Professional Documents

Culture Documents

PP10CC 00 6PGB Yr Abc 001 PDF

PP10CC 00 6PGB Yr Abc 001 PDF

Uploaded by

anbesivam87Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP10CC 00 6PGB Yr Abc 001 PDF

PP10CC 00 6PGB Yr Abc 001 PDF

Uploaded by

anbesivam87Copyright:

Available Formats

1

ISSUED FOR INFORMATION

JAP

JSI

CGP

07.02.13

ISSUED FOR INFORMATION

JAP

JSI

CGP

27.09.12

REV

DESCRIPTION

PREP

CHKD

APPD

DATE

PROJECT:

PP10 CCGT POWER STATION

CONTRACT NO: 31121111/00

CLIENT

CONSULTANT:

CONTRACTOR:

DOCUMENT TITLE:

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

COMPANY/ORIGINATOR:

PROJECT DOCUMENT NUMBER:

ARABIAN BEMCO

CONTRACTING COMPANY

DISTRIBUTION CODE:

PP10CC-00-6PGB-YR-ABC-001

SHEET NO.

I&C

1 OF 19

SIZE

REV.

SCALE:

A4

N.T.S

FILE NAME:

PP10CC-00-6PGB-YR-ABC-001-REV 1 CLOSED COOLING WATER FUNCTIONAL

DESCRIPTION

PP10CC-T13T-2563

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 2

/ 19

Rev.: 1

INDEX OF CONTENTS

1. INTRODUCTION............................................................................................................... 3

1.1.OBJECTIVE OF THE DOCUMENT .................................................................................. 3

1.2.SCOPE OF THE DOCUMENT.......................................................................................... 3

1.3.REFERENCE DOCUMENTATION ................................................................................... 3

2. SYSTEM DESCRIPTION .................................................................................................. 5

2.1.MAIN EQUIPMENT, PERMISSIVES AND INTERLOCKS ................................................ 5

2.2.MECHANICAL BATTERY LIMITS .................................................................................... 6

2.3.FUNCTIONALITY.............................................................................................................. 7

2.4.CONTROL INTERFACES WITH OTHER SYSTEMS ....................................................... 7

2.5.SIGNALS MONITORING .................................................................................................. 7

2.5.1. Measuring instrument....................................................................................... 7

2.5.2. Selection logic architecture ............................................................................. 8

2.5.3. Bad quality concept .......................................................................................... 9

2.6.PROCESS DRIVES/ACTUATORS ................................................................................... 9

2.6.1. Process drives/actuators ................................................................................. 9

2.6.2. Drives/Actuators Fault Tolerance .................................................................. 10

2.7.FUNCTIONAL GROUPS................................................................................................. 11

2.7.1. Number of Functional Groups ....................................................................... 11

2.7.2. Functional Groups Operation Modes ............................................................ 11

2.8.SYSTEM CONTROL LOCATION ................................................................................... 12

3. SYSTEM OPERATION MODES ..................................................................................... 13

3.1.POSITION IN THE PLANT GENERAL START-UP SEQUENCE ................................... 13

3.2.CRITERION FOR SYSTEM START-UP ......................................................................... 13

3.3.START-UP SEQUENCE ................................................................................................. 13

3.4.NORMAL OPERATION................................................................................................... 14

3.5.POSITION IN THE PLANT GENERAL SHUTDOWN SEQUENCE ................................ 14

3.6.CRITERION FOR SHUTDOWN...................................................................................... 15

3.7.SHUTDOWN SEQUENCE .............................................................................................. 15

3.8.EMERGENCY SHUTDOWN SEQUENCE ...................................................................... 15

4. LOGIC LOOPS/CONTROL DESCRIPTION ................................................................... 16

4.1.LOGIC LOOPS................................................................................................................ 16

4.2.CONTROL DESCRIPTION ............................................................................................. 18

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

Page 3

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

/ 19

Rev.: 1

1.

INTRODUCTION

1.1. OBJECTIVE OF THE DOCUMENT

The objective of the document is to provide the functional description of the CLOSED

COOLING WATER SYSTEM of the project.

For design information on the system, as well as details and functions of each item, refer to

PP10CC-0009-3PGB-MR-ABC-001 CLOSED COOLING WATER SYSTEM DESCRIPTION

1.2. SCOPE OF THE DOCUMENT

The scope of the document is to describe the followings topics:

