Professional Documents

Culture Documents

Shutdown Isolation Procedures

Shutdown Isolation Procedures

Uploaded by

eng20072007Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shutdown Isolation Procedures

Shutdown Isolation Procedures

Uploaded by

eng20072007Copyright:

Available Formats

Dsq.

Field Forthcoming planned S/D Hereunder are the depicted procedures for lines and vessels at inlet and outlet of CTP

in order to enable carry out S/D activities safely and smoothly

-

Some tasks will be carried out in concurrently while some to be in

consequentially

The next procedures to be followed:

-

Initiating total CTP plant S/Make sure the automatic S/D valves on all trunk

lines, are positively closed.

Open manual valves upstream pig receivers of NSG and NWSG wells

Use 2 cold flare lines to depressurize Sections upstream slug catcher of NSG

wells, SSG wells and 12 section of NWSG wells use valves B&C Refer to

attached Dwg. No. 1

6 trunk line of NSG1-1, 1-2

Both wells feeding the line will be closed-in using lower and upper master

valves and further isolated from well side via closing manual wing valve, gas

choke and manual 6 valve. Moreover, the 6 header manual isolation valve on

the duplex flow line will be closed

Completely depressurize the line Venting the gas from CTP side using 6 vent

line to flare header (open manual valve A Dwg 1),now 6 trunk line is

depressurized till SDV-30.01

Open 2 manual valve to cold flare to depressurize the line section from

automatic S/D valve.. till the 16 inlet header

Use 2 connection for tie-in with contractor (Spesco) N 2 supply for line purge

Refer to attached Dwg. No. 1

12 trunk line of NWSG1-1

The line will be kept pressurized till the automatic S/D valve SDV 32.06, then to

be depressurized from that point till the 16 inlet header using the 2 cold flare

vent

Upon assuring the line is depressurized, start replacement activities of the

passing 2, 6 and 12 manual valves on NWSG line to inlet header Refer to

attached Dwg. No. 1

Slug catcher

Switch over power generation to be used the diesel fuel generator.

Bypass protection instrumentation on slug catcher and Lower the liquid levels

(water to degasser and condensate to condensate stabilizer and) inside the

vessel as low as possible

Drive all liquids to closed drain vessel

Completely Depressurize slug catcher to flare using 2 depressurizing valve

and open manholes for ventilation

Upon measurement of O2 and gas concentration start vessel internal cleaning

All instrumentation particularly liquid monitoring (condensate and water levels

to be dismantled and re-calibrated)

Refer to Dwg. No 2 (slug catcher )

LTS

Bypass protection instrumentation on slug catcher and Lower the liquid levels

(condensate to condensate stabilizer and MEG to pertinent storage tanks)

inside the vessel as low as possible

That condensate to condensate stabilizer and MEG to pertinent storage tanks

Drive all liquids to closed drain system through nozzles 13 and 14

Then Completely Depressurize slug catcher to flare using 2 depressurizing

valve and open manholes for ventilation

Upon measurement of O2 and gas concentration start vessel internal cleaning

Start vessel internal cleaning

All instrumentation particularly liquid monitoring (condensate and MEG levels

to be dismantled and re-calibrated) regarding both vessels

Refer to Dwg. No 2 (slug catcher and Dwg. No. 3, 4 for LTSs A &B)

Degasser

Use degasser dumping pumps to lower produced water level till the trip level of

the pumps and isolate the degasser using the manual valves then completely

drain the vessel to closed drain system and depressurize to flare.

Refer to Dwg. No.

BVS1

Upon initiating GPSD,

Based on the sealing condition of 16 up and downstream the S/D valve SDV5302 there are two scenarios for isolation and depressurizing

First

Make sure 16 valves up and downstream S/D valve SDV- 5302 are positively

sealing by testing for leak through 0.5 bleeding nipple

Dismantle 0.5 connection of pressure gauges up/downstream the S/D valve

SDV- 5302 to depressurize the 16 line section then apply proper quantity of

N2 inside for purging.

