Professional Documents

Culture Documents

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yu

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yu

Uploaded by

SinhrooCopyright:

Available Formats

You might also like

- (Camp, 2002) Venture Capital Due Diligence PDFDocument267 pages(Camp, 2002) Venture Capital Due Diligence PDFlalall100% (2)

- The Joker and The Queen - Ed Sheeran Piano-Vocal-GuitarDocument3 pagesThe Joker and The Queen - Ed Sheeran Piano-Vocal-GuitarAngela HallNo ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Tramp Elements and Billet CarckingDocument7 pagesTramp Elements and Billet CarckingOmar TahaNo ratings yet

- Tratamientos ArticuloDocument9 pagesTratamientos ArticuloYersonAmayaNo ratings yet

- Effect of Coiling Temperature On Oxide Scale of Hot-Rolled StripDocument8 pagesEffect of Coiling Temperature On Oxide Scale of Hot-Rolled StripAnish ChaudharyNo ratings yet

- Coatings 10 01265Document15 pagesCoatings 10 01265Mani RameshNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- Thermodynamics and Agglomeration Behavior On SpineDocument16 pagesThermodynamics and Agglomeration Behavior On SpinePranjal SinghNo ratings yet

- The Influence of Hot-Working Conditions On A Structure of High-Manganese SteelDocument10 pagesThe Influence of Hot-Working Conditions On A Structure of High-Manganese SteelPiranha TourniquetNo ratings yet

- The Effect of Heat Treatment On The Structure of Scale LayerDocument8 pagesThe Effect of Heat Treatment On The Structure of Scale LayerNoel FrancisNo ratings yet

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingNo ratings yet

- Microstructural of Second Phases in Ascast and Homogenized Aluminum AlloyDocument7 pagesMicrostructural of Second Phases in Ascast and Homogenized Aluminum AlloyHamed NobariNo ratings yet

- X. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityDocument6 pagesX. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityTania DanielNo ratings yet

- Selection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessDocument6 pagesSelection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessIbnu AndriNo ratings yet

- Effect of Copper Content On The Hot Ductility Loss of Low Carbon SteelsDocument5 pagesEffect of Copper Content On The Hot Ductility Loss of Low Carbon SteelsBalakrishna G SettyNo ratings yet

- Full 5741 - Gray IronDocument12 pagesFull 5741 - Gray IronfondershellNo ratings yet

- D0501 01-2231 PDFDocument10 pagesD0501 01-2231 PDFRoyal GemNo ratings yet

- Gonzalez 21399Document11 pagesGonzalez 21399Yogesh S Yogi SNo ratings yet

- The Effect of Increasing Silicon On Mechanical ProDocument7 pagesThe Effect of Increasing Silicon On Mechanical ProSunil ShrivastavaNo ratings yet

- Jurnal SMA (1) RajeshDocument6 pagesJurnal SMA (1) RajeshMuhammad Falqi YusufNo ratings yet

- Influence of Cooling Rate On The Structure and Formation of Oxide Scale in LowDocument7 pagesInfluence of Cooling Rate On The Structure and Formation of Oxide Scale in LowVarun MangaloreNo ratings yet

- Analysis of Hydrogen Content in The Main Stages of Low-Alloy Aluminum Alloy Flat Ingot ManufactureDocument5 pagesAnalysis of Hydrogen Content in The Main Stages of Low-Alloy Aluminum Alloy Flat Ingot Manufacturedhinakaranme3056No ratings yet

- Effect of Intergranular Precipitation On The Internal Oxidation Behavior of CR - MN-N Austenitic Stainless SteelsDocument8 pagesEffect of Intergranular Precipitation On The Internal Oxidation Behavior of CR - MN-N Austenitic Stainless SteelsDomingo FernándezNo ratings yet

- Mag 05Document9 pagesMag 05Avinash KumarNo ratings yet

- Interface Between Sn-Sb-Cu Solder and Copper Substrate: Materials Science and Engineering ADocument6 pagesInterface Between Sn-Sb-Cu Solder and Copper Substrate: Materials Science and Engineering Aeid elsayedNo ratings yet

- Ductility Troughs in Microalloyed SteelDocument12 pagesDuctility Troughs in Microalloyed SteelAtanu MukherjeeNo ratings yet

- AL Si CuDocument7 pagesAL Si CuRiedl LaurentiuNo ratings yet

- Optmzn of HT - AMSDocument4 pagesOptmzn of HT - AMSsushmaxNo ratings yet

- InTech-Welding of Aluminum Alloys PDFDocument25 pagesInTech-Welding of Aluminum Alloys PDFCortesar ManuNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- Analysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthDocument10 pagesAnalysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthEvren ÇaprazNo ratings yet

