Professional Documents

Culture Documents

Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface Methodology

Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface Methodology

Uploaded by

sekharCopyright:

Available Formats

You might also like

- CMAS Training Manual P3Eng PDFDocument104 pagesCMAS Training Manual P3Eng PDFdigibillNo ratings yet

- Matter in Our Surroundings - Shobhit NirwanDocument17 pagesMatter in Our Surroundings - Shobhit NirwanDibya Biswal95% (80)

- Sundrop Swot AnalysisDocument18 pagesSundrop Swot AnalysisGopal Chandra Saha100% (3)

- Hospital PlanningDocument76 pagesHospital Planninghowardroark12394% (16)

- Fba Report BlankDocument3 pagesFba Report Blankapi-308475283No ratings yet

- Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface MethodologyDocument6 pagesOptimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface MethodologyNguyen HoaNo ratings yet

- Physicochemical Properties of Banana Peel Flour As Influenced by Variety and Stage of Ripeness Multivariate Statistical AnalysisDocument14 pagesPhysicochemical Properties of Banana Peel Flour As Influenced by Variety and Stage of Ripeness Multivariate Statistical AnalysisnalmondsNo ratings yet

- 1 s2.0 S1878535213000397 MainDocument13 pages1 s2.0 S1878535213000397 MainĐại HảiNo ratings yet

- 2093 6851 2 PBDocument11 pages2093 6851 2 PBDeyinta Apenabel SuryaNo ratings yet

- Protein Extraction From Sour Cherry Kernel PDFDocument10 pagesProtein Extraction From Sour Cherry Kernel PDFdr.sameer sainiNo ratings yet

- Ngampeerapong C 2019Document12 pagesNgampeerapong C 2019Fauzi SatriaNo ratings yet

- Innovative Food Science and Emerging Technologies: Zhendong Yang, Weiwei ZhaiDocument7 pagesInnovative Food Science and Emerging Technologies: Zhendong Yang, Weiwei ZhaiToñoSanjuanNo ratings yet

- tmp4E2F TMPDocument13 pagestmp4E2F TMPFrontiersNo ratings yet

- art3A10.10072Fs12161 013 9753 yDocument9 pagesart3A10.10072Fs12161 013 9753 yOvidiu Dumitru BucurNo ratings yet

- 2252-Article Text-8408-2-10-20201018Document17 pages2252-Article Text-8408-2-10-20201018Samantha Garcia NovoaNo ratings yet

- Cha2019 - G NGDocument7 pagesCha2019 - G NGCuong DoanNo ratings yet

- Yang 2019Document29 pagesYang 2019Joluis CcanahuireNo ratings yet

- Effect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean FlourDocument11 pagesEffect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean Flourdesy ratna purwantiNo ratings yet

- SachaDocument12 pagesSachaJuan Jair ▲No ratings yet

- Các đặc tính hóa lý, chống oxy hóa và cảm quan của bánh bông lan được tăng cường chiết xuất từ Clitoria ternateaDocument9 pagesCác đặc tính hóa lý, chống oxy hóa và cảm quan của bánh bông lan được tăng cường chiết xuất từ Clitoria ternateaQuangHiệpNo ratings yet

- DeletDocument15 pagesDeletErmias AbelnehNo ratings yet

- The Effect of Extraction Conditions On Total Phenolic Content and FreeDocument23 pagesThe Effect of Extraction Conditions On Total Phenolic Content and FreeClarisa DianNo ratings yet

- Food Chemistry: Research ArticleDocument7 pagesFood Chemistry: Research ArticleIris Bustamante PájaroNo ratings yet

- Foods: Microstructural, Textural, Sensory Properties and Quality of Wheat-Yam Composite Flour NoodlesDocument13 pagesFoods: Microstructural, Textural, Sensory Properties and Quality of Wheat-Yam Composite Flour NoodleslalallaNo ratings yet

- Studies On The Extraction of Jerusalem ArtichokeDocument9 pagesStudies On The Extraction of Jerusalem ArtichokeanradeljaNo ratings yet

- Edible Coating On Mango SlicesDocument10 pagesEdible Coating On Mango SlicesRameen TariqNo ratings yet

- Utilization of Banana Peel As A Functional Ingredient in Yellow NoodleDocument9 pagesUtilization of Banana Peel As A Functional Ingredient in Yellow NoodleKim GosengNo ratings yet

- Biochemical and Functional Properties of Moringa Oleifera Leaves and Their Potential As A Functional FoodDocument12 pagesBiochemical and Functional Properties of Moringa Oleifera Leaves and Their Potential As A Functional FoodKike PalaciosNo ratings yet

- (ảnh hưởng tủ đông) 200843-Article Text-503801-1-10-20201027Document7 pages(ảnh hưởng tủ đông) 200843-Article Text-503801-1-10-20201027Thii HvNo ratings yet

- Effect of Extraction Methods On Polysaccharide of Clitocybe Maxima StipeDocument4 pagesEffect of Extraction Methods On Polysaccharide of Clitocybe Maxima Stiperoberto veranoNo ratings yet

- Prebiotic Activity and Bioactive Compounds of The EnzymaticallyDocument9 pagesPrebiotic Activity and Bioactive Compounds of The Enzymaticallyquyen.phampnq172702No ratings yet

- Technology Processing For BlueberryDocument5 pagesTechnology Processing For BlueberryDevana DoanarestaNo ratings yet

- Salacheep2020 Article OptimizationOfUltrasound-assisDocument11 pagesSalacheep2020 Article OptimizationOfUltrasound-assisHuy ĐỗNo ratings yet

- Estimation of Sample Processing Uncertainty of Large-Size Crops in Pesticide Residue AnalysisDocument12 pagesEstimation of Sample Processing Uncertainty of Large-Size Crops in Pesticide Residue AnalysisĐăng LưuNo ratings yet

- Arruda 2016Document11 pagesArruda 2016Abdelouahab BenseddikNo ratings yet

- 43 Ijasroct201743Document10 pages43 Ijasroct201743TJPRC PublicationsNo ratings yet

- SimulationDocument8 pagesSimulationErmias AbelnehNo ratings yet

- Jurnal RSMDocument12 pagesJurnal RSMNurlailiFalasifaNo ratings yet

- PenelitianDocument6 pagesPenelitianAdrin Ma'rufNo ratings yet

- Gcms Analysis of Bioactive Components From Banana Peelmusa Sapientum Peel PDFDocument6 pagesGcms Analysis of Bioactive Components From Banana Peelmusa Sapientum Peel PDFCindy-chan DelfinNo ratings yet

- Shahbaz Et Al. 2016. Quencher GranadaDocument5 pagesShahbaz Et Al. 2016. Quencher GranadaDANIELA ALEXANDRA MAYHUA ESTEBANNo ratings yet

- Antidiabetic Compounds in Stem Juice From Banana: Food Analysis, Food Quality and NutritionDocument7 pagesAntidiabetic Compounds in Stem Juice From Banana: Food Analysis, Food Quality and Nutritionanon_54336515No ratings yet

