Professional Documents

Culture Documents

Stress Corrosion Cracking

Stress Corrosion Cracking

Uploaded by

Carlos VegaCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASTM - C642 - Standard Test Method For Density, Absorption, and Voids in Hardened Concrete1Document3 pagesASTM - C642 - Standard Test Method For Density, Absorption, and Voids in Hardened Concrete1Italo OliveiraNo ratings yet

- Answers - CallisterDocument6 pagesAnswers - CallisterLucas SeixasNo ratings yet

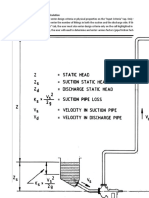

- Recomended Design Criteria Manual - Wastewater Collection and Treatment FacilitiesDocument139 pagesRecomended Design Criteria Manual - Wastewater Collection and Treatment FacilitiesCarlos VegaNo ratings yet

- Seamless Copper Water Tube (Metric) : Standard Specification ForDocument7 pagesSeamless Copper Water Tube (Metric) : Standard Specification ForCarlos VegaNo ratings yet

- Computational Fluid Dynamics Investigation of Air Cooled Heat ExchangersDocument6 pagesComputational Fluid Dynamics Investigation of Air Cooled Heat ExchangersCarlos VegaNo ratings yet

- Meyer 2004Document13 pagesMeyer 2004Carlos VegaNo ratings yet

- KSB Bomba PrincipalDocument6 pagesKSB Bomba PrincipalCarlos VegaNo ratings yet

- Chapter 1Document8 pagesChapter 1Carlos VegaNo ratings yet

- Manual DDFPDocument92 pagesManual DDFPCarlos VegaNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/62Document16 pagesCambridge IGCSE: PHYSICS 0625/62...No ratings yet

- Jennings Silicon Iron 1Document8 pagesJennings Silicon Iron 1Omar VegaNo ratings yet

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocument9 pagesRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Forسعید اینانلوNo ratings yet

- Pipeline Response To Buried Explosive Detonations: Volume I-SummaryDocument48 pagesPipeline Response To Buried Explosive Detonations: Volume I-SummaryAlan Gino GonzalesNo ratings yet

- Typical Slurry Pump CalculationDocument39 pagesTypical Slurry Pump CalculationAhmed GattoufiNo ratings yet

- Lightweight ConcreteDocument8 pagesLightweight ConcreteMADDIBOINA SISINDRINo ratings yet

- Assignment IDocument3 pagesAssignment Ieph100% (2)

- Casting Assignment: Department of Mechanical and Industrial EngineeringDocument7 pagesCasting Assignment: Department of Mechanical and Industrial EngineeringTeeNo ratings yet

- 1.812 In. Kit Tubing Cutter, HMX, Supercutter: Packing InformationDocument1 page1.812 In. Kit Tubing Cutter, HMX, Supercutter: Packing InformationmahsaNo ratings yet

- Geyser Mounting Horizontal Vs VerticalDocument1 pageGeyser Mounting Horizontal Vs VerticalRussell Collett0% (1)

- Thermal Effects On MaterialsDocument37 pagesThermal Effects On MaterialsChockkalingam SubramanianNo ratings yet

- Batching SystemDocument7 pagesBatching SystemHarshal TikekarNo ratings yet

- Workbook For Chemical Reactor Relief System SizingDocument123 pagesWorkbook For Chemical Reactor Relief System SizingRicardo BecNo ratings yet

- 1 s2.0 S0961953416300605 MainDocument10 pages1 s2.0 S0961953416300605 MainHoàng HuyNo ratings yet

- EMMA User Guide PDFDocument33 pagesEMMA User Guide PDFKarnalPreethNo ratings yet

- Ftir para Estudo Da Hidratação Do Cimento Com Adições Minerais - Estado Da ArteDocument13 pagesFtir para Estudo Da Hidratação Do Cimento Com Adições Minerais - Estado Da ArtecamilaabelhaNo ratings yet

- FEEDER Variable Frequency Drive For Screw FeedersDocument6 pagesFEEDER Variable Frequency Drive For Screw FeedersamitdharneNo ratings yet

- Report FEA Rev 03Document14 pagesReport FEA Rev 03hennrycaspersNo ratings yet

- CM 46-92Document4 pagesCM 46-92bcol4vrNo ratings yet

- Bunker CalculationDocument7 pagesBunker CalculationBorislav PetrovNo ratings yet

- Chemical Engineering Thermodynamics Problem Set 1: Bicol UniversityDocument5 pagesChemical Engineering Thermodynamics Problem Set 1: Bicol UniversityJohn Patrick Sanay NunezNo ratings yet

- Float Type DensitometerDocument13 pagesFloat Type Densitometerurvish_soni0% (1)

- Absorption: A, For The Absorption of SODocument3 pagesAbsorption: A, For The Absorption of SOErvz Mission0% (1)

- Scna Jan 2023Document2 pagesScna Jan 2023Sid ACHARYANo ratings yet

- Basic Properties and Behaviors of Oil and Gas Reservoirs PDFDocument97 pagesBasic Properties and Behaviors of Oil and Gas Reservoirs PDFZubairNo ratings yet

- Core Lab PackscanDocument6 pagesCore Lab Packscanpromothes476No ratings yet

- Interior Ballistic Simulations OftheDocument38 pagesInterior Ballistic Simulations OftheRashedNo ratings yet

- MEBC Assignment 1Document2 pagesMEBC Assignment 1atif irshadNo ratings yet

- I. Marshall Mix DesignDocument33 pagesI. Marshall Mix Designkarditobambang23No ratings yet

Stress Corrosion Cracking

Stress Corrosion Cracking

Uploaded by

Carlos VegaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stress Corrosion Cracking

Stress Corrosion Cracking

Uploaded by

Carlos VegaCopyright:

Available Formats

Corrosion Science, Vol. 20, pp.

997 to 1016

Pergamon Press Lid, 1980. Printed in Great Britain.

THE INTERACTION OF STRAIN-RATE A N D

REPASSIVATION RATE IN STRESS CORROSION CRACK

PROPAGATION*

J. C. SCULLY

Department of Metallurgy, The University of Leeds, Leeds LS2 9JT

Abstract--The events occurring at the tip of a propagating stress corrosion crack are analysed with

respect to the strain-rate, ~, and repassivation rate, ?, together with the charge required to cause a

crack increment. It is argued that the strain-rate and repassivation rate interact to maintain an

acidified solution at the tip of a propagating crack in halide solutions just below the pitting potential.

If ~ is too small or ? too large, repassivation will occur, resulting in crack arrest. It is further argued

that the morphology of cracking in active path cracking is dependent upon the ratio, ~/?. In a-brass

and mild steel, lowering ? causes a partial change in fracture mode from intergranular to transgranular. In austenitic stainless steels, raising ? promotes a partial change of the reverse kind. The

ratio ~/~ also determines crack velocity for a particular solution. Cracking morphology in systems

exhibiting hydrogen embrittlement cracking may not show a change as ? is altered since not all such

systems exhibit an alternative active path mode.

INTRODUCTION

IN 1967, the a u t h o r first p u t f o r w a r d the c o n c e p t that repassivation was a critical factor

in the p r o p a g a t i o n o f stress c o r r o s i o n cracks. F o l l o w i n g on directly from the w o r k o f

L o g a n ) the a r g u m e n t was a d v a n c e d t h a t the crucial event in the cycle o f events

p r o d u c i n g an increment o f crack g r o w t h was a critical delay in the repassivation time.

