Professional Documents

Culture Documents

Docslide - Us - Itp Structural Work

Docslide - Us - Itp Structural Work

Uploaded by

omda4wadyCopyright:

Available Formats

You might also like

- Acumen Fuse User GuideDocument124 pagesAcumen Fuse User Guideomda4wady0% (1)

- Certificate Aboveground PipingDocument5 pagesCertificate Aboveground Pipingsajeed76740No ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- مصطلحات إدارية مترجمة PDFDocument20 pagesمصطلحات إدارية مترجمة PDFMohamed Abulinein84% (25)

- GE Gas Turbine Generator Frame 6 Spare PartsDocument2 pagesGE Gas Turbine Generator Frame 6 Spare PartsAxelrose04100% (1)

- 1.2 Contoh Query List Demolition PDFDocument1 page1.2 Contoh Query List Demolition PDFhusnasyahidahNo ratings yet

- Request For NDT Test FormDocument1 pageRequest For NDT Test FormJohn OliverNo ratings yet

- Katalog ARITA 20199Document68 pagesKatalog ARITA 20199Fresly JayaNo ratings yet

- Arita Katalog Building - SmallDocument16 pagesArita Katalog Building - SmallAlamsyah PutraNo ratings yet

- Updated QAQC FormatDocument16 pagesUpdated QAQC FormatAkash Singh TomarNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- Project GuidelineDocument7 pagesProject GuidelineNg Kee NainNo ratings yet

- Checklist Installation and Start-UpDocument127 pagesChecklist Installation and Start-Uptaufik ramuliNo ratings yet

- Monitoring Shop DrawingDocument3 pagesMonitoring Shop DrawingYudan GlanstarNo ratings yet

- Hydrostatic Pressure Test Report External Pipeline & Main Pipe Complete With Ferrule and Communication PipeDocument2 pagesHydrostatic Pressure Test Report External Pipeline & Main Pipe Complete With Ferrule and Communication PipeRohmat HidayatNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- SMDB Live TestDocument33 pagesSMDB Live TestFiroze KuthabdeenNo ratings yet

- J910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.ADocument18 pagesJ910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.Arudi sarifudinNo ratings yet

- BoqDocument2 pagesBoqshyamsundar_ceNo ratings yet

- Air Cooled Condensing Unit Checklist: Mr. Aden LiuDocument45 pagesAir Cooled Condensing Unit Checklist: Mr. Aden LiuADEN LIUNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- GSB-Form-246 Dimension Inspection Report (Circum)Document1 pageGSB-Form-246 Dimension Inspection Report (Circum)Made GileeNo ratings yet

- Fire Hydrant SpecsDocument7 pagesFire Hydrant SpecsMajuraNo ratings yet

- ITP - Fire Hydrant InstallationDocument9 pagesITP - Fire Hydrant InstallationGultom Juliana LiliesNo ratings yet

- Alignment Survey ReportDocument1 pageAlignment Survey ReporttreyNo ratings yet

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Document10 pagesMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- 185 Spec Menara99 SoreangDocument5 pages185 Spec Menara99 SoreangHendra YuliantoNo ratings yet

- Millsheet Pipa Spindo - 01Document4 pagesMillsheet Pipa Spindo - 01Mellany SeprinaNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- Checklist - Ducting - Non Pressure Parts Drgs.Document4 pagesChecklist - Ducting - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDocument1 pageLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Contoh ItpDocument3 pagesContoh Itphafiz elektroNo ratings yet

- BMID Hydrant Test FormDocument2 pagesBMID Hydrant Test FormSheikh Faiz RockerNo ratings yet

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pages0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003No ratings yet

- P001 - Piping Fit Up Inspection ReportDocument1 pageP001 - Piping Fit Up Inspection ReportSuryakant Suraj0% (1)

- ITP For Wall Panels InstallationDocument3 pagesITP For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Handover To QAQC-Anand KumarDocument6 pagesHandover To QAQC-Anand KumarAnonymous fBkcEze1No ratings yet

- Form As Built Survey ReportDocument1 pageForm As Built Survey Reportarianto82No ratings yet

- Daily Welding Report PLD LogoDocument1 pageDaily Welding Report PLD Logonike_y2kNo ratings yet

- DOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportDocument2 pagesDOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportBharathiNo ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- Katalog Aksesoris HydrantDocument21 pagesKatalog Aksesoris HydrantPratikno SajaNo ratings yet

- 04 Pneumatic Testing Procedure Shell OKDocument6 pages04 Pneumatic Testing Procedure Shell OKEduardo GarciaNo ratings yet

- J910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)Document15 pagesJ910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)rudi sarifudinNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- Method Statement For Internal Painting Rev 2Document20 pagesMethod Statement For Internal Painting Rev 2Ngô Trung NghĩaNo ratings yet

- SikaBit W-15 Page 1 - 39Document52 pagesSikaBit W-15 Page 1 - 39Keesh RonoloNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- Larsen & Toubro Limited: Ecc DivisionDocument4 pagesLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- TDS Jotashield Heritage HB Fine GB English DecorativeDocument3 pagesTDS Jotashield Heritage HB Fine GB English Decorativeomda4wady100% (1)

- TDS Jotashield Alkali Resistant Primer GB English DecorativeDocument3 pagesTDS Jotashield Alkali Resistant Primer GB English Decorativeomda4wadyNo ratings yet

- Pep TocDocument2 pagesPep Tocomda4wadyNo ratings yet

- 2014 KSCE ResearchGateDocument30 pages2014 KSCE ResearchGateomda4wadyNo ratings yet

- ItpDocument64 pagesItpomda4wady100% (1)

- ITP of Admin Building NEW AutosavedDocument14 pagesITP of Admin Building NEW Autosavedomda4wady0% (1)

- Chief Estimator: Job DescriptionDocument2 pagesChief Estimator: Job Descriptionomda4wadyNo ratings yet

- Safety ManagerDocument1 pageSafety Manageromda4wadyNo ratings yet

- Land Surveyor: Job DescriptionDocument1 pageLand Surveyor: Job Descriptionomda4wadyNo ratings yet

- MEP Engineer: Job DescriptionDocument1 pageMEP Engineer: Job Descriptionomda4wadyNo ratings yet

- CAD Engineer: Job DescriptionDocument2 pagesCAD Engineer: Job Descriptionomda4wadyNo ratings yet

- اختصارات عقودDocument1 pageاختصارات عقودomda4wadyNo ratings yet

- EPC Project WBS PDFDocument1 pageEPC Project WBS PDFomda4wadyNo ratings yet

- Project Management Process Map: Develop Ment Imple-MentationDocument1 pageProject Management Process Map: Develop Ment Imple-Mentationomda4wadyNo ratings yet

- Time Impact AnalysisDocument5 pagesTime Impact AnalysisRenoMasrNo ratings yet

- ITPMProcess Guidelines ChecklistDocument1 pageITPMProcess Guidelines Checklistomda4wadyNo ratings yet

- Tempilstik°: Temperature IndicatorsDocument5 pagesTempilstik°: Temperature IndicatorssaapyNo ratings yet

- From Vibration Monitoring To Industry 4.0Document14 pagesFrom Vibration Monitoring To Industry 4.0ifm electronicNo ratings yet

- B Tech Supplementary Exam Timetable 2013Document14 pagesB Tech Supplementary Exam Timetable 2013studyurselfNo ratings yet

- High-Temperature Mechanical Properties of Concrete: M. Bastami, F. Aslani, and M. Esmaeilnia OmranDocument15 pagesHigh-Temperature Mechanical Properties of Concrete: M. Bastami, F. Aslani, and M. Esmaeilnia OmranAlan Said AbdulrahmanNo ratings yet

- Merida BikesDocument139 pagesMerida BikesLeopoldo PerezNo ratings yet

- Shock Manual: V3.1 EnglishDocument16 pagesShock Manual: V3.1 Englishmayur ladwaNo ratings yet

- TS-MES-3203-CGC - Fittings - 13.03.2023Document321 pagesTS-MES-3203-CGC - Fittings - 13.03.2023energy8001No ratings yet

- Welcome TO Daman & Vapi: Insat Trading CompanyDocument19 pagesWelcome TO Daman & Vapi: Insat Trading CompanyPranay BubnaNo ratings yet