System description

System operation

Control loops

1.3. REFERENCE DOCUMENTATION

PP10CC-0009-3PGB-MDD-ABC-001 P&ID CLOSED COOLING WATER SYSTEM

PP10CC-0009-3PGB-MR-ABC-001

CLOSED

COOLING

WATER

SYSTEM

DESCRIPTION

PP10CC-00-6PGB-YDY-ABC-001 CLOSED COOLING WATER SYSTEM LOGIC

DIAGRAMS

PP10CC-00-6Y-YR-ABC-001 CCPP OPERATION PHILOSOPHY

PP10CC-0009-6Y-YDZ-ABC-001 CONTROL TYPICAL DEVICES

PP10CC-0009-6Y-YLI-ABC-002 DEVICE DEFINITION CONCEPT

PP10CC-0009-6Y-YDY-ABC-001 MASTER LOGIC DIAGRAMS

PP10CC-0009-6Y-YDY-ABC-004

PERMANENT

STANDBY

PREPARATION

SEQUENCE

1

PP10CC-0009-6Y-YDY-ABC-002 CC SIMULTANEOUS START UP SEQUENCE

PP10CC-0009-6Y-YDY-ABC-005 CC SEQUENTIAL START UP SEQUENCE

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 4

/ 19

Rev.: 1

PP10CC-0009-6Y-YDY-ABC-003 NORMAL SHUT DOWN SEQUENCE

1

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 5

/ 19

Rev.: 1

2.

SYSTEM DESCRIPTION

2.1. MAIN EQUIPMENT, PERMISSIVES AND INTERLOCKS

The main equipments which belong to this system are 2 x 100% centrifugal pumps, one

1

atmospheric expansion tank and six fin fan coolers. The TAGs of these equipments are the

followings:

Centrifugal pumps: A119-PGB11-AP001 and A119-PGB12-AP001.

Fin fan coolers: A119-PGB10-AK001

Atmospheric expansion tank: A119-PGB50-BB001

CCW header pressure control valve: A119-PGB40-AA101

CCW filling line on-off motorized valve: A119-GHC15-AA051

For further information see system description PP10CC-0009-3PGB-MDD-ABC-001 P&ID

CLOSED COOLING WATER SYSTEM

The CCW system has the following permissive (start condition) and interlocks:

Instrument

A119-GHC15CF001

Service

Setting

Level

Consequences/Actions

Demin water flow

L > 60%

HHH

L > 55%

HH

Alarm

Override close A119-GHC15-AA051

A119-PGB50-

Atmospheric expansion

L > 50%

Close valve A119-GHC15-AA051

CL001

tank level

L < 20%

Open valve A119-GHC15-AA051

L < 15%

LL

Alarm

L < 8%

LLL

Trip pumps A119-PGB11/12-AP001

L > 60%

HHH

L > 55%

HH

Alarm

Override close A119-GHC15-AA051

A119-PGB50-

Atmospheric expansion

L > 50%

Close valve A119-GHC15-AA051

CL002

tank level

L < 20%

Open valve A119-GHC15-AA051

L < 15%

LL

Alarm

L < 8%

LLL

Trip pumps A119-PGB11/12-AP001

A119-PGB11-

CCW pump 1 Suction

P < 0,8 bara

LL

Alarm

CP001

Pressure

P < 0,4 bara

LLL

Trip A119-PGB11-AP001

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 6

/ 19

Rev.: 1

Instrument

Service

Setting

Level

Consequences/Actions

A119-PGB12-

CCW pump 2 Suction

P < 0,8 bara

LL

Alarm

CP001

Pressure

P < 0,4 bara

LLL

Trip A119-PGB12-AP001

CCW pumps

P > 7,5 barg

HH

Alarm

A119-PGB13-

Discharge Pressure

P > 6,8 barg

SP

Control SP A119-PGB40-AA101

CP001

P > 4,8 barg

LL

P > 7,5 barg

HH

Alarm

P > 6,8 barg

SP

Control SP A119-PGB40-AA101

P > 4,8 barg

LL

A > 50 ppm

HH

Alarm

T > 55C

HH

Alarm

A119-PGB13-

CCW pumps

CP002

Discharge Pressure

A119-PGB35-

CCW hot header oil

CQ001

detector

A119-PGB35-

CW hot header

CT001

temperature

A119-PGB35-

CW hot header

CP001

pressure

Alarm (pump change over

requirement)

Alarm (pump change over

requirement)

A119-PGB10-

CCW fin fan cooler outlet

T > 53C

Start additional fan

CT001

temperature

T < 47C

Stop one fan

T < 45C

LL

Alarm

T > 55C

HH

Alarm

A119-PGB10-

CCW fin fan cooler outlet

T > 53C

Start additional fan

CT002

temperature

T < 47C

Stop one fan

T < 45C

LL

Alarm

Note: (1) = All pressure trips will have a time delay

2.2. MECHANICAL BATTERY LIMITS

Terminal

Service

System From / To

Demin water supply

From demin water system

Corrosion inhibitor

pH correction

Ref. Document.

Point

PP10CC-0009-8GHC-MDDABC-001

From Chemical dosing

PP10CC-0009-3QC-MDD-

System

ABC-001

From Chemical dosing

PP10CC-0009-3QC-MDD-

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

Page 7

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

/ 19

Rev.: 1

Terminal

Service

System From / To

Ref. Document.