If this time was t o o short, insufficient c o r r o s i o n w o u l d occur to continue crack growth,

whereas, if it was t o o long, t o o m u c h c o r r o s i o n would occur, resulting, m o r p h o logically, in an elongated fissure o r pit rather t h a n a n a r r o w crack. Such ideas had

c o m e directly f r o m experiments 3 at various c o n s t a n t c r o s s h e a d speeds on a T i - 5 A I 2.5Sn alloy in an a q u e o u s NaC1 solution. These h a d shown clearly that repassivation

controlled the crack g r o w t h process. A t this stage 1 the essential d y n a m i c interaction

o f quite separate processes was e m p h a s i z e d : a creep process p r o d u c i n g fresh metal

area, a n d a repassivation process, together allowing c r a c k p r o p a g a t i o n to occur only

if repassivation was " i n a d e q u a t e " . The p r o p a g a t i o n process was considered to occur

as the result o f a specific relationship between the two processes.

In 1968, an a t t e m p t was m a d e 4 to indicate some o f the electrochemical aspects o f

stress c o r r o s i o n cracking with respect to p o l a r i z a t i o n curves, with a view to illustrating

the possible c o n n e c t i o n between alloying a n d repassivation. T h e i m p o r t a n c e o f the

ratio o f two different types o f ions at the c r a c k tip was also stressed. These could be

divided into two general classes: activating and passivating, i.e. p r o m o t i n g cracking

a n d inhibiting cracking.

Since that time the i m p o r t a n c e o f repassivation has been stressed by m a n y workers.

Staehle, 5 Vermilyea, 8 Parkins, 7 Engell, 8 Bignold 9 a n d Beck 1 have all included it in

m o d e l l i n g various stress c o r r o s i o n systems o f stainless steels, t i t a n i u m a n d m a g n e s i u m

*Manuscript received 17 October 1979.

997

998

J . C . SCULLY

alloys and low alloy steels. Some differences have arisen which may in some cases

arise from questions of definition, whereas at least one appears to be real, bearing in

mind the nature and difficulty of modelling stress corrosion crack propagation

processes. The original paper, I for example, implied that cracking stopped when

repassivation was complete, as described above, when the crack tip strain-rate in a

constant load test had fallen to a very low value. The lower the repassivation rate the

lower would be the strain-rate at which crack arrest occurred. In corrosive environments in which repassivation could not occur, instead of crack arrest, cracking would

give way to whatever form of corrosion occurred in the absence of stress, as is discussed

later. Where crack arrest did occur as a result of repassivation the value of the crack

tip strain-rate was designated ~r. 11 For any specimen it was proposed that any threshold

stress for stress corrosion cracking, or K~scc value, corresponded to the value of the

crack tip strain-rate being ~r. From such considerations, film repair could prevent

crack growth on a creeping crack tip surface. Such an idea, for which there is much

experimental evidence, is not in agreement with the model of Vermilyea, n who considers that crack growth restarts after repassivation when the strain in the surface

oxide becomes so great that it fractures. This point is discussed in detail below.

The physical significance of events giving rise to Er was not considered. 11 Whether,

for example, the film was ductile and extended and perhaps thickened so that it never

fractured to such a depth as to reveal bare metal at such low strain-rates was not

discussed. Instead, abundant data were provided that such a concept was realistic

whatever might be the precise physical reality of such an occurrence. In a Ti-O alloy,

for example, a2 in 3 ~ aqueous NaC1 solution, cracking occurred at a crosshead speed

of 8.3 ~tm/s but not at 3.3 l~m/s in SEN specimens. If, after crack initiation at the

higher crosshead speed, the crosshead speed was reduced to the lower value, crack

arrest occurred. Continued straining at the lower crosshead speed resulted in eventual

ductile failure. Stress corrosion cracking was never re-initiated. Similar events of

cracks arresting in specimens at low crack tip strain-rates have subsequently been

observed in a Mg alloy 7 in a CI-/CrO~ 2- solution, in 70Cu-30Zn brass in a neutral

ammoniacal solution in and in Type 304 austenitic stainless steel14 in MgCI~ solution

boiling at 154C. For these latter two examples the conditions under which ~, can be

reached so that cracking is arrested in a straining specimen are such that the crack

tip strain-rate is extremely low, a consequence of the low threshold stress values in

these alloys. Given the condition, however, that a passivation or filming event is

required to observe ~, then any such system where film formation occurs should be

capable of exhibiting such an arrest phenomenon.

The importance of repassivation was taken further in a later paper 11 which put

forward the Constant Charge Criterion. This paper developed the argument that an

increment of crack growth by an active path mechanism occurred when a minimum

charge, Q,,i,, passed in time, t, following the initial current transient, i, occurring

t

upon film rupture, corresponding to Q = ~ i.dt and depicted by the hatched area

in Fig. 1 which is reproduced from Ref. 11'. These ideas coincided with those of

Newman 15 who had put the principal idea to use in his investigation of stress corrosion

cracking in a C r - M o steel exposed to 8M NaOH at 100C. He had concluded that a

constant charge mechanism fitted his analysis of cracking in that system.

Interaction of strain-rate and repassivation rate

999

k,

time

FIG. 1. A schematic drawing of the current transient following the fracture of a film

under potentiostatic conditions. The hatched area represents the charge that passes

between the fracture of the film and its complete repair, xl

In the discussion below the interaction of a deforming surface and the repassivation event consequent upon film rupture is discussed further, particularly in relationship to the maintenance of a volume of liquid at the crack tip acidified to the necessary

condition by hydrolysis. Possible consequences of the relationship between crack tip

strain-rate, ~r, and repassivation rate, ~, are then discussed, followed by an analysis

of how the chemical composition of the liquid at the crack tip determines the crack

morphology in v.-brass, austenitic stainless steers, titanium alloys and zirconium alloys.

THE M A I N T E N A N C E OF THE CRACK TiP SOLUTION COMPOSITION

Galvele 16 and co-workers 17 have emphasized, both from theoretical considerations 1~ and from experimental results, ~7 that incipient pits are stabilized and grow

when local conditions are met such that the required amount of hydrolysis can occur

at the pit surface at such a rate that it is self-sustaining. The continuation of pit

growth depends upon the maintenance of the hydrolyzed volume of solution.

Over the last 10-15 yrs, various workers, particularly Brown, la have demonstrated

that the pH of the solutions at the tips of propagating cracks in A1 and Ti alloys and

in high strength steels is low and, in each case, it is in the same range of p H values

as that found inside pits in the same materials. Cracking commonly occurs just below

the pitting potential, as indicated in Fig. 2, at least for passivatable alloys susceptible

to stress corrosion cracking, e.g. austenitic stainless steels. If a similar explanation for

the occurrence of low p H values of solutions at the tips of cracks is to be made as is

made for the same occurrence in pitting, then for hydrolysis to occur at a sufficiently

high rate requires that the solution be provided with metal ions by the action of the

crack tip strain-rate in breaking or disturbing the growing film and providing a flux

of metal ions, since in the absence of the strain-rate the acidic solution will not be

produced nor maintained below the pitting potential. Unless the creep process occurs

at or above a certain minimum rate ( ~ ~,) the surface will repassivate completely

and simultaneously the p H of the solution will start to rise towards that of the bulk

solution since the hydrolysis reaction rate cannot be maintained. For the same reason

lO00

J.C.

SCULLY

,91__Cracking

Zone

Y

,

,,,,

log c.d.

F]o. 2. The potential zone in which stress corrosion is observed just below the pitting

potential.

the halide ion concentration at the crack tip will start to fall towards that o f the bulk

solution. An attempt is made to depict these in Fig. 3. The main feature which will be

discussed later is that u p o n complete repassivation the crack tip solution starts to

become less corrosive. This happens when the strain-rate falls to ~r, which is therefore

the strain-rate at and below which equilibrium hydrolysis conditions cannot be maintained at the crack tip.