- Bulldozer Diagrama ElctricoDocument18 pagesBulldozer Diagrama ElctricoAldo Lozoria MendietaNo ratings yet

- Piston ValvesDocument20 pagesPiston ValvesYogi173No ratings yet

- Prince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyDocument15 pagesPrince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyPRC Industrial Supply100% (1)

- CRV 2019 ManualDocument769 pagesCRV 2019 ManualJuan In Nippon0% (1)

- AP Physics B Exam Topics Since 1970Document7 pagesAP Physics B Exam Topics Since 1970Chris HansenNo ratings yet

- Axisymm TutorialDocument15 pagesAxisymm Tutorialmudur6No ratings yet

- Air Preheater Seal Upgrades Renew Plant EfficiencyDocument11 pagesAir Preheater Seal Upgrades Renew Plant EfficiencysdiamanNo ratings yet

- Godwin CD 103mDocument2 pagesGodwin CD 103mfire123123123No ratings yet

- Borang Pemeriksaan Air Kompressor PDFDocument1 pageBorang Pemeriksaan Air Kompressor PDFAnas AmeerNo ratings yet

- PTRL5005 2016 Group30 FinalReport GOSP PDFDocument90 pagesPTRL5005 2016 Group30 FinalReport GOSP PDFNour FathyNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Cc422 ElectricoDocument34 pagesCc422 ElectricoSamuel Moreno100% (2)

- Broad X Non-Electric Chiller: Model Selection & Design ManualDocument27 pagesBroad X Non-Electric Chiller: Model Selection & Design ManualdokundotNo ratings yet

- LV Motor EQP Global SD - T3 Brochure Rev 191121Document4 pagesLV Motor EQP Global SD - T3 Brochure Rev 191121Victor LinaresNo ratings yet

- Asme Sec Viii Div 1 Vs Asme Viii Div 2Document3 pagesAsme Sec Viii Div 1 Vs Asme Viii Div 2Jignesh ShahNo ratings yet

- Azkarra: Live Technology LiveDocument23 pagesAzkarra: Live Technology LiveSYED MAZHARNo ratings yet

- High Pressure Gear Motor Wm900Document16 pagesHigh Pressure Gear Motor Wm900Vladimir Illich Pinzon BallenNo ratings yet

- Bearing Stress Between A Lifting Lug and A Shackle PinDocument7 pagesBearing Stress Between A Lifting Lug and A Shackle PinYl WongNo ratings yet

- 05 CP90 Parts Section Serial# 125 - 130Document150 pages05 CP90 Parts Section Serial# 125 - 130CARLNo ratings yet

- 02.ah Installation of CELLFLEX Cables 2005-1Document118 pages02.ah Installation of CELLFLEX Cables 2005-1vaskoa1No ratings yet

- Newton's Laws 2. Some Particular Forces 3. Applying Newton's LawsDocument67 pagesNewton's Laws 2. Some Particular Forces 3. Applying Newton's LawsMario EscalonaNo ratings yet

Docslide - Us - Itp Structural Work

Docslide - Us - Itp Structural Work

Uploaded by

omda4wadyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Docslide - Us - Itp Structural Work

Docslide - Us - Itp Structural Work

Uploaded by

omda4wadyCopyright:

Available Formats

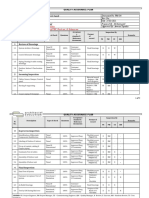

LARSEN & TOUBRO LIMITED

CLIENT : IOCL

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR

Approved By :

Rev : 0

DATE :

Dept : QA / QC

PAGE :

1 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No.

ACTIVITY

NATURE OF CHECK/INSPECTION

Method of

Check

Freequency

Reference

of Check Procedure / Document

Format for

Record

Inspection Authority

L&T-ECCD CLIENT

REMARKS

1 Material Inspection

Rolled section and plates f a. Mechanical

framing columns, beams,

bracing, members, stiffeners

etc.

b. Chemical

c. Dimensional & external defects

d. Raw material identification and

correlation of TC's

Review MTC

Heat No./

Batch No.