- Materials Letters: Bo Han, Sujun WuDocument4 pagesMaterials Letters: Bo Han, Sujun WuPiranha TourniquetNo ratings yet

- Microstructure of High-Pressure Die-Casting AM50 Magnesium AlloyDocument4 pagesMicrostructure of High-Pressure Die-Casting AM50 Magnesium AlloyrekyNo ratings yet

- EXP8 JominyDocument6 pagesEXP8 JominyDrShashikant DargarNo ratings yet

- Effects of ZR, Ti, and Al Additions On Impact ToughnessDocument12 pagesEffects of ZR, Ti, and Al Additions On Impact ToughnessDo Tuan DatNo ratings yet

- Met 56 1 2 63 66Document4 pagesMet 56 1 2 63 66JasminNo ratings yet

- Structural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsDocument8 pagesStructural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsmusonlyNo ratings yet

- Chapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureDocument18 pagesChapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureXimena Mercedez Palacios PortalNo ratings yet

- Materials 07 01173 PDFDocument15 pagesMaterials 07 01173 PDFSerkan ApayNo ratings yet

- FHM, Apr 2011Document4 pagesFHM, Apr 2011emediageNo ratings yet

- Study of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDocument43 pagesStudy of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDeepu ChoudharyNo ratings yet

- Al-Zn AlloyDocument7 pagesAl-Zn Alloymohamad60No ratings yet

- Aleaciones 7000 AlDocument20 pagesAleaciones 7000 AlDavid FellinNo ratings yet

- Regordosa-Llorca-Isern2016 Article ChemicalAndStructuralCharacterDocument15 pagesRegordosa-Llorca-Isern2016 Article ChemicalAndStructuralCharactersanjeev singhNo ratings yet

- Precipitation Hardening in 350 Grade Maraging SteelDocument14 pagesPrecipitation Hardening in 350 Grade Maraging SteelAriel NemcoNo ratings yet

- Corrosion of Aged and Annealed 18 Ni 250 Grade Maraging Steel in Phosphoric Acid MediumDocument16 pagesCorrosion of Aged and Annealed 18 Ni 250 Grade Maraging Steel in Phosphoric Acid MediumSharat ChandraNo ratings yet

- Volchok 22Document4 pagesVolchok 22amitkkambleNo ratings yet

- Slag From Production of Pig Iron and Steel Making and Posibilities of Their UtilizationDocument6 pagesSlag From Production of Pig Iron and Steel Making and Posibilities of Their Utilizationಯತೀಶ್ ಗೌಡNo ratings yet

- Influence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelDocument6 pagesInfluence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelElMacheteDelHuesoNo ratings yet

- Microstructure and Characterstis of ZR AlloyDocument8 pagesMicrostructure and Characterstis of ZR AlloyDGNPF IslamabadNo ratings yet

- The Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsDocument6 pagesThe Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsBANUNo ratings yet

- Qin2015 Article CorrosionBehaviorOfTheFrictionDocument12 pagesQin2015 Article CorrosionBehaviorOfTheFrictionDilipSinghNo ratings yet

- Capturing The Interaction Between Mold Flux and Different Steel Compositions During Industrial-Scale Continuous Casting TrialsDocument14 pagesCapturing The Interaction Between Mold Flux and Different Steel Compositions During Industrial-Scale Continuous Casting Trialsamannigam19940914No ratings yet

- Spangle FormationDocument16 pagesSpangle FormationMartin OloweNo ratings yet

- Effect of Calcium and Magnesium Treatment On Steel WeldabilityDocument7 pagesEffect of Calcium and Magnesium Treatment On Steel WeldabilitySuleyman HaliciogluNo ratings yet

- Segregation Effects Iii Welded Stairless Steels: Pinstech/Npd-121Document26 pagesSegregation Effects Iii Welded Stairless Steels: Pinstech/Npd-121Lenin CórdovaNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- Hydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysDocument5 pagesHydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysSinhrooNo ratings yet

- Effect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsDocument5 pagesEffect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsSinhrooNo ratings yet

- Foreign TechnologyDocument1 pageForeign TechnologySinhrooNo ratings yet

- Heating IN AN Electrically Conducting Layer Carbon-Containing Particles OFDocument4 pagesHeating IN AN Electrically Conducting Layer Carbon-Containing Particles OFSinhrooNo ratings yet

- 1006 1009Document4 pages1006 1009SinhrooNo ratings yet

- 390 394 PDFDocument5 pages390 394 PDFSinhrooNo ratings yet

- Hardness OF: CementiteDocument2 pagesHardness OF: CementiteSinhrooNo ratings yet

