Professional Documents

Culture Documents

Indra: For Construction

Indra: For Construction

Uploaded by

Iksan Adityo MulyoCopyright:

Available Formats

You might also like

- TA1179-D-5212-100X-3 - P&ID (Marked-Up)Document40 pagesTA1179-D-5212-100X-3 - P&ID (Marked-Up)Iksan Adityo Mulyo100% (2)

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocument17 pagesF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNo ratings yet

- Declaration of Performance K-Roc UKDocument2 pagesDeclaration of Performance K-Roc UKDavid midlandNo ratings yet

- MEmaco N 907 - Al ZourDocument1 pageMEmaco N 907 - Al Zouraruncg2No ratings yet

- MM Dresser FinalDocument236 pagesMM Dresser FinalPriyabrat Mohanty100% (1)

- Flexi Coil 340 Chisel Plow PDFDocument172 pagesFlexi Coil 340 Chisel Plow PDFАнатолій Гуменюк0% (1)

- KP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFDocument3 pagesKP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFUtku Can KılıçNo ratings yet

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Document13 pagesMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640No ratings yet

- MS CN0P-MTD-736-007 - Lighting Fixture, Receptacles and Wiring REV CDocument12 pagesMS CN0P-MTD-736-007 - Lighting Fixture, Receptacles and Wiring REV Cbrian sanchezNo ratings yet

- ELT-01-CQ-PC-XXXX Welding Consumables Receiving, Storage and HandlingDocument11 pagesELT-01-CQ-PC-XXXX Welding Consumables Receiving, Storage and HandlingjorgekarlosprNo ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- C-051-VP-040-CLTW-PRO-0007 Rev. A Pre Commissioning Commissioning ProcedureDocument11 pagesC-051-VP-040-CLTW-PRO-0007 Rev. A Pre Commissioning Commissioning ProcedureMidha NeerNo ratings yet

- RAPID-P0003-TRSA-CON-ITP-0001-0010 - ITP For Lighting System - R0Document12 pagesRAPID-P0003-TRSA-CON-ITP-0001-0010 - ITP For Lighting System - R0Namta GeorgeNo ratings yet

- Method Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonDocument16 pagesMethod Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonAhmad Rafly ZulfikarNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- HD1-2M90-1042-006 - B - Inspetion Test Plan - CODE BDocument5 pagesHD1-2M90-1042-006 - B - Inspetion Test Plan - CODE Bfreeman11072000No ratings yet

- Attachment 6 - Technical Query FormDocument1 pageAttachment 6 - Technical Query FormLai HuynhNo ratings yet

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- Work Method Statement: Installation of Waste Water Holding TanksDocument9 pagesWork Method Statement: Installation of Waste Water Holding TanksStansilous Tatenda NyagomoNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- ITP For Instrument InstallationDocument10 pagesITP For Instrument Installationnando_scribdNo ratings yet

- EDG Commissioning - Activity ReportDocument3 pagesEDG Commissioning - Activity ReportmohamedNo ratings yet

- Project Execution Plan For SMP Works (Long Son Project)Document11 pagesProject Execution Plan For SMP Works (Long Son Project)hoang nguyenNo ratings yet

- F-Final: 870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 A. AcceptedDocument57 pagesF-Final: 870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 A. Acceptedismariadi100% (1)

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document14 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiNo ratings yet

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- CE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentDocument20 pagesCE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentkristianNo ratings yet

- P6012MAB.000.10.03.771 - O3 - With JV Comments PDFDocument27 pagesP6012MAB.000.10.03.771 - O3 - With JV Comments PDFMukesh MuraleedharanNo ratings yet

- Inspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Document9 pagesInspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Namta GeorgeNo ratings yet

- Project Quality Control Plan Endorsment For Welding2Document23 pagesProject Quality Control Plan Endorsment For Welding2Tadaya KasaharaNo ratings yet

- SG6427-SY-CK0P-MTD-736-001 - Rev.B-Method Statement For Instrument Cabling WorksDocument12 pagesSG6427-SY-CK0P-MTD-736-001 - Rev.B-Method Statement For Instrument Cabling Worksbrian sanchezNo ratings yet

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- 930-PRC-OP-WIK-0024 - CC01 - Vendor Training Plan - APPROVEDDocument28 pages930-PRC-OP-WIK-0024 - CC01 - Vendor Training Plan - APPROVEDgerry rutmNo ratings yet

- Ebs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanDocument80 pagesEbs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanAsaad AdnanNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- On Plot HydrotestingDocument14 pagesOn Plot HydrotestingShambu S VtkNo ratings yet

- B Qac Pro 210 39161 ADocument12 pagesB Qac Pro 210 39161 AZaidiNo ratings yet

- Instrumentation ITPDocument19 pagesInstrumentation ITPMohammad IrfanNo ratings yet

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDocument2 pagesQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNo ratings yet

- ITR For Electrical Instrument PDFDocument4 pagesITR For Electrical Instrument PDFCokro YudhaNo ratings yet

- C823 3 Doc MST Mec 009Document24 pagesC823 3 Doc MST Mec 009721917114 47No ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document17 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- Site Specific Procedure (Junction Box)Document120 pagesSite Specific Procedure (Junction Box)Mohd Khairi AhmadNo ratings yet

- ITP Transformer Testing and CommissioningDocument1 pageITP Transformer Testing and CommissioningguspriyNo ratings yet

- Ms For Repair and Welding Jointscoating and PaintingDocument9 pagesMs For Repair and Welding Jointscoating and Paintingmansih457100% (1)

- Method Statement - Pouring Foundations-TemplateDocument13 pagesMethod Statement - Pouring Foundations-TemplateUğur BilenNo ratings yet

- T-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623Document77 pagesT-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623JosiahNo ratings yet

- Inspection Test Plan (Itp) : Mobile Fire ExtinguisherDocument4 pagesInspection Test Plan (Itp) : Mobile Fire Extinguisher87482127No ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- Cover Sheet: Zapsib-2 ProjectDocument12 pagesCover Sheet: Zapsib-2 ProjectAkhtar AnsariNo ratings yet

- QC Example Resume.01Document4 pagesQC Example Resume.01Guru SankarNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Process Map For EPC Construction ContractorDocument2 pagesProcess Map For EPC Construction Contractorrahul nandananNo ratings yet

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesDocument20 pagesNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- MS For Instrument InstallationDocument9 pagesMS For Instrument InstallationNijo JoseNo ratings yet