Each Lot

IS 2062

-doMeasurement

& Visual

Visual &

Review

-do100%

-doDrgs, BOQ & P.O

requirements

-do-

100%

Steel for gratings, cheque a. Mechanical

Review MTC

plate, hand rail etc.

b.Dimensional & external defects

Measurement

steel Plates

& visual

c) UT test for lamination check - As a Inspection

Each Lot

100%

Welding Electrodes

Each lot

Make, identification & certification m

Fasteners -Mild steel & Higa. Mechanical

strength friction grip bolts/

Foundation Bolts

b. Chemical

c. Dimensional & external defects

PAINTS

LEGEND :

Make,

identification & certification mark

MTC : MATERIAL TEST CERTIFICATE

LTR :LAB TEST REPORT

SIR : MATERIAL INSPECTION RECORD

Visual

Random

IS 2062 or equivalent LTCD/QAQC/STR/02

Drgs, BOM & P.O

requirements

IS 3644

Review of Manu. Each manu.

Certificates and heat batch

-doMeasurement

& Visual

-do100%

Visual

Each lot

LTCD/QAQC/STR/02

CP

RP

CP

CP

RP

RP

CP

RP

CP

CP

RP

RP

IS 815,816

ASME SEC -II part-C

Register

CP

RP

IS 3757

IS 6623

IS 1367

-doDrgs, BOM & P.O

requirements

LTCD/QAQC/STR/02

CP

RP

CP

CP

RP

RP

Client spec. / Mfg.

literture / IS codes

or equivalent

IS - 2074

LTCD/QAQC/STR/02

CP

RP

MIR : MATERIAL INSPECTION REPORT

CP : CHECK POINT

WP :WITNESS POINT

RP : REVIEW POINT

HP : HOLD POINT

( Mtc Should have

MR No. & Receipt

Date Stamp.

Register to Contain

Receipt & Issue

Information

LARSEN & TOUBRO LIMITED

CLIENT : IOCL

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR

Approved By :

Rev : 0

DATE :

Dept : QA / QC

PAGE :

2 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No.

NATURE OF CHECK/INSPECTION

ACTIVITY

Method of

Check

Freequency

Reference

of Check Procedure / Document

Format for

Record

Inspection Authority

L&T-ECCD CLIENT

2 In Process Inspection

2.1 Welding qualification test

2.1.1 WPS/PQR

2.1.2 WELDER Qualification test

2.2 Structural fabrication

2.2.1 Fitup

2.2.2 Edge Preparation

2.3 Welded Joints

Structural

Testing

-do-

Measurement

& Visual

Measurement

& Visual

100%

100%

LTCD/QAQC/WPS

IS 7307,ASME IX /

LTCD/QAQC/PQR

Equivalent

IS 817 / IS 7370 LTCD/QAQC/STR/WEL/01

Drawings /

Technical spec.

AWS D1.1 /

Technical Spec.

LTCD/QAQC/STR/03

LTCD/QAQC/STR/04

CP

RP

CP

WP

CP

RP

CP

RP

WP

RP

WP

RP

100%

AWS D 1.1 /

IS 9595

2.3.2 Fillet welds to major structural components

Visual

like reinforcements to flange / web of rolled

Sections , End plates, 'base plates,Splices &

Gusset plates, etc.

100%

-do-

1 test per 50 T

ASME Sec.V /

Tech spec.

LTCD/QAQC/STR/05

LTCD/QAQC/STR/06

CP

WP

As Per Tech.

Spec.

As Per Tech.

Spec.

IS - 2074

LTCD/QAQC/STR/08

CP

RP

Visual &DFT

100%

LTCD/QAQC/STR/08

Visual

Random

Mfg.recomm/

IS 5

IS 1477

Testing

2.5.1 Cleaning with wire Brushes & sand p Surface Finish

2.5.2 Surface Coating

2.5.3 Application

LEGEND :

100%

2.3.1 Butt welds to major

Visual

structural components like beams,columns

bracings, base plates etc.