- LWT - Food Science and Technology: Wenjie Wang, Jooyeoun Jung, Elizabeth Tomasino, Yanyun ZhaoDocument10 pagesLWT - Food Science and Technology: Wenjie Wang, Jooyeoun Jung, Elizabeth Tomasino, Yanyun ZhaoAires_DiegoNo ratings yet

- Evaluation of Glutathione Production Method Using PDFDocument9 pagesEvaluation of Glutathione Production Method Using PDFAndréia AnschauNo ratings yet

- Extraction and Identification of Anthocyanin From Purple Corn (Zea Mays L.)Document9 pagesExtraction and Identification of Anthocyanin From Purple Corn (Zea Mays L.)Hong Yee YongNo ratings yet

- International Journal of Pharma and Bio Sciences: Research Article Analytical ChemistryDocument7 pagesInternational Journal of Pharma and Bio Sciences: Research Article Analytical ChemistryMie YaNo ratings yet

- Optimization of Pectin Extraction From Kepok BananDocument7 pagesOptimization of Pectin Extraction From Kepok BananAdestya S. RamadhanNo ratings yet

- Banana Peel FlourDocument7 pagesBanana Peel FlourLutfi FiahNo ratings yet

- An Efficient Method For Extraction, Separation and PurificationDocument5 pagesAn Efficient Method For Extraction, Separation and PurificationE Gustiasih MaulidantiNo ratings yet

- Science Investigatory ProjectDocument13 pagesScience Investigatory ProjectMedrano, SophiaNo ratings yet

- Mulberry Jelly (2019 - 12 - 27 16 - 04 - 56 UTC)Document7 pagesMulberry Jelly (2019 - 12 - 27 16 - 04 - 56 UTC)tayyaba mehmoodNo ratings yet

- Food Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberDocument8 pagesFood Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberMaria MihaelaNo ratings yet

- Adekunbi Adetola Malomo FSAB 136 Early ViewDocument8 pagesAdekunbi Adetola Malomo FSAB 136 Early ViewbabaloseNo ratings yet

- CEL Drying (Marcus Poon 004681)Document35 pagesCEL Drying (Marcus Poon 004681)Mohammad Siddiq Jalil100% (1)

- Effectsof Green Banana Flouronthe Physical ChemicalandDocument10 pagesEffectsof Green Banana Flouronthe Physical ChemicalandMiranda MonichaNo ratings yet

- Effect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsDocument4 pagesEffect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsthesijNo ratings yet

- LWT - Food Science and Technology: Samart Sai-Ut, Soottawat Benjakul, Supaluck Kraithong, Saroat RawdkuenDocument8 pagesLWT - Food Science and Technology: Samart Sai-Ut, Soottawat Benjakul, Supaluck Kraithong, Saroat RawdkuenBea KimNo ratings yet

- Bài Báo Khoa Học Nhóm 1Document12 pagesBài Báo Khoa Học Nhóm 1Minh VịtNo ratings yet

- Drying GingerDocument10 pagesDrying GingerWinda Putri HaryantiNo ratings yet

- Kim 2019Document8 pagesKim 2019Shirley EspirituNo ratings yet

- Industrial Crops and ProductsDocument11 pagesIndustrial Crops and ProductsYAYON PAMULA MUKTINo ratings yet

- 1 OnlineDocument11 pages1 OnlineArif ElsanNo ratings yet

- Lu 2006Document7 pagesLu 2006Willian QuinteroNo ratings yet

- Effects of Micronization On The Physico-Chemical Properties of Peels of Three Root and Tuber CropsDocument5 pagesEffects of Micronization On The Physico-Chemical Properties of Peels of Three Root and Tuber CropsDadyan Raquel Flaquer FlorezNo ratings yet

- WEA (AMMAVODI) - CompressedDocument1 pageWEA (AMMAVODI) - CompressedsekharNo ratings yet

- Ammavodi 2 PDFDocument1 pageAmmavodi 2 PDFsekharNo ratings yet

- Wea (Ammavodi)Document1 pageWea (Ammavodi)sekharNo ratings yet

- Ammavodi 2Document1 pageAmmavodi 2sekharNo ratings yet

- Scanned by CamscannerDocument2 pagesScanned by CamscannersekharNo ratings yet

- Gravity Flow of G R A N U L A R Materials ( .S.S.R.Document23 pagesGravity Flow of G R A N U L A R Materials ( .S.S.R.sekharNo ratings yet

- Study Companion 201 Questions & Answers in Agricultural EngineeringDocument38 pagesStudy Companion 201 Questions & Answers in Agricultural Engineeringsekhar100% (1)

- Computer AwernesDocument145 pagesComputer AwernessekharNo ratings yet

- Da 201 Crop Production 2 by Greencross FoundationDocument89 pagesDa 201 Crop Production 2 by Greencross FoundationsekharNo ratings yet

- NPT ReportDocument7 pagesNPT ReportsekharNo ratings yet

- General Awareness 2016Document91 pagesGeneral Awareness 2016sekharNo ratings yet

- 1836 18391Document4 pages1836 18391sekharNo ratings yet

- Route:: Number of Industries in Palghar Taluka Co-Op Industrial Estate Is 57Document9 pagesRoute:: Number of Industries in Palghar Taluka Co-Op Industrial Estate Is 57Manthan KulkarniNo ratings yet

- AngelesDocument9 pagesAngelesjacknewman870100% (1)

- PDFDocument69 pagesPDFRuel Gonzales79% (14)

- List of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTDocument11 pagesList of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTSudheer KumarNo ratings yet

- NBR 14136 Plugs and Socket Outlets in BrazilDocument7 pagesNBR 14136 Plugs and Socket Outlets in BrazilCLOUD ALIGLOBALNo ratings yet

- Control Valve Sourcebook (Refining) PDFDocument198 pagesControl Valve Sourcebook (Refining) PDFnaraNJORNo ratings yet

- Sheet 6 Electronics - AnswerDocument10 pagesSheet 6 Electronics - AnswerOla SamirNo ratings yet

- About BioroboticsDocument2 pagesAbout Bioroboticspaulramesh100% (1)

- Affidavit of Respondent in Cases of Adultery: Form 56A.44ADocument2 pagesAffidavit of Respondent in Cases of Adultery: Form 56A.44AChristopher LojeroNo ratings yet

- Jeppview For Windows: General Information General InformationDocument39 pagesJeppview For Windows: General Information General Informationbooba100% (1)

- Braintech Engineers PVT LTDDocument8 pagesBraintech Engineers PVT LTDMANVENDRA SINGHNo ratings yet

- 6) Photoelectric Effect and Uncertainity ProblemsDocument4 pages6) Photoelectric Effect and Uncertainity ProblemsGame 1No ratings yet

- En GB-car Exchange AgreementDocument2 pagesEn GB-car Exchange Agreementbaby_charm100% (1)

- Questions: 1 About MeDocument8 pagesQuestions: 1 About MeC VNo ratings yet

- C DAC Winter Project Report 7 PDFDocument29 pagesC DAC Winter Project Report 7 PDFAbhinav TayadeNo ratings yet