C Iz"

pH

CI-

pH~

,

time

FIG. 3. Schematic drawing of the changes occurring in a crack tip solution following

repassivation and crack arrest as a result of the crack tip strain-rate falling to ~r. A t this

point the pH begins to rise and the halide ion concentration begins to fall while the

strain-rate continues to fall.

The relatively simple concept being put forward is that cracking in halide solutions

is similar to pitting, with the necessary condition that in the cracking process the

creep strain-rate is necessary in order to provide dissolving metal ions from newly

formed surfaces and thereby maintain the crack tip acidity which otherwise either

would not occur or would not be maintained. In the pitting model 16 the important

product is the bare metal current density multiplied by the diffusion distance. Since

crack velocities can change over several orders o f magnitude in a given system, the

influence o f strain-rate in maintaining crack propagation is best explained by en-

Interaction of strain-rate and repassivation rate

1001

visaging the crack tip metal surface as being covered by a film of varying composition

and, perhaps, morphology. In the extreme case the surface is bare, corresponding to

the maximum velocity often observed as a plateau velocity, itself dependent upon

p H and solution composition and reaching a maximum at the pitting potential, for

example, in Ti 19 and AI ~ alloys. It is this value that is sometimes used, in conjunction

with Faraday's Laws, to calculate the required maximum current density for an active

path cracking mechanism. In pitting studies current densities have been measured or

estimated in various alloys, e.g. 8 A/cm 2 in an austenitic stainless steel, 21 2 A/cm 2

on iron z2 and 0.3 A/cm z on aluminium. "3

The idea that the film on the crack tip surface may exhibit a range of properties

which determine the crack velocity is not new. It has been discussed

previously, 24 for example, to explain the influence of the I ion concentration on the

observed z plateau velocity on an aluminium alloy. The chemical and physical state

of this layer remains to be examined. It may, for example, be a mixed layer of oxide

and salt layer, with the latter component being the less protective. A direct comparison

can be made with the range of current densities observed on growing pit surfaces.

While much emphasis has been placed on the maximum values attained in various

alloy/electrolyte combinations, a study of pit propagation rates 25 shows that pits can

grow at significantly lower rates at potentials close to the protection potential. This

reduction is probably caused by the presence of a film on the pit surface, evidence for

which can be deduced from the high values of potential/log i changes that have been

recorded for pits, e.g. b

150 mV for A1z6 and 220 mV for an F e - C r alloy, 27 although

other interpretations of such results can be made.

REPASSIVATION

Since repassivation at crack tip surfaces occurs in a specific type of solution and

over a narrow range of potentials, it is important that repassivation experiments that

are designed to examine this aspect of cracking should replicate both the solution

conditions and the potential values. If, for example, repassivation in scratching or

straining electrode experiments is examined well below the pitting and cracking range

of potential in solutions quite different from those known to exist at crack tips, then

significant amounts of hydrolysis will not occur, repassivation will be relatively rapid,

and the film growth kinetics can be expected to obey a log i ~.--log t behaviour, typical

of passive film formation, and frequently observed. 28 3o Such results may have little

or no application, however, to crack tip repassivation. At the crack tip the fall in

pH can be expected to lower the repassivation rate, as will the increasing C1- ion

concentration. As already discussed, the type of film forming may be different. Film

growth kinetics under such conditions have not been widely investigated although a

slowing down as the potential approaches the pitting potential has been observed in

aluminium 32 and in austenitic stainless steels.31, z3 A computer simulation of a repassivating scratch on a stainless steel surface, 3z however, over a wide range of

potentials up to the pitting potential, has shown that near to the pitting potential the

log //log t decay is not a more accurate description of the decay process than an

exponential decay (log i ~ -- t) during the early stages (100 ms) of the film repair

process, even with no allowance being made for the significant amount of hydrolysis

occurring in that region of potential. Practical results ~4 for Fe in chloride/molybdate

1002

J.C. SCULLY

solutions in the pitting region of potential have indicated a similar conclusion: during

the early stages of repassivation (250 ms) the results fit two exponential decay lines of

slightly different slope and log//log t decay describes the process only after the early

stage has passed. It is the early stage of repassivation that is of importance since

cracking can be viewed as a series of current transients recurring at short time intervals.

The repassivation rate between such transients is what needs to be known accurately.

The type of decay law operating during repassivation has a direct relevance to any

electrochemical analysis of crack propagation, as has been described previously, ix

I f an exponential decay is operative then the current, i, flowing from a surface deforming at a constant strain-rate, ~:, is related: log i ~ ~, under constant potential conditions. If a different decay behaviour is operative then clearly a different dependency

between strain-rate and current will be observed. This is a very important point since

by the association of the creep rate with the repassivation process what is being

emphasized is that the relationship between i and t during an increment of crack

growth is both mechanically and electrochemically dependent.

The sequence of current transients emanating from a crack tip and observable

hypothetically under ideal experimental conditions is depicted in Fig. 4 where the

log i

time

FIG. 4. Schematic drawing of the effect of repeated identical crack tip strain transients

occurring at the tip of a propagating crack on the current/time relationship under a

condition of constant extension rate. The same charge flows in each increment which

nucleate each other successively.

conditions are intended to be a constant extension rate in a specimen under potentiostatic control. The overall creep rate is considered to be constant, giving rise to a

series of identical crack tip strain transients. The minimum charge, Qm;,, flows before

a further increment is generated and complete film repair does not therefore occur

before the next increment is initiated, i.e. ~ never falls to ~r. A general formula can be

advanced:

v = constant

Qrnin

t

(1)

Interaction of strain-rate and repassivation rate

1003

where v is the crack velocity and t is the time interval between successive slip events

which are initiated by the propagation of the crack. If v = 1 mm/h, for example,

and the slip line separation is 0.1 ~m, then 3 transients will occur approximately every

second. The repassivation kinetics over the first 330 ms will determine the charge

flowing during that time.

Under constant load conditions, drawn in Fig. 5, successive creep transients will

occur under conditions of gradually increasing stress. Each increment of crack growth

will occur in successively shorter time intervals. This sequence has been extensively

described previously, n The creep rate increases progressively with the propagation of

each increment because the load is being supported by a reducing cross section. The

maximum current attained at the beginning of the transient will gradually increase

and will reach a maximum determined by electrochemical factors. Beyond that point

the current will be at a maximum value for an increasing proportion of the transient

lifetime until it occupies it completely, a situation corresponding to the maximum

diffusion-controlled plateau velocity, as described at length previously, n Since the

current flowing at any creep rate depends upon the repassivation characteristics of the

solution, the time for Qminto pass is both a mechanical and an electrochemical

dependent.

log i

f

time

FIG. 5. Schematic drawing of the effect of consecutive slip transients occurring at the

tip of a propagating crack on the current/time relationship under conditions of constant

load. The reducing cross-sectioncauses the stress to rise, causing an increasing crack tip

strain-rate, 6, and thereby increasing the current, i, so that the same charge passes in

decreasing time intervals, i.e. the crack velocity increases.