- Cable Pulling Report (Instrument Cable) : Project Name CustomerDocument3 pagesCable Pulling Report (Instrument Cable) : Project Name CustomerAldeline SungahidNo ratings yet

- SA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeDocument16 pagesSA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeABAID ULLAHNo ratings yet

- Upper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Document15 pagesUpper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Anonymous xyZH2OaUVNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- Indra: Donggi Senoro LNG ProjectDocument17 pagesIndra: Donggi Senoro LNG ProjectIksan Adityo MulyoNo ratings yet

- Hse CommitteeDocument1 pageHse CommitteeIksan Adityo MulyoNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolau100% (1)

- F.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearDocument3 pagesF.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearIksan Adityo MulyoNo ratings yet

- List Kekurangan Isometric DrawingDocument8 pagesList Kekurangan Isometric DrawingIksan Adityo MulyoNo ratings yet

- Welding QualificationDocument5 pagesWelding QualificationIksan Adityo MulyoNo ratings yet

- 23 - PT Q&a 1-3 - PDFDocument49 pages23 - PT Q&a 1-3 - PDFbassamNo ratings yet

- QP - 02 Magnetic Particle Test, Rev 01Document13 pagesQP - 02 Magnetic Particle Test, Rev 01Iksan Adityo MulyoNo ratings yet

- Handout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Document96 pagesHandout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Iksan Adityo Mulyo100% (1)

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDocument7 pagesF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNo ratings yet

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocument6 pagesF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNo ratings yet

- Magnetic Particle Test: Job Safety Analysis WorksheetDocument1 pageMagnetic Particle Test: Job Safety Analysis WorksheetIksan Adityo MulyoNo ratings yet

- Section 01 - Typical Duties of Welding InspectorsDocument12 pagesSection 01 - Typical Duties of Welding InspectorsIksan Adityo MulyoNo ratings yet

- Indra: Donggi Senoro LNG ProjectDocument17 pagesIndra: Donggi Senoro LNG ProjectIksan Adityo MulyoNo ratings yet

- Vertical Multiphase Flow: Instructional ObjectivesDocument23 pagesVertical Multiphase Flow: Instructional ObjectivesIksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- S-900-3120-001 - 2 - 0001 (Concreate Building)Document23 pagesS-900-3120-001 - 2 - 0001 (Concreate Building)Iksan Adityo Mulyo100% (1)

- Indra: A NA Const/Pip/QC K. Tsunoda/M. Sakaki 04-Jun-2012 S. KuritsuboDocument17 pagesIndra: A NA Const/Pip/QC K. Tsunoda/M. Sakaki 04-Jun-2012 S. KuritsuboIksan Adityo MulyoNo ratings yet

- PROJ 1051 FAB 001 - 2 Fabrication ProcedureDocument13 pagesPROJ 1051 FAB 001 - 2 Fabrication ProcedureIksan Adityo MulyoNo ratings yet

- JSA Process Piping Inspection Onshore - 2006Document1 pageJSA Process Piping Inspection Onshore - 2006Iksan Adityo MulyoNo ratings yet

- 2 - Oil PropDocument38 pages2 - Oil PropIksan Adityo MulyoNo ratings yet

- 2 Inflow PerformanceDocument36 pages2 Inflow PerformanceIksan Adityo MulyoNo ratings yet

- JSA Pipeline Riser Inspection New Untuk DisimpanDocument1 pageJSA Pipeline Riser Inspection New Untuk DisimpanIksan Adityo MulyoNo ratings yet

- RoofingDocument20 pagesRoofingtbeedle33% (3)

- Asssembly and Installation Manual Zickert Z2013Document53 pagesAsssembly and Installation Manual Zickert Z2013Angelo MesquitaNo ratings yet

- 1 PB PDFDocument6 pages1 PB PDFAbdulsalam AbdulwasiuNo ratings yet

- CU AL Conversion FlyerDocument1 pageCU AL Conversion FlyerSyed Muhammad ZohairNo ratings yet

- Hydraulic Pipe SizingDocument44 pagesHydraulic Pipe Sizingmrmeraj100% (2)

- Addmie Expansion Budget LFN & LFZ (SIF-3)Document1 pageAddmie Expansion Budget LFN & LFZ (SIF-3)Faheem HussainNo ratings yet

- 2001 USDM Subaru Outback Service Manual BE-BHDocument4,267 pages2001 USDM Subaru Outback Service Manual BE-BHgigabyte3235840No ratings yet

- Pump Head CalculationDocument14 pagesPump Head CalculationSolymanElsayedSolymanNo ratings yet

- Markup: Markup For A Construction BusinessDocument9 pagesMarkup: Markup For A Construction BusinessjakejowersNo ratings yet

- Analysis and Design of Cellular Beam and Its VerificationDocument8 pagesAnalysis and Design of Cellular Beam and Its VerificationemmanuelNo ratings yet

- Panel RailFasteningSystemCATALOGDocument36 pagesPanel RailFasteningSystemCATALOGBerkan KayadanNo ratings yet

- Pre-Course-HW-Tailor BrownDocument2 pagesPre-Course-HW-Tailor BrownTailorNo ratings yet

- Material Take-Off: Saudi Arabian Oil CompanyDocument4 pagesMaterial Take-Off: Saudi Arabian Oil CompanybillNo ratings yet

- Planning, Analysis and Design of (G+20) Multi-Storey Residential Building Using Staad - ProDocument8 pagesPlanning, Analysis and Design of (G+20) Multi-Storey Residential Building Using Staad - ProShameer ShajiNo ratings yet

- Describe A BuildingDocument3 pagesDescribe A BuildingGresiShemaNo ratings yet

- Injection Mortar FIS V / FIS VS / FIS VWDocument4 pagesInjection Mortar FIS V / FIS VS / FIS VWrony asmNo ratings yet

- Tender Vol-4 CivilDocument184 pagesTender Vol-4 CivillokenderchaturvediNo ratings yet

- Brown Hettiarachchi 2008 PDFDocument9 pagesBrown Hettiarachchi 2008 PDFjorge BadilloNo ratings yet

- Section 1 PDFDocument438 pagesSection 1 PDFAnfal BarbhuiyaNo ratings yet

- Aquestia OCV TERMINALDocument12 pagesAquestia OCV TERMINALSony Nd AshaNo ratings yet

