Professional Documents

Culture Documents

Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding Bureau

Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding Bureau

Uploaded by

Danem HalasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding Bureau

Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding Bureau

Uploaded by

Danem HalasCopyright:

Available Formats

NATIONAL CERTIFIED PIPE WELDING BUREAU

WELDING PROCEDURE SPECIFICATION

NO. 8-32-1

FOR

GAS TUNGSTEN ARC WELDING (GTAW)

AND

SHIELDED METAL ARC WELDING (SMAW)

OF

AUSTENITIC STAINLESS STEEL PIPES, VALVES, FITTINGS AND FLANGES

USING F-5 ELECTRODE WITHOUT POSTWELD HEAT TREATMENT

This document is the property of

(NCPWB Member Company Name)

This Welding Procedure Specification (WPS) and Procedure Qualification Record(s) (PQR)

are issued by the NCPWB for adoption by its members. Reproduction or

use of this WPS and PQR(s) by anyone other than members of the NCPWB is

prohibited

NCPWB

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name:

WPS Number: 8-32-1

Original WPS Date: 3-19-75

Supporting PQRs: 87801, 87802

87803, 87804

Revision Number: 3

Revision Date: 10-1-13

Welding Process: Gas Tungsten Arc (GTAW) / Shielded Metal Arc (SWAW)

Type: Manual

Joints (QW-402)

Joint Design: Single-V or U, Double-V or U, Fillets, Repairs, Build-up

Details: See Typical Joint Designs

Backing: Optional for GTAW, Required for SMAW

Backing Material Type: Stainless Steel, when used

Filler Metals (QW-404)

Root

Balance

Specification Number (SFA):

5.9

5.4

Classification: ERXXX (See below) EXXX-16 (See Below)

F-number:

6

5

A-Number:

8

8

Maximum Deposited Weld

Metal Thickness - Groove:

8

8

- Fillet:

All

All

Maximum Bead Thickness:

1/8

3/8

Flux Trade Name:

N/A

N/A

Consumable Insert:

None

N/A

Postweld Heat Treatment

Technique (QW-410)

(QW-407)

Temp. Range: None

String or Weave Bead: Either

Time Range: N/A

Method of Backgouging: None

Base Metals (QW-403)

P-Number: 8

Group Number: 1

to P-Number: 8

Group Number: 1

Thickness Range

Groove Welds: 1/16 to 8

Fillet Welds: All

Pipe Diameter Range

Groove Welds: >1 O.D.

Fillet Welds: All

Positions (QW-405)

Welding Positions: All

Welding Progression: Uphill

Preheat and Interpass

Temperature (QW-406)

Electrical

Characteristics

(QW-409)

Current Type: DC

Polarity: See Table

Amperage: See Table

Initial and Interpass Cleaning: Grind to remove cutting oxide, solvent clean to remove

cutting oil. Grind or wire brush to remove

slag or silica deposits.

Orifice or Gas Cup Size: #4 to #12

Oscillation: N/A

Contact Tube to Work Distance: N/A

Multiple or Single Pass: Either

Multiple or Single Electrode: N/A

Minimum Preheat: 50F

Maximum Interpass: 350F*

Preheat Maintenance: Not Required

Gas (QW-408)

Electrode Feed Speed: N/A

Shielding Gas: 100% Argon

Voltage: N/A

Composition: Welding Gr.

Travel Speed: See Table

Flow Rate: 8-20 CFH

Tungsten Type: 2% Thoria

Peening: Not Permitted

Gas Backing: Ar or N at

Tungsten Size: 3/32, 1/8

Other:

When welding different types of 300 series

5-15 CFH

Pulsed Current: None

stainless to each other, select a filler metal

Trailing Shield: None

designated for both types.