- Cell Structure and Function Pretest: The Organelle Has A Phospholipid MembraneDocument28 pagesCell Structure and Function Pretest: The Organelle Has A Phospholipid MembranelayanhaliloNo ratings yet

- Chandra NamaskarDocument8 pagesChandra NamaskarSwati Rohan JadhavNo ratings yet

- Self - Assessment Guide Beuaty CareDocument13 pagesSelf - Assessment Guide Beuaty CareMac Dareel UrianoNo ratings yet

- Total Brochure UK LoRes 0609 PDFDocument32 pagesTotal Brochure UK LoRes 0609 PDFMohammed RayanNo ratings yet

- ScalpDocument17 pagesScalpKaruna PrabhuNo ratings yet

- Surgery KGMU Proff Chapterwise by Arif Naseem 2009-2021Document4 pagesSurgery KGMU Proff Chapterwise by Arif Naseem 2009-2021DR. PARDEEP SHARMANo ratings yet

- Prelim Types of SexualityDocument12 pagesPrelim Types of SexualityAngelica SinoyNo ratings yet

- Caterpillar C280 Series Engine Product GuideDocument221 pagesCaterpillar C280 Series Engine Product GuideIvan Aditya100% (1)

- Maternity Benefit PolicyDocument2 pagesMaternity Benefit Policyshrija nairNo ratings yet

- UC Davis General Catalog - Animal Science - 2022-03-13 - 231610Document17 pagesUC Davis General Catalog - Animal Science - 2022-03-13 - 231610XNo ratings yet

Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface Methodology

Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface Methodology

Uploaded by

sekharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface Methodology

Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface Methodology

Uploaded by

sekharCopyright:

Available Formats

International Journal of Food Sciences and Nutrition,

February 2011; 62(1): 9196

Optimization conditions for anthocyanin and phenolic content extraction

form purple sweet potato using response surface methodology

MARUF AHMED1,2, MST. SORIFA AKTER1, & JONG-BANG EUN1

Int J Food Sci Nutr Downloaded from informahealthcare.com by Seoul National University on 03/18/13

For personal use only.

Department of Food Science and Technology and Institute of Biotechnology, Chonnam National University, Gwangju,

South Korea, and 2Department of Food Processing and Preservation, Hajee Mohammad Danesh Science and Technology

University, Dinajpur, Bangladesh

Abstract

Purple sweet potato flour could be used to enhance the bioactive components such as phenolic compounds and anthocyanin

content that might be used as nutraceutical ingredients for formulated foods. Optimization of anthocyanin and phenolic

contents of purple sweet potato were investigated using response surface methodology. A face-centered cube design was used to

investigate the effects of three independent variables: namely, drying temperature 55 658C, citric acid concentration 1 3% w/v

and soaking time 1 3 min. The optimal conditions for anthocyanin and phenolic contents were 62.918C, 1.38%, 2.53 min

and 60.948C, 1.04% and 2.24 min, respectively. However, optimal conditions of anthocyanin content were not apparent.

The experimental value of anthocyanin content was 19.78 mg/100 g and total phenolic content was 61.55 mg/g. These data

showed that the experimental responses were reasonably close to the predicted responses. Therefore, the results showed that

treated flours could be used to enhance the antioxidant activities of functional foods.

Keywords: Purple sweet potato, response surface methodology, phenolic compounds, anthocyanin content

Introduction

Purple-fleshed sweet potatoes have an intense purple

color in the storage roots due to the accumulation of

anthocyanins (Terahara et al. 2004).The anthocyanins

in purple sweet potato are mono-acylated or di-acylated

forms of cyanidin and peonidin (Yang and Gadi 2008).

Sweet potatoes had intermediate antioxidant activity

among 43 vegetables (Huang et al. 2006). Recently

natural antioxidants have attracted considerable attention due to their positive health benefit (Huang et al.

2006). Rumbaboa et al. (2009) reported that anthocyanin from purple sweet potato has better radical

scavenging activity than that of red cabbage, grape skin,

elderberry and purple corn. Anthocyanins from purple

sweet potatoes have many biological functions, such as

scavenging free radicals, anti-mutagenicity, anti-carcinogen activity and antihypertensive effect (Oki et al.

2002). Several extraction methods have been used to

obtain extracts rich in anthocyanin and phenolic

content based on different solvents such as methanol,

ethanol, acetone, water or mixture (Pathirana and

Shahidi 2005, Huang et al. 2006). The stability of

anthocyanin and phenolic content were influenced by

several factors (Jiang 2000). Among them, polyphenol

oxidase plays an important role in the degradation of

anthocyanin and phenolic content. Citric acid has been

used extensively for the inhibitory activity on polyphenol oxidase and the anti-browning activity in

minimally processed fruits and vegetables. Citric acid

extracts have a double inhibitory effect by chelating

copper at lower pH (Altunkaya and Gokmen 2009).

Sweet potatoes can be processed into flour, which

are less bulky and more stable than the highly

perishable fresh root. Flour can be used as a thickener

in soup, gravy, fabricated snacks and bakery products.

It could be used to enhance food products through

color, flavor, natural sweetness and nutrients. Sing et al.

(2003) used potassium metabisulphite, citric acid and

sodium chloride to improve the quality of chips from

Correspondence: Jong-Bang Eun, Department of Food Science & Technology, Chonnam National University, 77 Yongbong-ro Buk-gu,

Gwangju 500-757, South Korea. Tel: 82 62 530 0255. Fax: 82 62 530 2149. E-mail: jbeun@jnu.ac.kr

ISSN 0963-7486 print/ISSN 1465-3478 online q 2011 Informa UK, Ltd.

DOI: 10.3109/09637486.2010.511167

92

M. Ahmed et al.

sweet potatoes. Response surface methodology (RSM)

has been successfully used to optimize biochemical

and biotechnological process related to food systems

(Cacace and Maza 2003, Pathirana and Shahidi

2005). Therefore, the goal of the present study was to

optimize different pretreatments such as drying

temperature, citric acid concentration and soaking

time for production of sweet potato flour with

high retention of anthocyanin and phenolic content

using RSM.

Materials and methods

Int J Food Sci Nutr Downloaded from informahealthcare.com by Seoul National University on 03/18/13

For personal use only.

Raw materials

Sweet potato (Ipomoea batatas L. Lam variety,

Sinjami) was purchased from a local farm. Roots

were washed with tap water to remove dirt and soil

and allowed to dry at ambient temperature (, 208C).

The washed sweet potatoes were stored at 148C for

15 days without curing.

Sample preparation and treatment

Sweet potatoes were peeled with a hand peeler (Han

Sung 27 stainless; Namdong Industry Park, Incheon,

South Korea). Then peeled samples were cut into slices

(1 mm thickness) using a slicing machine (HFS 350G;

Hankook fujee Industries Co. Ltd. Suwon-si,

Gyeonggi-do, Fujee, South Korea). Various levels of

citric acid concentration (1 3% w/v) were solubilized

in deionized water at room temperature (20 ^ 18C).