System

ABC-001

To Steam Turbine Lube Oil

PP10CC-0009-3MAV-MDD-

System

ABC-001

To ST HYDRAULIC FLUID

PP10CC-0009-3MAX-MDD-

SYSTEM

ABC-001

Point

-

Cooling water

Cooling water

Cooling water

To ST GENERATOR

321310700

COOLERS

Cooling water

To Sampling System

Cooling water

To Feed water System

Cooling water

To HRSG Recirculation

pumps

PP10CC-0009-1QU-MDDABC-001

PP10CC-00-4LAC-DD-TMP001

PP10CC-00-H-MDD-NEM-006

2.3. FUNCTIONALITY

The Closed Cooling Water system functionality is described in the system description. See:

PP10CC-0009-3PGB-MR-ABC-001

CLOSED

COOLING

WATER

DESCRIPTION

2.4. CONTROL INTERFACES WITH OTHER SYSTEMS

There arent control interfaces with other systems.

2.5. SIGNALS MONITORING

2.5.1.

Measuring instrument

The measuring instruments which belong to this system are the followings:

SYSTEM

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

Page 8

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

/ 19

Rev.: 1

Equipment/Line

A119-GHC15-BR001-253C1-NI

A119-PGB50-BB001

Service

Demin water flow

Atmospheric expansion

tank level

Instrument

FIT

A119-GHC15-CF001

LIT

A119-PGB50-CL001

A119-PGB50-CL002

A119-PGB11-BR001-300-

CCW pump 1 Suction

PIT

1A1-NI

Pressure

A119-PGB11-CP001

A119-PGB12-BR001-300-

CCW pump 2 Suction

PIT

1A1-NI

Pressure

A119-PGB12-CP001

A119-PGB13-BR001-300-

CCW pumps

1A1-NI

Discharge Pressure

A119-PGB35-BR003-3001A1-PP

CCW oil in water

PIT

A119-PGB13-CP001

A119-PGB13-CP002

AIT

A119-PGB35-CQ001

A119-PGB35-BR003-300-

CCW fin fan cooler inlet

TIT

1A1-PP

temperature

A119-PGB35-CT001

PP10CC-A119-PGB35-

CCW fin fan cooler inlet

PIT

BR003-300-1A1-PP

pressure

A119-PGB35-CP001

PP10CC-A119-PGB10-

CCW fin fan cooler

BR001-300-1A1-NI

outlet temperature

2.5.2.

TIT

A119-PGB10-CT001

A119-PGB10-CT002

Selection

Logic

Notes

DUAL

SELECT

DUAL

SELECT

DUAL

SELECT

Selection logic architecture

As a general rule, if a signal is out of configured range, an alarm shall be generated in the

control system.

When two or more measurements are available for the same process value, the value used

for interlocking will depend on the selected logic architecture.

In a DUAL SELECT logic architecture, two measures are available, if both are healthy the

average of the two measurements is used. In case of bad quality of one of the

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

Page 9

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

/ 19

Rev.: 1

measurements, automatic change-over to the healthy measurement takes place and an

alarm is generated.

In a MEDIAN SELECT logic architecture, three measures are available if all of them are

healthy the average of the three measurements is used. In case of bad quality of one of the

measurements, automatic change-over to the other healthy measurements takes place and

an alarm is generated.

The selected logic architecture of each instrument has been identified in the previous table

(see section 2.5.1).

2.5.3.

Bad quality concept

In case of bad quality of one of the redundant measurements, automatic change-over to

the healthy measurement will take place and an alarm will be generated. Bad quality

means that the signal is out of range < 4 or > 20 mA.

2.6. PROCESS DRIVES/ACTUATORS

2.6.1.

Process drives/actuators

The process drives/actuators which belong to this system are the followings:

Line/Equipment

Service

Drive/Actuator

Fail Safe

Notes

Position

A119-GHC15-BR001-253C1-NI

A119-PGB10-AK001

A119-PGB10-AK001

A119-PGB10-AK001

Demin water supply

CCW fin fan cooler

fan 1

CCW fin fan cooler

fan 2

CCW fin fan cooler

fan 3

A119-GHC15-AA051

FS

A119-PGB10-AN001

2, 3

A119-PGB10-AN002

2, 3

A119-PGB10-AN003

2, 3

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

Page 10

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

/ 19

Rev.: 1

Line/Equipment

Service

Drive/Actuator

Fail Safe

Notes

Position

A119-PGB10-AK001

A119-PGB10-AK001

A119-PGB10-AK001

A119-PGB40-BR001-2001A1-NI

CCW fin fan cooler

fan 4

CCW fin fan cooler

fan 5

CCW fin fan cooler

fan 6

A119-PGB10-AN004

2, 3

A119-PGB10-AN005

2, 3

A119-PGB10-AN006

2, 3

A119-PGB40-AA101

FC

CCW recirculation

line for pressure

control

Notes:

1.- Valve electrically actuated. Not fail safe position. Fail Steady (in position).

2.- Electrically actuated. Not fail safe position.

3.- The Fin Fan cooler skid A119-PGB10-AK001 will have six individual fans.

2.6.2.

Drives/Actuators Fault Tolerance

When redundant drives/actuators are available, at least one of the followings strategies

shall be configured:

Automatic pump selection

If there is a fault in one of the selected pumps which are in operation, the control system

will start automatically another pump in order to keep the required demand of pumps.