- Multispan DesignDocument4 pagesMultispan DesignJohn WayneNo ratings yet

- Devarsh Shah CVDocument1 pageDevarsh Shah CVDevarsh ShahNo ratings yet

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocument9 pagesAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaNo ratings yet

- Prefabricated Structures: Sumbitted To:-Prof. Sanjay Mehra Ar. Varun Jain Sumbitted By: - Yugal GuptaDocument25 pagesPrefabricated Structures: Sumbitted To:-Prof. Sanjay Mehra Ar. Varun Jain Sumbitted By: - Yugal GuptaSwapnil JainNo ratings yet

- Department of Town and Country Planning, Govt. of Haryana: Applying For Occupation CertificateDocument9 pagesDepartment of Town and Country Planning, Govt. of Haryana: Applying For Occupation CertificateIshan ChawlaNo ratings yet

- TransportDocument200 pagesTransportonix58No ratings yet

- ThesisDocument48 pagesThesisTac-an Design and Construction ServicesNo ratings yet

Indra: For Construction

Indra: For Construction

Uploaded by

Iksan Adityo MulyoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indra: For Construction

Indra: For Construction

Uploaded by

Iksan Adityo MulyoCopyright:

Available Formats

Total Sheet: 26

Vendors Name:

Owners Name:

Purchasers Name:

Project:

BANGUN CIPTA SHIMIZU JOINT OPERATION

PT. DONGGI SENORO LNG

PT. JGC INDONESIA AND JGC CORPORATION CONSORTIUM

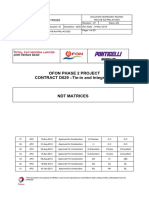

Donggi Senoro LNG Project

Vendors Document No: BSJO-CVL-QC-045

Document Title:

Inspection & Test Plan for Steel Structure Erection

(General)

FOR CONSTRUCTION

DSLNG PROJECT

ISSUE PURPOSE :

FC

)

A

AB

-

RESPONSIBLE DEPT:

Civil

REVIEWED BY:

H.Hosoda

RESULT CODE : A, B, N, F

NEXT STATUS : FA, FI, FC, AB

RESUBMISSION DATE:

Review Date:

A : Accepted without Comment

N : Not Approved

)

)

( 1st Aug 2012

B : Accepted with Comment

F : Not Subject to Review

Approval or review hereunder shall not be construed to relieve

Supplier / Subcontractor of his responsibilities and liability under

the Contract.

JOB NO.

0-5151-20

ORIG - PURCHASE ORDER NO.

PURCHASER DOC NO.

00

SERIAL

REV

V-3120-001-A-

045

23 July 2012

Issued for Construction

S. Jefri

CAlfaro

Y. Fukuoka

30 April 2012

Issued for Construction

S. Jefri

CAlfaro

Y. Fukuoka

Site Submission Records

0

26 April 2012

Issued for Construction

S. Jefri

CAlfaro

Y. Fukuoka

1B

17 april 2012

Issued for approval

S. Jefri

shahizan

Y. Fukuoka

Issued for Approval

S. Jefri

shahizan

Y. Fukuoka.

DESCRIPTION

PREPD

CHKD

APPD

1A

A

R

D

0

2

N

T

I 01-OC 12

REV

DATE

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 2 of 26

CONTENTS

1.0

INTRODUCTION .................................................................................................................................... 3

2.0

SCOPE ................................................................................................................................................... 3

3.0

TERMS AND CONDITION ....................................................................................................................... 3

4.0

REFERENCES ......................................................................................................................................... 3

5.0

LEGENDS............................................................................................................................................... 4

6.0

ITP ........................................................................................................................................................ 5

7.0

APPENDIX..............................................................................................................................................8

A

R

D

0

2

N

T

I 01-OC 12

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 3 of 26

1.0

INTRODUCTION

This document describes the inspection and testing requirements relating to Steel

Structure Erection (General) to be done in accordance to the applicable codes,

standards, specification documents, Quality record requirement and inspection

involvement by owner and purchaser.

This document shall be referred to when carrying out actual inspection and testing

shown on ITP.

2.0

Scope

This document is applicable during the Steel structure Erection work at the

construction phase of:

CIVIL WORKS PACKAGE 2

For

PT. DONGGI SENORO LNG

PT. JGC INDONESIA AND JGC CONSORTIUM

Donggi Senoro LNG Project

3.0

Terms and Condition

The following words and expressions shall have the same meaning hereby assigned

to them, except where the context otherwise requires:

3.1

3.2

3.3

3.4

Owner- means the owner of the plant named as PT. Donggi-Senoro LNG (DS

LNG)

Contractor-means JGCC

Subcontractor-means BSJO or any party appointed by contractor which carries

out the activities of the work.

Inspection-conformity evaluation by observation and judgments accompanied as

appropriate measurement, testing or gauging. (ISO-9000-2008)

4.0

REFERENCES

4.1

Code and Standard

A

R

D

0

2

N

T

I 01-OC 12

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 4 of 26

4.1.1 AISC 303-05 Code and Standard Practice for Steel Building and Bridges

4.1.2 AISC 360-05 Specification for Steel Building

4.1.3 RCSC

Specification for Structural Joints Using ASTM A325 or A490 Bolts

(RCSC: Research Council on Structural Connections)

4.1.4 SSPC

Steel Structure Painting Council Manual

4.1.5 AWS D1.1

Structural Welding Code

Project Specification and Drawing

4.2

4.2.1 S-900-1310-001 Detailed Engineering Design data for Civil and

Structures

4.2.2 S-900-3120-001 Construction Specification for Concrete work

4.2.3 S-900-3130-002 Construction specification for Erection of structural steel

4.2.4 S-900-13A0-001 Specification for Painting

4.2.5 Standard Drawing for Steel Structure General issued by JGC

4.2.6 S-900-1540-101 Quality Control Requirement to Subcontractor

Subcontractor Engineering Document

4.3

4.3.1 V-3120-001-A-024 Method Statement for Steel Structure Erection

4.3.2 V-3120-001-A-049 Welding procedure specification For Structural steel

Erection Including Embedded Plate

4.3.3 V-3120-001-A-046 Inspection and Test Plan for Embedded Plate

Fabrication Work

5.0

A

R

D

0

2

N

T

I 01-OC 12

LEGENDS

5.1

NR : Not Record.

5.2

WPS : Welding Procedure Specification.

5.3

IRC : Inspection Release Certificate.

