Professional Documents

Culture Documents

PDS 7618 11-2005 Sigmaline 445

PDS 7618 11-2005 Sigmaline 445

Uploaded by

Anonymous 613HTXOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDS 7618 11-2005 Sigmaline 445

PDS 7618 11-2005 Sigmaline 445

Uploaded by

Anonymous 613HTXCopyright:

Available Formats

DATA

SIGMALINE 445

4 pages

DESCRIPTION

November 2005

Revision of September 2004

two component high build amine adduct cured phenolic epoxy in situ lining

PRINCIPAL CHARACTERISTICS provides excellent protection in severe chemical and high temperature

service

excellent resistance to blistering from the "cold wall effect"

excellent for use in sweet and sour crude, brine and processed

petroleum products

resistant to produced water containing hydrogen sulfide and carbon

dioxide

COLOURS AND GLOSS

light green - flat

BASIC DATA AT 20C

(1 g/cm = 8.25 lb/US gal; 1 m/l = 40.7 ft/US gal)

(data for mixed product)

Mass density

Volume solids

VOC (supplied)

1.7 g/cm

70 2%

max. 155 g/kg (Directive 1999/13/EC, SED)

max. 264 g/l (approx. 2.2 lb/gal)

50 - 75 m depending on use

Recommended dry film

thickness

Theoretical spreading rate

Overcoating interval

Full cure after

14 m/l for 50 m *

min. 12 hours *

max. 5 days *

10 days *

(data for components)

Shelf life (cool and dry place)

Flash point

at least 12 months

base 52C, hardener 26C

* see additional data

RECOMMENDED

SUBSTRATE CONDITIONS

AND TEMPERATURES

Page 1/4

steel; chemically cleaned according to sheet 1493 or/and sand jetted,

dry and free from any contamination

substrate temperature should be above 10C and at least 3C above dew

point

DATA

SIGMALINE 445

November 2005

INSTRUCTIONS FOR USE

mixing ratio by volume: base to hardener 90 : 10

(do not vary proportions)

base and hardener should preferably be stored at a temperature of 1520C

power agitate base component to uniform consistency before adding

hardener, then again after adding hardener

add the hardener gradually to the base, using a mechanical mixer

no thinners should be added when used as an in situ coating

after mixing, commencement of the in situ application must be within 3

hours

Induction time

Pot life

15 minutes

6 hours at 20C *

* see additional data

IN SITU APPLICATION

application of this coating to internal pipe surfaces is accomplished by

the use of pigs, pupjoints, compressors and other specialized equipment

this application should be referred to contractors specializing and

experienced in this type of work

coating performance is dependent upon proper surface preparation,

application and curing; these factors are not under the control of Sigma

Coatings and therefore no warranty can be offered

after the application of each coat, dry air has to be blown through the

coated pipe until the next coat is applied (see table for minimum

overcoating intervals)

this will remove the solvents and accelerate the curing

after the last coat is applied, fresh air blowing has to continue for a

minimum of 24 hours

depending on line length, it may be necessary to switch the direction of

the fresh air

Recommended thinner

Sigma thinner 91-92

Ventilation

compressed air to be introduced into the line to remove all solvents during

and after coating or drying procedures

CLEANING SOLVENT

Sigma thinner 90-53

SAFETY PRECAUTIONS

for paint and recommended thinners see safety sheets 1430, 1431 and

relevant material safety data sheets

this is a solvent based paint and care should be taken to avoid inhalation of

spray mist or vapour as well as contact between the wet paint and exposed

skin or eyes

Page 2/4

DATA

SIGMALINE 445

November 2005

ADDITIONAL DATA

Film thickness and spreading rate

theoretical

14

spreading rate m/l

dft in m

50

Overcoating table

substrate

10C

temperature

minimum

24 hours

interval

maximum

7 days

interval

9.3

75

100

20C

30C

40C

12 hours

6 hours

3 hours

5 days

3 days

1 day

after the application of each coat, warm dry air can be applied after

sufficient ambient curing to accelerate the curing

it is beneficial to post cure the total coating system to increase the

chemical resistance

Curing table

substrate temperature

10C

15C

20C

25C

30C

35C

40C

curing time after final coat

24 days

26 days

10 days

7 days

5 days

3 days

2 days

adequate ventilation must be maintained during application and curing

(please refer to sheet 1433 and 1434)

Pot life (at application viscosity)

20C

25C

Worldwide availability

Page 3/4

6 hours

5 hours

Whilst it is always the aim of Sigma Coatings to supply the same product on

a worldwide basis, slight modification of the product is sometimes

necessary to comply with local or national rules/circumstances.