If repassivation occurs before Q,,i, has passed then crack arrest will occur. This

situation, previously described, xl is drawn in Fig. 6. For reasons already described

above and drawn in Fig. 3, the solution composition will then begin to change, Under

constant load conditions with the strain-rate falling and the crack arrested, no further

transient can be expected. If, however, the strain in the film becomes too large to be

sustained and it fractures, the consequent charge passed will be relatively small since

1004

J.C. SCULLY

log

1__

time

FIG. 6. Schematicdrawing of crack arrest arising because the crack tip strain-rate, /:,

has fallen to ~, before Q,~n has passed. The current/time relationship shows that the

current falls to the original background value upon repassivation.

the repassivation characteristics of the changed solution will be such that film repair

will be much more rapid to an extent that will depend upon the time interval between

repassivation and film fracture. In the model of Vermilyea 6 the important event is the

fracture of the film after repassivation. For many systems it is difficult to see that such

an event will re-initiate cracking. Where repassivation has already occurred cracking

will only be restarted by the production of a fresh transient large enough to produce

sufficient hydrolysis immediately, as must always happen, in general, whenever cracks

are initiated. This type of intermittent propagation is referred to as Interrupted

Loading Stress Corrosion Cracking and can occur as a result of increasing or oscillating

the applied load, both of which actions can have the effect of causing transient high

strain-rates. This seems a much greater disturbance of the crack tip than that

occasioned by the fracture of a film at a low strain-rate, which is the implication of the

Vermilyea model. In the present state of knowledge no further distinction can be made.

There is no intrinsic reason that the Vermilyea model should not apply to some systems

of stress corrosion cracking, particularly in those systems where the crack tip solution

may not be markedly different from the bulk solution, e.g. in nitrate and hydroxide

cracking of steels perhaps, although direct evidence about the crack tip solution composition in these solutions is surprisingly lacking. For cracking in halide solutions

with the attendant hydrolysis, solution changes after repassivation will render crack

re-initiation more difficult. The two types of transients after repassivation in a constant

load test and in an oscillating load test are shown in Fig. 7. The implication is that

the transient in the constant load test is too small to be of much significance, if any.

Much, of course, depends upon the mechanical properties of the film, which in turn

depend upon its structure. The implication of the description given above concerning

k, is of a layer adjusting continually to an extending surface which below the maximum

velocity is permanently covered with some oxide/salt film probably similar to that

occurring in pitting corrosion below the maximum rate. If such a picture is realistic

Interaction of strain-rate and repassivation rate

log i

1

film fractures

time

FIG. 7(a). Schematic diagram of crack arrest as shown in Fig. 6. Subsequently a small

transient occurs adding very little charge to that already passed before crack arrest since

it occurs in a solution that has already undergone the changes indicated in Fig. 3 to an

extent that will be dependent upon the time lapsed between the occurrence of ~, and the

occurrence of the transient.

A+B=Q

.

mln

C<Q

min

log i ' ~

oad increased

time

Figure 7(b). Schematic diagram of crack arrest as shown in Fig. 6. Additional or

oscillating loading causes a large increase in ~ and a substantial amount of additional

charge flows which, when added to that passed before crack arrest, exceeds Q . . . and

causes an additional crack increment. Crack arrest recurs because ~, is reached before

Q..,, has passed during the further period of crack growth.

1005

1006

J . c . SCULLY

then fracture after repassivation might depend upon a change in the mechanical

properties of the film, reflecting, perhaps, the development of a more resistant

thicker, passive film.

The value of 6, determines Kl,.cc and any other mechanical threshold between

failure and non-failure. It is environment-sensitive since the competition between

metal surface production rate, hydrolysis and neutralization kinetics will depend,

inter alia, on the nature of the bulk solution. For the same reason it will be potentialdependent, as is K I. . . . since as the potential is lowered to more active values the

repassivation rate will increase. The establishment and maintenance of the acidic

solution at the crack tip will be more difficult, i.e. it will require a higher rate of metal

surface production. This general effect is drawn in Fig. 8(a) which shows the boundaries

of cracking in relation to potential and strain-rate and which also shows how these

boundaries are moved by alterations to the solution. The boundaries indicate the

joint role of strain-rate, 6, and repassivation rate, f, dependent upon the value of the

potential, as already shown for aluminium a2 and austenitic stainless steels,31, 3s in

determining whether cracking occurs in an environment in which repassivation is

possible and in one in which it is not possible. The lower boundary value of k is

considered first.

pitting

SCC

increasing:

inhibitor

~ halide

viscosity

pitting

~lk

potential ~

inhibitor~

~.

~ d l ' ~ inhibitor

h,

"viscosity

Ductile

Fracture

;-_._~

Fro. 8(a). Schematic diagram of the relationship between electrode potential and

crack tip strain-rate, ~, for a solution in which passivation is possible. The boundaries are

determined by solution composition, particularlyinhibitors, halide ion concentration, pH

and solution viscosity.

The dependence of 6, upon pH can be contrasted with the general independence

of pitting potential upon pH. In the former case the occurrence of acidity is entirely

dependent upon the creep rate generating fresh metal area or disturbing the surface

film, while in the latter case the breakdown of the film and development of acidity is

entirely electrochemical. As the pH is lowered the boundary falls to lower values of

Interaction of strain-rate and repassivation rate

1007

g,, until when passivity is no longer possible, it is vertical, corresponding to where the

crack velocity is similar in rate to the corrosion rate (Fig. 8(b)). Below that value o f

the cracking will give way to whatever form of corrosion occurs in unstressed specimens. This is frequently intergranular corrosion. It can be expected that the b o u n d a r y

will be affected by passivating and film-forming inhibitors and, possibly, by adsorptiontype organic inhibitors too, although the effect o f the latter may not be continuous

in situations where the crack tip moves more rapidly than the rate o f diffusion o f the

organic molecules.

Corrosion + S C C

SCC

Ductile

Fracture

Fic. 8(b). Schematic diagram of the relationship between electrode potential and crack

tip strain-rate, ~, for a solution in which passivity cannot occur. At very low values of ~,

corresponding to tests lasting for a long period of time, corrosion occurs as on unstressed

specimens, e.g. general corrosion or intergranular corrosion. This is also likely to be

observed as the potential is raised in the noble direction. At active potentials cathodic

protection may be achieved. Over a wide range of potentials the crack propagation rate

will be constant, lg,~ Because of the corrosiveness of the solution the boundary between

corrosion and scc may be difficult to discern. The upper boundary may have a slight

positive slope.

In Fig. 8(a), the upper boundary of ~, above which cracking does not occur, is

drawn. This is sometimes referred to as depassivation, the implication being that

m u c h or even all o f the metal surface undergoes corrosion under these conditions and

crack initiation cannot occur. Ductile failure takes place in a relatively short time.

Cracking will be sustained to a higher value of ~ as ~ decreases with increasingly noble

potential. F o r this reason the line is not vertical. The addition o f inhibitors under

controlled potential conditions will lower the corrosion rate and move the b o u n d a r y

to lower values o f 6. Increasing the solution viscosity will have the same effect.

Increasing the halide ion will increase the maximum value of/;. The upper b o u n d a r y of

corresponds to the conditions for maximum crack velocity, observed as a constant

velocity in some systems. It is lowered by lowering the potential over a range o f pH

values19, 2 above a minimum value below which crack velocity is potential-independent

in some systems, e.g. A1 and Ti alloys,19, 2 as is shown in Fig. 8(b).

1008

J. C, SCULLY

The upper potential boundary in Fig. 8(a) corresponds to the pitting potential,

or possibly the protection potential, if that is different, since below that value pits do

not grow. This boundary is also affected by inhibitor and halide additions, as well

as by solution viscosity, 32 but it is generally independent of pH. The potential at

which pits nucleate and grow in straining aluminium specimens has, however, been

designated the pitting potential. ~7 At and above the pitting potential there is usually

a region of pitting and cracking which gives way to general disintegration as the

potential is raised. This may not be the situation for those systems exhibiting a pitting

inhibition potential where, perhaps, a region of non-cracking may occur, giving ductile

failure. For a-brass in neutral ammoniacal solutions, raising the potential to the value

at which the tarnish film dissolves lowers the crack velocity and eventually leads to a

region of non-susceptibility. Anodic polarization of mild steels also leads to eventual

non-susceptibility.