- 382 385 PDFDocument4 pages382 385 PDFSinhrooNo ratings yet

- 386 389 PDFDocument4 pages386 389 PDFSinhrooNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- 374 376 PDFDocument3 pages374 376 PDFSinhrooNo ratings yet

- Protective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasDocument4 pagesProtective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasSinhrooNo ratings yet

- Technology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsDocument5 pagesTechnology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsSinhrooNo ratings yet

- 9 (I,, TillDocument4 pages9 (I,, TillSinhrooNo ratings yet

- Effect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysDocument4 pagesEffect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysSinhrooNo ratings yet

- E 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetDocument1 pageE 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetSinhrooNo ratings yet

- Nursing Excellence StandardsDocument58 pagesNursing Excellence StandardsJyoti100% (1)

- FinanceDocument26 pagesFinanceBhargav D.S.No ratings yet

- 130 Publicacao05012009032220Document12 pages130 Publicacao05012009032220Fernando CostaNo ratings yet

- PXF4 ManualDocument24 pagesPXF4 ManualIgnacio Sebastian Cabello ArayaNo ratings yet

- Consolidated Invoice - Nexa Equity - Project ScubaDocument3 pagesConsolidated Invoice - Nexa Equity - Project ScubarhenkeNo ratings yet

- Research Paper On Emotional StabilityDocument8 pagesResearch Paper On Emotional Stabilityegw48xp5100% (1)

- DKT 373 - 2022.11.10 - Google Chat DeletionsDocument14 pagesDKT 373 - 2022.11.10 - Google Chat DeletionsTechCrunchNo ratings yet

- How To Refill HP Cartridge in General V 2Document8 pagesHow To Refill HP Cartridge in General V 2Raymond Aldrich NgoNo ratings yet

- Maple 11 User ManualDocument412 pagesMaple 11 User ManualMarlon Henry Arosemena ZúñigaNo ratings yet

- Hannah Gonzales ResumeDocument2 pagesHannah Gonzales Resumeapi-500481504No ratings yet

- Broadcast Video Media Producer in Austin Dallas TX Resume Glen ChurchwellDocument2 pagesBroadcast Video Media Producer in Austin Dallas TX Resume Glen ChurchwellGlenChurchwellNo ratings yet

- Voila User ManualDocument79 pagesVoila User ManualKristen HammerNo ratings yet

- ACN Micro Project-1Document23 pagesACN Micro Project-1ashutosh dudhaneNo ratings yet

- Combat Decision Making Process at The Tactical LevelDocument156 pagesCombat Decision Making Process at The Tactical LevelGreg Jackson100% (1)

- Review Aruna 3Document7 pagesReview Aruna 3Angel Francisco Zacarias MartinezNo ratings yet

- FB2750 M TMT2750CDocument8 pagesFB2750 M TMT2750Csiyavash seifNo ratings yet

- MZ Instruction and Maintenance ManualDocument25 pagesMZ Instruction and Maintenance ManualLakiLakicNo ratings yet

- X, Y, U, U U U: 5. Second Order Partial Differential Equations in Two VariablesDocument7 pagesX, Y, U, U U U: 5. Second Order Partial Differential Equations in Two VariablesTreba KomeNo ratings yet

- ALMM For Solar PV ModuleDocument53 pagesALMM For Solar PV Modulemandar kattiNo ratings yet

- Mikrotik Products PresentationDocument85 pagesMikrotik Products PresentationinnovativekaluNo ratings yet

- Practice Note For Authorized Persons, Buildings Department Registered Structural Engineers and ADV-33 Registered Geotechnical EngineersDocument79 pagesPractice Note For Authorized Persons, Buildings Department Registered Structural Engineers and ADV-33 Registered Geotechnical EngineersJacky LeongNo ratings yet

- SGX-Listed Hatten Land Diversifies Beyond Melaka Through Proposed Acquisition of Unicity in Seremban, MalaysiaDocument3 pagesSGX-Listed Hatten Land Diversifies Beyond Melaka Through Proposed Acquisition of Unicity in Seremban, MalaysiaWeR1 Consultants Pte LtdNo ratings yet

- Chapter-2 Plant Asset and Intangible AssetDocument2 pagesChapter-2 Plant Asset and Intangible AssetHayelom Tadesse GebreNo ratings yet

- Absolute Containers Brochure 2019 2 27 PDFDocument19 pagesAbsolute Containers Brochure 2019 2 27 PDFEduardo SolanoNo ratings yet

- Boq 103893 PDFDocument23 pagesBoq 103893 PDFpm_mascotNo ratings yet

- ABLE Contract Approval.Document5 pagesABLE Contract Approval.Ferris FerrisNo ratings yet

