Professional Documents

Culture Documents

Finishing A Basement Bathroom - Part 9: Liberty Sewage Pump

Finishing A Basement Bathroom - Part 9: Liberty Sewage Pump

Uploaded by

Brad Flores0 ratings0% found this document useful (0 votes)

48 views15 pagesThe basement bathroom project involves installing a sewage ejector pump and connecting it to the existing sewer line. A 3/4 HP Liberty sewage pump is installed in the sewage basin. The main sewer line is cut and a Fernco flexible tee fitting is installed to connect the pump discharge piping. 2 inch PVC pipe is used to connect the pump to the check valve and ball valve, and then run up to connect to the main sewer line above through 45 degree elbows. The vent line and high water alarm will be installed next before testing the system for leaks.

Original Description:

sfgg

Original Title

instalasi

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe basement bathroom project involves installing a sewage ejector pump and connecting it to the existing sewer line. A 3/4 HP Liberty sewage pump is installed in the sewage basin. The main sewer line is cut and a Fernco flexible tee fitting is installed to connect the pump discharge piping. 2 inch PVC pipe is used to connect the pump to the check valve and ball valve, and then run up to connect to the main sewer line above through 45 degree elbows. The vent line and high water alarm will be installed next before testing the system for leaks.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

48 views15 pagesFinishing A Basement Bathroom - Part 9: Liberty Sewage Pump

Finishing A Basement Bathroom - Part 9: Liberty Sewage Pump

Uploaded by

Brad FloresThe basement bathroom project involves installing a sewage ejector pump and connecting it to the existing sewer line. A 3/4 HP Liberty sewage pump is installed in the sewage basin. The main sewer line is cut and a Fernco flexible tee fitting is installed to connect the pump discharge piping. 2 inch PVC pipe is used to connect the pump to the check valve and ball valve, and then run up to connect to the main sewer line above through 45 degree elbows. The vent line and high water alarm will be installed next before testing the system for leaks.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 15

Finishing a Basement Bathroom Part 9

Basement, Bathroom, Plumbing, Remodeling

The sewage ejector pump and sewer plumbing connections are made in this exciting episode of the

project! Actually, I wasnt looking forward to cutting open the sewer line to install the Tee-fitting for

basement bathroom sewer hookup. As it were, it turned out to be a pleasant dirty job.

Liberty Sewage Pump

I bought a new Liberty 3/4 HP sewage on eBay.com for just $299.00 (the economy is bad and there

were no other bidders) compare this price to $753.00 for the same item at Grainger. I could have

gotten by with 1/2 HP pump, but opted for the 3/4 HP model for added reliability because I never want

to open the sewage basin and pull the pump that would be a dirty job. Consult the pump

manufacturers Engineering Specifications to size a pump for your particular needs.

In the photo below, the pump is shown with the gray mechanical float switch and white 2-inch threaded

PVC pipe adapter on the discharge outlet. As the water level rises, the metal ball in the float switch

rolls and closes the on/off switch contact to turn on the pump.

The water level should never rise more than half-way up the side of pump housing before the pump

turns on. This pump is rated at 60 gallons per minute at 20 feet of head for my situation. Head is the

vertical number of feet, including friction losses for plumbing elbows, that the pump must lift the

sewage. Given that I only have a shower that uses ~7 gallons per minute, 1.6 gallon per flush toilet and

sink, it will be impossible for the inflow to exceed more than 10 to 15 gallons per minute worst case.

Liberty Sewage Pump - Model LE71A2

The intake opening is shown here on the bottom of the pump. A cast iron impeller rotates at 1725 RPM

inside the housing. It runs vibration free and whisper quite.

Liberty Sewage Pump - Bottom View

Preparing the Sewage Basin

I cleaned the dirt and cement splatters off the 2-part metal cover to the sewage basin, revealing several

rust blisters under the paint. The rust spots were sanded down with a wire brush drill attachment and

treated with Naval Jelly rust killer. Four coats of Rust-Oleum black enamel spray were then applied.

Sewage Basin 2-Part Metal Cover

The metal cover is secured to the perimeter of the sewage basin by mirror mount nuts and bolts. The

old ones were rusted (left items) and replaced with six new assemblies. Mirror mount nuts splay out in

star pattern when tightened to fasten the nut securely to the plastic rim of the basin.