The lower potential boundary in Fig. 8 may be narrow or broad, depending upon

the nature of the solution, in particular the ratio of activating to passivating species at

the crack tip. As the solution becomes more aggressive the boundary widens until,

when passivation is no longer possible, it extends across the full range of k values and

downwards to that value of potential where cathodic protection becomes possible.

An attempt is made to depict the same diagram for a very acidic solution (e.g. pH =

0) in Fig. 8(b). Since repassivation is not possible, the cracking range of ~ is independent of potential over a wide range.

Figure 8(a) illustrates many of the principal features of stress corrosion cracking

systems: the cracking range of/; is both environment- and potential-dependent; the

highest value of ~ depends upon the maximum crack velocity of any system; the

cracking range depends upon potential, strain-rate and solution composition.

THE RELATIONSHIP BETWEEN STRAIN-RATE AND REPASSIVATION

RATE

The general model so far described1, n is based upon the crack tip strain-rate, ~,

and the repassivation rate, ~, being in a state of relative imbalance. Kinetically, this

would arise as a result of the relationship between the two which might be generally

described as a ratio: ~/f(i')wheref(~)is some unknown function. In a previous paper la

discussion centered around the ratio, R, of repassivation rate to strain-rate. The

inversion has been made only because it provides an easier presentation of the results

in references 13 and 41. Since the strain-rate generates area and the repassivation rate

is also concerned with area it would be easy to take, as a simple assumption, the ratio

~./L but the generalized ratio is preferred until such time as the precise nature of the

ratio is determined. The concept of the importance of the ratio between the two rates

must be qualified since there will be a limit, possibly quite narrow, to the values of

and ~ over which the ratio will apply and stress corrosion crack propagation occur.

Thus it must be supposed x > ~; > y and a > ~ > b, where x and a are maximum

values and y and b are minimum values of ~ and ~ respectively. It may also be expected

that even within these ranges high values of ~ and ~ (~ x and o) and low values of

and ~ ( ~ y and b) which give the same value ratio cannot necessarily be expected

to yield the same effect. With such general conditions it becomes possible to examine

the significance of the ratio for a limited number of reported experiments. Much

Interaction of strain-rate and repassivation rate

1009

w o r k has been r e p o r t e d for crack velocity as a function o f crosshead speed (and,

indirectly, strain-rate) b u t little w o r k has been r e p o r t e d on crack velocity as a function

o f repassivation effect. Several workers 35 7 have used repassivation ratios, e.g. the

values o f current at some time interval after the initiation o f repassivation for two

different potential values, or the times taken for the current to fall to some fraction

o f the transient m a x i m u m , as indicators o f repassivation significance but it is n o t

possible to use such d a t a for the present discussion. Effects can only be generally and

qualitatively inferred, e.g. that # increases as the potential is lowered or as the concentration o f an oxidizing i n h i b i t o r is a d d e d under c o n s t a n t potential conditions.

a-BRASS

C r a c k velocity measurements in J o h n s o n and Leja solutions at p H 6.8 have been

r e p o r t e d recently 13 as a function o f crosshead speed. Over a wide range o f values

(0.66 n m - 3 3 ~m/s) cracking was observed to be intergranular in a solution containing 6 g/l o f dissolved copper. Film f o r m a t i o n a n d r u p t u r e a p p e a r to be an imp o r t a n t p a r t o f the crack p r o p a g a t i o n process since a crack arrest p h e n o m e n o n was

detected in the c o n s t a n t crosshcad speed tests 13 a n d also in notched cantilever b e a m

experiments, 3s which can be a t t r i b u t e d directly to a film forming process. In the latter

case, r e m o v a l o f the film resulted in renewed crack p r o p a g a t i o n in the same solution.

If the crack tip strain-rate developed in such tests is assumed to be directly prop o r t i o n a l (and this p o i n t has been discussed previously) 13 to the i m p o s e d c r o s s h e a d

speed, then the results previously r e p o r t e d la for velocity vs. c r o s s h e a d speed can be

depicted schematically as shown in Fig. 9 in which the strain-rate, ~, is d i v i d e d by the

repassivation rate, ~, for t h a t p a r t i c u l a r solution, which is not known, a l t h o u g h a

% ductile

fra~re,

I

100

S~IG+TG

log v

//7..

oo.

P"

t"'lG

*'I'G

/h.<..,,,,;,

~.! > r2

FIG. 9. Schematic diagram of the relationship between the ratio ~/l(~) and crack velocity

for a-brass in neutral ammoniacal solutions, taken from ref. 13. The solid line - is for one solution (f (constant) - ?0. The dashed line . . . .

is for one crosshead

speed with ~ being lowered, the broken line - - - - - suggests how the velocity falls at

lower values of the ratio based upon a lower constant value or ~(~). The cracking/ductile

fracture barrier is also drawn on the diagram. This corresponds to the upper value of

in Fig. 8. The lower the crack velocity the earlier is ductile fracture encountered.

1010

J . C . SCULLY

growth rate of 90 nm/s has been reported a9 for a similar solution. In the same solution

any change that lowers t~results in (i) a fall in crack velocity, and (ii) a transition from a

completely intergranular fracture to a mixed mode fracture, intergranular/transgranular. Such changes are caused ~3 by (a) anodic polarization, (b) cathodic polarization, (c) the addition of halide ions, (d) lowering the dissolved copper concentration,

and (e) raising or lowering the pH from 6.8. The common effect of each of these

changes is to lower i. Most of these changes were examined at only one crosshead

speed. These results are drawn in Fig. 9. The solid line corresponds to a ratio derived

from a varying ~ and a constant ~ (il) with completely intergranular cracking. When

is lowered as a result of any of the changes listed in (a)-(e) the velocity falls and the

ratio increases. This change is drawn as a dashed line showing a falling velocity as

~/f(i) increases as a result of lowering ~ at a constant crosshead speed (~ constant).

Additionally, the same general shape of the solid line can be expected to be found for

solutions with a lower ~ value (t~2) but with lower values of velocity. An example of

such behaviour is drawn as a lower broken line. There is some support for such an

assumption. Crack velocity measurements in 15N ammoniacal solutions 4 have

shown that altering the potential or lowering the concentration of reactive species

(a) suppresses the complete log v/K curve, which is of the same form as Fig. 9, (b)

lowers the slope of the K-dependent velocity section, and (c) does not affect the

transition point of the two lines. The reduced slope drawn in Fig. 9 would be expected

from consideration of simple proportions. If the denominator in the ratio, ~, is

lowered, the values of the ratio will be further apart over the same range of crosshead

speeds (~ values).

Also shown in Fig. 9 is kr which for this alloy systems corresponds to a lower

crosshead speed than the lowest employed in the work ~z from which the figure is

derived. Crack arrest was observed in experiments in which the crosshead movement

was discontinued. This would correspond to some low, unmeasured crack velocity.

This initial part of the log v/log CHS graph was not determined and for that reason a

gap is left in the figure.

The upper limit of ~, corresponding to depassivation, can be expected to fall with

decreasing corrosion rate, as discussed in the previous section. As ~ increases, however,

cracking does not occur and the boundary of the cracking/ductile failure modes will

go towards lower ~/f(i') ratios, as is drawn. Thus x/a causes a higher crack velocity

than y/b, even when the two ratios have the same value.