- Overview MSSLDocument23 pagesOverview MSSLVijya GargNo ratings yet

- Intelsat VI: International Satellite DirectoryDocument1 pageIntelsat VI: International Satellite DirectorySaravanan ArumugamNo ratings yet

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yu

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yu

Uploaded by

SinhrooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yu

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08yu

Uploaded by

SinhrooCopyright:

Available Formats

M e t a l Science a n d Heat Treatment

Vol. 39, Nos. 11 - 12, 1997

UDC 620.191.32:669.14.018.262

PHASE C O M P O S I T I O N OF SCALE OF H O T - R O L L E D

A U T O M O B I L E SHEET STEEL 08Yu

Yu. A. M u k h i n , t A. V. Merzlyakov, ! A. F. Pimenov, t and A. P. S h a p o v a l o v t

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 2 8 - 30, December, 1997.

We studied the reasons behind the different rates of scale

dissolution in the pickling process. We cut specimens with

scale from various parts of ribbons fabricated at a low

(630~ and a high (710~ winding temperature. The scale

was removed from the base metal by deforming the specimens in a tensile testing machine.

It has been shown in [3, 4] that at low tw the main ironcontaining phase of the scale is magnetite (Fe304), whereas at

high tw the scale consists of magnetite with finely distributed particles of metallic iron.

The oxide phases were separated from specimens the

scale by the method of halogenation in an atmosphere of

gaseous chlorine. After transforming the oxide phases into a

solution an analysis of the constituent elements was made by

chemical and atomic-absorption methods. Table 2 presents

the compositions and amounts of the phases contained in the

scale. It can be seen that scale from ribbons obtained at different winding temperatures has virtually the same amounts of

silicon and aluminum oxides but differs substantially in the

contents of iron and its oxides. The total amount of oxides in

scale formed at t w = 630~ is about 1.5 times lower and that

of iron is about 2 times higher than in scale of ribbon wound

at tw = 710~

To determine the iron phases in the scale we resorted to

gamma-resonance spectroscopy. The spectra were taken from

scale specimens without any additional physicochemical

treatment. The spectra had the form of well-resolved Zeeman

sextets of magnetite, a-iron, and, with a syngate line in the

center, wiistite. The curves of the spectra of scale specimens

obtained at low and high winding temperatures are quite

The production process for automobile sheets in the Novolipetsk Iron-and-Steel Integrated Works includes hot rolling in a 2000 continuous wide-band mill, pickling of the hotrolled ribbon in a solution of hydrochloric acid, cold rolling

in a 2030 five-strand mill, heat treatment, and dressing [I].

Depending on the kind of heat treatment of the semifinished

rolled stock (batch treatment in ball furnaces or continuous

treatment in an installation for continuous annealing (ICA)),

the hot rolling is conducted by different temperature and rate

regimes.

Steel 08Yu (<0.07% C, 0 . 2 0 - 0 . 3 5 % Mn, _<0.01% Si,

< 0.02% P, < 0.025% S, _<0.03% Cr, _<0.06% Ni, _<0.06%

Cu, 0.02 - 0.07% AI) is rolled in a 2000 mill for ribbons over

2.6 mm thick by two variants (Table 1).

To provide the requisite high temperatures of final rolling

(tf~) and winding (t w) in the production of automobile sheet

steel by variant I a high temperature should be sustained over

the entire length of the mill, which is provided by distributing

the deformations between the rough and finishing groups (the

thickness of the rolled product before the finishing group is

40 - 45 mm) and sustaining elevated feeding rates (up to 11 12 m/sec in the 12th strand of the mill). However, an increase

in the temperature of hot rolling is accompanied by formation

of defects of the "rolled-in scale" type on the surface of the

rolled ribbon. These defects worsen the surface quality of the

final product. In addition, the output of the continuous pickling installations diminishes [2], because more time is required to remove scale from ribbon wound at a higher temperature.

Lipetsk Polytechnic Institute; 1. P. Bardin Central Research Institute of

Ferrous Metallurgy; A. A. Baikov Institute for Metals; Novolipetsk Ironand-Steel Integrated Works, Russia.

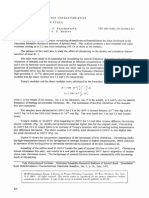

TABLE 2

tw, ~

630

TABLE I

Rolling

variant

Ifr,

t,,., ~

Form of heat treatment

710

870 - 920

720 - 760

Continuous annealing in an ICA

11

8 2 0 - 860

620 - 660

Annealing in bell furnaces

Sampling

place in

the ribbon

Content o f p h a s e s in scale of steel 08Yu, %

SiO2

AI203

Fe304

FeO

Fe203

Feme t

Beginning

Middle

1.5

2.40

1.3

I.I

59.2

48.3

7.00

38.0

41.2

62.0

59.8

End

1.70

I.I

30.4

28.3

38.5

61.5

Beginning

End

2.30

1.60

1.0

1.0

61.9

33.0

8.2

46.0

10.6

-

16.0

18.4

84.0

81.6

K_~

Total amount of oxides.