5.4

W : Witness Point-JGC and DSLNG has an intention to witness, however

Subcontractor can proceed the test/inspection when JGC and DSLNG

inspector is not present at the notified time.

5.5

SW : Spot Witness-JGC and DSLNG has an intention to witness at an early

stage and at other time as necessary, however Subcontractor can proceed

the test/inspection when JGC and DSLNG inspector is not present at the

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 5 of 26

notified time.

6.0

A

R

D

0

2

N

T

I 01-OC 12

5.6

: Initial Witness-Subcontractor is requested to notify JGC of the initial

IW

Inspection data/time. Subcontractor can proceed with the test /inspection

when the JGC and DSLNG inspector is not present at the notified time.

Subsequent test/inspection may not be witnessed if no deficiency is found at

the initial inspection.

5.7

S

: Surveillance-Subcontractor is not requested to notify JGC. JGC and

DSLNG inspector will monitor work in progress, tests and inspection during

his visit periodical.

5.8

R

: Document review-Review of inspection and test records, personnel

qualification and other inspection released documentation.

5.9

A

: Actual inspection/Testing-Subcontractor shall conduct the inspection

and test.

5.10

: Document Preparation- Preparation of inspection and test record,

P

personnel qualification and other inspection related documentation. All Quality

records shown in ITP shall be considered as official record. The subcontractor

is requested to provide the official record to be submitted as Manufacture

Data Report (MDR).

ITP (Inspection and Test Plan)

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 6 of 26

ITP for STEEL STRUCTURE WORKS

DONGGI - SENORO LNG PROJECT

Quality Control

INSPECTION AND TEST PLAN

BANGUN CIPTA - SHIMIZU

JOINT OPERATION

STEEL STRUCTURE ERECTION

ITEM

1 Advance Inspection

1,1 Material Receiving Check

REFERENCE / REQUIREMENT

FREQUENCY /

TIMING

RECORD / FORM

NO.

As per Drawings & Material Standard

Every Delivery

Material Certificate

1,2 Foundation / Anchor Bolts Check

As per Drawings & S-900-3130-002, Sec. 9.1

Every Foundation

1,2 Padding Plate Check

As per Drawings & S-900-3130-002, Sec. 9.1

1,3 Embedded Plate Check

1,4 High Strength Bolts/ M Bolts,

and all check

2 Inspection for High Strength Bolt Connection

2,1 Contact Surface Check

2,2 Bolt Tightening Inspection

(1) Mild Steel Bolt Connection

(2) High Strength Bolt Connection

2,3

Demonstration per AISC of High

Strenght Bolts Connection

3 Welding

3,1 Welding Qualification Test

(1) Welding Procedure Specification

(2) Welder Qualification Test

3,2 Welding Profile Visual

A

R

D

0

2

N

I 01-OCT 12

Document No.:

WITNESS / REVIEWED

REMARKS

BSJO

JGC

OWNER

A

IW

QR-3000-10

A/P

SW

S/R

Every Foundation

QR-3000-12

A/P

SW

S/R

As per Drawings & S-900-3130-002, Sec. 9.1

Every Structures

QR-3000-11

A/P

SW

S/R

As per Drawings & S-900-3130-002, Sec. 9.1

Every Structures

Material Certificate

and IRC

SW

S/R

As per S-900-3130-001, Sec. 9.2

Every Erection

N/R

SW

As per Drawings & S-900-3130-002, Sec. 9.2

As per Drawings & S-900-3130-002, Sec. 9.2

Every Erection

Every Erection

QR-3000-03

QR-3000-03

A/P

A/P

SW

SW

S/R

S/R

As per AISC & S-900-3130-002, Sec. 9.1

Before Initial

Tightening

N/R

SW

(If any)

As per AWS D1.1 & S-900-3130-002, Sec. 2.8 & 6

Each WPS

WPS

As per AWS D1.1 & S-900-3130-002, Sec. 2.8 & 6

Each Welder

Welder Test Certifcate

As per AWS D1.1 & S-900-3130-002, Sec.6

Every Welding

QR-3000-04

A/P

S/R

Snug tight method

Turn of nut method

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 7 of 26

ITEM

REFERENCE / REQUIREMENT

FREQUENCY /

TIMING

RECORD / FORM

NO.