Mirror Mount Nuts, Bolts and Washers

I also removed the rim from the inside of the sewage inlet with a Roto-Zip tool as I felt this lip would

only serve as a catch point another contractor quality oversight in my opinion. If you look

carefully, you can see the black plastic rim at the bottom of the basin.

Roto-Zipping the Sewage Inlet Rim

Sewage Pump Installation

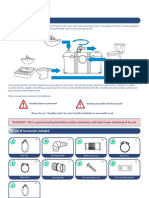

The following sewage pump installation diagram will be helpful to understand the following

installation steps.

Sewage Pump Installation Diagram (C) Liberty Pumps, Inc.

The sewage pump is lowered into the basin and aligned with the plumbing holes in the metal cover.

The rubber grommets for the sewer pipe, vent pipe and electrical connections are laying to the left.

Also notice the new mirror mounts nuts installed in the rim of the basin (gray circles).

Sewage Pump in the Basin

The combination check and ball valve is dry fitted to a 36 inch length of 2 inch PVC pipe to begin the

sewage line connections. I purchased mine from Grainger, part #4RG93, the item in the Grainger

catalog looks a little different than the one here. The purpose of the check valve is to prevent backflow

and the ball valve allows me to shutoff the sewer pipe for maintenance without backflow problems. Its

also required by the building code.

If I ever need to pull the pump, the check/ball valve has a slip union threaded joint to disconnect the

pipe.

Combo Check- and Ball Valve

The stem pipe is pushed down to the sewage pump through the rubber grommet in the basin lid. Im

still dry-fitting the piping and havent glued any connections.

Ball/Check Valve Stem Pipe and Pump

Closeup of the 2 inch PVC sewer pipe connection and pump inside the basin.

Sewage Pump and Stem Pipe

Splicing the Tee Fitting into the Main Sewer Line

The main 3 inch PVC sewer line must be cut to install the Fernco QT-300 Tee connector for the sewage

pump line. The installed Tee is shown below.

Sewer Line Ell Fitting by Fernco, Inc.

Sanitizing the Sewer Line

The 3 inch PVC sewer line in the photo above serves the master bathroom. In anticipation of cutting

the sewer line, I poured 1/2 gallon of bleach down the toilet in the master bath and flushed several

times to sanitize the PVC sewer pipe. The master bathroom was off-limits for 24 hours to allow the

sewer line to fully drain as I didnt want to get dripped on when I cut open the PVC line.

Installing the Flexible Tee Fitting

The section to be cut out from the main 3 inch PVC sewer line was marked as shown using the Fernco

QT-300 Tee as a reference. I removed one of the steel bands from the Tee and snugged it around the

PVC pipe to mark a perfect circle.

Fernco QT-300 Flexible Tee - 3 inch

The section to be cut out is shown in the next photo. This view is looking up directly overhead.

Main Sewer Line Marked and Ready for Cutting

I was concerned over what might spill out of the sewer line when I cut it open. I didnt know if it would

be dripping or filled with sludge or ??? I also dont like cleaning up messes. I therefore suspended a

plastic bin from the floor joist with wires as shown under the section of the sewer pipe to be cut out.

This would catch the saw dust, drips and section of PVC pipe.

Plastic Storage Bin for Catching the Debris

I used a Milwaukee Sawzall to make the cuts on the PVC sewer line.

Sawzall, Safety Glasses and Latex Gloves

The Sawzall cut the PVC pipe like butter in just seconds. The plastic bin caught the PVC shavings and

the section of pipe. To my surprise, the sewer line was bone dry and odor free! Next, I deburred the

PVC pipe ends by smoothing off the shavings with my gloved fingers.

Main Sewer Line Cuts

A closeup of the Fernco flexible Tee fitting installed on the main sewer line. I had considered using a

rigid PVC fitting and was happy I didnt because there was almost no give in the main sewer line

ends to install a rigid fitting. I had to partially fold the Fernco fitting to squeeze it between the two

pipe ends. All said and done, it took only a minute to fit it on the sewer pipe.

Fernco QT-300 Tee Fitting Installed

Another view of the installed Tee:

Flexible Tee Fitting Installed on Sewer Line

Working from the ground up, I completed the 2 inch PVC sewer pipe connections and cemented the

joints together. Remember the bottom of the check/ball valve is slip union connection for a quick

disconnect in case I ever need to pull the sewer pump.