AUSTENITIC STAINLESS STEELS

In austenitic stainless steels in MgCl~ solutions at 154C log v/log CHS results

have been reported by Takano. 41 These are reproduced in Fig. 10. Work under

potentiostatic conditions has yielded similar results34 Takano observed that fracture

was intergranular at lower temperatures as did Stalder and Duquette 4~ (which would

also include a lower chloride concentration). It has also been reported 4a that additions

of Mo promote intergranular cracking at 154C. All this indicates that as the repassivation rate, t~, increases, the cracking becomes, at least partly, intergranular. The results,

drawn in Fig. 11, are similar to s-brass, except that there is a morphological reversal:

the higher velocity is transgranular.

Interaction of strain-rate and repassivation rate

1011

-I

log

V

mm/s -2

-3

3

-2

-1

log C,H.S.

mm/s

FIG. 10. Reproduction of the results of Takano4*: Type 304 steel in MgCI., solution

at 154C.

Er

constant

log v

FI~. 11. Schematic diagram of the relationship between the ratio ~/f(i-) and crack

velocity for Type 304 austenitic stainless steel in a MgCi~ solution boiling at 154C.

Constant f refers to experiments done14 at a constant potential; constant g refers to

experiments dortet4 at a fixed crosshead speed under conditions of increasing f.

Figures 9 and 1 1 are based, as far as is currently possible, upon experimental

work. They place particular emphasis upon the repassivation rate in controlling the

crack propagation rate and crack morphology, together with the crack tip strain-rate.

The potential is indirectly a factor; its importance lies in its effect upon f. Where there

is no repassivation the crack propagation rate is constant (Fig. 8(b)).xg. 2 F o r any value

o f potential within the cracking range the repassivation rate will depend u p o n the

crack tip solution composition. As has already been emphasized with reference to

Fig. 1, the factor controlling propagation is the charge and the calculation o f this

incorporates the repassivation rate.

1012

J . C . SCULLY

CRACK TIP SOLUTION COMPOSITION AND CRACK PATH

The tentative descriptions of the relationship between stress corrosion crack

velocity and the ~/f(f) ratio are consistent with the observed cracking mode changes.

The type of fracture observed appears to depend upon the repassivation process at the

crack tip which, in turn, depends upon the value of the potential and the composition

of the crack tip solution. In ~-brass the filming characteristics control the crack path

in neutral ammoniacal solutions. 18 Rapidly tarnishing solutions cause intergranular

cracking and any change that lowers this rate produces transgranular cracking, as has

already been described, which propagates more slowly. This may be the consequence

of the increase in the number of reactive sites as a result of the slower film formation

rate: the same current is distributed over a higher number of sites. It may also arise

because the transgranular crack paths are less reactive than the grain boundaries,

although if this were true, the first argument would still need to be invoked to explain

why the crack followed the less reactive path.

In austenitic stainless steels the reverse change is seen. The commonly observed

transgranular fracture becomes intergranular in solutions that are less aggressive, i.e.

allow repassivation of slip steps, than those that cause transgranular cracking. In

such solutions, developing near to the crack arrest potential, 14 and in solutions containing inhibitors 14 and as the chloride ion concentration and temperature are lowered,

or as the Mo content is increased (which can be expected to increase the repassivation

rate) the emergent slip steps are repassivated but the grain boundaries are not and

intergranular cracking is observed. As in 0~-brass, intergranular cracking occurs when

the crack tip solution allows slip step repassivation. The explanation for these changes

is not clear. The less aggressive solution causing intergranular stress corrosion cracking

in the stainless steels may have undergone less hydrolysis since it is associated with

relatively low corrosion rate conditions. There may therefore be a greater deposition

rate from the solution. It is at least conceivable that different types of film are formed

in the two solutions. Compositional effects, e.g. P in the grain boundaries, may also

be of importance. There are many such possible causes but currently there is a lack of

experimental evidence to support any one of them.

The attempted analysis that the less aggressive, more rapidly filming solutions

cause intergranular cracking while the more aggressive, less rapidly filming solutions

cause transgranular cracking seems to apply to other systems of active path stress

corrosion cracking. Armco iron, for example, cracks intergranularly44 in phosphate

solutions of pH 9, probably in a similar way to steels in HCOa-/CO32-, O H - and NO3solutions with the formation of thick protective magnetite scales, possibly associated

with other compounds, 45 yet if tested at pH 4 it cracks partly transgranularly. 44 In the

acidic solution it can be supposed that the crack tip solution is sufficiently aggressive

to be less rapidly film forming and cause transgranular cracking. Plain carbon steels

also crack transgranularly in gaseous CO/CO2 mixtures 4e in which the rapid formation

of a protective three-dimensional film cannot be expected.

The circumstances under which such fracture mode transitions may be seen are

likely to be confined to a relatively small number of examples. Altering the solution

pH can be expected either to promote general corrosion, as a result of lowering f,

or to promote passivity, as a result of raising f, both of which effects will tend to

prevent stress corrosion crack propagation. Fracture mode transitions probably

Interaction of strain-rate and repassivation rate

1013

require small changes in solution causing small changes in t~. Transitions are rarely

complete. The changes observed in x-brass ~s and austenitic stainless steel ~4 are to

mixed modes, not complete transitions, indicative of very small changes in solution,

possibly not homogeneous along a propagating front.

For ~-brass and mild steel it is possible to observe that intergranular cracking is

associated with the rapid formation of relatively thick films. Under such circumstances rapid slip step repassivation may be achieved by the small amount of surface

revealed. An attempt is made to draw this in Fig. 12. If the film is relatively thick and

C

FIG. 12. Schematic diagram indicating how the amount of fresh surface exposed after

rupture of a surface film is reduced if the film grows at a significant rate. The area

exposed initially will be determined by the thickness of the film at the time of creation

of the step. The rate at which the exposed area is reduced will be determined by the

growth rate of the film. The diagram depicts a film growing inwardly. A similar situation

arises if the film grows outwardly.

growing rapidly, e.g. linearly at 90 nm/s over the first 3 s for ~-brass, sa then the charge

emanating from the freshly revealed step will be relatively small. For austenitic stainless steels, intergranular cracking at elevated temperatures, c a . 300C in chloridecontaminated steam, may be attributable to the same cause--the formation of thick

films, and as with ~-brass, by deposition from solution, which can produce rates that

do not diminish rapidly with increasing thickness. In MgCI~ solutions at 154C the

explanation is not so obviously applicable. There are no data on the relative thicknesses of films formed on slip steps and grain boundaries in this system but they are

not likely to be as thick as those formed on brass. Nor do they exhibit a linear growth

rate. Rather than thickness it is the relative rates of repassivation that are important.

Intergranular cracking occurs in less aggressive solutions in which slip steps are more

rapidly repassivated. In more aggressive solutions slip steps do not repassivate and

a more rapid transgranular cracking ensues. While an active path has been assumed,

it must also be pointed out that an alternative explanation is available. Recent

workS~, 53 has illustrated similarities between transgranular stress corrosion fractures

and hydrogen embrittlement fractures in austenitic stainless steels. This may indicate

that stress corrosion cracking in this material falls within the second category: inter-

1014

J.C. SCULLY

granular dissolution cracking and transgranular hydrogen cleavage cracking, with the

latter occurring in more aggressive solutions.

Inherent in this discussion is that in a-brass, austenitic stainless steels and plain

steels the transition in cracking mode is dependent upon crack tip chemistry causing

rapid film growth and not directly upon any mechanical variable such as strain,

strain-rate or stress, which is why it is possible to discuss it in terms of the ratio

~/f(i'), independently of stress.

