Professional Documents

Culture Documents

QAP - LT Panel PDF

QAP - LT Panel PDF

Uploaded by

Akshay AjayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAP - LT Panel PDF

QAP - LT Panel PDF

Uploaded by

Akshay AjayCopyright:

Available Formats

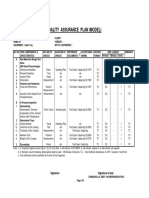

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

As per AN

Electricals

Drgs

AN

Electricals

AN Electricals

Measurement

Visual

Measurement

- do - do Apprd. Drwgs

&

Specifications

IS : 5082/

1897

- do - do AN

Electricals

Inspection

Record

- do - do AN Electricals

Measurement

IS :

1364/3063

AN

Electricals

Inspection

Record

- do -

AN Electricals

AN

Electricals

Inspection

Record

- do -

AN Electricals

QUALITY ASSURANCE PLAN

ITEM : SOLAR LT PANEL.

MATERIAL

INSPECTION

Busbar Support SMC/

DMC

BUSBAR

Hardware

Bolt / Nuts / Plain

Washer / Spring

Washer

Neoprene Rubber

Gasket

Conductor / Wire

A) Type Of

Support:

SMC

B) Dimensions

C) Surface Finish

A) Size & Cross

Section:

A) Dimensional

Confirmity

B) Plating : Zinc /

Cd

A) Dimensional

Confirmity

A) Verification of

Cross Section

make, Colour

Code , Grade etc.

Major

- do - do - do -

Major

Visual

- do -

- do -

- do -

- do -

Major

Page 1 of 8

Physical

Verification /

Measurement

- do Internal Std.

- do -

- do -

- do -

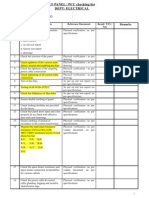

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

Physical

Verification /

Measurement

IS : 694

- do -

- do -

Approved Drg

- do -

- do -

- do -

- do -

- do -

B) Thickness of

Insulation

Air Ckt Breaker (ACB)

A) Verification of

Current rating

B) Verification of

Voltage Grade

C) Mounting

Arrangement &

Dimensions

- do -

Major

- do -

Visual

- do -

- do -

Measurement

- do -

- do -

- do -

D) Voltage Rating

of Closing Coil /

Shunt / Trip /

Under Voltage

- do -

Visual

- do -

- do -

- do -

E) Anti Pumping

/ Trip Free

Feature

- do -

Electrical

- do -

- do -

- do -

Visual

Approved

Drg.

AN

Electricals

Inspection

Record

- do -

AN Electrical

Terminal for Power &

Control

A) Size / Current

rating

Protective Relays

B ) Connecting

Arrangement

A) Mounting

Detail Setting

range Aux.

Contact Pos.

Air Break Contactors /

Timers / Time

switches

A) Mounting

Detail &

Mechanical

operation

Major

- do -

- do -

- do -

Major

Physical

verification

Approved Drg

Major

Physical

verification

Approved Drg

/ IS : 2959

Page 2 of 8

AN

Electricals

Inspection

Record

AN

Electricals

Inspection

Record

- do AN Electricals

AN Electricals

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

10

11

12

13

Current Transformer

Indicating Lamps &

Indicating

Instruments(Voltmeter,

Ammeter, Frequency,

KW, KWH, Meter etc.)