532

0026-067319711 I 12-0532518.00 9 1998 Plenum Publishing Corporation

Phase Composition of Scale of Hot-Rolled Automobile Sheet Steel 08Yu

similar. The main phase of the scale on the initial part of ribbons rolled at high and low tw is magnetite. In addition, at

high tw the scale contains a small amount of wiistite (FeO)

and hematite (Fe203) obviously formed due to transformation

of lower oxides into higher ones during the longer cooling

from the high winding temperature. The scale on the middle

part of the ribbon obtained at low tw contains predominantly

magnetite. In the end parts of the ribbons produced at low and

high tw the ratio of the concentrations of magnetite and

wiJstite fluctuates from l to 0.7. The quantitative ratio of the

oxide phases and metallic iron in the scale taken from the

edges and from the middle parts of the ribbons is the same

and does not depend on tw .

We did not find carbide phases of the M3C type in the

scale. Silicate and spinel inclusions of the Fe2SiO4, FeSiO3,

and FeO 9AI203 types have not been detected either. However, they can be present in the scale in an amount below 1%,

which cannot be determined by the method of nuclear gamma

resonance. These phases have high chemical stability as conceres dissolution in acids. They are present in the scale in the

form of point inclusions, can be "rolled" into the metal, and

are not removed in the pickling process [5].

Analyzing the results obtained we found that wiJstite as

well as magnetite can be the main phase in the scale of steel

08Yu at both a low and a high winding temperature of the ribbon. The presence of metallic iron in the oxide layer and its

amount are the main factor influencing the intensity of the

process of scale removal from the surface of a hot-rolled ribbon. The interaction between the metallic iron and the pickling solution causes release of molecular hydrogen, which

creates additional channels and cracks in the scale layer. This

provides rapid penetration of the pickling solution to the oxi-

533

d e - m e t a l interface. A decrease in amount of metallic iron

and, as a consequence, an increase in the amount of Scale decelerate the diffusion of the pickling solution, and it reaches

the o x i d e - m e t a l interface not everywhere simultaneously.

The metal surface becomes uneven because the pickling solution acts on it for different times. The interaction of any iron

oxide with the acid occurs slowly and cannot provide rapid

pickling of the rolled metal even at high temperatures.

CONCLUSION

To obtain a rolled product with a pure surface we should

conduct hot deformation by a regime (for example, at diminished temperatures of rolling and winding) that provides formation of a considerable amount (over 40%) of iron in the

scale, which promotes its rapid dissolution in the pickling

process. Defects of the "rolled-in"-scale type are virtually absent on the surface of rolled ribbons produced by such a regime.

REFERENCES

1. A. F. Pimenov, A. M. Pozhivanov, L. V. Meandrov, et al., Stal',

No. 5,42-44(1982).

2. Yu. A. Mukhin, A. P. Shapovalov, M. A. Bobrov, et al., Stal',

No. 4, 45 - 4 8 (1985).

3. B. Frisch, Arch. EisenhiJttenwes., 54(8), 311 - 316 (1983).

4. L. Hahtel, R. Bode, and L. Mayer, Ferrous Metals, No. 14, 3 - 8

(1984).

5. B. A. Gun'ko, S. A. Kiseleva, O. S. Tuchkina, and A. V. Merzlyakov, "Methods for analyzing the monitoring and testing of

metal structures," in: Coll. of Works of TsNIICsERMET [in Russian], Metallurgiya, Moscow (1983), pp. 72 - 75.

You might also like

- (Camp, 2002) Venture Capital Due Diligence PDFDocument267 pages(Camp, 2002) Venture Capital Due Diligence PDFlalall100% (2)

- The Joker and The Queen - Ed Sheeran Piano-Vocal-GuitarDocument3 pagesThe Joker and The Queen - Ed Sheeran Piano-Vocal-GuitarAngela HallNo ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Tramp Elements and Billet CarckingDocument7 pagesTramp Elements and Billet CarckingOmar TahaNo ratings yet

- Tratamientos ArticuloDocument9 pagesTratamientos ArticuloYersonAmayaNo ratings yet

- Effect of Coiling Temperature On Oxide Scale of Hot-Rolled StripDocument8 pagesEffect of Coiling Temperature On Oxide Scale of Hot-Rolled StripAnish ChaudharyNo ratings yet

