Professional Documents

Culture Documents

Materials Joining Homework 4

Materials Joining Homework 4

Uploaded by

Odb Ind0 ratings0% found this document useful (0 votes)

20 views6 pagesThe document discusses various types of materials joining techniques including electrical resistance welding, spot welding, and projection welding. It provides details on:

1) The process of electrical resistance welding where electrodes generate heat through electrical resistance to melt and join metal surfaces. Copper is commonly used for electrodes.

2) The mechanism of spot welding where cylindrical electrodes apply pressure and current to produce a nugget that joins two overlapping workpieces.

3) Projection welding modifies resistance welding to concentrate current and electrode pressure on a specific contact point for high welding speeds during automation.

Original Description:

Homework

Original Title

Materials Joining

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses various types of materials joining techniques including electrical resistance welding, spot welding, and projection welding. It provides details on:

1) The process of electrical resistance welding where electrodes generate heat through electrical resistance to melt and join metal surfaces. Copper is commonly used for electrodes.

2) The mechanism of spot welding where cylindrical electrodes apply pressure and current to produce a nugget that joins two overlapping workpieces.

3) Projection welding modifies resistance welding to concentrate current and electrode pressure on a specific contact point for high welding speeds during automation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

20 views6 pagesMaterials Joining Homework 4

Materials Joining Homework 4

Uploaded by

Odb IndThe document discusses various types of materials joining techniques including electrical resistance welding, spot welding, and projection welding. It provides details on:

1) The process of electrical resistance welding where electrodes generate heat through electrical resistance to melt and join metal surfaces. Copper is commonly used for electrodes.

2) The mechanism of spot welding where cylindrical electrodes apply pressure and current to produce a nugget that joins two overlapping workpieces.

3) Projection welding modifies resistance welding to concentrate current and electrode pressure on a specific contact point for high welding speeds during automation.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 6

Materials Joining

Homework 4

1.

Electric resistance welding using the principle of connecting

the metal surface in the form of sheet, and the blunt connection in the

form of reduced overlap with one another using the electrode. Then

their electrical resistance is generated from electric current flowed. The

electrical resistance of the current makes the surface becomes hot and

melted. In electrical resistance welding, electrodes made of copper

because copper properties very fulfilling the criteria desired electrode.

The nature of them that copper has a thermal conductivity and high

electrical, have a good deformation resistance, not easily contaminated

workpiece, and the price is cheap. In electrical resistance welding,

there are three important variables, namely: electrical resistance,

electrode pressure, time and current. Stages of spot welding work can

be explained in the figure below:

1) Aim and take electrode on the metal surface and apply a little

pressure on the surface.

2) The second phase occurs by applying an electric current to

the electrodes so as to make the surface becomes hot and melted. 3)

The third stage is to release previously given electric current and

electrodes were left in place so that the material can be cooled

Melting occurs in the middle of these two plates are connected because

of the electric current flowing from the surface down to the middle of

the plate, so that the melt plate while welding.

2.

Two overlapping sheets are connected using the principle of

local melting caused by concentrated flow between the electrodes are

cylindrical. Current concentration is determined by extensive contact

between the electrode and the workpiece. Here is a mechanism in Spot

Welding process:

Two cylindrical electrodes placed on the surface of the

workpiece connection and the workpiece to be spliced.

Heat generated from the provision of resistance combined

with the pressure will produce Spot Welding.

The heat will result in the formation of nuggets on the

surface of the connection of two workpieces. Generally, the diameter

of the nugget is 6-10 mm.

The resulting current ranges from 3000-40000 A and the

welding time is usually about 0.6 and 0.8 seconds.

Melting occurs in the middle of the two plates are connected

because the spot welding is expected on the surface of the electrical

resistance between the material surface (r3) while the electrical

resistivity of the material to be welded to the electrode should be as

small as possible (r1) and (r5) so that the heat generated melt the

middle of the plates to be joined.

3. Differences between flash welding and upset welding:

1) They actually have the same arrangement. However, the

main difference lies in the mechanism used to generate the movement.

2) Flash welding is usually applied to connect the components

with the same cross section from end to end.

3) Upset welding is usually applied to connect the wire or rod

with a small cross- sectional area as well as for connecting pipes.

4) Flash welding machine has a larger capacity than the upset

welding. However, both can be executed by using the same machine.

Flash welding

Upset welding

4. Schematic of the seam welding work cycle:

a) Steel sheet overlapping, connected using a round and

rotating electrode on the outskirts of the steel. Electrodes will suppress

the sheet steel.

b) The electrode generates heat resistance which will result in

an oval nuggets, which is lined in accordance with the speed of the

electrode.

c) There will be connection to the nugget area.

d) The current supplied by the connections along the split

electrode rollers.

