDFThirdy Pineda III0% (1)

- SEARCH WARRANT PrinciplesDocument2 pagesSEARCH WARRANT PrinciplesLuChie AntonetteNo ratings yet

- Garcia Vs MojicaDocument1 pageGarcia Vs MojicaJaja GkNo ratings yet

- G.R. Nos. 157294-95 DigestDocument2 pagesG.R. Nos. 157294-95 DigestHaze Q.No ratings yet