2.4 NDT on completed weld joiSurface & Internal Weld defects

a) UT test - As applicable

b. DPT

- as applicable

2.5 Painting

Doc. Review

MTC : MATERIAL TEST CERTIFICATE

LTR :LAB TEST REPORT

SIR : MATERIAL INSPECTION RECORD

MIR : MATERIAL INSPECTION REPORT

LTCD/QAQC/STR/08

CP : CHECK POINT

WP :WITNESS POINT

RP : REVIEW POINT

CP

RP

CP

RP

HP : HOLD POINT

REMARKS

LARSEN & TOUBRO LIMITED

CLIENT : IOCL

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR

Approved By :

Rev : 0

DATE :

Dept : QA / QC

PAGE :

3 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No.

ACTIVITY

3 Final Inspection

Assembly

NATURE OF CHECK/INSPECTION

Dimensions,match marking,

Painting & Completeness

4 Erection

Check foundation for prop Visual & Alignment

location & orientation as per

level / elevation.

Check Foundation Bolts/

Size/Location/Alignment

Method of

Check

Visual & Alignment

LEGEND :

Format for

Record

Inspection Authority

L&T-ECCD CLIENT

Visual

Complete

Drgs/Tech. Specs

LTCD/QAQC/STR/04

CP

RP

Visual,Water

level, spirit level,

plump pob,

Theodolite

Visual &

Measurement

100%

Drgs

LTCD/QAQC/STR/07

CP

RP

100%

Drgs./Tech.Specs

CP

RP

-do-

100%

Drgs

CP

WP

Every Batch

CP

RP

CP

RP

CP

RP

Check erected columns / -dobeams etc. before grouting

5 Grouting

5.1 Grouting with

Non-Shrink Grout

Freequency

Reference

of Check Procedure / Document

Material

Fluidity and expansion of Grout Mater Review of Tc

LTCD/QAQC/STR/07

- Surface preparation

Inspection

100%

- Supports and grout tightness of for

work

-Check for mixing & W/C Ratio

Inspection

Method

Statement

-do-

Inspection

-do-

CP

RP

-Verify estimated and consumed Qty

Inspection

-do-

CP

RP

-Curing

-Final Inspection

Inspection

Visual

1

1

-do-do-

CP

CP

RP

RP

MTC : MATERIAL TEST CERTIFICATE

LTR :LAB TEST REPORT

SIR : MATERIAL INSPECTION RECORD

MIR : MATERIAL INSPECTION REPORT

LTCD/QAQC/STR/01

CP : CHECK POINT

WP :WITNESS POINT

RP : REVIEW POINT

HP : HOLD POINT

REMARKS

LARSEN & TOUBRO LIMITED

CLIENT : IOCL

ECC DIVISION

ECCD

DOC No. : LTCD/ITP/STR

Approved By :

Rev : 0

DATE :

Dept : QA / QC

PAGE :

4 OF 4

10.02 INSPECTION & TEST PLAN - STRUCTURAL WORKS

Sr. No.

ACTIVITY

5.2 Grouting with

Cement Grout

6 GI Sheeting

LEGEND :