Second

If the manual valve up/downstream arent sealing

You will have to use the 4 vent valve to cold flare, in addition to the 4 vent

line to flare system (installed on temp. pig launcher ) to depressurize the 16

line section from CTP to the BVS1

(refer to Dwg..)to flare system

BVS-2 (RPF area)

List of requirements

-

NWSG TL:

2 X 2 X 600 Sp. w gasket

2 X 6 X 600 Sp. w gasket

2 X 12 X 600 Sp. w gasket

Slug Catcher:

2 X 24 RJ gasket

2 X 4 600 Sp. w gasket

4 X 2 X 600 Sp. w gasket

1 X 3 X 600 Sp. w gasket

LTS:

2 X 24 RJ gasket

3 X 2 600 Sp. w gasket Gasket

Degasser

You might also like

- SCSSVDocument8 pagesSCSSVSaqxank100% (4)

- Century Five Star AC DC Heavy Duty Welder Parts List 2Document6 pagesCentury Five Star AC DC Heavy Duty Welder Parts List 2b0beiii100% (2)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickNo ratings yet

- RTHC Svn02c enDocument16 pagesRTHC Svn02c enRicardo100% (1)

- Particle Physics Mind Map by Saad (Edexcel) PDFDocument1 pageParticle Physics Mind Map by Saad (Edexcel) PDFAhmedHassanIsmail50% (2)

- Shutdown Isolation Procedures1Document4 pagesShutdown Isolation Procedures1eng20072007No ratings yet

- Liquid Withdrawal Device: For Liquid Nitrogen 25LD, 35LD, 35LD-T and 50LD DewarsDocument4 pagesLiquid Withdrawal Device: For Liquid Nitrogen 25LD, 35LD, 35LD-T and 50LD DewarsmarcelloairesNo ratings yet

- Date: 04/10/2007: Area - TG UNIT - 3/4/5/6Document3 pagesDate: 04/10/2007: Area - TG UNIT - 3/4/5/6netygen1No ratings yet

- Pacakage Aircon MaintenanceDocument15 pagesPacakage Aircon Maintenancerjv.premi74No ratings yet

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-17Document3 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-17Tolias EgwNo ratings yet

- Vane Presiune DN40 - DN250Document28 pagesVane Presiune DN40 - DN250iza66bellNo ratings yet

- p100 - 13 Could BeDocument4 pagesp100 - 13 Could BeEudaldo SaltosNo ratings yet

- Well Maintenance ProcedureDocument14 pagesWell Maintenance ProcedureVlassis Sarantinos100% (1)

- Manual Pump Down On An Air ConditioningDocument7 pagesManual Pump Down On An Air ConditioningRay Ravel100% (1)

- General Control ValvesDocument42 pagesGeneral Control ValvesEric Vermeulen100% (1)

- Valves Station ManualDocument125 pagesValves Station Manual윤병택No ratings yet

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocument3 pagesACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002No ratings yet

- Sondex SFD6Document160 pagesSondex SFD6a.amangazinov1995No ratings yet

- Cooling Down Operation Prior ArrivalDocument3 pagesCooling Down Operation Prior Arrivalpvukovic91No ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit AgarwalNo ratings yet

- API 682 Short Guide Most Common Plans and Operational InformationDocument40 pagesAPI 682 Short Guide Most Common Plans and Operational InformationFarhan TalibNo ratings yet

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- 6 4 10 Cooling Down Cargo TanksDocument10 pages6 4 10 Cooling Down Cargo TanksSamarinerSinghNo ratings yet

- Slinger Degasser: 60 BROWN AVE. SPRINGFIELD, NJ 07081 (973) 376-7770Document27 pagesSlinger Degasser: 60 BROWN AVE. SPRINGFIELD, NJ 07081 (973) 376-7770Carlos Ivan SalazarNo ratings yet

- Boiler Hydro TestDocument35 pagesBoiler Hydro TestMoez HamoudiNo ratings yet

- Regulating ValveDocument18 pagesRegulating ValveMohammed Hassan B KorainaNo ratings yet