Maximum waiting time

When it is required to start a drive/actuator or to change its position, the control system

shall monitor the maximum admitted time to finish its maneuver. If this time is exceeded,

the control system will generate an alarm.

- CCW pumps expected starting time is 20 seconds

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 11

/ 19

Rev.: 1

- Motorized Valve open/close expected time is 30 seconds

- Fin fan coolers expected starting time is 20 seconds

Fail safe position

It will be considered the Fail Safe Position the one that the device will go to in case of

control signal, air supply or power supply failure.

The fail safe position of each actuator has been identified in the previous table (see 2.6.1).

2.7. FUNCTIONAL GROUPS

2.7.1.

Number of Functional Groups

There will be the following functional groups:

Closed Cooling Water System: CCWS / 9PGB10GF001

2.7.2.

Functional Groups Operation Modes

As a general rule, the system will operate in automatic mode, following not only required

sequences and settings, also taking into account required protections over the operation in

the control system. All functional groups could operate in one of the following modes:

Automatic mode

In auto mode the functional group will follow the control strategies configured in the control

system.

Manual mode

In manual mode the functional group will check required sequences, settings and

protections for system operation depending on control strategy, but in this case some

process actuators could be selected to be operated according to operators decision.

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 12

Rev.: 1

2.8. SYSTEM CONTROL LOCATION

The DCS controller location for this system is the STG Control Compartment.

/ 19

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 13

/ 19

Rev.: 1

3.

SYSTEM OPERATION MODES

The system operation modes are the followings:

Cold start-up: cover the initial filling and the initial preparation (system ready to start).

Hot start-up: cover all required sequences up to the moment the system is in operation.

Normal operation.

Shutdown: cover all required sequences up to the moment the system has been

stopped.

Emergency shutdown.

3.1. POSITION IN THE PLANT GENERAL START-UP SEQUENCE

This system belongs to preparation systems and it will be set in operation following the

steps described in this sequence:

1

PP10CC-0009-6Y-YDY-ABC-004

PERMANENT

STANDBY

PREPARATION

SEQUENCE

3.2. CRITERION FOR SYSTEM START-UP

From the plant general start-up sequence it will be required to start-up this system under

the following requirements:

Not Low Low Level in Atmospheric Expansion Tank (A119-PGB50-BB001 > LLL)

3.3. START-UP SEQUENCE

The start-up sequence of the system will follow the following steps:

Step 01: CCW pumps (A119-PGB11-AP001 & A119-PGB12-AP001), Demin water

supply MOV (A119-GHC15-AA051), CCW header pressure control valve (A119-PGB40AA101) and Fin Fan Coolers (A119-PGB10-AK001) to AUTO MODE.

Step 02: START selected CCW pump (A119-PGB11-AP001 or A119-PGB12-AP001).

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 14

/ 19

Rev.: 1

3.4. NORMAL OPERATION

This system operates as a closed circuit and in a normal operation one CCW pump will be

running to supply required cool water flow at the required pressure. There is a recirculation

line with a pressure control valve to maintain constant CCW pressure (6,8 barg) to coolers

when one of them has its cooling water shut off.

At the same time, the fin fan cooler installed upstream the pumps will release the heat of

the hot closed cooling water to the atmosphere, starting the required number of fans. So

the cold outlet water will be ready to be pumped again to the equipments in order to

evacuate the produced heat during normal operation.

On the other hand, demin water supply on-off valve (A119-GHC15-AA051) will make up for

the leakages produced in the closed cooling water system. During normal operation is not

expected to have leakages in the system so the filling of the system will be sporadic.

Interlock

For process interlocks see section 2.1.

Alarms

For process alarms see section 2.1.

3.5. POSITION IN THE PLANT GENERAL SHUTDOWN SEQUENCE

This system belongs to operation systems and it will be set out of operation following the

1

steps described in the normal shut down sequence PP10CC-0009-6Y-YDY-ABC-003

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 15

/ 19

Rev.: 1

3.6. CRITERION FOR SHUTDOWN

From the plant general shutdown sequence it will be required to stop this system under the

following requirements:

- The Combined Cycle has been shut-down.

3.7. SHUTDOWN SEQUENCE

The shutdown sequence of the system will follow the following steps:

Step 01: STOP selected CCW pump (A119-PGB11-AP001 & A119-PGB12-AP001).

Step 02: STOP Fin Fan Coolers (A119-PGB10-AK001).

1

3.8. EMERGENCY SHUTDOWN SEQUENCE

There is not emergency shutdown of CCW system.

In case of an emergency shutdown (blackout), CCW pumps and fin fan coolers have to be

feed from the essential system in order to continue in operation and to continue cooling

required systems.

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 16

/ 19

Rev.: 1

4.