NATURE OF CHECK/INSPECTION

Materials

-Cement

-Sand Grading

-Surface preparation

-Mix preparation

-Form work grout tightness,

Supports

Mixing

-Placing and compaction

-Curing

-Final Inspection

Method of

Check

Freequency

Reference

of Check Procedure / Document

Review of Tc

Lab Test

Inspection

Inspection

Inspection

Every Batch

1

1

100%

1

Tech Specs

Tech Specs

Tech Specs

Inspection

Inspection

Inspection

1

100%

1

Tech Specs

Tech Specs

Tech Specs

-Check for Material

-Check for sequence of

Sheeting

-Check for metering / Overlap

Inspection

Inspection

1 per source

1

Inspection

-Slopes. Lines. Levels of Sheets

Format for

Record

Inspection Authority

L&T-ECCD CLIENT

CP

CP

CP

CP

CP

RP

RP

RP

RP

RP

CP

CP

CP

RP

WP

WP

Tech Specs

Drawings

CP

CP

RP

RP

100%

Drawings

CP

RP

Inspection

100%

Drawings

CP

RP

-Barge Boards, Ridges & Gutters

Inspection

100%

Drawings

CP

RP

-Checks for slopes of rain

Gutters,Downtake Pipes &

Supports of Gutters

-Check for Overhang of Sheets

Inspection

Drawings

CP

RP

Inspection

Drawings

CP

RP

-Check for Proper size of bolts, Wash

Leak in any final inspection

Inspection

WP/FIN/09

CP

RP

MTC : MATERIAL TEST CERTIFICATE

LTR :LAB TEST REPORT

SIR : MATERIAL INSPECTION RECORD

MIR : MATERIAL INSPECTION REPORT

LTR

LTCD/QAQC/STR/01

LTCD/QAQC/FIN/09

CP : CHECK POINT

WP :WITNESS POINT

RP : REVIEW POINT

HP : HOLD POINT

REMARKS

You might also like

- Acumen Fuse User GuideDocument124 pagesAcumen Fuse User Guideomda4wady0% (1)

- Certificate Aboveground PipingDocument5 pagesCertificate Aboveground Pipingsajeed76740No ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- مصطلحات إدارية مترجمة PDFDocument20 pagesمصطلحات إدارية مترجمة PDFMohamed Abulinein84% (25)

- GE Gas Turbine Generator Frame 6 Spare PartsDocument2 pagesGE Gas Turbine Generator Frame 6 Spare PartsAxelrose04100% (1)

- 1.2 Contoh Query List Demolition PDFDocument1 page1.2 Contoh Query List Demolition PDFhusnasyahidahNo ratings yet

- Request For NDT Test FormDocument1 pageRequest For NDT Test FormJohn OliverNo ratings yet

- Katalog ARITA 20199Document68 pagesKatalog ARITA 20199Fresly JayaNo ratings yet

- Arita Katalog Building - SmallDocument16 pagesArita Katalog Building - SmallAlamsyah PutraNo ratings yet

- Updated QAQC FormatDocument16 pagesUpdated QAQC FormatAkash Singh TomarNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- Project GuidelineDocument7 pagesProject GuidelineNg Kee NainNo ratings yet

- Checklist Installation and Start-UpDocument127 pagesChecklist Installation and Start-Uptaufik ramuliNo ratings yet

- Monitoring Shop DrawingDocument3 pagesMonitoring Shop DrawingYudan GlanstarNo ratings yet

- Hydrostatic Pressure Test Report External Pipeline & Main Pipe Complete With Ferrule and Communication PipeDocument2 pagesHydrostatic Pressure Test Report External Pipeline & Main Pipe Complete With Ferrule and Communication PipeRohmat HidayatNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- SMDB Live TestDocument33 pagesSMDB Live TestFiroze KuthabdeenNo ratings yet

- J910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.ADocument18 pagesJ910-DH02-P10ZEN-040007 - (AHF) Field ITP For Bund Wall Work For Ash Handling Facilities - Rev.Arudi sarifudinNo ratings yet

- BoqDocument2 pagesBoqshyamsundar_ceNo ratings yet

- Air Cooled Condensing Unit Checklist: Mr. Aden LiuDocument45 pagesAir Cooled Condensing Unit Checklist: Mr. Aden LiuADEN LIUNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- GSB-Form-246 Dimension Inspection Report (Circum)Document1 pageGSB-Form-246 Dimension Inspection Report (Circum)Made GileeNo ratings yet

- Fire Hydrant SpecsDocument7 pagesFire Hydrant SpecsMajuraNo ratings yet

- ITP - Fire Hydrant InstallationDocument9 pagesITP - Fire Hydrant InstallationGultom Juliana LiliesNo ratings yet

- Alignment Survey ReportDocument1 pageAlignment Survey ReporttreyNo ratings yet

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Document10 pagesMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- 185 Spec Menara99 SoreangDocument5 pages185 Spec Menara99 SoreangHendra YuliantoNo ratings yet

- Millsheet Pipa Spindo - 01Document4 pagesMillsheet Pipa Spindo - 01Mellany SeprinaNo ratings yet

- Project Report On Threading Drill PipesDocument34 pagesProject Report On Threading Drill PipesVamshi KrishnaNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- Checklist - Ducting - Non Pressure Parts Drgs.Document4 pagesChecklist - Ducting - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDocument1 pageLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Contoh ItpDocument3 pagesContoh Itphafiz elektroNo ratings yet

- BMID Hydrant Test FormDocument2 pagesBMID Hydrant Test FormSheikh Faiz RockerNo ratings yet