- Lessons Learned-FINAL-NEW PDFDocument8 pagesLessons Learned-FINAL-NEW PDFImtinan MohsinNo ratings yet

- Guideline To Design of Deluge Water Spray SystemDocument6 pagesGuideline To Design of Deluge Water Spray SystemHenry TanNo ratings yet

- SFD 13 Samlet ManualDocument95 pagesSFD 13 Samlet ManualHüseyin TekinNo ratings yet

- how to design of deluge water spray system - 副本Document7 pageshow to design of deluge water spray system - 副本Henry TanNo ratings yet

- 7 Start-Up: Tart Up General InformationDocument8 pages7 Start-Up: Tart Up General InformationRiki KurniaNo ratings yet

- 7 Start-Up: Tart Up General InformationDocument5 pages7 Start-Up: Tart Up General InformationRiki KurniaNo ratings yet

- 7 Start-Up: Tart Up General InformationDocument7 pages7 Start-Up: Tart Up General InformationRiki KurniaNo ratings yet

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- Tcpl-1X63.75 MW Power Plant, Gummidipoondi - 1Document5 pagesTcpl-1X63.75 MW Power Plant, Gummidipoondi - 1SelvaNo ratings yet

- ServicingDocument19 pagesServicingjontis jasoliyaNo ratings yet

- Skill Development On P25ABC LOSES DIS FLOW.Document5 pagesSkill Development On P25ABC LOSES DIS FLOW.00083583rfNo ratings yet

- Sporlan Adlse-2Document12 pagesSporlan Adlse-2Serrefriair Garcia RefriNo ratings yet

- 5 107 Vaporizers and DemisterDocument7 pages5 107 Vaporizers and DemisterLeonidas PetrouNo ratings yet

- DKC-DMC enDocument46 pagesDKC-DMC enmarine_dieselNo ratings yet

- Boiler Hydro TestDocument26 pagesBoiler Hydro TestKuntal Satpathi83% (6)

- Control de FlujoDocument40 pagesControl de FlujojnpaisNo ratings yet

- Steam Jet Spindle Operated ThermocompressorDocument3 pagesSteam Jet Spindle Operated ThermocompressorjfejfeNo ratings yet

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Manual Pump Down On An Air ConditioningDocument5 pagesManual Pump Down On An Air ConditioningRay RavelNo ratings yet

- The Safe Operation of Pressure Vessels and BoilersDocument11 pagesThe Safe Operation of Pressure Vessels and BoilersTrainer 01No ratings yet

- Autotrol Performa Valve With 400 Series Control Installation InstructionsDocument24 pagesAutotrol Performa Valve With 400 Series Control Installation InstructionsWattsNo ratings yet

- PID NotesDocument40 pagesPID Notesmegha ingulkarNo ratings yet

- Cold Startup 1Document51 pagesCold Startup 1Vel MuruganNo ratings yet

- Control Valve SizingDocument9 pagesControl Valve Sizingjmclaug502No ratings yet

- Functional Description of The Vacuum Pump Set-1Document8 pagesFunctional Description of The Vacuum Pump Set-1jigneshluharNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve ASiddharth GupteNo ratings yet

- Engineering Technical Bulletins: Selecting Valves and Piping CoilsDocument4 pagesEngineering Technical Bulletins: Selecting Valves and Piping Coilsforevertay2000No ratings yet

- AccessoriesDocument31 pagesAccessoriesLuke ArandidNo ratings yet

- Experiment No 7Document7 pagesExperiment No 7Faizan Ahmed67% (3)

- PV Valves Operation and Maintenance ProcedureDocument6 pagesPV Valves Operation and Maintenance ProcedureJeet SinghNo ratings yet

- 89 Sub Surface Safety Valves SSSV InstallationDocument16 pages89 Sub Surface Safety Valves SSSV InstallationManuel Coxe100% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Oklahoma Corporation Commission: Packer Setting ReportDocument2 pagesOklahoma Corporation Commission: Packer Setting Reporteng20072007No ratings yet