- Coatings 10 01265Document15 pagesCoatings 10 01265Mani RameshNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- Thermodynamics and Agglomeration Behavior On SpineDocument16 pagesThermodynamics and Agglomeration Behavior On SpinePranjal SinghNo ratings yet

- The Influence of Hot-Working Conditions On A Structure of High-Manganese SteelDocument10 pagesThe Influence of Hot-Working Conditions On A Structure of High-Manganese SteelPiranha TourniquetNo ratings yet

- The Effect of Heat Treatment On The Structure of Scale LayerDocument8 pagesThe Effect of Heat Treatment On The Structure of Scale LayerNoel FrancisNo ratings yet

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingNo ratings yet

- Microstructural of Second Phases in Ascast and Homogenized Aluminum AlloyDocument7 pagesMicrostructural of Second Phases in Ascast and Homogenized Aluminum AlloyHamed NobariNo ratings yet

- X. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityDocument6 pagesX. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityTania DanielNo ratings yet

- Selection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessDocument6 pagesSelection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessIbnu AndriNo ratings yet

- Effect of Copper Content On The Hot Ductility Loss of Low Carbon SteelsDocument5 pagesEffect of Copper Content On The Hot Ductility Loss of Low Carbon SteelsBalakrishna G SettyNo ratings yet

- Full 5741 - Gray IronDocument12 pagesFull 5741 - Gray IronfondershellNo ratings yet

- D0501 01-2231 PDFDocument10 pagesD0501 01-2231 PDFRoyal GemNo ratings yet

- Gonzalez 21399Document11 pagesGonzalez 21399Yogesh S Yogi SNo ratings yet

- The Effect of Increasing Silicon On Mechanical ProDocument7 pagesThe Effect of Increasing Silicon On Mechanical ProSunil ShrivastavaNo ratings yet

- Jurnal SMA (1) RajeshDocument6 pagesJurnal SMA (1) RajeshMuhammad Falqi YusufNo ratings yet

- Influence of Cooling Rate On The Structure and Formation of Oxide Scale in LowDocument7 pagesInfluence of Cooling Rate On The Structure and Formation of Oxide Scale in LowVarun MangaloreNo ratings yet

- Analysis of Hydrogen Content in The Main Stages of Low-Alloy Aluminum Alloy Flat Ingot ManufactureDocument5 pagesAnalysis of Hydrogen Content in The Main Stages of Low-Alloy Aluminum Alloy Flat Ingot Manufacturedhinakaranme3056No ratings yet

- Effect of Intergranular Precipitation On The Internal Oxidation Behavior of CR - MN-N Austenitic Stainless SteelsDocument8 pagesEffect of Intergranular Precipitation On The Internal Oxidation Behavior of CR - MN-N Austenitic Stainless SteelsDomingo FernándezNo ratings yet

- Mag 05Document9 pagesMag 05Avinash KumarNo ratings yet

- Interface Between Sn-Sb-Cu Solder and Copper Substrate: Materials Science and Engineering ADocument6 pagesInterface Between Sn-Sb-Cu Solder and Copper Substrate: Materials Science and Engineering Aeid elsayedNo ratings yet

- Ductility Troughs in Microalloyed SteelDocument12 pagesDuctility Troughs in Microalloyed SteelAtanu MukherjeeNo ratings yet

- AL Si CuDocument7 pagesAL Si CuRiedl LaurentiuNo ratings yet

- Optmzn of HT - AMSDocument4 pagesOptmzn of HT - AMSsushmaxNo ratings yet

- InTech-Welding of Aluminum Alloys PDFDocument25 pagesInTech-Welding of Aluminum Alloys PDFCortesar ManuNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- Analysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthDocument10 pagesAnalysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthEvren ÇaprazNo ratings yet

- Materials Letters: Bo Han, Sujun WuDocument4 pagesMaterials Letters: Bo Han, Sujun WuPiranha TourniquetNo ratings yet

- Microstructure of High-Pressure Die-Casting AM50 Magnesium AlloyDocument4 pagesMicrostructure of High-Pressure Die-Casting AM50 Magnesium AlloyrekyNo ratings yet

- EXP8 JominyDocument6 pagesEXP8 JominyDrShashikant DargarNo ratings yet

- Effects of ZR, Ti, and Al Additions On Impact ToughnessDocument12 pagesEffects of ZR, Ti, and Al Additions On Impact ToughnessDo Tuan DatNo ratings yet

- Met 56 1 2 63 66Document4 pagesMet 56 1 2 63 66JasminNo ratings yet

- Structural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsDocument8 pagesStructural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsmusonlyNo ratings yet

- Chapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureDocument18 pagesChapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureXimena Mercedez Palacios PortalNo ratings yet