WITNESS / REVIEWED

BSJO

JGC

OWNER

4 Inspection of Anchor Bolt Tightening

4.1 Tightness of Anchor Bolt

As per Drawings

Every Structure

QR-3000-03

A/P

SW

S/R

4.2 Joint Survey (After Installation)

4,2,1 Anchor Bolt

4,2,2 Padding Plate

4,2,3 Embedded Plate

As per Drawings

As per Drawings

As per Drawings

Every Structure

Every Structure

Every Structure

QR-3000-10

QR-3000-12

QR-3000-11

A/P

A/P

A/P

W

W

W

S/R

S/R

S/R

As per S-900-3130-001, Sec. 9.2

Every Assembly

Visual

SW

5.2 Plumbness of Column

As per Drawings & S-900-3130-002, Appendix-1

Every Assembly

QR-3000-01

A/P

SW

S/R

5.3 Alignment of Beam

As per Drawings & S-900-3130-002, Appendix-1

Every Assembly

QR-3000-02

A/P

SW

S/R

As per Drawings

Every Assembly

QR-3000-08

A/P

SW

S/R

6.2 Handrail and Safety Gates

As per Drawings

Every Assembly

QR-3000-07

A/P

SW

S/R

6.3 Grating, Chekered Plate, etc

As per Drawings

Every Assembly

QR-3000-05

QR-3000-06

A/P

SW

S/R

As per S-900-3130-002, Sec. 5.6/ S-900-13A0-001

Every Touch up

QR-3000-09

A/P

SW

S/R

As per S-900-3130-002, Sec. 5.6/ S-900-13A0-001

Every Embedded

QR-3000-09

A/P

SW

S/R

8 Grouting

As per S-900-3130-002, Sec. 4.3

Every Structure

QR-3000-15

A/P

SW

S/R

9 Final Acceptance Record

9.1 Ensure all record are complied and

submitted to client

As per S-900-3130-002, Sec. 5.6 / S-900-13A0-001

Every Structure

QR-3000-13

A/P

As per Drawing

Every Member

QR-3000-14

A/P

SW

S/R

10.2 Welding

As per AWS D1.1 &S-900-3130-002, Sec. 6

Every Welding

QR-3000-04

A/P

S/R

10.3 Touch Up Waiting

As per S-900-3130-002, S-900-13A0-001

Every touch up

QR-3000-09

A/P

SW

S/R

5 Erection Inspection

5.1 Damage Material : Steel and Concrete

6 Other Members Assembly

6.1 Platforms and Ladders

REMARKS

7 Painting

7.4 Touch-up Painting

7.5 Final Paiting (Top Coat)

10 Site Fabrication

10.1 Dimensional Check

A

R

D

0

2

N

I 01-OCT 12

Using DFT Device

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 8 of 26

7. APPENDIX

A

R

D

0

2

N

T

I 01-OC 12

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 9 of 26

FABRICATION TOLERANCE

A

R

D

0

2

N

T

I 01-OC 12

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 10 of 26

A

R

D

0

2

N

T

I 01-OC 12

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 11 of 26

A

R

D

0

2

N

T

I 01-OC 12

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 12 of 26

QR-3000-01

Donggi-Senoro LNG

Civil Work Package 2

Project

Bangun Cipta - Shimizu

Joint Operation

REPORT No.:

Quality Control

JOB NO.:

OWNER: PT . DONGGI-SENORO

LNG

DATE:

S TRUCTURAL ALIGNMENT

COLUMNS

SYSTEM NO.:

AREA:

PCWBS:

FWBS:

STRUCTURE NAM E / DRAWING NO.

COLUM N

LINE

NUM BER

BASE PLATE ELEV.

ROW

NUM BER

SIZE

DESIGN

ACTUA

L

PLUM B

DEVIAT N.

(JOB NS &

EW)

REM ARKS:

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 13 of 26

QR-3000-02

Bangun Cipta - Shimizu

Joint Opera tion

Donggi-Senoro LNG Civil Work

Package 2 Project

DATE:

S TRUCTURAL ALIGNMENT BEAMS

AREA:

STRUCTURE NAM E /

DRAWING NO.

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

SYSTEM NO.:

Quality Control

PCWBS:

FWBS:

TOP OF STRUCTURE ELEVATION

BEAM PIECE

M ARK

END "A"

DESIGN

ACTUAL

END "B"

DEVIA.

DESIGN

ACTUAL

REM ARKS:

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

DEVIA.

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 14 of 26

QR-3000-03

Bangun Cipta - Shimizu

Joint Opera tion

Donggi-Senoro LNG Civil

Work Package 2 Project

DATE:

HIGH S TRENGTH BOLTING REPORT

PCWBS:

FWBS:

AREA:

STRUCTURE NAM E / DRAWING

NO.

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

SYSTEM NO.:

Quality Control

BOLT SPEC.

TENSION

METHOD

LOCATION OF BOLTS

TENSION CHECKED

INSPECTION RESULT

ACCEPT

UNACCEPT

REM ARKS:

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 15 of 26

QR-3000-04

Quality

Bangun Cipta - Shimizu

Joint Operation

Donggi-Senoro LNG Civil Work Package 2

Project

OWNER: PT. DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

WELDING VIS UAL INPECTION

AREA:

NO

JOB NO.:

PCWBS:

FWBS:

STRUCTURE

MARKING

MATERIAL

DIMENSION &

THICKNESS

(mm)

QTY

WELDING

DATE OF WELDING

WELDER

NOT

FIT UP PROCESS ACCEPTED

STAMP

ACCEPTED

SKETCH : AS PER ATTACHED

Note

BSJO

NA

M

E

SIG

NA

DA

TE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

REMARK

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 16 of 26

QR-3000-05

Donggi-Senoro LNG Civil Work Package

2 Project

Bangun Cipta - Shimizu

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

GRATING INS PECTION RECORD

PCWBS:

FWBS:

AREA:

GRATING ARRANGEMENT

NO

Quality Control

GRID LINE

FIXING CLIP

QTY

ACCEPTED

QTY

NOT ACCEPTED

ACCEPTED NOT ACCEPTED

SKETCH : AS PER ATTACHED

REMARKS :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 17 of 26

QR-3000-06

Bangun Cipta - Shimizu

Joint Operation

Donggi-Senoro LNG Civil Work Package 2

Project

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

DATE:

REPORT No.:

SYSTEM NO.:

PCWBS:

CHECKERED PLATE INS PECTION RECORD

AREA:

FWBS:

CHECKERED PLATE ARRANGEMENT

NO

Quality Control

GRID LINE

WELDING VISUAL

QTY

ACCEPTED

QTY

NOT ACCEPTED

ACCEPTED

NOT ACCEPTED

SKETCH : AS PER ATTACHED

REMARKS :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 18 of 26

QR-3000-07

Bangun Cipta - Shimizu

Joint Operation

Donggi-Senoro LNG Civil Work

Package 2 Project

DATE:

PCWBS:

HANDRAIL INS PECTION RECORD

AREA:

FWBS:

BOLT

NO

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

SYSTEM NO.:

Quality Control

HANDRAIL MARKING

QTY

INSTALL

COMPLETE

TIGHTENING

TAPERED

WASHER

REMARK

SKETCH : AS PER ATTACHED

REMARKS :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 19 of 26

QR-3000-08

Donggi-Senoro LNG Civil Work

Package 2 Project

Bangun Cipta - Shimizu

Joint Operation

Quality Control

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

PLATFORM AND LADDER INS PECTION RECORD

AREA:

PCWBS:

FWBS:

MARKING

BOLT

NO

QTY

Platform

INSTALL

COMPLETE

Ladder

TIGHTENING

TAPERED

WASHER

REMARK

SKETCH : AS PER ATTACHED

REMARKS :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 20 of 26

QR-1300-09

Bangun Cipta - Shimizu

Joint Operation

RECORD NO.: 1200-02

Donggi-Senoro LNG

Civil Work Package

2 Project

DRY FILM

THICKNESS (DFT)

SYSTEM :

PCWBS: :

Quality Control

JOB NO.:

OWNER: PT. DONGGI-SENORO LNG

REPORT NO.:

DATE:

FWBS:

ITEM :

DRAWING REFERENCE:

NO. OF COATING USED:

Intermediate Coat

Top Coat

PAINTING SYSTEM :

M IN. TOTAL DFT: 200 m

DEVICE:

LOC ATION

ACCEPTABLE

READING

TYPE

1st

APPROVED

AVERAGE

YES

2nd

NO

BSJO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

NOTE : ATTACHED TESTING LAYOUT SKETCH

REM ARKS:

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

JGC

DS

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 21 of 26

QR-3000-10

Bangun Cipta - Shimizu

Joint Operation

Donggi-Senoro LNG Civil

Work Package 2 Project

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

PCWBS:

ANCHOR BOLT

AREA:

STRUCTURE NAME / DRAWING NO.