Filler Metal

Current

Weld Layer

Welding

Process

Class

Dia. (in)

Type/Polarity

Amps

1

2

Balance

Balance

Balance

Balance

GTAW

GTAW

SMAW

SMAW

SMAW

SMAW

As Above

As Above

As Above

As Above

As Above

As Above

3/32 or 1/8

3/32 or 1/8

3/32

1/8

5/32

3/16

DCSP

DCSP

DCRP

DCRP

DCRP

DCRP

60-100

70-100

40-80

65-110

100-150

120-190

Volts

Travel

Speed *

(ipm)

2-4

2-4

2-4

2-6

4-8

Other

Base

Filler Metal

Metal

304

308, 308L, 316, 316L

304L

308L, 316, 316L

316

316, 316L

316L

316L

321,347

308L, 321

*These values are recommended

only, not mandatory

The undersigned contractor, a member of the National Certified Pipe Welding Bureau, hereby adopts this

jointly developed procedure as its company Welding Procedure Specification and certifies that this

procedure has been qualified as shown on the attached Procedure Qualification Record.

Contractor:

By:

Date:

Title:

NCPWB Form QW-482 4/87

For use by NCPWB members only (NCPWB)

WPS 8-32-1

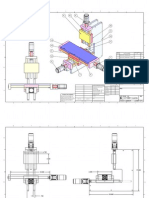

Typical Joint Designs

Other joint designs shown on Engineering drawings supersede these joint details

Butt welds

30 to 45

3/32 to

1/8

See note 1

30 to 45

3/32 to 1/8

See Note 1

3/16 Nom.

3/32 to 1/8

Note 1: 1/8 inch maximum except for B31.1 and B31.5 work, 1/16 inch maximum

Fillet, Nozzle and Branch Connection Welds

Throat

dimension

Size (leg)

Dimension

1/16

max

1/8

min

45 min

Socket and Slip-on Flange Welds

1/16 min

Y

1/16 min

Smaller of

T or 1/4

Approximately

1/16 before

welding

T = The nominal thickness of the pipe

X = the lesser of 1.4T or the hub thickness unless another size is shown on the engineering drawings

Y = the lesser of 1.1T or the fitting thickness unless another size is shown on the engineering drawings

Z = for B31.9 work, minimum of the greater of the pipe nominal wall thickness or 14 in. (6 mm) and face

fillet is not required unless specified by the design.

September 20, 2012

For use by NCPWB Members Only ( NCPWB)

PROCEDURE QUALIFICATION RECORD (PQR)

WPS followed during welding of test coupon:

Welding Process(s) used:

Base Metal Specification:

P-No:

SA-312 type 304

Group No: 1

Plate:

to P-No:

Diameter if pipe:

Group No:

70

Interpass Temp ( F):

Tungsten Type/Size:

NA

Postweld Heat Treatment (F):

Shielding Gas Composition :

Stringer/Weave Bead:

Oscillation:

350

NA

E308-16

F-No.:

Supplementary Filler Metal:

Welding Position/Progression:

CFH Backing Gas:

Transfer Mode:

Single/Multi-Pass:

Multi

0.12

1G Rolled

NA

NA

Process

Filler Class

Diameter

Amperage

Travel Speed (ipm)

SMAW

E308-16

3/32

90

4.5

SMAW

E308-16

1/8

105

2.5

SMAW

E308-16

5/32

100

2.5

ipm

CFH

Single/Multi-Arc:

Layer

NA

DC

Polarity:

RP

Travel Speed: below

Heat Treatment Time (Hrs):

NA

None

NA

0.280

Maximum Pass Thickness :

Current:

Weave

SA-312 type 304

Single V-Groove, P-8 Backing Ring, 3/16 Root Gap

0.280

2-3-84

Manual

Thickness:

AWS Classification:

3/32,1/8

Weld Metal Deposit Thickness :

Preheat Temp ( F):

Joint Type:

SFA 5.4

Filler Metal Size:

Test Date:

Type:

to Base Metal Specification:

Filler Metal Specification:

A-No.:

SP-313K, Rev 0

Shielded Metal Arc

Single

Other

Reduced Section Tensile Tests

Specimen No.

Width/Dia.