After that, peeled slices were dipped in aqueous citric

acid solutions (1 3% w/v) for different soaking times

(1 3 min) at room temperature.

Preparation of sweet potato flour

The slices were dried using a convection drying oven

(Dasol Scientific Co. Ltd, Seoul, South Korea) at

different temperatures 558C, 608C, and 658C for

7 8 h. The sweet potato flour (moisture content

6 7%) was obtained by milling the dried slices using a

blender (FM-681C; Hanil, Gwangju, Korea), and

sieved through an 80-mesh (Chung gye sang gongsa,

Seoul, South Korea) screen.

Experimental design for RSM analysis

A three-factor (X1, X2 and X3) and three-level ( 1, 0

and 1) face-centered cube design were employed in

this study, and 15 individual run points were taken for

analysis (Wanasundara and Shahidi 1999). The actual

and corresponding values are presented in Table I.

The multiple regression equation was used to fit the

second-order polynomial equation based on the

experimental data as follows:

Y b0 b1 X1 b2 X2 b3 X3 b11 X1 X1

b22 X2 X2 b33 X3 X3 b12 X1 X2 b13 X1 X3

b23 X2 X3

where Y is the response variable, b0 is the intercept, b1,

b2, b3, b11, b22, b33 and b12, b13, b23 are linear,

quadratic and interaction coefficients respectively, and

X1, X2 and X3 are the coded independent variables.

Verification of model

RSM was used to optimize anthocyanin and phenolic

contents from purple sweet potato. The experimental

and predicted values were compared to confirm the

validity of the model.

Analysis of anthocyanin contents

The content of anthocyanin was determined following

the procedures of Proctor (1974) and Huang et al.

(2006) The sweet potato flour (1 g) was treated with

15 ml HCl methanol (0.15% HCl:methanol

15:85) for 4 h. The extract was filtered and its

absorbance was determined at 530 nm. The anthocyanin content was calculated on the basis of the

Table I. Three-factor, three-level, face-centered cube design for RSM.

Assay number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Factor X1

Factor X2

Factor X3

Variable

Drying temperature (8C)

Concentration (%)

Soaking time (min)

Anthocyanin (mg/100 g)

Total phenolics (mg/g)

55 (21)

55(21)

55(21)

55(21)

60(0)

60(0)

60(0)

60(0)

65( 1)

65(21)

65( 1)

65( 1)

60(0)

60(0)

60(0)

2(0)

1(21)

2(0)

3( 1)

3( 1)

1(21)

3( 1)

1(21)

2(0)

1(21)

2(0)

3( 1)

2(0)

2(0)

2(0)

3( 1)

2(0)

1(21)

2(0)

3( 1)

1(21)

1(21)

3( 1)

3( 1)

2(0)

1(21)

2(0)

2(0)

2(0)

2(0)

40.32 ^ 1.32

39.56 ^ 1.03

40.79 ^ 0.60

37.40 ^ 2.08

34.17 ^ 4.72

32.53 ^ 2.73

24.45 ^ 4.96

24.51 ^ 0.37

29.16 ^ 3.64

26.49 ^ 1.83

24.55 ^ 0.29

22.45 ^ 0.28

23.94 ^ 0.57

20.02 ^ 1.18

21.63 ^ 0.17

56.85 ^ 8.28

47.77 ^ 1.53

47.18 ^ 5.73

47.52 ^ 4.02

44.64 ^ 0.34

51.69 ^ 0.19

56.38 ^ 0.39

63.38 ^ 1.02

46.46 ^ 1.07

51.65 ^ 2.37

51.65 ^ 2.37

52.03 ^ 2.43

45.70 ^ 0.41

49.39 ^ 0.81

58.91 ^ 1.18

93

Optimizing anthocyanin and phenolic content of purple sweet potato flour

following equation:

(a)

Anthocyanin content A MW DF 100=e W

2176.82

236.84***

224.72

247.49***

6.19

21.65

37.69

20.16

20.30

25.97**

0.80

39.39

29.55

3.00

2.33

1.67

58.33

ture (C

)

Tempe

ra

Table III. Analysis of variance for the response surface quadratic

model for anthocyanin and phenolic contents.

Degree

of freedom

For anthocyanin

Lack of fit

Pure error

Total error

For total phenolic

Lack of fit

Pure error

Total error

Sum

of squares

Mean square

F value

3

2

5

7.50

7.76

15.26

2.50

3.88

3.05

0.64

3

2

5

18.75

92.91

111.67

6.25

46.45

22.33

0.93

%)

49.22

ak

0.04

0.39

4.43***

0.97

n(

(b)

61.67

20.04

24.76

21.95

tra

tio

1.00

55.00

65.00

0.28***

3.12***

3.92***

en

nc

58.33

ture (C

)

Co

61.67

Tempe

ra

19.72

R 2, coefficient of multiple determination. ***Significant at

P # 0.01. **Significant at P # 0.05.

Source

1.67

n)

1240.40***

19.72

65.00

mi

b0

Linear

b1

b2

b3

Quadratic

b11

b22

b33

Cross-product

b12

b13

b23

R2

Phenolic content

2.33

e(

Anthocyanin content

3.00

tim

Coefficient

29.55

ing

Table II. Regression coefficients of predicted quadratic polynomial

for the response anthocyanin and phenolic contents.

Anthocyanins (mg/100 g)

The total phenolic content was determined using

Folin Ciocalteau reagent according to a slightly

modified method (Swain and Hills 1959). The sample

(0.1 g) was extracted three times with 20 ml of 75%

methanol and was filtered through Whatman No. 2

filter paper. Extracts were combined and concentrated

in a rotary vacuum evaporator (Rikakikai Co. Ltd,

Tokyo, Japan) at 408C; the volume was adjusted to

20 ml with 75% methanol. One milliliter of extract,

5 ml distilled water and 2 ml of 10% Folin Ciocalteau

reagent were added into a Falcon tube. After 3 min at

room temperature, 2 ml of 7.5% Na2CO3 solution was

added and the sample was diluted to 20 ml with

distilled water. Each sample was allowed to stand for

39.39

1.00

55.00

So

Int J Food Sci Nutr Downloaded from informahealthcare.com by Seoul National University on 03/18/13

For personal use only.

Analysis of total phenolic contents

49.22

Anthocyanins (mg/100 g)

where A is the absorbance, MW is the molecular

weight of cyanidin-3-glucoside (MW 449.2), DF is

the dilution factor, 1 is the molar absorptivity

(34,300), and W is the sample weight (g).

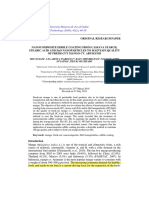

Figure 1. Response surface plots of the anthocyanin content of

purple sweet potato flour as affected by temperature, citric acid

concentration and soaking time. (a) Temperature and concentration.

(b) Temperature and soaking time.

1 h at room temperature and absorbance was

measured at 760 nm (UV-1201; Shimadzu, Kyoto,

Japan). The total phenolic content was calculated on

the basis of standard curves of gallic acid, and

expressed as milligrams of gallic acid equivalents per

gram of sample on a wet weight basis.