Control Switch

Space Heater

B) Current Rating

/ Make

C) No. Of

Contacts

A) Mounting

Detail &

Dimensions

- do -

- do -

- do -

- do -

- do -

- do -

- do -

- do -

- do -

- do -

Minor

Physical

Verification

B) CT Ratio ,

Class Of

Accuracy

Critical

Document

verification

A) Mounting

Detail &

Dimensions

Minor

Physical

Verification

Approved Drg

B) Accuracy Class

Major

Visual

Approved drg

IS : 1248

IS : 2419

C) Routine / Type

Test

A) Visual

Major

Electrical

Minor

Physical

verification

Approved drg

IS : 6875

Approved Drg

Major

Visual

- do -

Functional

test

Visual /

Physical

inspection

- do -

B) Contact Rating

AC / DC

C) Operational

Test

A) Mounting

Detail

- do Minor

Page 3 of 8

Approved Drg

- do -

Approved Drg

AN

Electricals

Inspection

Record

Manufacturer

TC

AN Electricals

Manufacturer

TC

Manufacturer

- do -

Manufacturer

TC

AN

Electricals

Inspection

Record

- do - do AN

Electricals

Inspection

Record

Manufacturer

- do -

Manufacturer

AN Electricals

- do - do AN Electricals

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

B) Verification of

Volt / Watt

Rating

Major

Visual

- do -

14

MCB / MCCB

A) Verification of

rating & Make

Major

Electrical

Approved drg

15

Push Button

A) Verification of

Rating & Contact

Arrangement

Major

Electrical

Approved drg

B) Mounting

Arrangement

C) Operational /

Functional

16

INPROCESS

INSPECTION

PANEL FABRICATION

A) Visual check

for weld,

dressing,

deburing,

straightness &

dimensional

control

- do -

- do -

- do -

- do -

- do -

- do -

Minor

B) Dimensions

- do -

C) Lifting

Facilities

D) Cable Entry

E) Waviness

- do - do - do -

Page 4 of 8

Physical

Verification

Process (

Physical

check before

assembly)

Internal Std.

- do -

AN

Electricals

Inspection

Record

AN

Electricals

Inspection

Record

- do - do -

Internal

Inspection

record

- do -

AN Electricals

AN Electricals

- do - do -

AN Electricals

- do -

- do -

- do -

- do -

- do -

- do -

- do -

- do - do -

- do - do -

- do - do -

- do - do -

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

17

Panel Painting

18

Assembly

F) Gasket

Arrangement

- Paint

Thickness

- Finish

A) Alignment of

Panel & Busbar

b) Check for

Busbar Mounting

1) Tightness of

Busbar Joints

- do - do - do Major

- do -

- do Measurement

Visual

Physical

verification

Physical test

by Torque

Wrench

- do -

- do -

- do -

- do -

- do -

- do -

- do IS : 101

Internal Std.

- do Internal

Inspection

record

- do AN Electricals

- do -

- do -

2) Busbar

Mounting on

Insulators

- do -

- do -

- do -

- do -

- do -

3) Busbar jointing

Arrangement &

Overlapping

- do -

- do -

- do -

- do -

- do -

4) Busbar

bending &

Drilling

- do -

- do -

- do -

- do -

- do -

Physical

- do -

- do -

- do -

Visual Check

- do -

- do -

- do -

5) Phase

Identification &

Clearance

6) Busbar

Sleeving

Critical

Minor

C) Check for CT

Mounting

Page 5 of 8

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

1) Mounting &

Adequate

Supports of CT

19

Wiring

Final Inspection

Physical

verification

- do -

- do -

- do -

2) Provision for

Shorting link on

CT terminal

- do -

- do -

- do -

- do -

- do -

D) Mechanical

Interlocking

Arrangement

- do -

Functional

check

- do -

- do -

- do -

F) Arrangement of

Components &

Terminations

- do -

Physical

Verification

- do -

- do -

- do -

A) Proper Wire

Clamping

B) Continuity &

Ferruling as per

wiring diagram

C) Proper

crimping of lugs /

connections

tightening at

terminals &

components

20

Major

A) Verification of

Component,

Rating,

Arrangement as

per GA Drg make

Minor

- do -

- do -

Major

Page 6 of 8

Visual

Visual / test

- do -

Physical

Verification

Internal Std

- do -

Internal

records

- do -

- do -

- do -

Approved Drg

IS : 8625/ IS

: 4237/ IS :

2127

Internal

records

AN Electricals

- do -

- do -

AN Electricals

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

C) Wiring Cubicle

& Ckt. Function

test , operation of

indicating

instruments

wiring

completeness

- do -

D) Continuity test

E) HV/Megger

Test on both

Power / Control

Ckt

F) Phase

Indication

- do Critical

G ) Check for

Busbar clearance

, Tightness of

electrical /

mechanical

interlock

- do -

Visual /

Physical

verification of

torque

wrench

- do -

- do -

- do -

H ) Degree of

protection by

insertion of thin

paper / light test

- do -

Test

- do -

- do -

- do -

Visual

- do Physical

Verification

- do - do - do -

- do - do - do -

- do - do - do -

I ) Final Painting

1) Shade

2) Surface Finish

3) Thickness

Major

- do Minor

Major

Page 7 of 8

- do -

Routine test

- do -

Visual

- do -

- do -

- do -

- do - do -

- do - do -

- do - do -

Approved Drg

IS : 8623 / IS

: 4237 / IS :

2127

Internal

Records

AN Electricals

S.No.