Thickness

Area

Ult. Load (lbs)

Ult. Stress (psi)

T-1

0.753

0.270

0.203

18,900

93,100

Failure

Location

Base Metal

T-2

0.761

0. 261

0.198

18,400

92,900

Base Metal

Guided Bend Tests [

] QW-452.2 (Side)

Face

Face

Welders Name:

[ X ] QW-462.3(a) (Trans R&F)

No defects-acceptable

No defects-acceptable

Len Wertelet

Root

Root

Stamp No.

LM

]QW-462.3(b)(Long R&F)

No defects-acceptable

No defects-acceptable

Test Number:

846988

Welding Witnessed by :

James J. Sekely

Specimens Evaluated by :

Earl Gallagher, PTL

We Certify that the statements in this record are correct, and that the test coupons were prepared, welded

and tested in accordance with the requirements of Section IX of the ASME Code.

Contractor:

By:

NATIONAL CERTIFIED

PIPE WELDING BUREAU

Date:

BY:

Chairman, Technical Committee

NCPWB Form QW-483 4/87

For use by NCPWB members only (NCPWB)

PQR Number: 87801

PROCEDURE QUALIFICATION RECORD (PQR)

WPS followed during welding of test coupon:

WP-43, Rev 17, 1/21/83

PQR Number:

Welding Process(s) used:

Date Test Coupon was welded:

2-11-83

GTAW, Manual

Base Metal Specification:

P Number:

SA-240, Type 304

Group No:

to P Number:

Base Metal Thickness(in.): 1.75

Filler Metal Specification:

A-No.:

to Base Metal Specification:

8

Group No:

SFA5.9

Classification:

3/32, 1/8

Preheat Temperature (F): 50

Current Type:

DC

Straight

350

Below

Backing Gas (CFH): Argon, 25 to 35

N/A

Oscillation:

Single/Multi-Electrode:

None

<1/8

N/A

GMAW Transfer Mode:

Both

Multiple

Postweld Heat Treatment (F):

F-No.:

Welding Position/Progression: 3G uphill

Travel Speed (ipm):

1/8 2% Thoriated

Single/Multi-Pass:

ER308L ER308

Supplementary Filler Metal:

Interpass Temperature (F):

Polarity:

Stringer/Weaver Bead:

Plate

Maximum Pass Thickness (in.):

Shielding Gas Composition (CFH): Welding Grade Argon, 25 to 35

Tungsten Size/Type:

SA-240, Type 304

Plate/Pipe Diameter:

Joint Type: Single V-groove welded fom one side, 1/8 root opening

Deposited Weld Metal Thickness (in.): 1.75

Filler Metal Size (in.):

87802

N/A

Single

Heat Treatment Time(hr.):

N/A

Other:

Layer

Process

Filler Classification

Diameter

Amperage

Travel Speed

1,2

3

4/81

GTAW

GTAW

GTAW

ER308L

ER308

ER308

3/32

1/8

1/8

90

110

125 to 145

2.4 to 2.5 ipm

2 ipm

2 to 3 ipm

Reduced Section Tensile Tests

Ult.imate Load (lbs)

0.508

0.203

17,800

0.510

0.510

0.510

0.204

0.204

0.204

18,400

18,400

18,100

90,200

90,200

88,700

T-1

T-2

T-3

T-4

Thickness (in)

Trans. Root and Face (QW462.3a)

Trans. Side (QW-462.2)

Failure Location

Base Metal

Base Metal

Base Metal

Base Metal

Long.Root and Face (QW-462.3b)

Type

Results

Type

Results

Side

Acceptable

Side

Acceptable

Side

Acceptable

Side

Acceptable

Toughness Test

Notch

Location

Charpy Specimen Size:

None

Test Temperature

Charpy V-Notch Test

Foot-Lbs.

Ft-lb Av.

Percent Shear

Other

Full-Section Specimen

Area (sq in)

Width/Dia. (in)

Specimen

Number

Turned Specimens

Heat Input

Ultimate

Stress

(psi)

87,700

Specimen

Bend Tests:

Rectangular Specimens

Volts

N/A

Drop-Weight Test

Lateral Exp. (mils)

Break

No Break

Fillet Weld Test Macro Examination

Fillet Weld Test Leg Sizes:

Weld Deposit Analysis:

Other Tests:

Welders Name: J. Hancock, H. Cain Stamp No. 731, 13-65 Welding Witnessed By: L.M. Petrick, Ebasco

Test Conducted by:

Lucius Pitkin, Inc, NYC

Laboratory Test Number: M-6988

We Certify that the statements in this record are correct and that the test welds were prepared, welded and tested

in accordance with the requirements of Section IX of the ASME Code.