The three systems described above are commonly thought to crack by an active

path mechanism. For the more mechanical types of stress corrosion cracking, exhibiting cleavage modes of failure attributable to embrittlement by absorbed hydrogen,

e.g. Ti alloys 12 and zircaloy-2, 47 the transition from intergranular dissolution to

transgranular cleavage in corrosive mixtures of CH3OH/HC1 is associated with a

cleavage initiation stress. The cleavage failure is still observed even if the grain

boundaries are repassivated by corrosion-inhibition additions of water to the corrosive

mixture or if experiments are conducted in neutral aqueous NaCI solutions in which

intergranular fracture is not seen. In such examples the less aggressive passivating

solution does not prevent the occurrence of transgranular cleavage. These are not

examples of one crack path being preferred to the other because of differences in

repassivation rate. They are examples of hydrogen being absorbed to a sufficient degree

to cause cleavage fracture during the repassivation of slip steps at a ~ > ~r- For

zircaloy-2 anodic polarization is required to obtain transgranular cleavage in aqueous

NaCI solution which suggests that Ecor~ is below the lower boundary in Fig. 9.

It appears that a simple distinction can be made between active path stress

corrosion cracking and that caused by hydrogen absorption. In the former type the

crack path is independent of the stress and is determined by the crack tip solution

composition. In the latter type cleavage occurs at a certain stress which probably

depends, at least in some alloys, upon the amount of hydrogen absorbed. What

happens below that value of stress depends upon the type of corrosion occurring on

unstressed specimens, which is commonly either no corrosion or intergranular

corrosion, which means that either only cleavage is seen or cleavage is preceded by

intergranular cracking.

CONCLUSION

A detailed analysis of events occurring at the tip of a propagating crack is difficult

to make, particularly of a quantitative nature, because there are so many unknown

factors. Some of these are rarely discussed. Two general examples can be quoted.

First, it can be supposed that the corrosion of a stressed metal may release dislocations

as the result of the dissolution of a dislocation barrier. 4a If this happens, and it would

seem to be more likely to occur as the amount of corrosion occurring increases, then

locally ~ will be increased. This effect coutd be developed as an argument that

increases as ~ decreases and thereby allows more corrosion to occur. This dissolution

of dislocation barriers is implicit in the description provided for Figs. 4 and

5. Corrosion periodically releases dislocations and causes high local strain-rates. A

more specific explanation is required, of course, in order to delineate why such an

effect gives rise to a crack, and this must be derived from morphological studies.

Why, for example, do transgranular cracks in austenite, 49 a-brass and Al-alloys 5

Interaction of strain-rate and repassivation rate

1015

follow (110) p l a n e s ? Secondly, a selective a d s o r p t i o n o f species f r o m s o l u t i o n on to

the emerging metal surface m a y occur a n d t h e r e b y alter the crack tip s o l u t i o n significantly, sx Such a d s o r p t i o n effects, if they occur, would d e p e n d u p o n a range o f surface

t o p o g r a p h i c a l a n d c o m p o s i t i o n a l factors.

Several other areas o f equal possible i m p o r t a n c e (e.g. de-alloying) c o u l d be cited,

b u t little o r no direct evidence can be cited a n d these areas c a n n o t be p u r s u e d currently.

The discussion a b o v e has therefore been a relatively simple description o f w h a t are

u n d o u b t e d l y c o m p l e x interactions. A n a t t e m p t has been m a d e to d e p i c t c r a c k i n g as

occurring when the relationship between the crack tip strain-rate, ~, a n d r e p a s s i v a t i o n

rate, ~, is such t h a t an acidic solution can be m a i n t a i n e d at the c r a c k tip a n d c o m p l e t e

repassivation is delayed. It has been a r g u e d t h a t in active p a t h c r a c k i n g the solution

c o m p o s i t i o n determines the crack path, with r a p i d l y filming solutions giving interg r a n u l a r cracking, a n d slowly filming solutions giving t r a n s g r a n u l a r cracking. M u c h

o f the b e h a v i o u r o f stress c o r r o s i o n cracks can be explained by c o n s i d e r i n g the

relationship between ~ and t~.

Acknowledgement--It is a pleasure to acknowledge that much of this paper was written while the author

was a Visiting Professor in the Department of Metallurgy and Materials Science of the University of

Florida, in Gainesville, Florida.

REFERENCES

1. J. C. SCULLY, Corros. Sci. 7, 197 (1967).

2. H. L. LOGAN,J. Res. nat. Bur. Std48, 99 (1952).

3. J. C. SCULLYand D. T. POWELL, Corros. Sci. 10, 371 (1970).

4. J. C. SCULLY, Corros. Sci. 8, 513 (1968).

5. R. W. STAIBHLE,The Theory of Stress Corrosion Cracking in Alloys, p. 223 (Ed. J. C. SCULLY).

NATO, Brussels (1971).

6. D. A. VERMILYEA,J. electrochem. Soc. 119, 405 (1972).

7. W. R. W~ARMOUTH,G. P. DEANand R. N. PARKINS,Corrosion 29, 251 (1973).

8. H. J. ENGELL, ref. 5, p. 68.

9. G. BIGNOt.D, Corrosion 28, 307 (1972).

10. T. R. BECK,J. electrochem. Soc. 115, 890 (1968).

11. J. C. SCULLY, Corros. Sci. 15, 207 (1975).

12. J. C. SCULLVand T. A. ADEPOJU, Corros. ScL 17, 789 (1977).

13. M. K~RMANIand J. C. SCULLY, Corros. Sci. 19, 89 (1979).

14. M. TALEBIANand J. C. SCULLY,to be published.

15. J. F. N~WMAN,C.E.R.L. Report RD/L/N 120/78 November (1978).

16. J. R. GALVEL~,J. electrochem. Soc. 123, 434 (1976).

17. S. B. DE WEXLERand J. R. GALWLE,J. electrochem. Soc. 121, 1272 (1974).

18. B. F. BRow~, ref. 5, p. 186.

19. M. J. BLACKnURN,J. A. FEENi~Yand T. R. BECK, Advances in Corrosion Science and Technology

(Eds. M. G. For,rrANAand R. W. STAEHLE),Vol. 3, p. 67. Plenum Press, New York (1973).

20. M. O. SPEIDEL,ref. 5, p. 289.

21. N. SATO,T. NAKAOAWA,K. KUDO and M. SAKASHITA,Trans. Japan Inst. Metals 13, 103 (1972).

22. K. J. V~T'rER and H. H. STRI~HBLOW,Ber. Bunsenges. Physik. Chem. 74, 1024 (1970).

23. H. KA~c~m, Z. Physik. Chem. N.F. 34, 87 (1962).

24. J. C. SCULLY, Third International Congress on Fracture, Munich, 1973. PL-1V-222, Proo~dings,

Dusseldorf (1973).

25. B. C. S ~ T r , Corrosion 33, 221 (1977).

26. H. KAI~SCHE, Z.Physik. Chem. NF34, 87 (1962).

27. N. SATO, T. NAKAOAWA,K. KUDO and M. SAKASmTX,Localized Corrosion, p. 447, N.A.C.E.,

Houston (1974).

28. D. M. BRASh~Rand A. H. KI~GSBURY,Trans. Faraday Soc..54, 1214 (1958).

29. N. SATOand M. COHEN,J. electrochem. Soc. 111, 512 (1964).

30. G. M. BULMANand A. C. C. TSEUNG, Corros. Sci. 12, 415 (1972).

1016

J . C . SCULLY

31. P. ENGSETH and J. C. SCULLY,Corros. Sci. 15, 505 (1975).

32. W. J. RUDD and J. C. SCULLY, Corros. Sci. 20, 611 (1980).

33. M. BARBOSAand J. C. SCULLY, Environment-Sensitive Fracture of Engineering Materials (Ed. Z. A.

FOROULIS), p. 91. A.I.M.E., New York (1979).