Component /

Operation

Characteristics

Checked

Classification

Method /

Type of Check

Acceptance

Norm

Format of

Record

Agency

Internal

Specs

- do -

Inspection

Record

- do -

AN Electricals

1) Function

2) HV / IR test

Major

- do -

Page 8 of 8

Physical

verification

Routine test

- do -

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

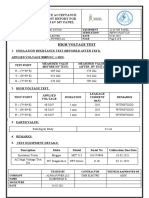

- Test Report For Current TransformerDocument6 pagesTest Report For Current Transformershiv2411100% (2)

- Panel Inspection Report FormatDocument5 pagesPanel Inspection Report Formatp mahesh goud100% (2)

- LT PANEL Testing ProcedureDocument5 pagesLT PANEL Testing Procedureaslam shaikh71% (7)

- Electrical Control Panel Testing and Inspection ChecklisttDocument2 pagesElectrical Control Panel Testing and Inspection ChecklisttRanjit Singh100% (7)

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad75% (4)

- Earthpit Resistance Testing RecordsheetDocument1 pageEarthpit Resistance Testing RecordsheetawsomeNo ratings yet

- LV Cable Commissioning Test ReportDocument1 pageLV Cable Commissioning Test ReportNghiemNo ratings yet

- Protocol-Motor Trial Run FormatDocument6 pagesProtocol-Motor Trial Run FormatAnuj Gautam0% (1)

- Cable Test ReportDocument6 pagesCable Test ReportVasuNo ratings yet

- 1.PRIMARY-PU01 RS2 11kV CABLE REPORTDocument3 pages1.PRIMARY-PU01 RS2 11kV CABLE REPORTGajendran Sriram50% (2)

- Testing of Control PanelDocument7 pagesTesting of Control PanelsasikumarNo ratings yet

- TEST REPORT After Earth ImprovementDocument3 pagesTEST REPORT After Earth ImprovementShami Mudunkotuwa78% (9)

- List of Applicable Electrical StandardsDocument3 pagesList of Applicable Electrical StandardsShadab Waseem67% (6)

- MOTOR INSTALLATION ChecklistDocument4 pagesMOTOR INSTALLATION ChecklistWisnu Hartono100% (2)

- Rmu Visual Inspection ChecklistDocument1 pageRmu Visual Inspection ChecklistJoe_Average100% (3)

- Cold Test Report 3Document1 pageCold Test Report 3Venkitesh PG100% (1)

- 0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)Document2 pages0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)ResearcherNo ratings yet

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Motor Commisioning FormatDocument6 pagesMotor Commisioning Formataapakamukesh100% (1)

- Earthing Test ReportDocument2 pagesEarthing Test Reportprabhumanoc100% (4)

- Aoh Checklist LT and HT MotorDocument8 pagesAoh Checklist LT and HT MotorElectrical Team100% (1)

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth SolaNo ratings yet

- Annexure 4 - TransformerDocument36 pagesAnnexure 4 - TransformerBala MNo ratings yet

- 1.6 Kva Transformer Testing ReportDocument5 pages1.6 Kva Transformer Testing ReportVikrant DeshmukhNo ratings yet

- Presonus Series III Cheat Sheet 1.1Document2 pagesPresonus Series III Cheat Sheet 1.1Sage SwayneNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Acdb FQPDocument9 pagesAcdb FQPAnonymous vcadX45TD7No ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- HT Panel ChecklistDocument1 pageHT Panel ChecklistMahfuza MansuraNo ratings yet

- HT Panel ChecklistDocument1 pageHT Panel Checklisttango member0% (1)

- Insulation Resistance Test (Primary To Earth 500 Volt, Secondary To Earth 500 Volt, Primary To Secondary 500 Volt)Document2 pagesInsulation Resistance Test (Primary To Earth 500 Volt, Secondary To Earth 500 Volt, Primary To Secondary 500 Volt)MD JAHANGEER0% (1)