Statistical analysis

All determinations were carried out in triplicate and

the experimental results are expressed as means ^

standard deviation. Statistical analysis of the verification results was carried out by analysis of variance and

Duncans multiple-range tests using SAS (version

94

M. Ahmed et al.

(a)

62.5

64.46

60.0

1.5

21.20

38.90

25.62

43.32

30.05

47.75

3.0

49.17

3.00

2.33

34.47

41.53

65.00

(b) 65.0

Temperature (C)

1.67

61.67

58.33

re (C)

Tempera

tu

62.5

1.00

55.00

(b)

60.0

57.5

64.46

Figure 2. Contour plots showing the effects of temperature, citric

acid concentration and soaking time on anthocyanin content of

purple sweet potato flour. (a) Temperature and citric acid

concentration. (b) Temperature and soaking time.

56.82

49.17

3.00

n)

34.47

2.33

41.53

65.00

9.1). The optimal conditions were estimated through

three-dimensional response surface analyses of the

three independent variables and each dependent

variable.

1.67

61.67

58.33

Tempera

tu

re (C)

1.00

55.00

mi

30.05

47.75

e(

25.62

43.32

tim

21.20

38.90

3.0

ing

2.0

2.5

Soaking time (min)

ak

Anthocyanins (mg/100 g)

1.5

So

55.0

1.0

Phenolic content (mg/g)

Int J Food Sci Nutr Downloaded from informahealthcare.com by Seoul National University on 03/18/13

For personal use only.

Anthocyanins (mg/100 g)

2.0

2.5

Concentration (%)

%)

55.0

1.0

56.82

Co

nc

en

tra

tio

n(

57.5

Phenolic content (mg/g)

Temperature (C)

(a) 65.0

Figure 3. Response surface plots of the phenolic contents of purple

sweet potato flour as affected by temperature, citric acid

concentration and soaking time. (a) Temperature and

concentration. (b) Temperature and soaking time.

Results and discussion

Fitting the models

Analysis of variance using SAS was performed to

determine the significance of the linear, quadratic,

cross-product (Table II) and the lack of fit (Table III)

of the independent variables on the anthocyanin and

phenolic contents. The lack-of-fit test is a measure of

the failure of a model to represent data in the

experimental domain at the points that were not

included in the regression (Montgomery 1984).

However, the R 2 value of the dependent variables

was approximately 0.80, indicating that a high

proportion of variability was explained by the data

(Varnalis et al. 2004). Therefore, the results showed

that the experimental model was adequate due to no

significant lack of fit and satisfactory levels of R 2.

Effect of pretreatment on anthocyanin and phenolic

contents

The anthocyanin content of sweet potato flours ranged

from 20.02 to 40.79 mg/100 g wet weight basis

(Table I). The contents of anthocyanin were much

higher than those of sweet potato puree (Steed and

Truong 2008) and of steamed or kneaded flours

(Huang et al. 2006). The results of multiple regression

analysis showed that the anthocyanin contents were

significantly (P # 0.001) affected by the linear term of

temperature and soaking time, the quadratic of all

terms and the interaction term of concentration and

soaking time (Table II). The predicted model obtained

Optimizing anthocyanin and phenolic content of purple sweet potato flour

Temperature (C)

(a) 65.0

62.5

60.0

57.5

55.0

1.0

1.5

2.0

2.5

3.0

Concentration (%)

42.68

56.43

46.12

59.87

49.56

63.31

Y 2176:82 2 5:97X2 X3

62.5

60.0

57.5

55.0

1.0

1.5

2.0

2.5

3.0

Soaking time (min)

Phenolic content (mg/g)

42.68

56.43

46.12

59.87

49.56

63.31

the anthocyanin structure could be varying with pH

(Cevallos-Casala and Cisneros-Zevallos 2004).

The total phenolic content of sweet potato

flours ranged from 44.64 to 64.32 mg/g wet weight

basis (Table I). These results were much higher

than those reported in literature for fresh and

steamed sweet potato flours (Yang and Gadi 2008).

The results of multiple regression showed that the

total phenolic content was significantly affected by the

interaction term of concentration and soaking time

(X2, X3, P # 0.05). The final predictive model for

phenolic content is given below:

53.00

(b) 65.0

Temperature (C)

Int J Food Sci Nutr Downloaded from informahealthcare.com by Seoul National University on 03/18/13

For personal use only.

Phenolic content (mg/g)

95

53.00

Figure 4. Contour plots showing the effects of temperature, citric

acid concentration and soaking time on phenolic contents of purple

sweet potato flour. (a) Temperature and citric acid concentration.

(b) Temperature and soaking time.

The response surface plots in Figures 3 and 4 show the

relationship between the phenolic content and drying

temperatures, citric acid concentrations and soaking

times. The total phenolic content increased with

increasing drying temperatures (Figure 3a,b). This

might release more bound phenolic compounds from

the breakdown of cellular constituents. Huang et al.

(2006) found that steaming treatment increased the

total phenolic content of purple sweet potato flour.

Dewanto et al. (2002a) also found that the free

phenolic content of sweet corn increased with

increasing heating temperature and time. However,

thermal processing had no effect on the phenolic

content of tomato (Dewanto et al. 2002b). On the other

hand, total phenolic contents decreased with increasing the concentration and soaking time (Figure 4a,b).

This was probably because some phenolic compounds

were more hydrolyzed or oxidized because dispersions

were prepared in the presence of ambient oxygen.

for Y is given below:

Y 1240:40 2 36:84X1 2 47:49X3 0:28X21

Optimization of pretreatments and verification of models

3:12X22 3:92X23 4:43X2 X3

Figures 1 and 2 show the response surface plots of the

relationship between anthocyanin content and drying

temperatures, citric acid concentrations and soaking

times. Anthocyanin contents decreased with increasing drying temperatures (Figure 1a,b). This was as

expected because heating opened the structure of

anthocyanin to form chalcones, which was degraded

further to form brown products (Delgado-Vargas et al.

2000). However, the anthocyanin content increased

with increasing soaking time and concentration

(Figure 2a,b). This might be due to interaction

between citric acid and anthocyanin. In acidic media,

The predicted and experimental results are presented

in Table IV. For the phenolic content, the predicted

response surface of the stationary point was a saddle

point. Thus the estimated surface did not have a

unique optimum. However, for the anthocyanin

content, the predicted response surface of the

stationary point was a minimum. Therefore, different

optimum conditions were obtained for both responses.

The optimal conditions for anthocyanin and phenolic

contents were 62.918C, 1.38%, 2.53 min, whereas for

total phenolic contents they were drying temperature

60.948C, citric acid concentration 1.04% and soaking

time 2.24 min. However, optimal conditions of the

anthocyanin content were not apparent. This is due to

Table IV. Comparison of predicted and experimental values for the response of anthocyanin and phenolic contents.