LOGIC LOOPS/CONTROL DESCRIPTION

4.1. LOGIC LOOPS

In this system there are the following logic loops:

Loop

Atmospheric Expansion Tank

Level Control

Instrument TAG:

PV

Level

A119-PGB50-CL001

A119-PGB50-CL002

SP

Permissives

Open if L < 20%

Close if L > 50%

-

Instrument TAG:

Override

Force to Close if HHH

A119-PGB50-CL001

A119-PGB50-CL002

Actuator

Loop

Motorized valve

Fin Fan Cooler (A119-PGB10-AK001)

Temperature Control

A119-GHC15-AA051

Instrument TAG:

PV

Temperature

A119-PGB10-CT001

A119-PGB10-CT002

SP

Start one fan if T > 53C

(if after 2 min T > 53C, other fan will be started)

Stop if T < 47C

(if after 2 min T < 47C, other fan will be stopped)

Permissives

Interlock

A119-PGB10-AN001

Actuator

Fin Fan Cooler

A119-PGB10-AN002

A119-PGB10-AN003

A119-PGB10-AN004

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 17

/ 19

Rev.: 1

Loop

Fin Fan Cooler (A119-PGB10-AK001)

Temperature Control

A119-PGB10-AN005

A119-PGB10-AN006

Loop

Closed Cooling Water pumps

CCW water supply

PV

SP

Selected pump always running.

Permissives

For both pumps

Atmospheric expansion tank level Low Low (LLL)

Interlock

For A119-PGB12-AP001

Suction pressure Low Low (LLL)

Loop

A119-PGB50-CL001

A119-PGB50-CL002

For A119-PGB11-AP001

Suction pressure Low Low (LLL)

Actuator

Instrument TAG:

Electric Pumps

CCW header

Pressure Control

A119-PGB11-CP001

A119-PGB12-CP001

A119-PGB11-AP001

A119-PGB12-AP001

Instrument TAG:

PV

Pressure

A119-PGB13-CP001

A119-PGB13-CP002

SP

SP = 6,8 barg

Override

Force to Close if valve position demand 6%

Actuator

Pneumatic control valve

Permissives

A119-PGB40-AA101

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 18

/ 19

Rev.: 1

4.2. CONTROL DESCRIPTION

Once the Demin Water System is in operation, the Master Sequence Following Controller

(M.S.F.C) will send an automatic command to Closed Cooling Water System Functional

Group (CCWS GROUP) to set in AUTO MODE this system. The CCWS GROUP will

send an automatic command to each CCW Pump, motorized valve, control valve and fin

fan cooler. After being in AUTO MODE, the M.S.F.C will start the system sending a start

command to the Functional Group (CCWS GROUP) which will start the auto change over

block. The auto change over bloc will start selected CCW Pump.

In operation one pump will be running and if a fault happens the system will automatically

change over the standby pump. CCW header pressure control valve will maintain constant

CCW header pressure (6,8 barg) to coolers.

To control the closed cooling water system temperature the system will start/stop the

required number of fans. When the temperature increases above 53C the system will start

1

an additional fan. If after 2 minutes the temperature is still higher than 53C an additional

fan will be started, and soon after the temperature is lower than 53C.

On the contrary when the temperature decreases below 47C the system will stop one fan.

If after 2 minutes the temperature is still lower than 47C an additional fan will be stopped,

and soon after the temperature is higher than 47C.

In order to equilibrate fans working hours, the DCS will start the fan with less working hours

when is required to start a fan according to process conditions. On the contrary, The DCS

will stop the fan with more working hours when is required to stop a fan according to

process conditions.

The Atmospheric Expansion Tank level will be controlled through a MOV which will open

when the level decreases below 20% and will close when the level increases above 50%.

PP10CC Combined Cycle

Document Code

Date

PP10CC-00-6PGB-YR-ABC-001

07/02/13

CLOSED COOLING WATER SYSTEM FUNCTIONAL DESCRIPTION

Page 19

/ 19

Rev.: 1

On the contrary, during the shutdown sequence, the M.S.F.C will stop the system sending

a stop command to the Functional Group (CCWS GROUP) which will stop the fin fan

1

cooler and the auto change over block which will stop selected CCW Pump.

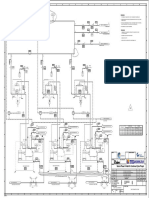

See attached sketch for better understanding of above explanation.

HHH

MV-01

FT

AUTO / MANUAL

HI_LO_MON

GROUP

CCWS

9PGB10GF001

AUTO / MANUAL

START / STOP

M.S.F.C

AUTO / MANUAL

START / STOP

DEMIN WATER

DISTRIBUTION

AUTO

CHANGE OVER

LT

ATMOSPHERIC

EXPANSION TANK

LLL

DUALSEL

HI_LO_MON

START / STOP

LT

HI_LO_MON

HI_LO_MON

LL

LLL

LVMP-09

HI_LO_MON

PT

START / STOP

DUALSEL

DUALSEL

FILTER

TT

PT

TT

PT

COLD HEADER

HI_LO_MON

LLL

LVMP-09

PT

LVMF-03

LVMF-03

LVMF-03

LVMF-03

LVMF-03

FILTER

CV-01

LVMF-03

OIL

FIN FAN COOLER

PT

TT

AT

HOT HEADER

CLOSED COOLING WATER SYSTEM

You might also like

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionDocument8 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionHai Nguyen100% (1)