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi50% (2)

- High Voltage Test: Site Acceptance Test Report For 22 KV MV PanelDocument2 pagesHigh Voltage Test: Site Acceptance Test Report For 22 KV MV PanelGajendran Sriram100% (1)

- Contact Resistance Test FormatDocument1 pageContact Resistance Test Formatrudra abhi100% (1)

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla Vietor100% (1)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil Patel100% (2)

- Dry Type Transformer Test Report: Page 1 of 2Document2 pagesDry Type Transformer Test Report: Page 1 of 2erwin5sambas5aryanaNo ratings yet

- Bus Bar Contact Resistance TestDocument1 pageBus Bar Contact Resistance TestGajendran Sriram100% (1)

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Site Test Report For Potential Transformer: StepcDocument2 pagesSite Test Report For Potential Transformer: StepcRAM SHANMUGAMNo ratings yet

- 11 - SOP For Earthing Pit and EarthingDocument15 pages11 - SOP For Earthing Pit and Earthingtryu frtgeuwNo ratings yet

- DCDB - Function TestDocument5 pagesDCDB - Function TestAmr ElkadyNo ratings yet

- Test Report For Protection Relay and Current Transformer: Schneider Vamp 50Document2 pagesTest Report For Protection Relay and Current Transformer: Schneider Vamp 50RamaNo ratings yet

- Checklist For Erection of USSDocument3 pagesChecklist For Erection of USSsasikumarNo ratings yet

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanNo ratings yet

- Form Motor Solo Run Interlock FuncDocument1 pageForm Motor Solo Run Interlock FuncImam HanafiNo ratings yet

- 11KV SWGR HipotDocument2 pages11KV SWGR HipotSathi Reddy Thondapu100% (1)

- VCB Maint ChecklistDocument3 pagesVCB Maint ChecklistAshish MahapatraNo ratings yet

- Site Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyDocument3 pagesSite Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyGajendran SriramNo ratings yet

- 11 KV VCB PanelDocument29 pages11 KV VCB PanelPrakash Rout100% (6)

- Milli Volt Drop Test PDFDocument2 pagesMilli Volt Drop Test PDFkazishah67% (3)

- Inspection and Test Plan For Bus Duct PDFDocument4 pagesInspection and Test Plan For Bus Duct PDFwandinuari100% (1)

- Bet VT Test ReportDocument2 pagesBet VT Test ReportSathi Reddy ThondapuNo ratings yet

- Earth Resistance Testing ReportDocument2 pagesEarth Resistance Testing ReportGalif Aftabul Mamood100% (2)

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- SQIDocument84 pagesSQIEng-Mohamed SaifNo ratings yet

- Checklist - CostingDocument7 pagesChecklist - CostingAkshay AjayNo ratings yet

- Earthing PracticesDocument59 pagesEarthing PracticesAkshay AjayNo ratings yet

- Active Power Management of Electric Power System Using Emerging Power Electronics Technology AimDocument3 pagesActive Power Management of Electric Power System Using Emerging Power Electronics Technology AimAkshay AjayNo ratings yet

- InstructionsDocument70 pagesInstructionsAkshay AjayNo ratings yet

- Facts STTPDocument38 pagesFacts STTPAkshay AjayNo ratings yet

- Miniproject Control SystemsDocument4 pagesMiniproject Control SystemsAkshay Ajay100% (1)

- Vibration Transducers BrochureDocument20 pagesVibration Transducers BrochureZdenko SemanNo ratings yet

- Radiant 1Document7 pagesRadiant 1Senki AlphonsNo ratings yet

- ADSS-24F4K-120 Test Report (6028)Document1 pageADSS-24F4K-120 Test Report (6028)Adriana RosadoroNo ratings yet

- Eq Generacion Electrica Iluminacion Olympian GEP445Document6 pagesEq Generacion Electrica Iluminacion Olympian GEP445jedu202No ratings yet

- Read Chapter 3, The 8051 Microcontroller Architecture, Programming and Applications by Kenneth .J.AyalaDocument40 pagesRead Chapter 3, The 8051 Microcontroller Architecture, Programming and Applications by Kenneth .J.AyalaJithu TvmNo ratings yet