Optimum conditions

Response variable

Stationary point

Anthocyanin

Total phenolics

Minimum

Saddle

Values

Temperature (8C)

Soaking time (min)

Soaking concentration (%)

Experimental

Predicted

62.91

60.64

2.53

1.04

1.38

2.24

19.78 ^ 0.97

61.55 ^ 2.9

19.71

52.89

96

M. Ahmed et al.

the fact that the optimization point was a minimum.

The optimal value of anthocyanin content was

lower than expected values. This might be related to

the anthocyanin extraction conditions by secondorder polynomials (Fan et al. 2008). The corresponding experimental responses of anthocyanin and

total phenolic contents were 19.78 mg/100 g and

61.55 mg/g, respectively. These data showed that the

experimental responses were reasonably close to the

predicted responses.

Int J Food Sci Nutr Downloaded from informahealthcare.com by Seoul National University on 03/18/13

For personal use only.

Conclusion

The results of anthocyanin and phenolic contents were

higher than the previous reported values for raw, steam

and kneaded sweet potato flours. Therefore, treated

flours could be used to make the higher quality products

that would be more attractive to product developers and

consumers.

Declaration of interest: The authors report no

conflicts of interest. The authors alone are responsible

for the content and writing of the paper.

References

Altunkaya A, Gokmen V. 2009. Effect of various anti-browning

agents on phenolic compounds profile of fresh lettuce (L. Sativa).

Food Chem 117:122126.

Cacace JE, Mazza G. 2003. Optimization of extraction of

anthocyanins from black currants with aqueous ethanol. J Sci

Food Agric 68:240248.

Cevallos-Casala BA, Cisneros-Zevallos L. 2004. Stability of

anthocyanin-based aqueous extracts of Andean purple corn

and red-fleshed sweet potato to synthetic and natural colorants.

Food Chem 86:6977.

Delgado-Vargas F, Jimenez AR, Paredes-Lopez O. 2000. Natural

pigments: Carotenoids, anthocyanins, and betalainscharacteristics, biosynthesis, processing and stability. Crit Rev Food Sci

Nutr 40:173289.

Dewanto V, Xianzhong WU, Adom KK, Liu RH. 2002a. Thermal

processing enhances the nutritional value of tomatoes by

increasing total antioxidant activity. J Sci Food Agric 50:

30103014.

Dewanto V, Xianzhong WU, Adom KK, Liu RH. 2002b. Processed

sweet corn has higher antioxidant activity. J Sci Food Agric 50:

49594964.

Fan G, Han Y, Gu Z, Chen D. 2008. Optimization conditions for

anthocyanins extraction from purple sweet potato using response

surface methodology (RSM). LWT Food Sci Technol 41:

155 160.

Huang YC, Chang YH, Shao YY. 2006. Effects of genotype and

treatment on the antioxidant activity of sweet potato in Taiwan.

Food Chem 98:529538.

Jiang Y. 2000. Role of anthocyanins, polyphenoloxidase and phenols

in lychee pericarp browning. J Sci Food Agric 80:305310.

Montgomery DC. 1984. Design and analysis of experiments. 2nd ed.

New York: John Wiley and Sons.

Oki T, Masuda M, Furuta S, Nishiba Y, Terahara N, Suda I. 2002.

Involvement of anthocyanins and other phenolic compounds in

radical-scavenging activity of purple-fleshed sweet potato

cultivars. J Food Sci 67:17521756.

Pathirana LC, Shahidi F. 2005. Optimization of extraction of

phenolic compounds from wheat using response surface

methodology. Food Chem 93:47 56.

Proctor JTA. 1974. Colour stimulation in attached apples with

supplementary light. Can J Plant Sci 54:499503.

Rumbaboa RGO, Cornago DF, Geronimo IM. 2009. Phenolic

content and antioxidant capacity of Philippine sweet potato

(Ipomoea batatas) varieties. Food Chem 113:11331138.

Sing S, Raina CS, Bawa AS, Saxena DC. 2003. Optimization of

processing variables in the preparation of sweet potato chips

using response surface methodology. Euro Food Res Technol

217:374381.

Steed LE, Truong VD. 2008. Anthocyanin content, antioxidant

activity and selected physical properties of flowable purplefleshed sweet potato purees. J Food Sci 73:215221.

Swain T, Hillis WE. 1959. The phenolic constituents of prunus

domestica. I. The quantitative analysis of phenolic constituents.

J Sci Food Agric 10:63 68.

Terahara N, Konczak I, Ono H, Yoshimoto M, Yamakewa O. 2004.

Characterization of acylated anthocyanins in callus induced from

storage root of purple-fleshed sweet potato, Ipomoea batatas L.

J Biomed Biotechnol 5:279286.

Varnalis AI, Brenan JG, Macdougall DB, Gilmour SG. 2004.

Optimization of high temperature puffing of potato cubes using

response surface methodology. J Food Eng 61:153163.

Wanasundara UN, Shahidi F. 1999. Concentration of omega

polyunsaturated fatty acids of seal blubber oil by urea

complexation: Optimization of reaction conditions. Food Chem

65:4149.

Yang J, Gadi RL. 2008. Effects of steaming and dehydration

on anthocyanins, antioxidant activity, total phenols and

color characteristics of purple-fleshed sweet potatoes

(Ipomoea batatas). Am J Food Technol 3:224 234.

You might also like

- CMAS Training Manual P3Eng PDFDocument104 pagesCMAS Training Manual P3Eng PDFdigibillNo ratings yet

- Matter in Our Surroundings - Shobhit NirwanDocument17 pagesMatter in Our Surroundings - Shobhit NirwanDibya Biswal95% (80)

- Sundrop Swot AnalysisDocument18 pagesSundrop Swot AnalysisGopal Chandra Saha100% (3)

- Hospital PlanningDocument76 pagesHospital Planninghowardroark12394% (16)

- Fba Report BlankDocument3 pagesFba Report Blankapi-308475283No ratings yet

- Optimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface MethodologyDocument6 pagesOptimization Conditions For Anthocyanin and Phenolic Content Extraction Form Purple Sweet Potato Using Response Surface MethodologyNguyen HoaNo ratings yet

- Physicochemical Properties of Banana Peel Flour As Influenced by Variety and Stage of Ripeness Multivariate Statistical AnalysisDocument14 pagesPhysicochemical Properties of Banana Peel Flour As Influenced by Variety and Stage of Ripeness Multivariate Statistical AnalysisnalmondsNo ratings yet

- 1 s2.0 S1878535213000397 MainDocument13 pages1 s2.0 S1878535213000397 MainĐại HảiNo ratings yet

- 2093 6851 2 PBDocument11 pages2093 6851 2 PBDeyinta Apenabel SuryaNo ratings yet

- Protein Extraction From Sour Cherry Kernel PDFDocument10 pagesProtein Extraction From Sour Cherry Kernel PDFdr.sameer sainiNo ratings yet

- Ngampeerapong C 2019Document12 pagesNgampeerapong C 2019Fauzi SatriaNo ratings yet