- Envelope Envelope-11Document1 pageEnvelope Envelope-11eng20072007No ratings yet

- Adding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017Document1 pageAdding PID Controllers in Aspen HYSYS: Dynamic Simulation Course 2017eng20072007No ratings yet

- Factory PidDocument1 pageFactory Pideng20072007No ratings yet

- City Director of Public Works Organizational Chart: Description/DateDocument2 pagesCity Director of Public Works Organizational Chart: Description/Dateeng20072007No ratings yet

- El Sayed Amer Last UpdatedDocument3 pagesEl Sayed Amer Last Updatedeng20072007No ratings yet

- BlocksDrilling Line Rev-Peview PDFDocument11 pagesBlocksDrilling Line Rev-Peview PDFLa Ode Hadi AugustmanNo ratings yet

- Block ProposalDocument11 pagesBlock Proposaleng20072007No ratings yet

- 1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3Document1 page1.3 Reliability Terminology: An Introduction To Reliability and Risk Assessment 3eng20072007No ratings yet

- Reliability and Risk Assessment: Ace 4 ApDocument1 pageReliability and Risk Assessment: Ace 4 Apeng20072007No ratings yet

- Warna Three: What Is Marketing?Document11 pagesWarna Three: What Is Marketing?eng20072007No ratings yet

- SuperbizDocument11 pagesSuperbizeng20072007No ratings yet

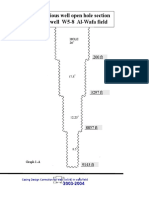

- Previous Well Open Hole Section For Well W5-8 Al-Wafa FieldDocument4 pagesPrevious Well Open Hole Section For Well W5-8 Al-Wafa Fieldeng20072007No ratings yet

- 1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers SpecificationDocument18 pages1007 DISQ 0 M SS 42005 Air Cooled Heat Exchangers Specificationeng20072007No ratings yet

- Gad SeparatorDocument3 pagesGad Separatoreng20072007No ratings yet

- 5-1 13 3/8" Surface Casing DesignDocument10 pages5-1 13 3/8" Surface Casing Designeng20072007No ratings yet

- احدث CVDocument4 pagesاحدث CVeng20072007No ratings yet

- 5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)Document6 pages5.2.3 Tension Loading:: Casing Depth, (FT) Tension, (LB) Over Pull 100000, (LB) Apply-DF 1.6 (LB)eng20072007No ratings yet

- 1007 DISQ 0 J SS 33030 Control Valve SpecificationDocument18 pages1007 DISQ 0 J SS 33030 Control Valve Specificationeng20072007No ratings yet

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pages1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- 1007 Disq 0 M Ss 42008 Rev 2 Gas Diesel Engine SpecificationDocument26 pages1007 Disq 0 M Ss 42008 Rev 2 Gas Diesel Engine Specificationeng20072007No ratings yet

- 1007 DISQ 0 J SS 33033 Shutdown Valve SpecificationDocument15 pages1007 DISQ 0 J SS 33033 Shutdown Valve Specificationeng20072007100% (1)

- Out Standing ItemsDocument1 pageOut Standing Itemseng20072007No ratings yet

- Cairo HSEQ P 13 PDFDocument7 pagesCairo HSEQ P 13 PDFeng20072007No ratings yet

- Cairo-HSEQ-P-22 Suco Safety Observation Reporting March, 2011 Authorized By: SUCO Operations Gen. Mgr. Page 1 of 5Document5 pagesCairo-HSEQ-P-22 Suco Safety Observation Reporting March, 2011 Authorized By: SUCO Operations Gen. Mgr. Page 1 of 5eng20072007No ratings yet

- Luk Dual Mass FlywheelDocument48 pagesLuk Dual Mass FlywheeljurjitoNo ratings yet