NATIONAL CERTIFIED

PIPE WELDING BUREAU

Contractor:

By:

Date :

By:

Chairman, Technical Committee

NCPWB Form QW-483 6/91

For use by NCPWB members only (NCPWB)

PQR Number 87802

PROCEDURE QUALIFICATION RECORD (PQR)

WPS followed during welding of test coupon:

Welding Process(s) used:

8

SA 182 F304

Group No: 1

Plate:

to P-No:

Diameter if pipe:

Group No:

20

Filler Metal Size :

Preheat Temp (F):

Manual

SA 182 F304

Thickness:

1.968

AWS Classification: IN-308/ER308L/E308-16 F-No.:6/6/4

Supplementary Filler Metal:

0.375/1.593

Tungsten Type/Size:

2% Thoria, 1/8

Postweld Heat Treatment (F):

None

8-19-82

Single V-Groove with consumable insert

5/32,3/32,1/8,5/32

Interpass Temp (F):

60

Joint Type:

Weld Metal Deposit Thickness :

Type:

to Base Metal Specification:

Filler Metal Specification: SFA5.30/SFA5.9/SFA5.4

A-No.:

Test Date:

Gas Tungsten Arc / Shielded Metal Arc

Base Metal Specification:

P-No:

SPBV 309, Rev 0

Maximum Pass Thickness :

350

Welding Position/Progression:

Current:

NA

0.125/0.25

5G Uphill

DC

Polarity:

SP/RP Travel Speed: below ipm

Heat Treatment Time (Hrs):

NA

Shielding Gas Composition: Welding Grade Argon, 15-25 CFH

Backing Gas:

Argon, 10

Stringer/Weave Bead:

String/Weave/Weave

Transfer Mode:

NA

Oscillation:

NA

Single/Multi-Pass:

Multi

CFH

Single/Multi-Arc:

Layer

Process

Filler Class

Dia/size

Amperage

Travel Speed(ipm)

Root

GTAW

IN-308 Class 1

5/32

100

2/8

GTAW

ER308

3/32

80-100

Balance

SMAW

E308-16

3/32

90

5.5

Balance

SMAW

E308-16

1/8

110

2.5

Balance

SMAW

E308-16

5/32

150

3.5

Single

Other

35 Passes, 15 Layers

Delta Ferrite

Measured 10/15 FN

Passed Corrosion Test

per ASTM A708

Reduced Section Tensile Tests

Specimen No.

Width/Dia.

Thickness

Area

Ult. Load (lbs)

Ult. Stress (psi)

T-1

0.743

1.876

1.394

124,400

89,200

Failure

Location

Base Metal

T-2

0.748

1.876

1.403

124,000

88,700

Base Metal

Guided Bend Tests [ X ] QW-452.2 (Side)

] QW-462.3(a) (Trans R&F)

]QW-462.3(b)(Long R&F)

Side

No Defects-Acceptable

Side

No Defects-Acceptable

Side

No Defects-Acceptable

Side

No Defects-Acceptable

Welders Name:

Morrison, Chuba, Hiliman, Tudor

Stamp No.

Various

Test Number:

830360

Welding Witnessed by :

James J. Sekely

Specimens Evaluated by :

Earl Gallagher, PTL

We Certify that the statements in this record are correct, and that the test coupons were prepared, welded

and tested in accordance with the requirements of Section IX of the ASME Code.