Quality Control

FWBS:

LINE

NUMBER

ROW

NUMBER

INSPECTOR

SIZE

BSJO

JGC

DS

SKETCH :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 22 of 26

QR-3000-11

Bangun Cipta - Shimizu

Joint Operation

Donggi-Senoro LNG Civil

Work Package 2 Project

Quality Control

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

PCWBS:

EMBEDDED PLATE

AREA:

FWBS:

INSPECTOR

STRUCTURE NAME / DRAWING NO.

GRIDLINE

LOCATION

TYPE

BSJO

JGC

DS

SKETCH :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 23 of 26

QR-3000-12

Bangun Cipta - Shimizu

Joint Operation

Donggi-Senoro LNG Civil

Work Package 2 Project

Quality Control

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

PADDING PLATE

AREA:

PCWBS:

FWBS:

ELEVATION

STRUCTURE NAME / DRAWING NO.

INSPECTOR

GRIDLINE

DRAWING

ACTUAL

BSJO

JGC

DS

SKETCH :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 24 of 26

QR-3000-13

Donggi-Senoro LNG Civil

Work Package 2 Project

Bangun Cipta - Shimizu

Joint Operation

Quality Control

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

S TEEL S TRUCTURES FINAL

ACCEPTANCE

SYSTEM NO.:

PCWBS:

FWBS:

AREA:

DESCRIPTION OF STRUCTURE:

OPERATION

EQUIPM ENT NO.:

REQUIRED

YES

DATE

COM PLETE

NO

CIVIL INSPECTOR

BSJO

DS LNG

INSPECTOR

JGC

FOUNDATION ACCEPTED BY CIVIL INSPECTOR

M ATERIALS POSITIVELY IDENTIFIED AND IN

ACCORDANCE WITH DRAWINGS

ANCHOR BOLTS CHECKED AND ACCEPTED

STRUCTURE PLUM B AND LEVEL

BOLTING CORRECT TYPE AND LENGTH AND

TIGHTENED

HIGH STRENGTH BOLT TENSIONING ACCEPTED

WELDING ACCEPTED

NDE OF FIELD WELDS ACCEPTED

PLATFORM S AND LADDERS ACCEPTED

GRATING, DECK PLATE SECURED & ALIGNED

M ISC. BRACKETS AND SUPPORTS COM PLETE

TEM PORARY GUYS, BRACES, CRIBBING

REM OVED

HANDRAILS SAFETY GATES ACCEPTED

FIELD COATING ACCEPTED

BASEPLATES GROUTED AND ACCEPTED

FIREPROOFING ACCEPTED

COATING OF WELDS ACCEPTED

PUNCH LIST ITEM S COM PLETED AND ACCEPTED

FINAL INSPECTION: STRUCTURE ACCEPTED

REM ARKS:

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 25 of 26

QR-3000-14

Bangun Cipta - Shimizu

Joint Operation

Quality Control

Donggi-Senoro LNG Civil

Work Package 2 Project

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

REPORT No.:

DATE:

SYSTEM NO.:

PCWBS:

S ITE FABRICATION

AREA:

FWBS:

INSPECTOR

STRUCTURE NAME / DRAWING NO.

GRIDLINE

LOCATION

MEMBER NO.

BSJO

JGC

DS

SKETCH :

BSJO

NAM E

SIGNATURE

DATE

A

R

D

0

2

N

T

I 01-OC 12

JGC

DS LNG

Doc No: V-3120-001-A-045 <Rev.1>

Steel Structure Works Inspection & Test Plan For Steel Structure Erection (General)

Sheet 26 of 26

QR-3000-15

Donggi-Senoro LNG Civil

Work Package 2 Project

Bangun Cipta - Shimizu

Joint Operation

Quality Control

JOB NO.:

OWNER: PT . DONGGI-SENORO LNG

RECORD NO.:

REPORT NO.:

SYSTEM NO.:

GROUTING for steel Structure

DATE:

ITEM :

FWBS :

PCWBS:

POUR DESCRIPTION:

DRAWING REFERENCE:

REQUIRED

ITEM

YES

NO

ACCEPT ABLE

YES

NO

CIVIL INSPECTOR

BSJO

JGC DS LNG

REMARKS

PREPARATION

Surfaces have been chipped & brushed to

remove weak upper layer

Surface cleaned (preferably by compressed

air) to remove dust and dirt.

Anchor bolt pockets roughened and shims

placed with 50mm cover to sides and top

flush with finished level.

Surface soaked with clean water twenty four

(24 ) hours before grouting.

Check on vent holes, foundation bolts and

jacking screws tape wrapped or greased to

prevent bond, expansion joints provided if

required and bolt sleeves filled prior to base

plate grouting.

M ATERIAL & APPLICATION VERIFICATION.

M aterial Approval

Compressive Strenght Result

ACCEPTANCE-FINAL CHECK.

Check to verify grout free of hollow areas

and application is acceptable

REM ARK:

BSJO

JGC

NAM E

SIGNAT URE

DATE

A

R

D

0

2

N

T

I 01-OC 12

DS LNG

You might also like

- TA1179-D-5212-100X-3 - P&ID (Marked-Up)Document40 pagesTA1179-D-5212-100X-3 - P&ID (Marked-Up)Iksan Adityo Mulyo100% (2)

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocument17 pagesF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNo ratings yet

- Declaration of Performance K-Roc UKDocument2 pagesDeclaration of Performance K-Roc UKDavid midlandNo ratings yet

- MEmaco N 907 - Al ZourDocument1 pageMEmaco N 907 - Al Zouraruncg2No ratings yet

- MM Dresser FinalDocument236 pagesMM Dresser FinalPriyabrat Mohanty100% (1)

- Flexi Coil 340 Chisel Plow PDFDocument172 pagesFlexi Coil 340 Chisel Plow PDFАнатолій Гуменюк0% (1)

- KP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFDocument3 pagesKP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFUtku Can KılıçNo ratings yet

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Document13 pagesMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640No ratings yet

- MS CN0P-MTD-736-007 - Lighting Fixture, Receptacles and Wiring REV CDocument12 pagesMS CN0P-MTD-736-007 - Lighting Fixture, Receptacles and Wiring REV Cbrian sanchezNo ratings yet