34. T. KODAMA and J. R. AMBROSE, Corrosion 33, 155 (1979).

35. Y. S. PARK, J. R. GALVELE, A. K. AGRAWALand R. W. STAEHLE, Corrosion 34, 413 (1978).

36. J. RXMBERTand J. PAGETTI, Corros. Sci. 20, 189 (1980).

37. R. N. PARKINS, Corros. Sci. 20, 147 (1980).

38. M. KERMANI and J. C. SCULLY,Corros. Sci. 19, 111 (1979).

39. J. A. S. GREEN, H. D. MENGELBERGand H. T. YOLKEN, J. electrochem. Soc. 117, 433 (1970).

40. M. KERMANI and J. C. SCULLV, Corros. Sci. 18, 883 (1978).

41. M. TAKANO, Corrosion 28, 332 (1972).

42. F. STALDER and D. J. DUQUETTE, Corrosion 33, 67 (1977).

43. H. OKADA,Y. HOSOI and S. ABE, Corrosion 27, 424 (1971).

44. J. FLIS, Corros. Sci. 19, 151 (1979).

45. R. N. PARKINS,N. J. H. HOLROYD and R. R. F'ESSLER,Corrosion 34, 253 (1978).

46. A. BROWN, J. T. HARRISON and R. WILKINS, Corros. Sci. 10, 547 (1970).

47. P. M. MAJUMDARand J. C. SCULLY, Corros. Sci. 19, 141 (1979).

48. J. C. SCULLY, The Physical Basis of Yield and Fracture, p. 119. The Institute of Physics, London

(1966).

49. G. M. SCAMANSand P. R. SWANN, Corros. Sci. 18, 983 (1978).

50. J. L. NELSON and J. A. BEAVERS, Met. Trans. 10A, 658 (1979).

51. J. C. SCULLY, Brit. Corros. J. 1, 355 (1966).

52. D. ELIEZER, D. G. CHAKRAPANX,C. J. ALSTETTER and E. N. PUGH, Met. Trans. IOA, 935 (1979).

53. H. HANNINEN artd T. HAKKARAINEN, Met. Trans. 10A, 1196 (1979).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASTM - C642 - Standard Test Method For Density, Absorption, and Voids in Hardened Concrete1Document3 pagesASTM - C642 - Standard Test Method For Density, Absorption, and Voids in Hardened Concrete1Italo OliveiraNo ratings yet

- Answers - CallisterDocument6 pagesAnswers - CallisterLucas SeixasNo ratings yet

- Recomended Design Criteria Manual - Wastewater Collection and Treatment FacilitiesDocument139 pagesRecomended Design Criteria Manual - Wastewater Collection and Treatment FacilitiesCarlos VegaNo ratings yet

- Seamless Copper Water Tube (Metric) : Standard Specification ForDocument7 pagesSeamless Copper Water Tube (Metric) : Standard Specification ForCarlos VegaNo ratings yet

- Computational Fluid Dynamics Investigation of Air Cooled Heat ExchangersDocument6 pagesComputational Fluid Dynamics Investigation of Air Cooled Heat ExchangersCarlos VegaNo ratings yet

- Meyer 2004Document13 pagesMeyer 2004Carlos VegaNo ratings yet

- KSB Bomba PrincipalDocument6 pagesKSB Bomba PrincipalCarlos VegaNo ratings yet

- Chapter 1Document8 pagesChapter 1Carlos VegaNo ratings yet

- Manual DDFPDocument92 pagesManual DDFPCarlos VegaNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/62Document16 pagesCambridge IGCSE: PHYSICS 0625/62...No ratings yet

- Jennings Silicon Iron 1Document8 pagesJennings Silicon Iron 1Omar VegaNo ratings yet

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocument9 pagesRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Forسعید اینانلوNo ratings yet

- Pipeline Response To Buried Explosive Detonations: Volume I-SummaryDocument48 pagesPipeline Response To Buried Explosive Detonations: Volume I-SummaryAlan Gino GonzalesNo ratings yet

- Typical Slurry Pump CalculationDocument39 pagesTypical Slurry Pump CalculationAhmed GattoufiNo ratings yet

- Lightweight ConcreteDocument8 pagesLightweight ConcreteMADDIBOINA SISINDRINo ratings yet

- Assignment IDocument3 pagesAssignment Ieph100% (2)

- Casting Assignment: Department of Mechanical and Industrial EngineeringDocument7 pagesCasting Assignment: Department of Mechanical and Industrial EngineeringTeeNo ratings yet

- 1.812 In. Kit Tubing Cutter, HMX, Supercutter: Packing InformationDocument1 page1.812 In. Kit Tubing Cutter, HMX, Supercutter: Packing InformationmahsaNo ratings yet

- Geyser Mounting Horizontal Vs VerticalDocument1 pageGeyser Mounting Horizontal Vs VerticalRussell Collett0% (1)

- Thermal Effects On MaterialsDocument37 pagesThermal Effects On MaterialsChockkalingam SubramanianNo ratings yet

- Batching SystemDocument7 pagesBatching SystemHarshal TikekarNo ratings yet

- Workbook For Chemical Reactor Relief System SizingDocument123 pagesWorkbook For Chemical Reactor Relief System SizingRicardo BecNo ratings yet

- 1 s2.0 S0961953416300605 MainDocument10 pages1 s2.0 S0961953416300605 MainHoàng HuyNo ratings yet

- EMMA User Guide PDFDocument33 pagesEMMA User Guide PDFKarnalPreethNo ratings yet

- Ftir para Estudo Da Hidratação Do Cimento Com Adições Minerais - Estado Da ArteDocument13 pagesFtir para Estudo Da Hidratação Do Cimento Com Adições Minerais - Estado Da ArtecamilaabelhaNo ratings yet

- FEEDER Variable Frequency Drive For Screw FeedersDocument6 pagesFEEDER Variable Frequency Drive For Screw FeedersamitdharneNo ratings yet

- Report FEA Rev 03Document14 pagesReport FEA Rev 03hennrycaspersNo ratings yet

- CM 46-92Document4 pagesCM 46-92bcol4vrNo ratings yet

- Bunker CalculationDocument7 pagesBunker CalculationBorislav PetrovNo ratings yet

- Chemical Engineering Thermodynamics Problem Set 1: Bicol UniversityDocument5 pagesChemical Engineering Thermodynamics Problem Set 1: Bicol UniversityJohn Patrick Sanay NunezNo ratings yet

- Float Type DensitometerDocument13 pagesFloat Type Densitometerurvish_soni0% (1)

- Absorption: A, For The Absorption of SODocument3 pagesAbsorption: A, For The Absorption of SOErvz Mission0% (1)

- Scna Jan 2023Document2 pagesScna Jan 2023Sid ACHARYANo ratings yet

- Basic Properties and Behaviors of Oil and Gas Reservoirs PDFDocument97 pagesBasic Properties and Behaviors of Oil and Gas Reservoirs PDFZubairNo ratings yet

- Core Lab PackscanDocument6 pagesCore Lab Packscanpromothes476No ratings yet

- Interior Ballistic Simulations OftheDocument38 pagesInterior Ballistic Simulations OftheRashedNo ratings yet

- MEBC Assignment 1Document2 pagesMEBC Assignment 1atif irshadNo ratings yet

- I. Marshall Mix DesignDocument33 pagesI. Marshall Mix Designkarditobambang23No ratings yet