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pages0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003No ratings yet

- P001 - Piping Fit Up Inspection ReportDocument1 pageP001 - Piping Fit Up Inspection ReportSuryakant Suraj0% (1)

- ITP For Wall Panels InstallationDocument3 pagesITP For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Handover To QAQC-Anand KumarDocument6 pagesHandover To QAQC-Anand KumarAnonymous fBkcEze1No ratings yet

- Form As Built Survey ReportDocument1 pageForm As Built Survey Reportarianto82No ratings yet

- Daily Welding Report PLD LogoDocument1 pageDaily Welding Report PLD Logonike_y2kNo ratings yet

- DOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportDocument2 pagesDOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportBharathiNo ratings yet

- Sa01 Genxxx SDGG PRTS 0107 V00Document7 pagesSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNo ratings yet

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- Katalog Aksesoris HydrantDocument21 pagesKatalog Aksesoris HydrantPratikno SajaNo ratings yet

- 04 Pneumatic Testing Procedure Shell OKDocument6 pages04 Pneumatic Testing Procedure Shell OKEduardo GarciaNo ratings yet

- J910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)Document15 pagesJ910-DH02-P10ZEN-040001 Field ITP For Earth Work For Ash Handling Facilities - Rev.1 (AFC)rudi sarifudinNo ratings yet

- Inspection Log Book PLMB - 040915Document42 pagesInspection Log Book PLMB - 040915Rahmad DesmanNo ratings yet

- Method Statement For Internal Painting Rev 2Document20 pagesMethod Statement For Internal Painting Rev 2Ngô Trung NghĩaNo ratings yet

- SikaBit W-15 Page 1 - 39Document52 pagesSikaBit W-15 Page 1 - 39Keesh RonoloNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Repair Procedure For Rubber LiningDocument1 pageRepair Procedure For Rubber LiningChuah Cheong JinNo ratings yet

- Larsen & Toubro Limited: Ecc DivisionDocument4 pagesLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- TDS Jotashield Heritage HB Fine GB English DecorativeDocument3 pagesTDS Jotashield Heritage HB Fine GB English Decorativeomda4wady100% (1)

- TDS Jotashield Alkali Resistant Primer GB English DecorativeDocument3 pagesTDS Jotashield Alkali Resistant Primer GB English Decorativeomda4wadyNo ratings yet

- Pep TocDocument2 pagesPep Tocomda4wadyNo ratings yet

- 2014 KSCE ResearchGateDocument30 pages2014 KSCE ResearchGateomda4wadyNo ratings yet

- ItpDocument64 pagesItpomda4wady100% (1)

- ITP of Admin Building NEW AutosavedDocument14 pagesITP of Admin Building NEW Autosavedomda4wady0% (1)

- Chief Estimator: Job DescriptionDocument2 pagesChief Estimator: Job Descriptionomda4wadyNo ratings yet

- Safety ManagerDocument1 pageSafety Manageromda4wadyNo ratings yet

- Land Surveyor: Job DescriptionDocument1 pageLand Surveyor: Job Descriptionomda4wadyNo ratings yet

- MEP Engineer: Job DescriptionDocument1 pageMEP Engineer: Job Descriptionomda4wadyNo ratings yet

- CAD Engineer: Job DescriptionDocument2 pagesCAD Engineer: Job Descriptionomda4wadyNo ratings yet

- اختصارات عقودDocument1 pageاختصارات عقودomda4wadyNo ratings yet

- EPC Project WBS PDFDocument1 pageEPC Project WBS PDFomda4wadyNo ratings yet

- Project Management Process Map: Develop Ment Imple-MentationDocument1 pageProject Management Process Map: Develop Ment Imple-Mentationomda4wadyNo ratings yet

- Time Impact AnalysisDocument5 pagesTime Impact AnalysisRenoMasrNo ratings yet

- ITPMProcess Guidelines ChecklistDocument1 pageITPMProcess Guidelines Checklistomda4wadyNo ratings yet

- Tempilstik°: Temperature IndicatorsDocument5 pagesTempilstik°: Temperature IndicatorssaapyNo ratings yet