Sewage Pump Pipe and Check/Ball Valve Connections

2 inch PVC riser pipe is installed to carry the waste water up to the main sewer line. The sewage is

pumped upward as indicated by the red arrows.

Sewer Line Riser Piping

The sewage pump discharge lines must empty into the main line from above, hence the 45 degree

elbows to clear the existing feeder line and floor joist. Red arrows indicate the direction of flow.

Hanger straps are called out by the blue arrows.

Overhead Connections to the Main Sewer Line

I was very happy with how this job went. In part 10 of this project, Ill connect the exterior vent line to

the sewage basin and install the high water alarm. Then Ill be ready to test the system for leaks. After

that, the only thing left to do is set the toilet and vanity! The finish line is within sight!

You might also like

- Linde 350 03 GB 0412Document258 pagesLinde 350 03 GB 0412Фалкор Д100% (1)

- CK25-1 Webm007000 PDFDocument306 pagesCK25-1 Webm007000 PDFMagdalena BujaraNo ratings yet

- Magnetic ORMUS Vortex TrapDocument10 pagesMagnetic ORMUS Vortex TrapZach Royer100% (2)

- Polaris 280 Repair ManualDocument42 pagesPolaris 280 Repair ManualPool Supply Sales100% (3)

- Technical DataDocument202 pagesTechnical DataIsaac JebNo ratings yet

- RT-124 Troubleshooting & Maintenance On Injection Control UnitDocument21 pagesRT-124 Troubleshooting & Maintenance On Injection Control UnitKhalid Najmi100% (2)

- Rotary Spoa7-9 Spo9 400 Series Install PDFDocument16 pagesRotary Spoa7-9 Spo9 400 Series Install PDFFranck RoyerNo ratings yet

- Dosagem de ConcretoDocument40 pagesDosagem de ConcretoRobertoVitorianoNo ratings yet

- Continuous Drip System Aka The Betta Wall: Please Read It All Before StartingDocument5 pagesContinuous Drip System Aka The Betta Wall: Please Read It All Before StartingmlapasoaresNo ratings yet

- House PlumbingDocument12 pagesHouse PlumbingEmanuel EmanuelNo ratings yet

- Easy Tips For Home Plumbing Repairs by Clearly PlumbingDocument26 pagesEasy Tips For Home Plumbing Repairs by Clearly Plumbingclearlybooks100% (2)

- Division 14 16Document6 pagesDivision 14 16Bailey LoveNo ratings yet

- Liquid Pump Mercury Switch ConductanceDocument7 pagesLiquid Pump Mercury Switch ConductanceMudasir BawaNo ratings yet

- Water Pump Remove and Replace: 2002 VTX 1800CDocument10 pagesWater Pump Remove and Replace: 2002 VTX 1800CGheorghe DanielNo ratings yet

- Smacks Booster - Addition de Gaz de Brown Produit Par Electrolyse de L'eau Dans Un Moteur ConventionelDocument15 pagesSmacks Booster - Addition de Gaz de Brown Produit Par Electrolyse de L'eau Dans Un Moteur ConventionelThe DoctorNo ratings yet

- Smacks Booster MPGDocument14 pagesSmacks Booster MPGjoetylorNo ratings yet

- Tanks - Pump ConnectionDocument5 pagesTanks - Pump ConnectionPraveen KaluraNo ratings yet

- Plumbing Installation 25Document1 pagePlumbing Installation 25mohansafNo ratings yet

- SCOUT Product Demonstration Prop Building Instructions: Task 1: AircraftDocument18 pagesSCOUT Product Demonstration Prop Building Instructions: Task 1: Aircraftindependent_mindNo ratings yet

- Standpipe Piezo DatasheetDocument2 pagesStandpipe Piezo DatasheetQoudar RamdhaniNo ratings yet

- Standpipe PiezoDocument2 pagesStandpipe PiezoConciselyNo ratings yet

- Raw FAQs Category9Document4 pagesRaw FAQs Category9Anh NguyenNo ratings yet

- VBHC Value Homes PVT LTD.: Checklist For On Site Inspection Handing Over of CP & Sanitary Fittings (Commissioning)Document4 pagesVBHC Value Homes PVT LTD.: Checklist For On Site Inspection Handing Over of CP & Sanitary Fittings (Commissioning)hazihappyNo ratings yet