- LS-TSZD - QJ005 Turbine Bypass System Commissioning ProcedureDocument24 pagesLS-TSZD - QJ005 Turbine Bypass System Commissioning ProcedureBharath Nadimpalli100% (1)

- Shilpashatra in Ancient India-Digital LibraryDocument41 pagesShilpashatra in Ancient India-Digital LibraryAshok Nene43% (7)

- BIR Form 1906Document1 pageBIR Form 1906rafael soriaoNo ratings yet

- PP10CC 0009 6mal Yr Abc 001Document30 pagesPP10CC 0009 6mal Yr Abc 001anbesivam87No ratings yet

- PP10CC 00 6lca Yr Abc 001 PDFDocument20 pagesPP10CC 00 6lca Yr Abc 001 PDFanbesivam87100% (1)

- BOP - DCS IO List Rev 2.4 (27.01.2014)Document566 pagesBOP - DCS IO List Rev 2.4 (27.01.2014)vinospaceshuttleNo ratings yet

- Ea 682808 001 R05Document7 pagesEa 682808 001 R05anbarasusivaprakasam100% (1)

- Uong Bi 300 MW Extension Power Plant: OwnerDocument32 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- Operation Philosophy of 209HA CCPP BhikkiDocument34 pagesOperation Philosophy of 209HA CCPP BhikkiMunibNo ratings yet

- Reference LAC50 DMDocument41 pagesReference LAC50 DMVivek Singh100% (1)

- Va1 Ac 00qea M m4b SPC 0001.titleDocument1 pageVa1 Ac 00qea M m4b SPC 0001.titleDương Thế Tính100% (1)

- Instrument List For Condensate Polishing Plant PDFDocument8 pagesInstrument List For Condensate Polishing Plant PDFKasthuri CoimbatoreNo ratings yet

- T07073-LBH-SY-M001 Rev.A PDFDocument43 pagesT07073-LBH-SY-M001 Rev.A PDFRanjanaWajeNo ratings yet

- NS1-18CQA-I-YEA-0229 - R1 HP Bypass Control Logic Diagram PDFDocument13 pagesNS1-18CQA-I-YEA-0229 - R1 HP Bypass Control Logic Diagram PDFHung NgoNo ratings yet

- Io ListDocument4 pagesIo ListsswahyudiNo ratings yet

- Gresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectDocument56 pagesGresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectwahyuNo ratings yet

- f08643s-k0101 I&c Description and Drawing CatalogDocument8 pagesf08643s-k0101 I&c Description and Drawing CatalogSalmanEjazNo ratings yet

- SH 51MW Bop 033 I 001 Rev.2Document15 pagesSH 51MW Bop 033 I 001 Rev.2Mathivanan AnbazhaganNo ratings yet

- Turbine Control GraphicDocument54 pagesTurbine Control Graphicminhhoang091100% (1)

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Document8 pagesLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255No ratings yet

- Datasheet For LV SwitchgearDocument22 pagesDatasheet For LV SwitchgearAtty AttyNo ratings yet

- Pid of A Piping SystemDocument4 pagesPid of A Piping SystemBandaluppi VenkateshNo ratings yet

- MRT-DN02-P2LBA-830001 (Commissioning Procedure) HP&IP&LP Steam System Rev.1Document57 pagesMRT-DN02-P2LBA-830001 (Commissioning Procedure) HP&IP&LP Steam System Rev.1Alvin PanjaitanNo ratings yet

- JO003-10-LA - MDD-IDM-001-4 Feedwater System P&IDDocument3 pagesJO003-10-LA - MDD-IDM-001-4 Feedwater System P&IDHasan MustafaNo ratings yet

- Saudi Arabia Qurayyah: Functional Description and Logic Diagram For Block Load ControlDocument20 pagesSaudi Arabia Qurayyah: Functional Description and Logic Diagram For Block Load Controlanbesivam87100% (1)

- RDJ-GG-008-040 (En)Document41 pagesRDJ-GG-008-040 (En)fouad kerkarNo ratings yet

- Piping and Instrument Diagram For TermonorteDocument41 pagesPiping and Instrument Diagram For TermonorteLeonardo CoronadoNo ratings yet

- Fuel Oil System Tanks Data Sheet: I.P.D.C Shirvan Gas Turbine Power Plant (Bop2 Portion)Document7 pagesFuel Oil System Tanks Data Sheet: I.P.D.C Shirvan Gas Turbine Power Plant (Bop2 Portion)epbamdadNo ratings yet

- Yazd-System Description For Start Up & Blow Down SystemDocument6 pagesYazd-System Description For Start Up & Blow Down Systemandri.motoGNo ratings yet

- Process Control and Instrumentation For BoilerDocument76 pagesProcess Control and Instrumentation For BoilertuyencntnNo ratings yet

- CCPPDocument34 pagesCCPPphanindra100% (2)

- Electrical Data SheetDocument5 pagesElectrical Data Sheetrajpre1213100% (1)