- Innovative Food Science and Emerging Technologies: Zhendong Yang, Weiwei ZhaiDocument7 pagesInnovative Food Science and Emerging Technologies: Zhendong Yang, Weiwei ZhaiToñoSanjuanNo ratings yet

- tmp4E2F TMPDocument13 pagestmp4E2F TMPFrontiersNo ratings yet

- art3A10.10072Fs12161 013 9753 yDocument9 pagesart3A10.10072Fs12161 013 9753 yOvidiu Dumitru BucurNo ratings yet

- 2252-Article Text-8408-2-10-20201018Document17 pages2252-Article Text-8408-2-10-20201018Samantha Garcia NovoaNo ratings yet

- Cha2019 - G NGDocument7 pagesCha2019 - G NGCuong DoanNo ratings yet

- Yang 2019Document29 pagesYang 2019Joluis CcanahuireNo ratings yet

- Effect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean FlourDocument11 pagesEffect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean Flourdesy ratna purwantiNo ratings yet

- SachaDocument12 pagesSachaJuan Jair ▲No ratings yet

- Các đặc tính hóa lý, chống oxy hóa và cảm quan của bánh bông lan được tăng cường chiết xuất từ Clitoria ternateaDocument9 pagesCác đặc tính hóa lý, chống oxy hóa và cảm quan của bánh bông lan được tăng cường chiết xuất từ Clitoria ternateaQuangHiệpNo ratings yet

- DeletDocument15 pagesDeletErmias AbelnehNo ratings yet

- The Effect of Extraction Conditions On Total Phenolic Content and FreeDocument23 pagesThe Effect of Extraction Conditions On Total Phenolic Content and FreeClarisa DianNo ratings yet

- Food Chemistry: Research ArticleDocument7 pagesFood Chemistry: Research ArticleIris Bustamante PájaroNo ratings yet

- Foods: Microstructural, Textural, Sensory Properties and Quality of Wheat-Yam Composite Flour NoodlesDocument13 pagesFoods: Microstructural, Textural, Sensory Properties and Quality of Wheat-Yam Composite Flour NoodleslalallaNo ratings yet

- Studies On The Extraction of Jerusalem ArtichokeDocument9 pagesStudies On The Extraction of Jerusalem ArtichokeanradeljaNo ratings yet

- Edible Coating On Mango SlicesDocument10 pagesEdible Coating On Mango SlicesRameen TariqNo ratings yet

- Utilization of Banana Peel As A Functional Ingredient in Yellow NoodleDocument9 pagesUtilization of Banana Peel As A Functional Ingredient in Yellow NoodleKim GosengNo ratings yet

- Biochemical and Functional Properties of Moringa Oleifera Leaves and Their Potential As A Functional FoodDocument12 pagesBiochemical and Functional Properties of Moringa Oleifera Leaves and Their Potential As A Functional FoodKike PalaciosNo ratings yet

- (ảnh hưởng tủ đông) 200843-Article Text-503801-1-10-20201027Document7 pages(ảnh hưởng tủ đông) 200843-Article Text-503801-1-10-20201027Thii HvNo ratings yet

- Effect of Extraction Methods On Polysaccharide of Clitocybe Maxima StipeDocument4 pagesEffect of Extraction Methods On Polysaccharide of Clitocybe Maxima Stiperoberto veranoNo ratings yet

- Prebiotic Activity and Bioactive Compounds of The EnzymaticallyDocument9 pagesPrebiotic Activity and Bioactive Compounds of The Enzymaticallyquyen.phampnq172702No ratings yet

- Technology Processing For BlueberryDocument5 pagesTechnology Processing For BlueberryDevana DoanarestaNo ratings yet

- Salacheep2020 Article OptimizationOfUltrasound-assisDocument11 pagesSalacheep2020 Article OptimizationOfUltrasound-assisHuy ĐỗNo ratings yet

- Estimation of Sample Processing Uncertainty of Large-Size Crops in Pesticide Residue AnalysisDocument12 pagesEstimation of Sample Processing Uncertainty of Large-Size Crops in Pesticide Residue AnalysisĐăng LưuNo ratings yet

- Arruda 2016Document11 pagesArruda 2016Abdelouahab BenseddikNo ratings yet

- 43 Ijasroct201743Document10 pages43 Ijasroct201743TJPRC PublicationsNo ratings yet

- SimulationDocument8 pagesSimulationErmias AbelnehNo ratings yet

- Jurnal RSMDocument12 pagesJurnal RSMNurlailiFalasifaNo ratings yet

- PenelitianDocument6 pagesPenelitianAdrin Ma'rufNo ratings yet

- Gcms Analysis of Bioactive Components From Banana Peelmusa Sapientum Peel PDFDocument6 pagesGcms Analysis of Bioactive Components From Banana Peelmusa Sapientum Peel PDFCindy-chan DelfinNo ratings yet

- Shahbaz Et Al. 2016. Quencher GranadaDocument5 pagesShahbaz Et Al. 2016. Quencher GranadaDANIELA ALEXANDRA MAYHUA ESTEBANNo ratings yet

- Antidiabetic Compounds in Stem Juice From Banana: Food Analysis, Food Quality and NutritionDocument7 pagesAntidiabetic Compounds in Stem Juice From Banana: Food Analysis, Food Quality and Nutritionanon_54336515No ratings yet

- LWT - Food Science and Technology: Wenjie Wang, Jooyeoun Jung, Elizabeth Tomasino, Yanyun ZhaoDocument10 pagesLWT - Food Science and Technology: Wenjie Wang, Jooyeoun Jung, Elizabeth Tomasino, Yanyun ZhaoAires_DiegoNo ratings yet

- Evaluation of Glutathione Production Method Using PDFDocument9 pagesEvaluation of Glutathione Production Method Using PDFAndréia AnschauNo ratings yet

- Extraction and Identification of Anthocyanin From Purple Corn (Zea Mays L.)Document9 pagesExtraction and Identification of Anthocyanin From Purple Corn (Zea Mays L.)Hong Yee YongNo ratings yet

- International Journal of Pharma and Bio Sciences: Research Article Analytical ChemistryDocument7 pagesInternational Journal of Pharma and Bio Sciences: Research Article Analytical ChemistryMie YaNo ratings yet

- Optimization of Pectin Extraction From Kepok BananDocument7 pagesOptimization of Pectin Extraction From Kepok BananAdestya S. RamadhanNo ratings yet

- Banana Peel FlourDocument7 pagesBanana Peel FlourLutfi FiahNo ratings yet

- An Efficient Method For Extraction, Separation and PurificationDocument5 pagesAn Efficient Method For Extraction, Separation and PurificationE Gustiasih MaulidantiNo ratings yet

- Science Investigatory ProjectDocument13 pagesScience Investigatory ProjectMedrano, SophiaNo ratings yet

- Mulberry Jelly (2019 - 12 - 27 16 - 04 - 56 UTC)Document7 pagesMulberry Jelly (2019 - 12 - 27 16 - 04 - 56 UTC)tayyaba mehmoodNo ratings yet