5.

The working principle of projection welding is a modification

of a resistance welding. The mechanism is to provide current

concentration and pressure of the electrode on the workpiece area.

However, in the initial preparation to note that the current flow

centered on a specific contact point.

Advantages

Produce neater result of current flow and focus electrode

High welding speed

Adaptable to automation in the production of high-speed

Disadvantages

Lap joint cause weight gain

Low fatigue strength

Equipment is more expensive than arc welding

Difficult to repair errors

6.

Good material for welding are steel, aluminium, copper. This is

because steel has a fairly high electrical resistance and low thermal

conductivity (52 W / mK) compared to copper electrodes, which makes

the welding process becomes much easier. Then is aluminum,

aluminum has a value of electrical resistance and thermal conductivity

(109 W / mK) are approaching a copper (385 W / mK) but its melting

point is lower than copper, weldingnya process is still possible to use

higher current.

7.

8.

In the manufacture of ERW steel pipe used high-frequency

currents due to concentrated on the surface to be joined by two probes

that make light contact with the connection part, the required current is

smaller and also smaller electrical contacts. By increasing the

frequency of the applied current up to 450 Hz and increasing the

voltage of the unit into tens, developed a process called high-frequency

resistance welding (HFRW). The role of the frequency of the pipe

connection is made light contact between the probes ith connection

portion so that the current required is smaller as well as electrical

contacts.

Advantages

High speed

Weld quality

Disadvantages

9.

Not suitable in slow speed

Stop and restart causing visual discontinouties

Projection welding has fewer variables that affect the resistance

welding process as compared to spot welding. The most important

variables of this assembly technique are the quality of the projections

and the response of the cylinder as the projection collapses during the

welding time.

10.

Terms of quality of welding with spot welding analyzed from

nugget size and tensile shear test results are as follows:

Nugget Size

Size nuggets of melted metal is associated with an area of

contact between the workpiece and the electrode, which in this case is

also influenced by the concentration of the current extensive contact.

Diameter of the nugget as a condition of the quality of the welding spot

welding is 6-10 mm.

Test Results of Tensile and Shear stress

Shear strength of the nuggets generally should be sufficient to

ensure that when a connection is broken then the rated voltage up to

break up occurs on the sheet around the nuggget. The important thing

to note is that spot welding strength can be obtained through

mechanical tests in the form of shear strength and cross section test.

Indicators are often used to determine the toughness of welds,

especially on a hard material that has a high afford is the ratio between

the cross section strength (ft) and shear strength (fs). When the ratio of

fs / ft approaching one, welds can be said to be resilient while the ratio

of fs / ft is close to zero, brittle welds.

11. A

B. Imagine D1 = 10mm ; D2 = 8mm

Then t = 5(s) * 0.5

So, D1 = 5(10) * 0.5 = 25mm D2 = 5(8) * 0.5 = 20mm

12.

For welding of zinc coated steel, required higher currents. This

is due to the presence of Zn coating layer on the steel surface. Zn

coating must be melted before we continue on steel joints. Melting

point of Zn is lower than steel. So that during the welding process, Zn

combined with steel will reduce the resistivity. Therefore we need a

higher current to weld these zinc coated steel.

You might also like

- Fundamentals of Vehicle Dynamics by Thomas D GillespieDocument99 pagesFundamentals of Vehicle Dynamics by Thomas D GillespieYogesh Chandrawanshi0% (1)

- Resistance and Special WeldingDocument24 pagesResistance and Special WeldingKBSMANITNo ratings yet

- DIY Bench Top Tubing BenderDocument17 pagesDIY Bench Top Tubing BenderMalcolm DiamondNo ratings yet

- Mac Pricelist 0810Document72 pagesMac Pricelist 0810rich475100% (1)

- CH 5Document49 pagesCH 5MuhammadMansoorGoharNo ratings yet

- Experiment No 02: AIM To Study Resistance Welding & Its SetupDocument6 pagesExperiment No 02: AIM To Study Resistance Welding & Its Setuprahul9981759900No ratings yet

- WELDINGDocument8 pagesWELDINGManibhusan MohapatroNo ratings yet

- Welding: Edge PreparationsDocument8 pagesWelding: Edge PreparationsManibhusanNo ratings yet

- Chapter 3-Electric WeldingDocument32 pagesChapter 3-Electric WeldingAMAR CHAND MEENANo ratings yet

- UeetDocument21 pagesUeetIts FickNo ratings yet

- Electric Welding: Some of The Advantages of Welding AreDocument11 pagesElectric Welding: Some of The Advantages of Welding ArePriyadarshi MNo ratings yet