NATIONAL CERTIFIED

PIPE WELDING BUREAU

Contractor:

By:

Date:

BY:

Chairman, Technical Committee

NCPWB Form QW-483 4/87

For use by NCPWB members only (NCPWB)

PQR Number: 87803

Procedure Qualification Record (PQR)

Identification of WPS followed during welding of test coupon: SP-302 Rev 2

Welding Process(es) used: GTAW, Manual

Date coupon was welded: 7-7-77

Base Metal Specification:

SA-312 Type 304

to Base Metal Specification: SA-312 Type 304

P-Number: 8

Group No: 1 to P-Number: 8 Group No: 1 Plate/Pipe Diameter: NPS 6 Sch 40

Base Metal Thickness(in.): 0.280

Joint Type: Single V-groove welded one side F-Number: 6

Filler metal specification:

SFA 5.9

AWS Classification: ER308

A-Number: 1

Weld Deposit Thickness(es)(in.): 0.280

Maximum Pass Thickness: 0.10

Filler metal size:

1/16, 3/32, 1/8

Supplementary filler metal: N/A

Preheat temperature (F): 60 Interpass temp. (F) 350

Welding position/progression: 1G Rolled

Current Type and polarity:

DCEN

Travel speed (ipm):

see below

Shielding gas composition, CFH: Argon, 15 to 25

Backing gas composition, CFH: Argon, 10 to 20

Tungsten size/type: EWTh-2, 3/32

GMAW transfer mode: N/A

Postweld Heat treatment (F): None

Postweld heat treatment time (hr.):

N/A

Stringer/Weave bead: Both, 3X the wire size

Oscillation: N/A

Single/Multi-pass:

Multiple

Single/Multi-electrode: Single

Other:

Weld

Layer

Root

Fill

Fill

Electrode or

filler metal

ER308

ER308

ER308

Process

GTAW

GTAW

GTAW

Size (in)

1/16

3/32

1/8

Reduced Section Tensile Tests

Specimen

1

2

Width/dia (in.)

0.753

0.752

Bend Tests

Type

Root

Face

Toughness Tests

Specimen

Type/Polarity

DCEN

DCEN

DCEN

Current

Volts

X Rectangular

Thickness (in.)

0.200

0.216

Area (in^2)

0.151

0.162

Turned

Load (lbs.)

13,250

14,150

Transverse Face and Root

Side

Result

Acceptable

Acceptable

Result

Acceptable

Acceptable

Type

Face

Root

Charpy Specimen Size

Notch location

Ft-lbs

Travel Speed

(ipm)

2

2

2

Amps

95

105

120

Other

Full Section

Tensile Str. (psi)

88,000

87,100

Location of failure

Weld Metal

Weld Metal

Longitudinal Face and Root

Type

Result

Test Temperature

Lateral Expansion (mils)

Percent Shear

Drop Weight Break

No Break

Weld deposit analysis:

Other tests:

Welders name:

Jim Gilcrest

Stamp: F-305

Welding Witnessed by: James J. Sekely

Tests conducted by: Earl Gallagher, Pittsburgh Testing Laboratory.

Laboratory test number: 776238

We hereby certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with the

requirements of Section IX of the ASME Code.

National Certified

Company:

Pipe Welding Bureau

By:

Chairman, Technical Committee

Date:

PQR Number 87804

For use by NCPWB members only (NCPWB)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MCT-08001 Assembly - Sheet1Document4 pagesMCT-08001 Assembly - Sheet1ModularCNC100% (2)

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDocument26 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasNo ratings yet

- CV Ait KoufiDocument3 pagesCV Ait KoufiDanem HalasNo ratings yet

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocument3 pagesCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesDanem HalasNo ratings yet

- Ut Proceduregeneral 141118232235 Conversion Gate02Document24 pagesUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasNo ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- WLD 290 Submerged Arc WeldingDocument52 pagesWLD 290 Submerged Arc WeldingDanem HalasNo ratings yet

- 8a Codes and Q & CDocument35 pages8a Codes and Q & CDanem HalasNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- 154614Document108 pages154614Danem HalasNo ratings yet

- 5000 XXXX HY80 HSLA100D1.1Document2 pages5000 XXXX HY80 HSLA100D1.1Danem HalasNo ratings yet