- Elecrtic Motors Universal Protection Device: Service ManualDocument31 pagesElecrtic Motors Universal Protection Device: Service ManualIgor MândruNo ratings yet

- Protection Engineer: XXXXXDocument4 pagesProtection Engineer: XXXXXTaimoor Nafees BajwaNo ratings yet

- 3tm Vacuum Contactors enDocument2 pages3tm Vacuum Contactors enThalia ParcoNo ratings yet

- PROMAG P300 - Installation ManualDocument92 pagesPROMAG P300 - Installation ManualFernando SantosNo ratings yet

- Modules-Stada 2022Document36 pagesModules-Stada 2022akbar raizoNo ratings yet

- GE Energy Industrial Solutions. SEN Plus. SEN Plus LV EquipmentDocument48 pagesGE Energy Industrial Solutions. SEN Plus. SEN Plus LV EquipmentLamia BekehchiNo ratings yet

- How To Disassemble HP Pavilion Dv2 Laptop - Inside My LaptopDocument22 pagesHow To Disassemble HP Pavilion Dv2 Laptop - Inside My LaptopPage UpNo ratings yet

- Simplex 4100es Fire Control Panels 2120 Bmux Cpu Upgrade Equipment Transponder Interface Module 4100 6065 5684392071Document4 pagesSimplex 4100es Fire Control Panels 2120 Bmux Cpu Upgrade Equipment Transponder Interface Module 4100 6065 5684392071phuong daoNo ratings yet

- 5 Temperature Rise PDFDocument51 pages5 Temperature Rise PDFVM Alvarez100% (1)

- JMAG ProductsDocument20 pagesJMAG Productskhio buNo ratings yet

- SIGA AB4G Audible Detector Base Installation SheetDocument6 pagesSIGA AB4G Audible Detector Base Installation SheetSalman HafeezNo ratings yet

- Model G0513 Series Heavy-Duty 17" Bandsaw: Owner'S Manual (MODELS G0513, G0513A40 & EXTREME MODELS G0513X2, G0513X2BF)Document100 pagesModel G0513 Series Heavy-Duty 17" Bandsaw: Owner'S Manual (MODELS G0513, G0513A40 & EXTREME MODELS G0513X2, G0513X2BF)John SlorNo ratings yet

- Two Layer Soil ModelDocument11 pagesTwo Layer Soil ModelAmany HamdyNo ratings yet

- FACTS Technologies SVC PDFDocument9 pagesFACTS Technologies SVC PDFKrishnanNo ratings yet

- Current Electricity: E.M.F. CurrentDocument114 pagesCurrent Electricity: E.M.F. CurrentgolusodoNo ratings yet

- Implementation of PWM Based Firing Scheme For Multilevel Inverter Using MicrocontrollerDocument52 pagesImplementation of PWM Based Firing Scheme For Multilevel Inverter Using MicrocontrollerAbdulaziz MuhammedNo ratings yet

- Isc SMADocument8 pagesIsc SMAWaseem Al OmariNo ratings yet

- Grade 6 Unit 4 HomeworkDocument5 pagesGrade 6 Unit 4 HomeworkLaila Khan100% (1)

- Bits TimetableDocument172 pagesBits Timetableanon_585647613No ratings yet

- ST Microelctronics by Element14 Batch 1Document9 pagesST Microelctronics by Element14 Batch 167409b5322No ratings yet

- FPGA Based Flexible Autopilot Platform For Unmanned Systems: W. Alvis, S. Murthy, K. Valavanis, W. Moreno, S. KatkooriDocument9 pagesFPGA Based Flexible Autopilot Platform For Unmanned Systems: W. Alvis, S. Murthy, K. Valavanis, W. Moreno, S. KatkooriParth ChopraNo ratings yet

- Control Unit Let-Off Digi-KastDocument3 pagesControl Unit Let-Off Digi-KastMễro ĢANo ratings yet

- Trafo Erection and MAINTENANCEDocument23 pagesTrafo Erection and MAINTENANCEgm29No ratings yet

- MPM 867 01 12Document23 pagesMPM 867 01 12Mousa PetrolNo ratings yet