Under these circumstances an alternative product data sheet is used.

DATA

SIGMALINE 445

November 2005

REFERENCES

Explanation to product data sheets

Safety indications

Safety in confined spaces and health safety

Explosion hazard - toxic hazard

Safe working in confined spaces

Directives for ventilation practice

Internal chemical cleaning of steel pipes in-situ application

see information sheet 1411

see information sheet 1430

see information sheet 1431

see information sheet 1433

see information sheet 1434

see information sheet 1493

LIMITATION OF LIABILITY

The information in this data sheet is based upon laboratory tests we believe to be accurate and is intended for guidance

only. All recommendations or suggestions relating to the use of the products made by Sigma Coatings, whether in technical

documentation, or in response to a specific enquiry, or otherwise, are based on data which to the best of our knowledge

are reliable. The products and information are designed for users having the requisite knowledge and industrial skills and

it is the end-user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors affecting the use

and application of the product. Sigma Coatings does therefore not accept any liability arising from loss, injury or damage

resulting from such use or the contents of this data sheet (unless there are written agreements stating otherwise).

The data contained herein are liable to modification as a result of practical experience and continous product development.

This data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure that this sheet

is current prior to using the product.

The English text of this document shall prevail over any translation thereof.

DS

lightgreen

Page 4/4

7618

You might also like

- Jane Greene and Anthony M. Grant. Solution Focused Coaching Managing People in A Complex World 2003. MomentumDocument209 pagesJane Greene and Anthony M. Grant. Solution Focused Coaching Managing People in A Complex World 2003. MomentumJadith Jesus Ezaine Gutierrez100% (2)

- FINAL SYNOPSIS On It ParkDocument11 pagesFINAL SYNOPSIS On It ParkAr Sonali Hadke100% (4)

- UTGDocument16 pagesUTGPackirisamy Baskar100% (2)

- ROS Cheat SheetDocument2 pagesROS Cheat SheetAndrea SpencerNo ratings yet

- Ars Magna - CardanoDocument291 pagesArs Magna - Cardanosidelu100% (3)

- T24 Knowledge Bank - T24 Programs and RoutinesDocument9 pagesT24 Knowledge Bank - T24 Programs and RoutinesAswani MucharlaNo ratings yet

- ASTM D 2709 - 06 Water and Sediment in Middle Distillate Fuels by CentrifugeDocument3 pagesASTM D 2709 - 06 Water and Sediment in Middle Distillate Fuels by CentrifugeAlfonso MartínezNo ratings yet

- 7479 - Sigmacover 510Document0 pages7479 - Sigmacover 510eraswastaNo ratings yet

- Sigmacover 456: Description Principal CharacteristicsDocument5 pagesSigmacover 456: Description Principal Characteristicsmayukhguhanita2010No ratings yet

- 7465 - Sigmacover 435Document0 pages7465 - Sigmacover 435eraswastaNo ratings yet

- Sigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableDocument4 pagesSigmadur Gloss: Description PRINCIPAL CHARACTERISTICS - Unlimited RecoatableKopnang AristideNo ratings yet

- Sigma Cover 510Document4 pagesSigma Cover 510supriadi90315100% (1)

- PDS 7435 09-2005 Sigma Phenguard 935 (English)Document4 pagesPDS 7435 09-2005 Sigma Phenguard 935 (English)KyNo ratings yet

- Sigmafast 278Document4 pagesSigmafast 278MekhmanNo ratings yet

- Sigmadur 520 (English)Document4 pagesSigmadur 520 (English)KyNo ratings yet

- PDS 8316S 10-05-2004 Sigma Coltura Ep Flooring - Trowel Floor Composition (English) PDFDocument4 pagesPDS 8316S 10-05-2004 Sigma Coltura Ep Flooring - Trowel Floor Composition (English) PDFAnonymous jaEllxtL0aNo ratings yet

- All DatasheetsDocument485 pagesAll Datasheetssflynn79No ratings yet

- B22 7537 11-2006 Sigmadur 550Document4 pagesB22 7537 11-2006 Sigmadur 550Muhamad HassanNo ratings yet