- Lara Super Thermal Power Project (2X800 MW) Comment Reply SheetDocument25 pagesLara Super Thermal Power Project (2X800 MW) Comment Reply SheetA N MadhavanNo ratings yet

- 421FN 6se38028+l08Document64 pages421FN 6se38028+l082003vinay0% (1)

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeDocument1 pageFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarNo ratings yet

- E-I-04-Instrument List PDFDocument4 pagesE-I-04-Instrument List PDFManu BadilloNo ratings yet

- What Is Instrument I - O ListDocument1 pageWhat Is Instrument I - O ListzhangyiliNo ratings yet

- Coal Boiler OptimizationDocument45 pagesCoal Boiler OptimizationSuriyan ArifNo ratings yet

- 12 - Loop Wiring DiagramsDocument161 pages12 - Loop Wiring Diagramsabid aliNo ratings yet

- MC-ST-I-31-F00100 - 2 (Inst Flow Diagram - Loop Diagram)Document59 pagesMC-ST-I-31-F00100 - 2 (Inst Flow Diagram - Loop Diagram)Zillur RahmanNo ratings yet

- 003-Auxiliary Power Consumption PGT ProcedureDocument9 pages003-Auxiliary Power Consumption PGT ProcedureK R Kumar Ranjan100% (1)

- Commissioning Procedure For Soot BlowerDocument44 pagesCommissioning Procedure For Soot BlowerLan RungNo ratings yet

- MuaraKarang CCPP - Drawing List 310518Document165 pagesMuaraKarang CCPP - Drawing List 310518putra2503No ratings yet

- SNO-I-DS-005 - C Instrument Data Sheet For Radar Level TransmitterDocument95 pagesSNO-I-DS-005 - C Instrument Data Sheet For Radar Level Transmitterono_czeNo ratings yet

- 12 MGDP I 1150 0 (Instr Utility Air Calculation)Document2 pages12 MGDP I 1150 0 (Instr Utility Air Calculation)cytech6619No ratings yet

- 11V02 Acc SPC M 0001 V2 Part ADocument182 pages11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- c13153-54 - Instrument Index - Rev 3Document1 pagec13153-54 - Instrument Index - Rev 3trung2iNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument53 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- 3103 - Level TransmitterDocument10 pages3103 - Level Transmittersudhiryadav99No ratings yet

- Fichtner I & CDocument23 pagesFichtner I & CMathivanan Anbazhagan100% (1)

- NGP-000-INS-15.02-0001-00-00-Instrument IndexDocument267 pagesNGP-000-INS-15.02-0001-00-00-Instrument Indexwqs_19No ratings yet

- Cover Sheet: Signature Not VerifiedDocument14 pagesCover Sheet: Signature Not VerifiedvdrizzilsNo ratings yet

- Vol Ii CDocument161 pagesVol Ii Ckumarcv89No ratings yet

- SH1-DHI-P1MAN-M-M01-PHL-5355 - Operating Description For Hydraulic Power Unit For HPLP Bypass SystemDocument17 pagesSH1-DHI-P1MAN-M-M01-PHL-5355 - Operating Description For Hydraulic Power Unit For HPLP Bypass Systemminhhoang091No ratings yet

- Itp: Acidification Vessel: Tag: A-325-02-01-C3Document8 pagesItp: Acidification Vessel: Tag: A-325-02-01-C3Jeroan AyamNo ratings yet

- Stim-03.014 - en Piping Design Requirements Condensate LinesDocument9 pagesStim-03.014 - en Piping Design Requirements Condensate LinesbikendiaguirreNo ratings yet

- Control System Functional Description (Propylene Refrigerant Compressor)Document96 pagesControl System Functional Description (Propylene Refrigerant Compressor)man_y2k100% (1)

- PP10CC 00 6LBB Yr Abc 001 PDFDocument26 pagesPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87No ratings yet

- Pp12-00-Pgb-mdd-bgs-001 Rev 0 P&id Closed Cooling Water System For GTDocument2 pagesPp12-00-Pgb-mdd-bgs-001 Rev 0 P&id Closed Cooling Water System For GTfaiyazirfanNo ratings yet

- Ahu Hah 70701 AbDocument14 pagesAhu Hah 70701 AbEzrizalSaidinNo ratings yet

- Fluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryFrom EverandFluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- PP10CC 0009 6mal Yr Abc 001Document30 pagesPP10CC 0009 6mal Yr Abc 001anbesivam87No ratings yet

- PP10CC 00 Lab MR Abc 001Document7 pagesPP10CC 00 Lab MR Abc 001anbesivam87No ratings yet

- PP10CC 00 6lca Yr Abc 001 PDFDocument20 pagesPP10CC 00 6lca Yr Abc 001 PDFanbesivam87100% (1)

- PP10CC 00 3mav MR Abc 001Document9 pagesPP10CC 00 3mav MR Abc 001anbesivam87No ratings yet

- PP10CC 00 6LBB Yr Abc 001 PDFDocument26 pagesPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87No ratings yet