- ELT-01-CQ-PC-XXXX Welding Consumables Receiving, Storage and HandlingDocument11 pagesELT-01-CQ-PC-XXXX Welding Consumables Receiving, Storage and HandlingjorgekarlosprNo ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- C-051-VP-040-CLTW-PRO-0007 Rev. A Pre Commissioning Commissioning ProcedureDocument11 pagesC-051-VP-040-CLTW-PRO-0007 Rev. A Pre Commissioning Commissioning ProcedureMidha NeerNo ratings yet

- RAPID-P0003-TRSA-CON-ITP-0001-0010 - ITP For Lighting System - R0Document12 pagesRAPID-P0003-TRSA-CON-ITP-0001-0010 - ITP For Lighting System - R0Namta GeorgeNo ratings yet

- Method Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonDocument16 pagesMethod Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonAhmad Rafly ZulfikarNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- HD1-2M90-1042-006 - B - Inspetion Test Plan - CODE BDocument5 pagesHD1-2M90-1042-006 - B - Inspetion Test Plan - CODE Bfreeman11072000No ratings yet

- Attachment 6 - Technical Query FormDocument1 pageAttachment 6 - Technical Query FormLai HuynhNo ratings yet

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- Work Method Statement: Installation of Waste Water Holding TanksDocument9 pagesWork Method Statement: Installation of Waste Water Holding TanksStansilous Tatenda NyagomoNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- ITP For Instrument InstallationDocument10 pagesITP For Instrument Installationnando_scribdNo ratings yet

- EDG Commissioning - Activity ReportDocument3 pagesEDG Commissioning - Activity ReportmohamedNo ratings yet

- Project Execution Plan For SMP Works (Long Son Project)Document11 pagesProject Execution Plan For SMP Works (Long Son Project)hoang nguyenNo ratings yet

- F-Final: 870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 A. AcceptedDocument57 pagesF-Final: 870310-S-1247064-CST-H03-0001 Quality Control Plan Endorsement For Piping Prefab & Erection 04 A. Acceptedismariadi100% (1)

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document14 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiNo ratings yet

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- CE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentDocument20 pagesCE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentkristianNo ratings yet

- P6012MAB.000.10.03.771 - O3 - With JV Comments PDFDocument27 pagesP6012MAB.000.10.03.771 - O3 - With JV Comments PDFMukesh MuraleedharanNo ratings yet

- Inspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Document9 pagesInspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Namta GeorgeNo ratings yet

- Project Quality Control Plan Endorsment For Welding2Document23 pagesProject Quality Control Plan Endorsment For Welding2Tadaya KasaharaNo ratings yet

- SG6427-SY-CK0P-MTD-736-001 - Rev.B-Method Statement For Instrument Cabling WorksDocument12 pagesSG6427-SY-CK0P-MTD-736-001 - Rev.B-Method Statement For Instrument Cabling Worksbrian sanchezNo ratings yet

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- 930-PRC-OP-WIK-0024 - CC01 - Vendor Training Plan - APPROVEDDocument28 pages930-PRC-OP-WIK-0024 - CC01 - Vendor Training Plan - APPROVEDgerry rutmNo ratings yet

- Ebs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanDocument80 pagesEbs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanAsaad AdnanNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- On Plot HydrotestingDocument14 pagesOn Plot HydrotestingShambu S VtkNo ratings yet

- B Qac Pro 210 39161 ADocument12 pagesB Qac Pro 210 39161 AZaidiNo ratings yet

- Instrumentation ITPDocument19 pagesInstrumentation ITPMohammad IrfanNo ratings yet

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDocument2 pagesQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNo ratings yet

- ITR For Electrical Instrument PDFDocument4 pagesITR For Electrical Instrument PDFCokro YudhaNo ratings yet

- C823 3 Doc MST Mec 009Document24 pagesC823 3 Doc MST Mec 009721917114 47No ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document17 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- Site Specific Procedure (Junction Box)Document120 pagesSite Specific Procedure (Junction Box)Mohd Khairi AhmadNo ratings yet

- ITP Transformer Testing and CommissioningDocument1 pageITP Transformer Testing and CommissioningguspriyNo ratings yet

- Ms For Repair and Welding Jointscoating and PaintingDocument9 pagesMs For Repair and Welding Jointscoating and Paintingmansih457100% (1)

- Method Statement - Pouring Foundations-TemplateDocument13 pagesMethod Statement - Pouring Foundations-TemplateUğur BilenNo ratings yet

- T-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623Document77 pagesT-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623JosiahNo ratings yet

- Inspection Test Plan (Itp) : Mobile Fire ExtinguisherDocument4 pagesInspection Test Plan (Itp) : Mobile Fire Extinguisher87482127No ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- Cover Sheet: Zapsib-2 ProjectDocument12 pagesCover Sheet: Zapsib-2 ProjectAkhtar AnsariNo ratings yet

- QC Example Resume.01Document4 pagesQC Example Resume.01Guru SankarNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Process Map For EPC Construction ContractorDocument2 pagesProcess Map For EPC Construction Contractorrahul nandananNo ratings yet

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesDocument20 pagesNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- MS For Instrument InstallationDocument9 pagesMS For Instrument InstallationNijo JoseNo ratings yet

- Cable Pulling Report (Instrument Cable) : Project Name CustomerDocument3 pagesCable Pulling Report (Instrument Cable) : Project Name CustomerAldeline SungahidNo ratings yet

- SA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeDocument16 pagesSA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeABAID ULLAHNo ratings yet

- Upper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Document15 pagesUpper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Anonymous xyZH2OaUVNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- Indra: Donggi Senoro LNG ProjectDocument17 pagesIndra: Donggi Senoro LNG ProjectIksan Adityo MulyoNo ratings yet

- Hse CommitteeDocument1 pageHse CommitteeIksan Adityo MulyoNo ratings yet

- P&IDDocument18 pagesP&IDhectornicolau100% (1)

- F.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearDocument3 pagesF.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearIksan Adityo MulyoNo ratings yet

- List Kekurangan Isometric DrawingDocument8 pagesList Kekurangan Isometric DrawingIksan Adityo MulyoNo ratings yet

- Welding QualificationDocument5 pagesWelding QualificationIksan Adityo MulyoNo ratings yet