- Toilet Installation Instructions: Instrucciones para Instalación de SanitariosDocument2 pagesToilet Installation Instructions: Instrucciones para Instalación de SanitarioswilfredoNo ratings yet

- PVC Chicken Waterer - AllDocument10 pagesPVC Chicken Waterer - AllticleanulNo ratings yet

- Architect + Consultant + Project Manager Master Plumber + AcademeDocument68 pagesArchitect + Consultant + Project Manager Master Plumber + AcademeJett SorianoNo ratings yet

- 6189 L2u10 ppt6Document33 pages6189 L2u10 ppt6bendeniNo ratings yet

- Hand Powered Water PumpsDocument25 pagesHand Powered Water PumpsFredrik GaddNo ratings yet

- Hydraulic Ram Pump v1 1Document18 pagesHydraulic Ram Pump v1 1Israel HernandezNo ratings yet

- Model UC-2 Installation InstructionsDocument8 pagesModel UC-2 Installation InstructionsWattsNo ratings yet

- Date Labour Details Plumber Helper Working Hours: SL NoDocument8 pagesDate Labour Details Plumber Helper Working Hours: SL NoskumarsrNo ratings yet

- Diseño Con FuentesDocument11 pagesDiseño Con FuentesIvAldreteNo ratings yet

- Blue Points: 1 " Well Point Installation InstructionsDocument8 pagesBlue Points: 1 " Well Point Installation InstructionsRobert McAlisterNo ratings yet

- Smack's Booster: The Safety GearDocument18 pagesSmack's Booster: The Safety GearДмитрий ЛяшковNo ratings yet

- Building Laws Building Utilities - Unrecognizable TextDocument32 pagesBuilding Laws Building Utilities - Unrecognizable TextAlecsisRoeEstañolFrascoNo ratings yet

- Novatek Metermatic Water Softener 51877 EnglishDocument12 pagesNovatek Metermatic Water Softener 51877 EnglishCastoriadisNo ratings yet

- Scout Prop Building InstructionsDocument14 pagesScout Prop Building Instructionsindependent_mindNo ratings yet

- Filter Construction ManualDocument14 pagesFilter Construction ManualLuqman WibowoNo ratings yet

- Biogas Revolution Secrets Biogas PlansDocument16 pagesBiogas Revolution Secrets Biogas PlanslimlerianNo ratings yet

- DYI Walnut Shell Blasting SS 3-27-13Document15 pagesDYI Walnut Shell Blasting SS 3-27-13sorin clauNo ratings yet

- PilotSystem Gas15Gal 1BBL - V5Document21 pagesPilotSystem Gas15Gal 1BBL - V5antonio alberto gutierrez suarezNo ratings yet

- Water Softeners Residential 5600 Valve Softeners US ManualDocument12 pagesWater Softeners Residential 5600 Valve Softeners US ManualPromagEnviro.comNo ratings yet

- Description Picture: Name: Nhimrod M. San Jose Date: 5/03/23 Section: CIV 202 Professor: Alfredo A. MarianoDocument5 pagesDescription Picture: Name: Nhimrod M. San Jose Date: 5/03/23 Section: CIV 202 Professor: Alfredo A. MarianoNhimrod SanjoseNo ratings yet

- Phil Arch Review BDocument32 pagesPhil Arch Review BAr. Ryan OrtigasNo ratings yet

- Building Laws Building Utilities - Unrecognizable TextDocument32 pagesBuilding Laws Building Utilities - Unrecognizable TextAe R ONNo ratings yet

- RC Submarine Free How To Build PlansDocument15 pagesRC Submarine Free How To Build Plansdac_18_ag100% (2)

- Hydro Li Cram Pump DesignDocument37 pagesHydro Li Cram Pump Designngoclinhtu9816No ratings yet

- The House Drain 1Document41 pagesThe House Drain 1ClasolNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- ALE Building LawsDocument32 pagesALE Building LawsiloilocityNo ratings yet

- LTH Ram Pump V 1 2Document19 pagesLTH Ram Pump V 1 2Dong TejeroNo ratings yet

- Waste Pipe and Soil PipeDocument4 pagesWaste Pipe and Soil PipeJeong Hannie100% (1)

- Ormus Water Collection Home Plumbing InstructionsDocument12 pagesOrmus Water Collection Home Plumbing InstructionsDanilo Dante50% (4)