- Cu Math H CC10 2021Document5 pagesCu Math H CC10 2021avirup deNo ratings yet

- Boiler Heating SurfacesDocument12 pagesBoiler Heating SurfacesHai NguyenNo ratings yet

- 001.kyoto ProtocolDocument6 pages001.kyoto Protocolmuna saputraNo ratings yet

- DJ12 40Document2 pagesDJ12 40ParvezNo ratings yet

- Plogarithm Edited Report 1 NowDocument44 pagesPlogarithm Edited Report 1 NowSrinivasa bnNo ratings yet

- SIP WhitePaperDocument18 pagesSIP WhitePaperHouser_BRNo ratings yet

- Petronas Technical Standards: Pts Publications and Standard SpecificationsDocument38 pagesPetronas Technical Standards: Pts Publications and Standard SpecificationsadamNo ratings yet

- Books For GATE Mechanical EngineeringDocument9 pagesBooks For GATE Mechanical EngineeringNikhilChauhanNo ratings yet

- Sweet Cheeks Sales PreviewDocument2 pagesSweet Cheeks Sales PreviewIrina Botea BucanNo ratings yet

- Fundamental of Building PhysicsDocument43 pagesFundamental of Building PhysicsfuadNo ratings yet

- TMO 720-4 Oil Burner Control BoxDocument6 pagesTMO 720-4 Oil Burner Control BoxYanuar AndriyantoNo ratings yet

- O-Rings: By: Muhammad Shoaib FareedDocument68 pagesO-Rings: By: Muhammad Shoaib Fareedsaadpervaiz14No ratings yet

- Pages From Iom LPG Comp - Ie101hDocument8 pagesPages From Iom LPG Comp - Ie101hRamius HamdaniNo ratings yet

- IEEE STD 1584A 2004 Guide For Performing Arc Flash Hazard Calculations Amendment 1 PDFDocument9 pagesIEEE STD 1584A 2004 Guide For Performing Arc Flash Hazard Calculations Amendment 1 PDFjose manuel valle fabianNo ratings yet

- Next Generation Oleo & SurfactantDocument18 pagesNext Generation Oleo & SurfactantHugh MantaNo ratings yet

- Physics ProjectDocument46 pagesPhysics ProjectAdrije GuhaNo ratings yet

- Recycled Asphalt Pavement Presentation SlideDocument25 pagesRecycled Asphalt Pavement Presentation SlideArisan Iqma75% (8)

- OECD Common Approach On Environment and Supported Export CreditsDocument8 pagesOECD Common Approach On Environment and Supported Export CreditsGuillermo BarragánNo ratings yet

- Science Speed of Sound WorksheetsDocument1 pageScience Speed of Sound Worksheetsbart PorcadillaNo ratings yet

- A2 5 Lifecycle Flow TemplatemanufactureDocument1 pageA2 5 Lifecycle Flow Templatemanufactureapi-247436935No ratings yet

- Manual On Industrial Hazardous Waste Management For Authorities in Low and Middle Income EconomiesDocument432 pagesManual On Industrial Hazardous Waste Management For Authorities in Low and Middle Income Economiesashraf refaatNo ratings yet

- Job Description Remarks: Single Phase Preventer and Y/ Timer) Decoloursation, BurnsDocument2 pagesJob Description Remarks: Single Phase Preventer and Y/ Timer) Decoloursation, Burnssanjeev267No ratings yet

- Important TRD ParametersDocument4 pagesImportant TRD ParametersLakshmiVishwanathan100% (1)

- Energy Chemistry NotesDocument11 pagesEnergy Chemistry NotesClayton Feng100% (1)

- Fundamentals of PhotolithographyDocument8 pagesFundamentals of PhotolithographyRafaelNo ratings yet

- SPX Curve BookDocument38 pagesSPX Curve BookCarlos Alberto Ramirez GarciaNo ratings yet

- 2.lab Techniques (Repaired) PDFDocument52 pages2.lab Techniques (Repaired) PDFSomu Yashawant ChaudhariNo ratings yet