- FBC Operation II OperationDocument21 pagesFBC Operation II Operationanbesivam87No ratings yet

- 000 3DT Ee 03584 000Document135 pages000 3DT Ee 03584 000anbarasusivaprakasam100% (4)

- Commissioning Requirements For Generating Systems PDFDocument17 pagesCommissioning Requirements For Generating Systems PDFanbesivam87No ratings yet

- Saudi Arabia Qurayyah: Functional Description and Logic Diagram For Block Load ControlDocument20 pagesSaudi Arabia Qurayyah: Functional Description and Logic Diagram For Block Load Controlanbesivam87100% (1)

- 000 3DT 00005 000 - 2Document116 pages000 3DT 00005 000 - 2anbesivam87No ratings yet

- Rent Receipt - Tax2winDocument5 pagesRent Receipt - Tax2winAdityaNo ratings yet

- De 1Document6 pagesDe 1Thắng Phạm ĐứcNo ratings yet

- Topsolid 2014 What'S New in Topsolid'Design V6.15Document12 pagesTopsolid 2014 What'S New in Topsolid'Design V6.15Nina GregorioNo ratings yet

- Competition Law in Digital Markets in THDocument19 pagesCompetition Law in Digital Markets in THexams_sbsNo ratings yet

- POPIA Code of Conduct For ResearchDocument12 pagesPOPIA Code of Conduct For ResearchKayla RobinsonNo ratings yet

- Posse. Analecta Vaticana. 1878.Document240 pagesPosse. Analecta Vaticana. 1878.Patrologia Latina, Graeca et OrientalisNo ratings yet

- Tds Details For The Year 2019-20: This Report Is Generated On 30-Mar-2021 17:15:09 PMDocument2 pagesTds Details For The Year 2019-20: This Report Is Generated On 30-Mar-2021 17:15:09 PMSaksham SinghalNo ratings yet

- Communicationskillunit1 - LSRWDocument187 pagesCommunicationskillunit1 - LSRWjasjisha4No ratings yet

- MSS - Manual Bernoulli FilterDocument3 pagesMSS - Manual Bernoulli FilterFLTR PURPLE E.No ratings yet

- Homeserve Terms & ConditionsDocument2 pagesHomeserve Terms & ConditionsCharlestonCityPaperNo ratings yet

- Timeline: 2 To 3 Weeks Timeline 4-5 WeeksDocument1 pageTimeline: 2 To 3 Weeks Timeline 4-5 WeeksKester Ray de VeraNo ratings yet

- LDTP TutorialDocument46 pagesLDTP Tutorialjimmyjin_maillistNo ratings yet

- Maham Ke Bari GaandDocument13 pagesMaham Ke Bari GaandFaisal GNo ratings yet

- Lesson 2 PrelimDocument6 pagesLesson 2 PrelimArvin OrtegaNo ratings yet

- Cap Observation Form 1 Announced PolizzoittiDocument3 pagesCap Observation Form 1 Announced Polizzoittiapi-317761911No ratings yet

- Course Overview A1.1 5L EdDocument2 pagesCourse Overview A1.1 5L EdTere Huestis VargasNo ratings yet

- Animal Nutrition 21-22Document12 pagesAnimal Nutrition 21-22lowkeydeadNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument154 pages@airbus: Component Maintenance Manual With Illustrated Part Listjoker hotNo ratings yet

- Russian Future 2030Document108 pagesRussian Future 2030AnamariaMaximNo ratings yet

- CHAPTER 4 (Review Questions) : Direction: Read Each Question Carefully. Encircle The Letter of The Correct AnswerDocument11 pagesCHAPTER 4 (Review Questions) : Direction: Read Each Question Carefully. Encircle The Letter of The Correct AnswerChery PerialdeNo ratings yet

- Spouses Buado Vs Court of Appeals - DigestDocument2 pagesSpouses Buado Vs Court of Appeals - DigestJohn Leo SolinapNo ratings yet

- L-s1 Specification For Low Voltage Internal Electrical InstallationDocument154 pagesL-s1 Specification For Low Voltage Internal Electrical InstallationKW LeeNo ratings yet

- Bank Guarantees in International TradeDocument36 pagesBank Guarantees in International TradeMasud AhmedNo ratings yet

- No Place To Go ReportDocument33 pagesNo Place To Go ReportKatherine McNennyNo ratings yet

- Bayview's Last Stand: Protecting Historic Black Neighborhoods - John William Templeton Speaker FilmmakerDocument5 pagesBayview's Last Stand: Protecting Historic Black Neighborhoods - John William Templeton Speaker FilmmakerJW TempletonNo ratings yet

- Republic v. PLDT, 26 SCRA 620Document1 pageRepublic v. PLDT, 26 SCRA 620YANG FLNo ratings yet

- Genius PHYSICS: Real and Virtual ImagesDocument73 pagesGenius PHYSICS: Real and Virtual ImagesVansh RajpootNo ratings yet

- Bread and Pastry NC II CGDocument22 pagesBread and Pastry NC II CGrayna JUHAILINo ratings yet