- Electric WeldingDocument19 pagesElectric WeldingRaghupatruni SowmyaNo ratings yet

- 6 Electric WeldingDocument19 pages6 Electric WeldingSujan MajiNo ratings yet

- Resistance Welding Qs and AsDocument7 pagesResistance Welding Qs and AssoliddreamsNo ratings yet

- Electric WeldingDocument56 pagesElectric WeldingKilaru Sai KiranNo ratings yet

- MT - 2Document15 pagesMT - 2Arnav PandeyNo ratings yet

- Electric WeldingDocument19 pagesElectric WeldingAnonymous e3XZzQNo ratings yet

- Welding Technology Unit 6008Document10 pagesWelding Technology Unit 6008loganathanNo ratings yet

- Electric Resistance WeldingDocument30 pagesElectric Resistance WeldingSenthil KumarNo ratings yet

- "Spot Welding": Mindanao University of Science and Technology C.M. Recto Avenue, Lapasan, Cagayan de Oro CityDocument10 pages"Spot Welding": Mindanao University of Science and Technology C.M. Recto Avenue, Lapasan, Cagayan de Oro CityAcerz VillagraciaNo ratings yet

- Resistance WeldingDocument18 pagesResistance WeldingAnand JainNo ratings yet

- WWS Group An Introduction To Manual Metal Arc Stick WeldingDocument11 pagesWWS Group An Introduction To Manual Metal Arc Stick WeldingnamkvalNo ratings yet

- Electro Mechanical PartDocument18 pagesElectro Mechanical Partmahendra161024No ratings yet

- Resistance and Special Welding.0001Document100 pagesResistance and Special Welding.0001KKNo ratings yet

- Spot Welding BasicDocument6 pagesSpot Welding BasicPaulNo ratings yet

- Resistance WeldingDocument13 pagesResistance WeldingAashishSethiNo ratings yet

- Unit 4 Lesson 4Document7 pagesUnit 4 Lesson 4mahmoud yarahmadiNo ratings yet

- Resistance WeldingDocument21 pagesResistance WeldingAyush KumarNo ratings yet

- Notes-22 7Document20 pagesNotes-22 7Dan JonNo ratings yet

- Continental Institute of Engineering & Technology: Welding ShopDocument8 pagesContinental Institute of Engineering & Technology: Welding ShopAjay RanaNo ratings yet

- 3-2 Spot WeldingDocument29 pages3-2 Spot WeldingNaram AppannaNo ratings yet

- Arc Welding SessionalDocument13 pagesArc Welding Sessionalnehar shubheschaNo ratings yet

- PPAC Module - III Welding-1Document14 pagesPPAC Module - III Welding-1Albin DonyNo ratings yet

- Amta5 6 Applying Shielded Metal Arc Welding Smaw TechniquesDocument132 pagesAmta5 6 Applying Shielded Metal Arc Welding Smaw TechniquesSaurav Kumaar GuptaNo ratings yet

- Lab Session 04 - Arc WeldingDocument6 pagesLab Session 04 - Arc WeldingZaid BaigNo ratings yet

- Arc Welding Refers To A Group Of: SolderingDocument12 pagesArc Welding Refers To A Group Of: SolderingBhushan VermaNo ratings yet

- Ultrasonic Non-Destructive Evaluation For Spot Welding in The Automotive IndustryDocument6 pagesUltrasonic Non-Destructive Evaluation For Spot Welding in The Automotive IndustryCarlos MusellaNo ratings yet

- Fundamentals of Electric Resistance WeldingDocument40 pagesFundamentals of Electric Resistance WeldingRajkumar ArumugamNo ratings yet

- Welding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Document14 pagesWelding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Bouzaida MaherNo ratings yet

- Electric Welding ProcessesDocument19 pagesElectric Welding ProcessesUnzillahNo ratings yet

- Welding Processes & Welding Defects: Welding Metallurgy Kanchan KumarDocument74 pagesWelding Processes & Welding Defects: Welding Metallurgy Kanchan KumarsubhaNo ratings yet

- Submerge Arc WeldingDocument7 pagesSubmerge Arc WeldingUsman Saeed KianiNo ratings yet

- Smaw and Tig WeldingDocument46 pagesSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- Resistance Welding ProcessesDocument63 pagesResistance Welding ProcessesJay DaveNo ratings yet

- Seam Welding MachineDocument63 pagesSeam Welding MachinemboomiNo ratings yet

- Arc WeldingDocument73 pagesArc WeldingAzaad MaverickNo ratings yet

- Lab Report 2..weldingDocument7 pagesLab Report 2..weldingUsman Saeed Kiani100% (1)

- Spot Welding Process LabDocument4 pagesSpot Welding Process Labjunaid gujratiNo ratings yet