- Sigmaguard 720Document4 pagesSigmaguard 720Danny DurhamNo ratings yet

- Pds Sigmadcover 410Document4 pagesPds Sigmadcover 410sibi_s_rajNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Sigmacover 522Document4 pagesSigmacover 522Asela BollegalaNo ratings yet

- 00 6825 PDFDocument5 pages00 6825 PDFibrahim_mohamed3361100% (1)

- Sigmacover 630 March 13Document6 pagesSigmacover 630 March 13leonciomavarezNo ratings yet

- Sigmacap PriCoat 155 V2Document3 pagesSigmacap PriCoat 155 V2ajuhaseenNo ratings yet

- Sigmatherm Thermovit 600 (HR)Document2 pagesSigmatherm Thermovit 600 (HR)shibushineNo ratings yet

- 7430 - Sigmacover 630Document0 pages7430 - Sigmacover 630eraswastaNo ratings yet

- Sigmarine 24: Description Principal CharacteristicsDocument3 pagesSigmarine 24: Description Principal CharacteristicsJose Antonio GomezNo ratings yet

- Sigmazinc 109 HSDocument5 pagesSigmazinc 109 HSKrishna VachaNo ratings yet

- Sigmacover 246Document5 pagesSigmacover 246Carlos Monsalve VejarNo ratings yet

- Sigma PrimeDocument7 pagesSigma Primegstketut0% (1)

- Dimetcote 9 PDS AIDocument3 pagesDimetcote 9 PDS AIAmer Y KNo ratings yet

- 7117 - Sigmarine 28Document0 pages7117 - Sigmarine 28eraswastaNo ratings yet

- 7190 - Sigmarine 81Document0 pages7190 - Sigmarine 81eraswastaNo ratings yet

- Amercoat ABC 3Document0 pagesAmercoat ABC 3Stefano CostaNo ratings yet

- Phenguard 935Document6 pagesPhenguard 935Trịnh Minh KhoaNo ratings yet

- Sika PDS E Sikagard-950Document4 pagesSika PDS E Sikagard-950lwin_oo2435No ratings yet

- Sigmadur 550Document4 pagesSigmadur 550gstketutNo ratings yet

- Phenguard™ 940: Product Data SheetDocument6 pagesPhenguard™ 940: Product Data SheetTrịnh Minh Khoa100% (1)

- Pintuur 550Document5 pagesPintuur 550faniaaaNo ratings yet

- 7285 - Sigma Ecofleet 238Document0 pages7285 - Sigma Ecofleet 238eraswastaNo ratings yet

- Sigmafast 278 en-US - 6829 - AprobadoDocument5 pagesSigmafast 278 en-US - 6829 - AprobadoMiguel Puma SuclleNo ratings yet

- Sigmarine 28Document3 pagesSigmarine 28aangNo ratings yet

- Amercoat 3279 DatasheetDocument0 pagesAmercoat 3279 Datasheetmekag94No ratings yet

- Sigmafast 278Document5 pagesSigmafast 278kaleshNo ratings yet

- Amer Coat 383 Sigma Fast TdsDocument5 pagesAmer Coat 383 Sigma Fast TdsVINAY SARDANo ratings yet

- 7564 Sigmatherm 540Document2 pages7564 Sigmatherm 540Ibrahim MahranNo ratings yet

- Sigmafast™ 278 / Amercoat® 278: Product Data SheetDocument5 pagesSigmafast™ 278 / Amercoat® 278: Product Data SheetStuart LemonNo ratings yet

- PT 290 Plus HMLCDocument4 pagesPT 290 Plus HMLCvictorNo ratings yet

- 7860 Sigmacap Filler 850Document3 pages7860 Sigmacap Filler 850Stephen Francis BothelloNo ratings yet

- Sikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsDocument4 pagesSikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsSholikhinIbnuRamadhanNo ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- en-US 7000Document4 pagesen-US 7000Jose Manuel Guizado SolisNo ratings yet

- SigmaPlane Ecol HS Antifouling PDFDocument3 pagesSigmaPlane Ecol HS Antifouling PDFCarlos VillacrizNo ratings yet

- Sigmatherm 175: Description Principal CharacteristicsDocument3 pagesSigmatherm 175: Description Principal CharacteristicsJose Antonio GomezNo ratings yet