- 03 23814 MvolaDocument13 pages03 23814 MvolaDanem HalasNo ratings yet

- 5092 P8 P1 SM 01Document5 pages5092 P8 P1 SM 01Danem HalasNo ratings yet

- Gravure Article PDFDocument9 pagesGravure Article PDFsomeOneNo ratings yet

- Powder CharacteristicsDocument17 pagesPowder CharacteristicsVasantha SudasinghaNo ratings yet

- Galvilite Aug2019Document2 pagesGalvilite Aug2019Dhanush santhoshNo ratings yet

- DesmiDocument285 pagesDesmiJhon SanabriaNo ratings yet

- Instruction Writing Magnetic Testing For Single Vee Butt WeldDocument5 pagesInstruction Writing Magnetic Testing For Single Vee Butt WeldVu PhamNo ratings yet

- WPS&PQR Examination Taghavi.0002Document50 pagesWPS&PQR Examination Taghavi.0002Anon YmousNo ratings yet

- Htea Chemical TreatDocument58 pagesHtea Chemical TreatJames WankerNo ratings yet

- Child Class Description Asset Code Brand Serial, Plate, Re Gistration #Document3 pagesChild Class Description Asset Code Brand Serial, Plate, Re Gistration #AhmerNo ratings yet

- Spot WeldingDocument37 pagesSpot WeldingSabhari Natarajan100% (1)

- LM6 Alloy DetailDocument4 pagesLM6 Alloy DetaildsoNo ratings yet

- VBTDocument5 pagesVBTMohdHuzairiRusliNo ratings yet

- Membrane Reactor by Shivani MunishwarDocument32 pagesMembrane Reactor by Shivani MunishwarShivani MunishwarNo ratings yet

- Magbojos, Berny - ResumeDocument4 pagesMagbojos, Berny - ResumeShiela May HerreraNo ratings yet

- Hardtop Ultra PDFDocument4 pagesHardtop Ultra PDFBiju_PottayilNo ratings yet

- Section 19 Welded JointsDocument14 pagesSection 19 Welded JointsJ T Mendonça SantosNo ratings yet

- Water-Based Dot Markers: FeaturesDocument2 pagesWater-Based Dot Markers: FeaturesALEXA AlonsoNo ratings yet

- Paper # 143 - A New Baffles System in Sag Mill Trommel at The Shahrebabak Copper ComplexDocument11 pagesPaper # 143 - A New Baffles System in Sag Mill Trommel at The Shahrebabak Copper ComplexEdú BrizuelaNo ratings yet

- HiHide 670Document4 pagesHiHide 670Francisco RodríguezNo ratings yet

- Engineering Shop: Multiple ChoiceDocument7 pagesEngineering Shop: Multiple ChoiceAlfredo CondeNo ratings yet

- Coating DefectDocument46 pagesCoating Defectwtwilightw0% (1)

- Vacuum DegasserDocument6 pagesVacuum Degasserreza haghjooNo ratings yet

- Micromanufacturing: Bulk Micromanufacturing Surface Micromachining The LIGA ProcessDocument25 pagesMicromanufacturing: Bulk Micromanufacturing Surface Micromachining The LIGA Processvivek ghatbandheNo ratings yet

- Chapter 10 Manufacturing EngineeringDocument17 pagesChapter 10 Manufacturing EngineeringM Singgih Iman S100% (1)

- Lathe Spindle Nose Mounting Identification ChartDocument1 pageLathe Spindle Nose Mounting Identification ChartYahia Mustafa Alfazazi100% (1)

- Product Application - PDF 20190816110105 3833 Interzone 1000 Uk LRDocument2 pagesProduct Application - PDF 20190816110105 3833 Interzone 1000 Uk LRPutra NugrahaNo ratings yet

- Locating Principle and LocatorsDocument36 pagesLocating Principle and LocatorsRoyNo ratings yet

- First Page PDFDocument1 pageFirst Page PDFMuhammad NaeemNo ratings yet

- 1 A Polishing Machine BookDocument35 pages1 A Polishing Machine BookPradeep AdsareNo ratings yet

- MA8110 TDS Rev11Document2 pagesMA8110 TDS Rev11Rushikesh DeshpandeNo ratings yet