- Resis Weld 28 May 09Document22 pagesResis Weld 28 May 09skumarNo ratings yet

- Spot & TIG WeldingDocument17 pagesSpot & TIG WeldingMostafizur Rahman SobujNo ratings yet

- WELDINGDocument94 pagesWELDINGharshaNo ratings yet

- Lec 7Document28 pagesLec 7Omar AssalNo ratings yet

- Expt 5 Welding ShopDocument6 pagesExpt 5 Welding Shopvivoyseries21No ratings yet

- Arc Welding in DetailDocument34 pagesArc Welding in DetailSohen PatelNo ratings yet

- Welding Technology: Department of Mechanical Engineering National Institute of Technology RaipurDocument66 pagesWelding Technology: Department of Mechanical Engineering National Institute of Technology RaipuryashNo ratings yet

- Submerged Arc WeldingDocument11 pagesSubmerged Arc Weldingmiteshpatel191No ratings yet

- Ddugky Welding Lab ManualDocument15 pagesDdugky Welding Lab ManualprakashNo ratings yet

- Literature Survey: Weldability of MaterialsDocument15 pagesLiterature Survey: Weldability of MaterialsEng-Mohammed Abu NuktaNo ratings yet

- 2 WeldingDocument24 pages2 WeldingpriyanshuvraoNo ratings yet

- An Essential Guide to Electronic Material Surfaces and InterfacesFrom EverandAn Essential Guide to Electronic Material Surfaces and InterfacesNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Unit-4 Unconventional Manufacturing ProcessDocument18 pagesUnit-4 Unconventional Manufacturing Processbrijkishor201767% (3)

- Din 931 PDFDocument2 pagesDin 931 PDFsorinenngNo ratings yet

- Dice Vault - PARAGONDocument5 pagesDice Vault - PARAGONWolfcreed87No ratings yet

- Catalogue Black&Decker - 2014Document102 pagesCatalogue Black&Decker - 2014ZorbanfrNo ratings yet

- CIG WELD Deposition Rate PDFDocument7 pagesCIG WELD Deposition Rate PDFgitaNo ratings yet

- C. AnvilDocument8 pagesC. AnvilJade Carlo AntonioNo ratings yet

- Specification Sheet For RCD Drill BitDocument6 pagesSpecification Sheet For RCD Drill Bitmevice63No ratings yet

- VSM Metal Brochure ENDocument12 pagesVSM Metal Brochure ENforough sardarzadehNo ratings yet

- Automotive Transmission-ShaftDocument7 pagesAutomotive Transmission-Shaftfileuse.fNo ratings yet

- Pescador Hidraulico MecanicoDocument1 pagePescador Hidraulico MecanicoElderNo ratings yet

- Machine Tool DrillingDocument17 pagesMachine Tool DrillingomkardashetwarNo ratings yet

- Gap Preparation and AlignmentDocument16 pagesGap Preparation and AlignmentRadoi OlteanuNo ratings yet

- Module Handbook Mechanical - 2Document198 pagesModule Handbook Mechanical - 2Pratik RautNo ratings yet

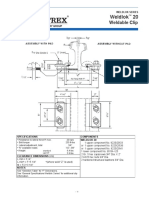

- Weldlok 20Document2 pagesWeldlok 20Nicolas DelpNo ratings yet

- Turning Process PDFDocument41 pagesTurning Process PDFAakunoori Ganesh100% (1)

- BMP Paper With SolutionDocument58 pagesBMP Paper With SolutionAtul GaurNo ratings yet

- Franks Cabot - Q02 - 11 de 17 - FRONT - SUSPENSION PDFDocument5 pagesFranks Cabot - Q02 - 11 de 17 - FRONT - SUSPENSION PDFcarlospais2100% (2)

- Types of ThreadDocument13 pagesTypes of ThreadK.S.MAYILVAGHANANNo ratings yet

- Bolt Action 3Document10 pagesBolt Action 3browar444100% (3)

- MEC Lowrider Rack InstallationDocument2 pagesMEC Lowrider Rack InstallationtruepeersNo ratings yet

- Hot LockDocument36 pagesHot LockcasalasNo ratings yet

- Equivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronDocument2 pagesEquivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronNagarjun ReddyNo ratings yet

- History: Parts DescriptionDocument9 pagesHistory: Parts DescriptionClaudiu RotariuNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Astm A 563 2014Document9 pagesAstm A 563 2014Marlonnog100% (2)

- Lathe MachineMP IDocument44 pagesLathe MachineMP IMetalAnand ChelliahNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- TDC 6 388Document3 pagesTDC 6 388sonnu151No ratings yet