- Food Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberDocument8 pagesFood Research International: Alma Fernanda Sánchez Maldonado, Elizabeth Mudge, Michael G. Gänzle, Andreas SchieberMaria MihaelaNo ratings yet

- Adekunbi Adetola Malomo FSAB 136 Early ViewDocument8 pagesAdekunbi Adetola Malomo FSAB 136 Early ViewbabaloseNo ratings yet

- CEL Drying (Marcus Poon 004681)Document35 pagesCEL Drying (Marcus Poon 004681)Mohammad Siddiq Jalil100% (1)

- Effectsof Green Banana Flouronthe Physical ChemicalandDocument10 pagesEffectsof Green Banana Flouronthe Physical ChemicalandMiranda MonichaNo ratings yet

- Effect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsDocument4 pagesEffect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsthesijNo ratings yet

- LWT - Food Science and Technology: Samart Sai-Ut, Soottawat Benjakul, Supaluck Kraithong, Saroat RawdkuenDocument8 pagesLWT - Food Science and Technology: Samart Sai-Ut, Soottawat Benjakul, Supaluck Kraithong, Saroat RawdkuenBea KimNo ratings yet

- Bài Báo Khoa Học Nhóm 1Document12 pagesBài Báo Khoa Học Nhóm 1Minh VịtNo ratings yet

- Drying GingerDocument10 pagesDrying GingerWinda Putri HaryantiNo ratings yet

- Kim 2019Document8 pagesKim 2019Shirley EspirituNo ratings yet

- Industrial Crops and ProductsDocument11 pagesIndustrial Crops and ProductsYAYON PAMULA MUKTINo ratings yet

- 1 OnlineDocument11 pages1 OnlineArif ElsanNo ratings yet

- Lu 2006Document7 pagesLu 2006Willian QuinteroNo ratings yet

- Effects of Micronization On The Physico-Chemical Properties of Peels of Three Root and Tuber CropsDocument5 pagesEffects of Micronization On The Physico-Chemical Properties of Peels of Three Root and Tuber CropsDadyan Raquel Flaquer FlorezNo ratings yet

- WEA (AMMAVODI) - CompressedDocument1 pageWEA (AMMAVODI) - CompressedsekharNo ratings yet

- Ammavodi 2 PDFDocument1 pageAmmavodi 2 PDFsekharNo ratings yet

- Wea (Ammavodi)Document1 pageWea (Ammavodi)sekharNo ratings yet

- Ammavodi 2Document1 pageAmmavodi 2sekharNo ratings yet

- Scanned by CamscannerDocument2 pagesScanned by CamscannersekharNo ratings yet

- Gravity Flow of G R A N U L A R Materials ( .S.S.R.Document23 pagesGravity Flow of G R A N U L A R Materials ( .S.S.R.sekharNo ratings yet

- Study Companion 201 Questions & Answers in Agricultural EngineeringDocument38 pagesStudy Companion 201 Questions & Answers in Agricultural Engineeringsekhar100% (1)

- Computer AwernesDocument145 pagesComputer AwernessekharNo ratings yet

- Da 201 Crop Production 2 by Greencross FoundationDocument89 pagesDa 201 Crop Production 2 by Greencross FoundationsekharNo ratings yet

- NPT ReportDocument7 pagesNPT ReportsekharNo ratings yet

- General Awareness 2016Document91 pagesGeneral Awareness 2016sekharNo ratings yet

- 1836 18391Document4 pages1836 18391sekharNo ratings yet

- Route:: Number of Industries in Palghar Taluka Co-Op Industrial Estate Is 57Document9 pagesRoute:: Number of Industries in Palghar Taluka Co-Op Industrial Estate Is 57Manthan KulkarniNo ratings yet

- AngelesDocument9 pagesAngelesjacknewman870100% (1)

- PDFDocument69 pagesPDFRuel Gonzales79% (14)

- List of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTDocument11 pagesList of Suppliers Who Have Submitted Their Consent For Including in The DPMC of Palnadu DTSudheer KumarNo ratings yet

- NBR 14136 Plugs and Socket Outlets in BrazilDocument7 pagesNBR 14136 Plugs and Socket Outlets in BrazilCLOUD ALIGLOBALNo ratings yet

- Control Valve Sourcebook (Refining) PDFDocument198 pagesControl Valve Sourcebook (Refining) PDFnaraNJORNo ratings yet

- Sheet 6 Electronics - AnswerDocument10 pagesSheet 6 Electronics - AnswerOla SamirNo ratings yet

- About BioroboticsDocument2 pagesAbout Bioroboticspaulramesh100% (1)

- Affidavit of Respondent in Cases of Adultery: Form 56A.44ADocument2 pagesAffidavit of Respondent in Cases of Adultery: Form 56A.44AChristopher LojeroNo ratings yet

- Jeppview For Windows: General Information General InformationDocument39 pagesJeppview For Windows: General Information General Informationbooba100% (1)

- Braintech Engineers PVT LTDDocument8 pagesBraintech Engineers PVT LTDMANVENDRA SINGHNo ratings yet

- 6) Photoelectric Effect and Uncertainity ProblemsDocument4 pages6) Photoelectric Effect and Uncertainity ProblemsGame 1No ratings yet

- En GB-car Exchange AgreementDocument2 pagesEn GB-car Exchange Agreementbaby_charm100% (1)

- Questions: 1 About MeDocument8 pagesQuestions: 1 About MeC VNo ratings yet

- C DAC Winter Project Report 7 PDFDocument29 pagesC DAC Winter Project Report 7 PDFAbhinav TayadeNo ratings yet

- Cell Structure and Function Pretest: The Organelle Has A Phospholipid MembraneDocument28 pagesCell Structure and Function Pretest: The Organelle Has A Phospholipid MembranelayanhaliloNo ratings yet

- Chandra NamaskarDocument8 pagesChandra NamaskarSwati Rohan JadhavNo ratings yet

- Self - Assessment Guide Beuaty CareDocument13 pagesSelf - Assessment Guide Beuaty CareMac Dareel UrianoNo ratings yet

- Total Brochure UK LoRes 0609 PDFDocument32 pagesTotal Brochure UK LoRes 0609 PDFMohammed RayanNo ratings yet

- ScalpDocument17 pagesScalpKaruna PrabhuNo ratings yet

- Surgery KGMU Proff Chapterwise by Arif Naseem 2009-2021Document4 pagesSurgery KGMU Proff Chapterwise by Arif Naseem 2009-2021DR. PARDEEP SHARMANo ratings yet

- Prelim Types of SexualityDocument12 pagesPrelim Types of SexualityAngelica SinoyNo ratings yet

- Caterpillar C280 Series Engine Product GuideDocument221 pagesCaterpillar C280 Series Engine Product GuideIvan Aditya100% (1)

- Maternity Benefit PolicyDocument2 pagesMaternity Benefit Policyshrija nairNo ratings yet

- UC Davis General Catalog - Animal Science - 2022-03-13 - 231610Document17 pagesUC Davis General Catalog - Animal Science - 2022-03-13 - 231610XNo ratings yet