- Materials 07 01173 PDFDocument15 pagesMaterials 07 01173 PDFSerkan ApayNo ratings yet

- FHM, Apr 2011Document4 pagesFHM, Apr 2011emediageNo ratings yet

- Study of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDocument43 pagesStudy of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDeepu ChoudharyNo ratings yet

- Al-Zn AlloyDocument7 pagesAl-Zn Alloymohamad60No ratings yet

- Aleaciones 7000 AlDocument20 pagesAleaciones 7000 AlDavid FellinNo ratings yet

- Regordosa-Llorca-Isern2016 Article ChemicalAndStructuralCharacterDocument15 pagesRegordosa-Llorca-Isern2016 Article ChemicalAndStructuralCharactersanjeev singhNo ratings yet

- Precipitation Hardening in 350 Grade Maraging SteelDocument14 pagesPrecipitation Hardening in 350 Grade Maraging SteelAriel NemcoNo ratings yet

- Corrosion of Aged and Annealed 18 Ni 250 Grade Maraging Steel in Phosphoric Acid MediumDocument16 pagesCorrosion of Aged and Annealed 18 Ni 250 Grade Maraging Steel in Phosphoric Acid MediumSharat ChandraNo ratings yet

- Volchok 22Document4 pagesVolchok 22amitkkambleNo ratings yet

- Slag From Production of Pig Iron and Steel Making and Posibilities of Their UtilizationDocument6 pagesSlag From Production of Pig Iron and Steel Making and Posibilities of Their Utilizationಯತೀಶ್ ಗೌಡNo ratings yet

- Influence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelDocument6 pagesInfluence of Tungsten and Carbon Addition On Electrochemical Behaviour of 9 % CR Creep-Resistant SteelElMacheteDelHuesoNo ratings yet

- Microstructure and Characterstis of ZR AlloyDocument8 pagesMicrostructure and Characterstis of ZR AlloyDGNPF IslamabadNo ratings yet

- The Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsDocument6 pagesThe Effect of Alloying and of The Structure On Active-Passive Transition Potential Range of 17% Chromium Ferritic Stainless SteelsBANUNo ratings yet

- Qin2015 Article CorrosionBehaviorOfTheFrictionDocument12 pagesQin2015 Article CorrosionBehaviorOfTheFrictionDilipSinghNo ratings yet

- Capturing The Interaction Between Mold Flux and Different Steel Compositions During Industrial-Scale Continuous Casting TrialsDocument14 pagesCapturing The Interaction Between Mold Flux and Different Steel Compositions During Industrial-Scale Continuous Casting Trialsamannigam19940914No ratings yet

- Spangle FormationDocument16 pagesSpangle FormationMartin OloweNo ratings yet

- Effect of Calcium and Magnesium Treatment On Steel WeldabilityDocument7 pagesEffect of Calcium and Magnesium Treatment On Steel WeldabilitySuleyman HaliciogluNo ratings yet

- Segregation Effects Iii Welded Stairless Steels: Pinstech/Npd-121Document26 pagesSegregation Effects Iii Welded Stairless Steels: Pinstech/Npd-121Lenin CórdovaNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- Hydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysDocument5 pagesHydrostatic Extrusion at 100°C and Its Effect On The Grain Size and Mechanical Properties of Magnesium AlloysSinhrooNo ratings yet

- Effect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsDocument5 pagesEffect of Various Kinds of Thermomechanical Treatment On The Structure and Properties of Steels Studied Using Acoustomicroscopic MethodsSinhrooNo ratings yet

- Foreign TechnologyDocument1 pageForeign TechnologySinhrooNo ratings yet

- Heating IN AN Electrically Conducting Layer Carbon-Containing Particles OFDocument4 pagesHeating IN AN Electrically Conducting Layer Carbon-Containing Particles OFSinhrooNo ratings yet

- 1006 1009Document4 pages1006 1009SinhrooNo ratings yet

- 390 394 PDFDocument5 pages390 394 PDFSinhrooNo ratings yet

- Hardness OF: CementiteDocument2 pagesHardness OF: CementiteSinhrooNo ratings yet

- 382 385 PDFDocument4 pages382 385 PDFSinhrooNo ratings yet

- 386 389 PDFDocument4 pages386 389 PDFSinhrooNo ratings yet

- Hardening From The Liquid StateDocument5 pagesHardening From The Liquid StateSinhrooNo ratings yet

- 374 376 PDFDocument3 pages374 376 PDFSinhrooNo ratings yet

- Protective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasDocument4 pagesProtective Properties of A Nitrogen Atmosphere With An Admixture of Natural GasSinhrooNo ratings yet

- Technology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsDocument5 pagesTechnology of Heat Treatment: Volume-Surface Hardening of by A High-Speed Water Stream Railroad Transport PartsSinhrooNo ratings yet