- 23 - PT Q&a 1-3 - PDFDocument49 pages23 - PT Q&a 1-3 - PDFbassamNo ratings yet

- QP - 02 Magnetic Particle Test, Rev 01Document13 pagesQP - 02 Magnetic Particle Test, Rev 01Iksan Adityo MulyoNo ratings yet

- Handout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Document96 pagesHandout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Iksan Adityo Mulyo100% (1)

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDocument7 pagesF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNo ratings yet

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocument6 pagesF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNo ratings yet

- Magnetic Particle Test: Job Safety Analysis WorksheetDocument1 pageMagnetic Particle Test: Job Safety Analysis WorksheetIksan Adityo MulyoNo ratings yet

- Section 01 - Typical Duties of Welding InspectorsDocument12 pagesSection 01 - Typical Duties of Welding InspectorsIksan Adityo MulyoNo ratings yet

- Indra: Donggi Senoro LNG ProjectDocument17 pagesIndra: Donggi Senoro LNG ProjectIksan Adityo MulyoNo ratings yet

- Vertical Multiphase Flow: Instructional ObjectivesDocument23 pagesVertical Multiphase Flow: Instructional ObjectivesIksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- S-900-3120-001 - 2 - 0001 (Concreate Building)Document23 pagesS-900-3120-001 - 2 - 0001 (Concreate Building)Iksan Adityo Mulyo100% (1)

- Indra: A NA Const/Pip/QC K. Tsunoda/M. Sakaki 04-Jun-2012 S. KuritsuboDocument17 pagesIndra: A NA Const/Pip/QC K. Tsunoda/M. Sakaki 04-Jun-2012 S. KuritsuboIksan Adityo MulyoNo ratings yet

- PROJ 1051 FAB 001 - 2 Fabrication ProcedureDocument13 pagesPROJ 1051 FAB 001 - 2 Fabrication ProcedureIksan Adityo MulyoNo ratings yet

- JSA Process Piping Inspection Onshore - 2006Document1 pageJSA Process Piping Inspection Onshore - 2006Iksan Adityo MulyoNo ratings yet

- 2 - Oil PropDocument38 pages2 - Oil PropIksan Adityo MulyoNo ratings yet

- 2 Inflow PerformanceDocument36 pages2 Inflow PerformanceIksan Adityo MulyoNo ratings yet

- JSA Pipeline Riser Inspection New Untuk DisimpanDocument1 pageJSA Pipeline Riser Inspection New Untuk DisimpanIksan Adityo MulyoNo ratings yet

- RoofingDocument20 pagesRoofingtbeedle33% (3)

- Asssembly and Installation Manual Zickert Z2013Document53 pagesAsssembly and Installation Manual Zickert Z2013Angelo MesquitaNo ratings yet

- 1 PB PDFDocument6 pages1 PB PDFAbdulsalam AbdulwasiuNo ratings yet

- CU AL Conversion FlyerDocument1 pageCU AL Conversion FlyerSyed Muhammad ZohairNo ratings yet

- Hydraulic Pipe SizingDocument44 pagesHydraulic Pipe Sizingmrmeraj100% (2)

- Addmie Expansion Budget LFN & LFZ (SIF-3)Document1 pageAddmie Expansion Budget LFN & LFZ (SIF-3)Faheem HussainNo ratings yet

- 2001 USDM Subaru Outback Service Manual BE-BHDocument4,267 pages2001 USDM Subaru Outback Service Manual BE-BHgigabyte3235840No ratings yet

- Pump Head CalculationDocument14 pagesPump Head CalculationSolymanElsayedSolymanNo ratings yet

- Markup: Markup For A Construction BusinessDocument9 pagesMarkup: Markup For A Construction BusinessjakejowersNo ratings yet

- Analysis and Design of Cellular Beam and Its VerificationDocument8 pagesAnalysis and Design of Cellular Beam and Its VerificationemmanuelNo ratings yet

- Panel RailFasteningSystemCATALOGDocument36 pagesPanel RailFasteningSystemCATALOGBerkan KayadanNo ratings yet

- Pre-Course-HW-Tailor BrownDocument2 pagesPre-Course-HW-Tailor BrownTailorNo ratings yet

- Material Take-Off: Saudi Arabian Oil CompanyDocument4 pagesMaterial Take-Off: Saudi Arabian Oil CompanybillNo ratings yet

- Planning, Analysis and Design of (G+20) Multi-Storey Residential Building Using Staad - ProDocument8 pagesPlanning, Analysis and Design of (G+20) Multi-Storey Residential Building Using Staad - ProShameer ShajiNo ratings yet

- Describe A BuildingDocument3 pagesDescribe A BuildingGresiShemaNo ratings yet

- Injection Mortar FIS V / FIS VS / FIS VWDocument4 pagesInjection Mortar FIS V / FIS VS / FIS VWrony asmNo ratings yet

- Tender Vol-4 CivilDocument184 pagesTender Vol-4 CivillokenderchaturvediNo ratings yet

- Brown Hettiarachchi 2008 PDFDocument9 pagesBrown Hettiarachchi 2008 PDFjorge BadilloNo ratings yet

- Section 1 PDFDocument438 pagesSection 1 PDFAnfal BarbhuiyaNo ratings yet

- Aquestia OCV TERMINALDocument12 pagesAquestia OCV TERMINALSony Nd AshaNo ratings yet

- Multispan DesignDocument4 pagesMultispan DesignJohn WayneNo ratings yet

- Devarsh Shah CVDocument1 pageDevarsh Shah CVDevarsh ShahNo ratings yet

- Axial Load Capacity of Columns: (Short) : N ST G ST G ST STDocument9 pagesAxial Load Capacity of Columns: (Short) : N ST G ST G ST STAurora VillalunaNo ratings yet

- Prefabricated Structures: Sumbitted To:-Prof. Sanjay Mehra Ar. Varun Jain Sumbitted By: - Yugal GuptaDocument25 pagesPrefabricated Structures: Sumbitted To:-Prof. Sanjay Mehra Ar. Varun Jain Sumbitted By: - Yugal GuptaSwapnil JainNo ratings yet

- Department of Town and Country Planning, Govt. of Haryana: Applying For Occupation CertificateDocument9 pagesDepartment of Town and Country Planning, Govt. of Haryana: Applying For Occupation CertificateIshan ChawlaNo ratings yet

- TransportDocument200 pagesTransportonix58No ratings yet

- ThesisDocument48 pagesThesisTac-an Design and Construction ServicesNo ratings yet