- 7240 - Sigmarine 49Document0 pages7240 - Sigmarine 49eraswastaNo ratings yet

- Sigma Marine Coatings Manual - Part97Document2 pagesSigma Marine Coatings Manual - Part97Tommy2020No ratings yet

- Product Data Sheet: DescriptionDocument4 pagesProduct Data Sheet: DescriptionJose Manuel Guizado SolisNo ratings yet

- SikalasticDuochem390 FpdsDocument4 pagesSikalasticDuochem390 FpdsHielene Corpin PaatNo ratings yet

- Ultraconductive Coating: Conductive Coating For LSPDocument3 pagesUltraconductive Coating: Conductive Coating For LSPfaradaiNo ratings yet

- 1411 - Explanation To Product Data SheetsDocument0 pages1411 - Explanation To Product Data SheetseraswastaNo ratings yet

- Sigmafast 278Document6 pagesSigmafast 278stolemkd3No ratings yet

- SigmaAlphagen 230 PDFDocument3 pagesSigmaAlphagen 230 PDFCarlos VillacrizNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- A Path To Efficient Data Migration in Core BankingDocument8 pagesA Path To Efficient Data Migration in Core BankingCognizantNo ratings yet

- Digital System DesignDocument2 pagesDigital System DesignYaswanthNo ratings yet

- Tag - Number Inst - Type - Desc Service - Desc Equipment - TAG - NO. Manufacturer - N AME Model - NameDocument2 pagesTag - Number Inst - Type - Desc Service - Desc Equipment - TAG - NO. Manufacturer - N AME Model - NameFirdaus NasirNo ratings yet

- SandyDocument1 pageSandykarthick2601No ratings yet

- Isl 88731Document1 pageIsl 88731JahmoNo ratings yet

- Mcdonals PDFDocument29 pagesMcdonals PDFPancho1407No ratings yet

- Handbook 1pr Q.F. Gun 1902Document13 pagesHandbook 1pr Q.F. Gun 1902aakk75No ratings yet

- Glossary of Urban Planning Terms Flashcards - QuizletDocument60 pagesGlossary of Urban Planning Terms Flashcards - QuizletEma AhmedNo ratings yet

- Relience CommunicationDocument27 pagesRelience CommunicationSagar SharmaNo ratings yet

- Motor John DeereDocument12 pagesMotor John DeereAlberto Ferradás50% (6)

- Joining Fiberglass To Steel RecommendationsDocument1 pageJoining Fiberglass To Steel RecommendationsFernandoNo ratings yet

- SpendAccount 8335 - 2022 12Document1 pageSpendAccount 8335 - 2022 12Dan BNo ratings yet

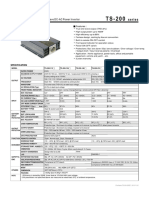

- TS 200Document2 pagesTS 200Kmila ClavijoNo ratings yet

- Shin YoDocument10 pagesShin YoROFLknifeNo ratings yet

- Two Stroke AircraftDocument10 pagesTwo Stroke AircraftVinti Bhatia100% (1)

- The Design and Stress Analysis of A 10.000 Barrel Fixed Roof Crude Oil Storage TankDocument8 pagesThe Design and Stress Analysis of A 10.000 Barrel Fixed Roof Crude Oil Storage TankMahmoud HafezNo ratings yet

- McSL-016 Solvedlab Manual - Advance HTMLDocument18 pagesMcSL-016 Solvedlab Manual - Advance HTMLsounak kumar pandey100% (1)

- Hobart AWS Auto Wrapper Operator ManualDocument72 pagesHobart AWS Auto Wrapper Operator ManualRic WagonerNo ratings yet

- Filters For Industrial Applications 10-2017 ENDocument12 pagesFilters For Industrial Applications 10-2017 ENCalin DiaconuNo ratings yet

- An Overview Of: Robot That Used PID ControlDocument20 pagesAn Overview Of: Robot That Used PID ControlTeck Soon TeoNo ratings yet

- CV Ioana Teodorescu enDocument7 pagesCV Ioana Teodorescu enIoana Bucur-TeodorescuNo ratings yet

- Extending Ansible - Sample ChapterDocument16 pagesExtending Ansible - Sample ChapterPackt PublishingNo ratings yet

- HA17458 HitachiDocument10 pagesHA17458 HitachiStevenNo ratings yet