- Replace Old PlumbingDocument103 pagesReplace Old PlumbingvivaaemulusNo ratings yet

- QTYSUR Reports Merged 558 590Document33 pagesQTYSUR Reports Merged 558 590Abegail Marie Almero LibresNo ratings yet

- Uapga - BLDG Laws & UtilitiesDocument32 pagesUapga - BLDG Laws & UtilitiesSheila Marie DomalantaNo ratings yet

- MailattDocument32 pagesMailattMitz ZieNo ratings yet

- Building LawsDocument32 pagesBuilding LawsChris EquipadoNo ratings yet

- Plumbing: by Jarick AcostaDocument10 pagesPlumbing: by Jarick AcostabenNo ratings yet

- Building Laws Building UtilitiesDocument32 pagesBuilding Laws Building UtilitiesjbonvierNo ratings yet

- Provide Expansion Loop in Vertical DropDocument12 pagesProvide Expansion Loop in Vertical DropVikash TiwariNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- GORBEL Freestanding Jib Crane - ManualDocument20 pagesGORBEL Freestanding Jib Crane - Manualaiyubi2100% (1)

- Crusher 2000HD VSI OM (En) PDFDocument115 pagesCrusher 2000HD VSI OM (En) PDFRoberth Alexander Ríos NievesNo ratings yet

- Blown Film CatalogueDocument12 pagesBlown Film CatalogueMohammad-reza NabavinezhadNo ratings yet

- Murray 42505x92aDocument25 pagesMurray 42505x92aDavidNo ratings yet

- Hazet Complete 2011Document296 pagesHazet Complete 2011jordachehaNo ratings yet

- S7 Me - Course Handout PDFDocument119 pagesS7 Me - Course Handout PDFSatyajéèt KankeNo ratings yet

- Parts: Trailer Mounted Pump Model B20 Illustrated Part ManualDocument167 pagesParts: Trailer Mounted Pump Model B20 Illustrated Part ManualTimur CakiciNo ratings yet

- Wa430 6HDocument1,339 pagesWa430 6HDzung Hoang100% (6)

- Flexi Spare Parts ListsDocument107 pagesFlexi Spare Parts ListsHandy Lee100% (3)

- Docmine: Spare Parts ListDocument31 pagesDocmine: Spare Parts ListNuno PaivaNo ratings yet

- General Twin Seal 4 Way IOM 2002 PDFDocument16 pagesGeneral Twin Seal 4 Way IOM 2002 PDFtxlucky80No ratings yet

- Concertina WireDocument20 pagesConcertina WireViswanathan GanapathiNo ratings yet

- Evoko Room Manager - Mounting InstructionsDocument17 pagesEvoko Room Manager - Mounting InstructionsFacundo RaneaNo ratings yet

- Machine Design Examination 6Document5 pagesMachine Design Examination 6SYBRELLE CRUZNo ratings yet

- Second Periodical Test in TleDocument3 pagesSecond Periodical Test in TleSusan M. Palicpic100% (2)

- 001 - Valvuals, AjustarDocument6 pages001 - Valvuals, AjustarAparecidaMarquesNo ratings yet

- Fx1100b-E Fx1100b-E MJ-FX1100B'06Document0 pagesFx1100b-E Fx1100b-E MJ-FX1100B'06Ray Cepeda MenaNo ratings yet

- Cuidados Instalacion Bobina Motor EcotecDocument2 pagesCuidados Instalacion Bobina Motor Ecotecflash_24014910No ratings yet

- XXV No 87Document1 pageXXV No 87Camilo Andrés Vargas JiménezNo ratings yet

- Makita DDF459 Service ManualDocument4 pagesMakita DDF459 Service ManualtecnoNo ratings yet

- MQ SP M 4001 PDFDocument25 pagesMQ SP M 4001 PDFjaseelNo ratings yet

- 2018 Aug 787 - SCI - AWLDocument822 pages2018 Aug 787 - SCI - AWLAviation Documents ManualsNo ratings yet

- 7 Precision Ball ScrewsDocument124 pages7 Precision Ball ScrewsMihai AlexandruNo ratings yet

- Feed Management System Manual Rev 6-04Document15 pagesFeed Management System Manual Rev 6-04Ehsan KhayalNo ratings yet