- 9 (I,, TillDocument4 pages9 (I,, TillSinhrooNo ratings yet

- Effect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysDocument4 pagesEffect of Alloying, Heat Treatment, and Deformation On The Structure and Properties of Damping Z N - A I AlloysSinhrooNo ratings yet

- E 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetDocument1 pageE 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetSinhrooNo ratings yet

- Nursing Excellence StandardsDocument58 pagesNursing Excellence StandardsJyoti100% (1)

- FinanceDocument26 pagesFinanceBhargav D.S.No ratings yet

- 130 Publicacao05012009032220Document12 pages130 Publicacao05012009032220Fernando CostaNo ratings yet

- PXF4 ManualDocument24 pagesPXF4 ManualIgnacio Sebastian Cabello ArayaNo ratings yet

- Consolidated Invoice - Nexa Equity - Project ScubaDocument3 pagesConsolidated Invoice - Nexa Equity - Project ScubarhenkeNo ratings yet

- Research Paper On Emotional StabilityDocument8 pagesResearch Paper On Emotional Stabilityegw48xp5100% (1)

- DKT 373 - 2022.11.10 - Google Chat DeletionsDocument14 pagesDKT 373 - 2022.11.10 - Google Chat DeletionsTechCrunchNo ratings yet

- How To Refill HP Cartridge in General V 2Document8 pagesHow To Refill HP Cartridge in General V 2Raymond Aldrich NgoNo ratings yet

- Maple 11 User ManualDocument412 pagesMaple 11 User ManualMarlon Henry Arosemena ZúñigaNo ratings yet

- Hannah Gonzales ResumeDocument2 pagesHannah Gonzales Resumeapi-500481504No ratings yet

- Broadcast Video Media Producer in Austin Dallas TX Resume Glen ChurchwellDocument2 pagesBroadcast Video Media Producer in Austin Dallas TX Resume Glen ChurchwellGlenChurchwellNo ratings yet

- Voila User ManualDocument79 pagesVoila User ManualKristen HammerNo ratings yet

- ACN Micro Project-1Document23 pagesACN Micro Project-1ashutosh dudhaneNo ratings yet

- Combat Decision Making Process at The Tactical LevelDocument156 pagesCombat Decision Making Process at The Tactical LevelGreg Jackson100% (1)

- Review Aruna 3Document7 pagesReview Aruna 3Angel Francisco Zacarias MartinezNo ratings yet

- FB2750 M TMT2750CDocument8 pagesFB2750 M TMT2750Csiyavash seifNo ratings yet

- MZ Instruction and Maintenance ManualDocument25 pagesMZ Instruction and Maintenance ManualLakiLakicNo ratings yet

- X, Y, U, U U U: 5. Second Order Partial Differential Equations in Two VariablesDocument7 pagesX, Y, U, U U U: 5. Second Order Partial Differential Equations in Two VariablesTreba KomeNo ratings yet

- ALMM For Solar PV ModuleDocument53 pagesALMM For Solar PV Modulemandar kattiNo ratings yet

- Mikrotik Products PresentationDocument85 pagesMikrotik Products PresentationinnovativekaluNo ratings yet

- Practice Note For Authorized Persons, Buildings Department Registered Structural Engineers and ADV-33 Registered Geotechnical EngineersDocument79 pagesPractice Note For Authorized Persons, Buildings Department Registered Structural Engineers and ADV-33 Registered Geotechnical EngineersJacky LeongNo ratings yet

- SGX-Listed Hatten Land Diversifies Beyond Melaka Through Proposed Acquisition of Unicity in Seremban, MalaysiaDocument3 pagesSGX-Listed Hatten Land Diversifies Beyond Melaka Through Proposed Acquisition of Unicity in Seremban, MalaysiaWeR1 Consultants Pte LtdNo ratings yet

- Chapter-2 Plant Asset and Intangible AssetDocument2 pagesChapter-2 Plant Asset and Intangible AssetHayelom Tadesse GebreNo ratings yet

- Absolute Containers Brochure 2019 2 27 PDFDocument19 pagesAbsolute Containers Brochure 2019 2 27 PDFEduardo SolanoNo ratings yet

- Boq 103893 PDFDocument23 pagesBoq 103893 PDFpm_mascotNo ratings yet

- ABLE Contract Approval.Document5 pagesABLE Contract Approval.Ferris FerrisNo ratings yet

- Overview MSSLDocument23 pagesOverview MSSLVijya GargNo ratings yet

- Intelsat VI: International Satellite DirectoryDocument1 pageIntelsat VI: International Satellite DirectorySaravanan ArumugamNo ratings yet