- From Vibration Monitoring To Industry 4.0Document14 pagesFrom Vibration Monitoring To Industry 4.0ifm electronicNo ratings yet

- B Tech Supplementary Exam Timetable 2013Document14 pagesB Tech Supplementary Exam Timetable 2013studyurselfNo ratings yet

- High-Temperature Mechanical Properties of Concrete: M. Bastami, F. Aslani, and M. Esmaeilnia OmranDocument15 pagesHigh-Temperature Mechanical Properties of Concrete: M. Bastami, F. Aslani, and M. Esmaeilnia OmranAlan Said AbdulrahmanNo ratings yet

- Merida BikesDocument139 pagesMerida BikesLeopoldo PerezNo ratings yet

- Shock Manual: V3.1 EnglishDocument16 pagesShock Manual: V3.1 Englishmayur ladwaNo ratings yet

- TS-MES-3203-CGC - Fittings - 13.03.2023Document321 pagesTS-MES-3203-CGC - Fittings - 13.03.2023energy8001No ratings yet

- Welcome TO Daman & Vapi: Insat Trading CompanyDocument19 pagesWelcome TO Daman & Vapi: Insat Trading CompanyPranay BubnaNo ratings yet

- Bulldozer Diagrama ElctricoDocument18 pagesBulldozer Diagrama ElctricoAldo Lozoria MendietaNo ratings yet

- Piston ValvesDocument20 pagesPiston ValvesYogi173No ratings yet

- Prince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyDocument15 pagesPrince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyPRC Industrial Supply100% (1)

- CRV 2019 ManualDocument769 pagesCRV 2019 ManualJuan In Nippon0% (1)

- AP Physics B Exam Topics Since 1970Document7 pagesAP Physics B Exam Topics Since 1970Chris HansenNo ratings yet

- Axisymm TutorialDocument15 pagesAxisymm Tutorialmudur6No ratings yet

- Air Preheater Seal Upgrades Renew Plant EfficiencyDocument11 pagesAir Preheater Seal Upgrades Renew Plant EfficiencysdiamanNo ratings yet

- Godwin CD 103mDocument2 pagesGodwin CD 103mfire123123123No ratings yet

- Borang Pemeriksaan Air Kompressor PDFDocument1 pageBorang Pemeriksaan Air Kompressor PDFAnas AmeerNo ratings yet

- PTRL5005 2016 Group30 FinalReport GOSP PDFDocument90 pagesPTRL5005 2016 Group30 FinalReport GOSP PDFNour FathyNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Cc422 ElectricoDocument34 pagesCc422 ElectricoSamuel Moreno100% (2)

- Broad X Non-Electric Chiller: Model Selection & Design ManualDocument27 pagesBroad X Non-Electric Chiller: Model Selection & Design ManualdokundotNo ratings yet

- LV Motor EQP Global SD - T3 Brochure Rev 191121Document4 pagesLV Motor EQP Global SD - T3 Brochure Rev 191121Victor LinaresNo ratings yet

- Asme Sec Viii Div 1 Vs Asme Viii Div 2Document3 pagesAsme Sec Viii Div 1 Vs Asme Viii Div 2Jignesh ShahNo ratings yet

- Azkarra: Live Technology LiveDocument23 pagesAzkarra: Live Technology LiveSYED MAZHARNo ratings yet

- High Pressure Gear Motor Wm900Document16 pagesHigh Pressure Gear Motor Wm900Vladimir Illich Pinzon BallenNo ratings yet

- Bearing Stress Between A Lifting Lug and A Shackle PinDocument7 pagesBearing Stress Between A Lifting Lug and A Shackle PinYl WongNo ratings yet

- 05 CP90 Parts Section Serial# 125 - 130Document150 pages05 CP90 Parts Section Serial# 125 - 130CARLNo ratings yet

- 02.ah Installation of CELLFLEX Cables 2005-1Document118 pages02.ah Installation of CELLFLEX Cables 2005-1vaskoa1No ratings yet

- Newton's Laws 2. Some Particular Forces 3. Applying Newton's LawsDocument67 pagesNewton's Laws 2. Some Particular Forces 3. Applying Newton's LawsMario EscalonaNo ratings yet